Method for calibrating center jitter

A top, radial runout technology, used in measuring devices, instruments, mechanical devices, etc., can solve problems such as high precision and instability

Active Publication Date: 2011-01-05

CHANGZHOU TIANSHAN HEAVY IND MACHINERY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, it is found in practice that the workpiece corrected by the above correction method still has the problem of high precision and instability after grinding.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

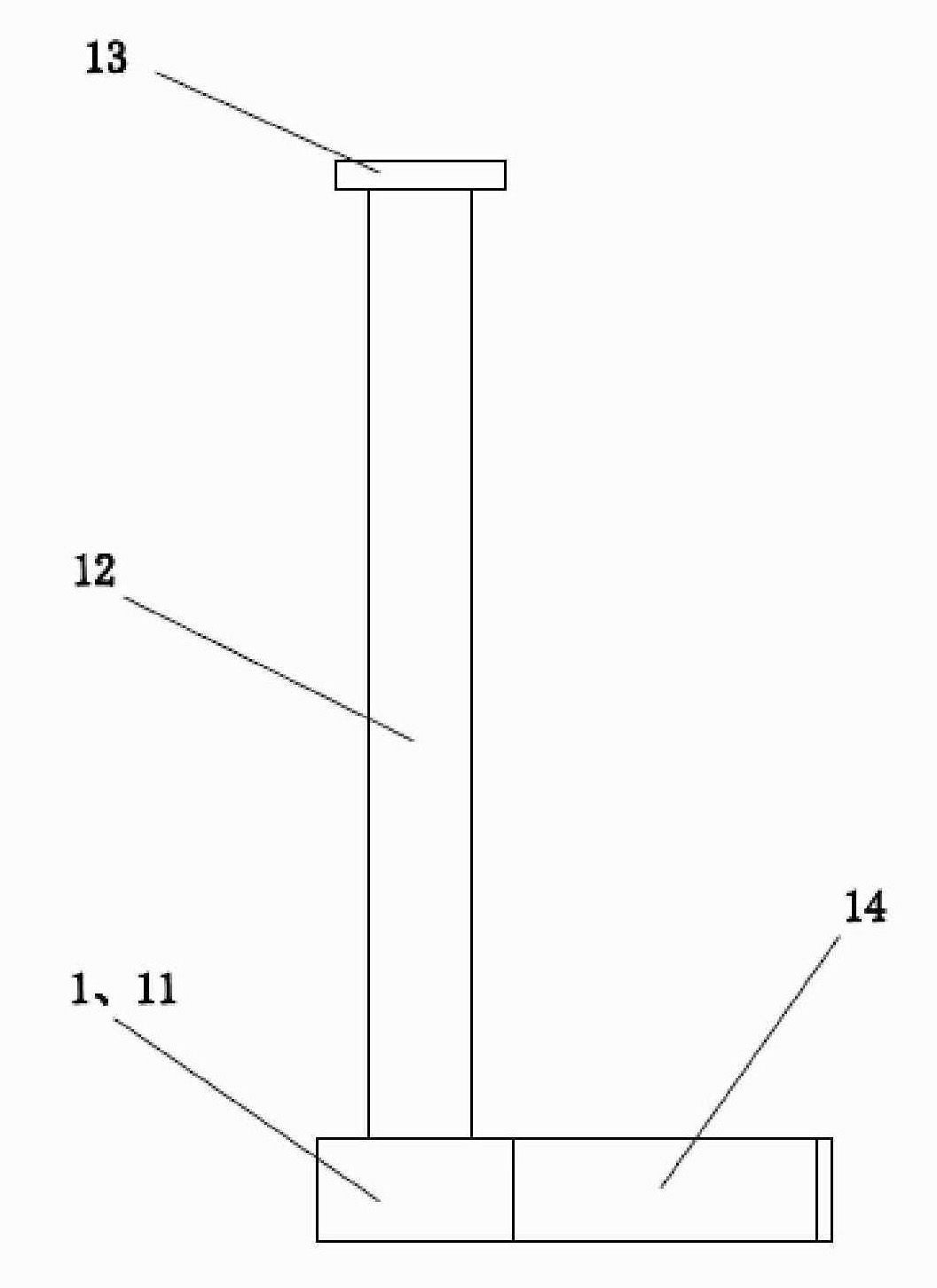

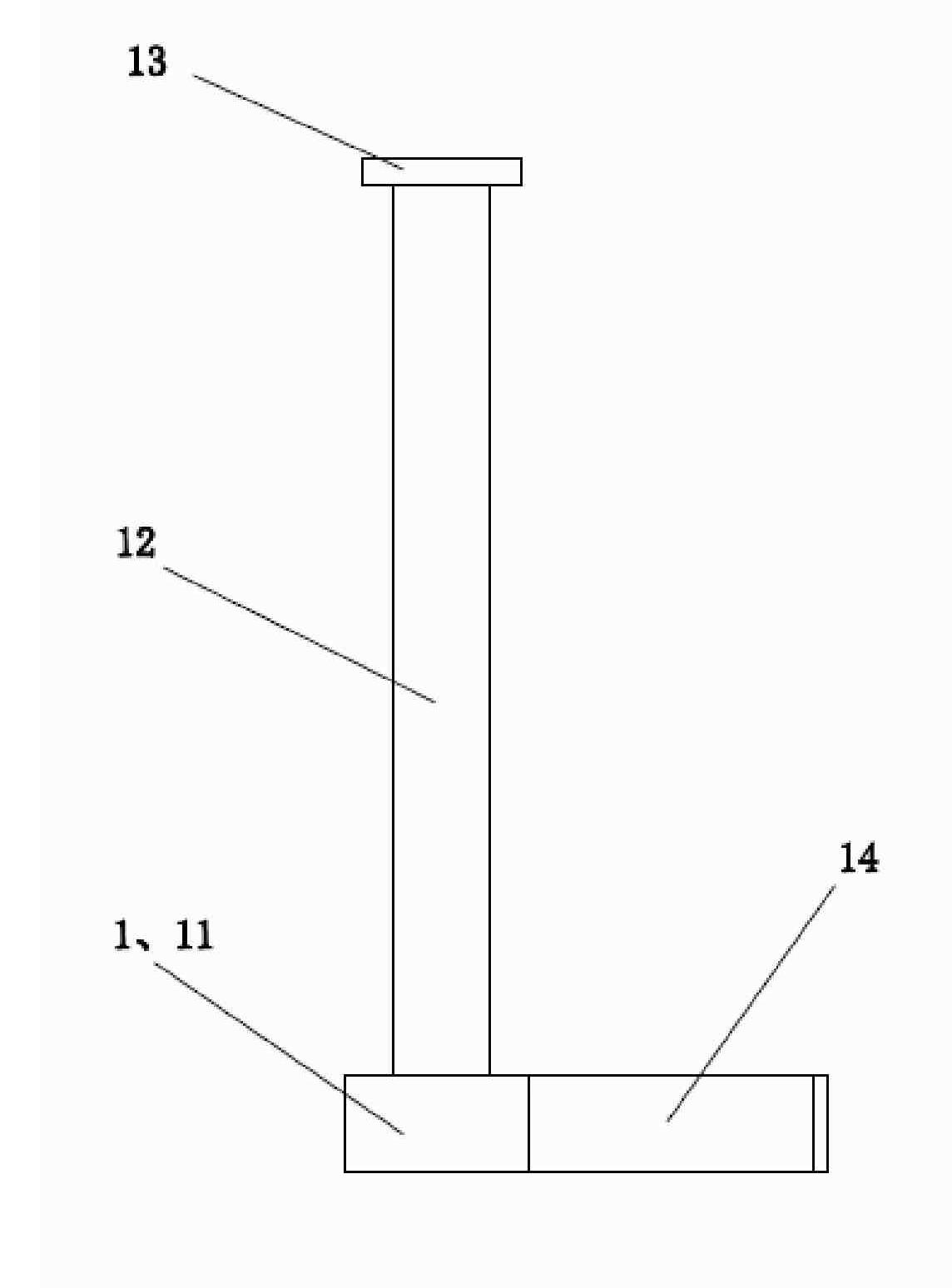

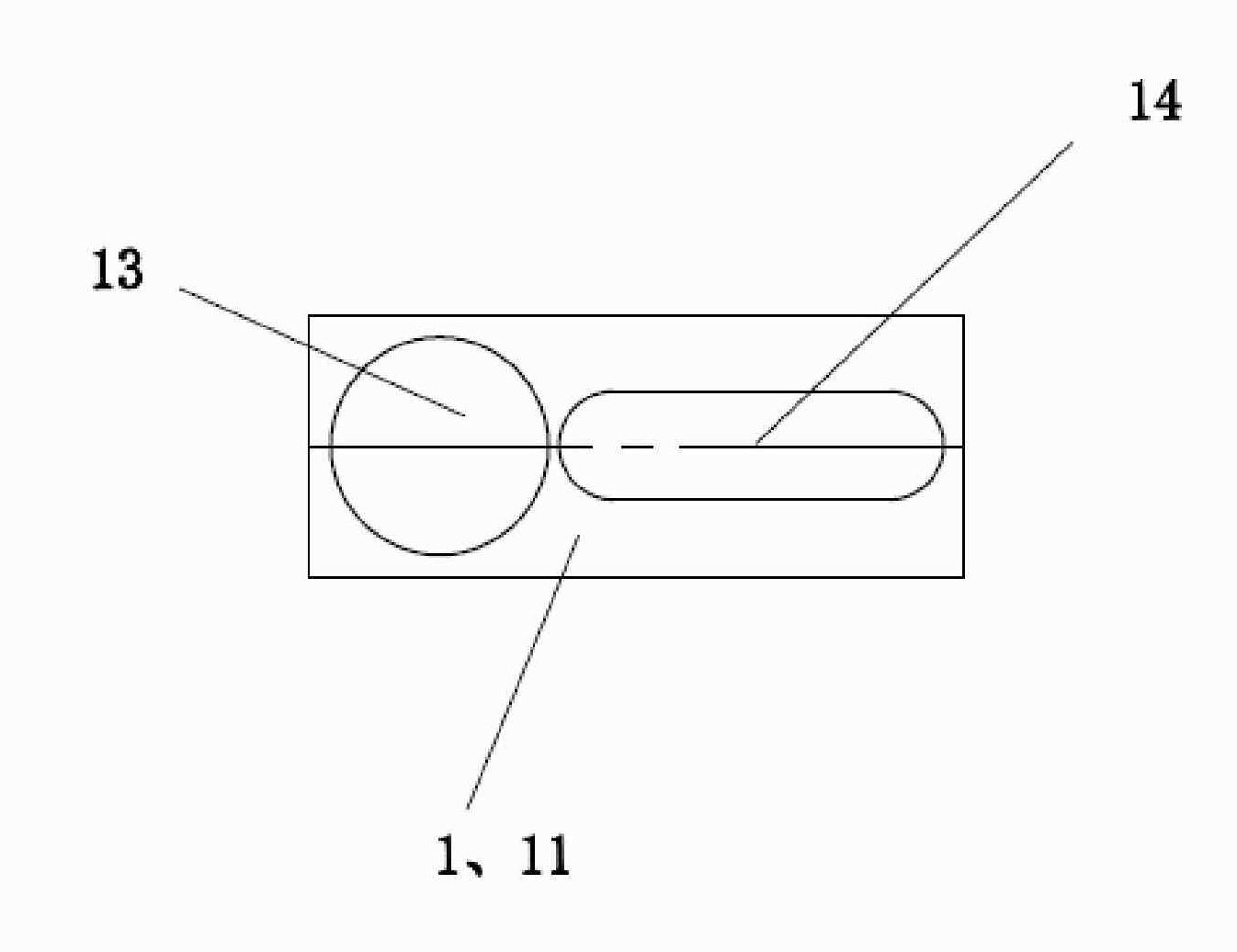

The invention discloses a device and a method for calibrating center jitter. The device comprises a magnetic meter base, a first measuring meter and a second measuring meter, as well as a measuring frame, a T-shaped screw rod, a nut and a gasket; the measuring frame