Split type multi-energy-saving lamp illumination system

A lighting system and technology of energy-saving lamps, which are applied in the fields of household and public safety lighting, can solve the problems of increased volume and cost, increased product volume and cost, and low power factor, so as to reduce volume and finished products, reduce electronic waste, and reduce power consumption. factor high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with a preferred embodiment of the present invention and accompanying drawing, the present invention will be further described:

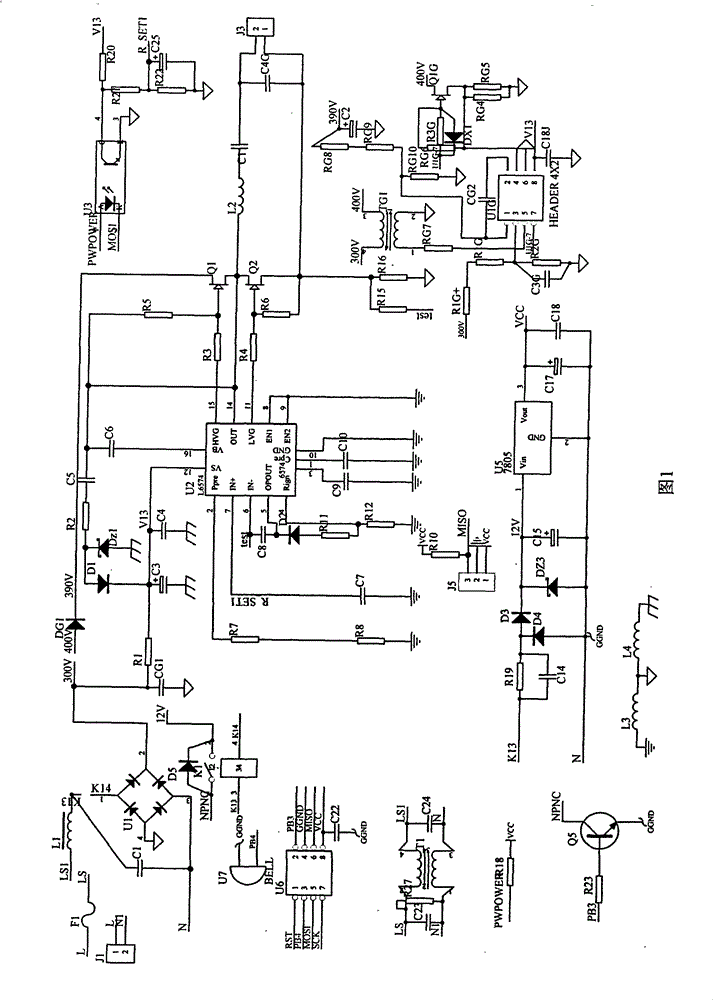

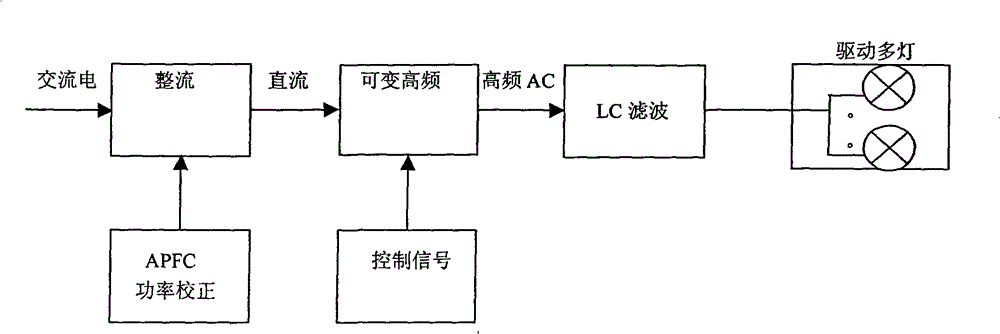

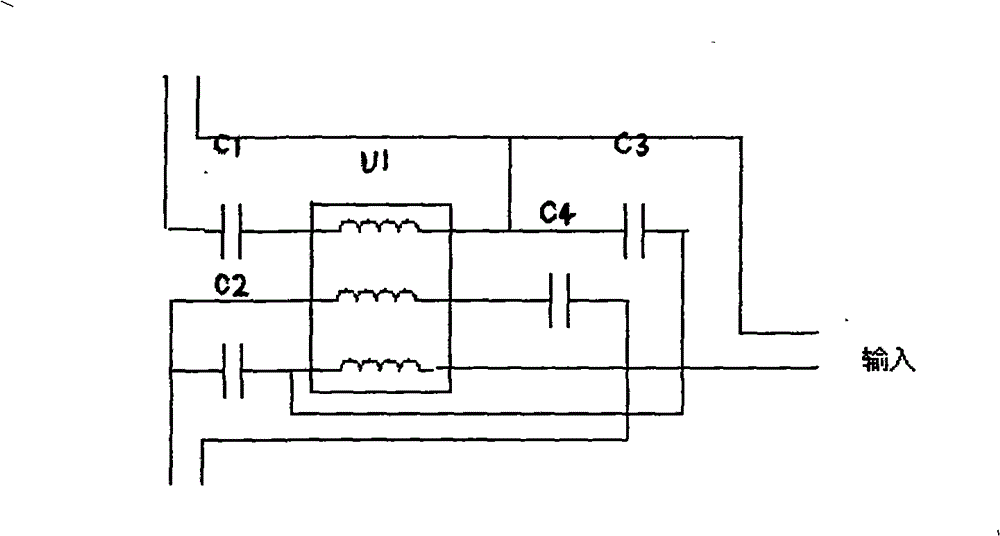

[0010] In this embodiment, the bridge output end of the rectifier circuit is connected to the high-frequency conversion circuit, the half-bridge output of the high-frequency conversion circuit is connected to the filter circuit, and finally the drive circuit is connected. Such as figure 2 As shown, the present invention first rectifies the alternating current, can add APFC power correction, then performs high-frequency conversion, can add frequency modulation and dimming to obtain high-frequency AC, and then filters through LC, and finally connects multiple driving circuits to drive multiple energy-saving lamps. as attached figure 1 As shown, transformer T1, C23, C24, and R27 form a filter circuit for alternating current, C23 and R27 are connected to terminals 1 and 2 of T1 in parallel, and C24 is connected to terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com