comprises a base and a straight rod which is vertically fixed on the base, a steel upper base plate with the upper surface parallel to the bottom surface of the base is fixed at the upper end of the straight rod; and a screw rod slot is arranged on the base. The calibration method comprises one time of lower center calibration andtwo times of upper center calibration. The calibration method can accurately detect that the central line of an upper center at the time is not coincided with the rotation center, thereby carrying out the corresponding adjustment of the position of a work piece and further avoiding the precision bias during the processing of a gear shaft.

Description

Method of Correcting Top Runout technical field The invention relates to a device for correcting top runout and a method for correcting the top runout, in particular to a device for correcting the radial runout of the upper top of a gear grinding machine and a method for correcting the top runout. Background technique When the gear grinding machine processes gear shaft parts, two tops are often used to position and clamp the shaft blank in the up and down direction, and then perform gear grinding on the shaft blank. Among them, the lower center (referring to the mold with the lower center) is fixed on the rotary table, and the axis of the lower center is required to coincide with the rotation center of the table, and the upper center (referring to the mold with the upper center, the tire The tool comes with the gear grinding machine) is fixed on the upper top frame, the upper top frame can move up and down and rotate relative to the frame of the gear grinding machine, but ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B5/252

Inventor 许娟萍许仁伟戚剑禹罗柏彬

Owner CHANGZHOU TIANSHAN HEAVY IND MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com