Yarn winding machine and yarn winding method

A winding machine and yarn technology, which is applied in the field of yarn winding machines, can solve problems such as damaged effects and inability to eliminate bulging phenomena, and achieve the effect of eliminating convex edge winding and eliminating bulging phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

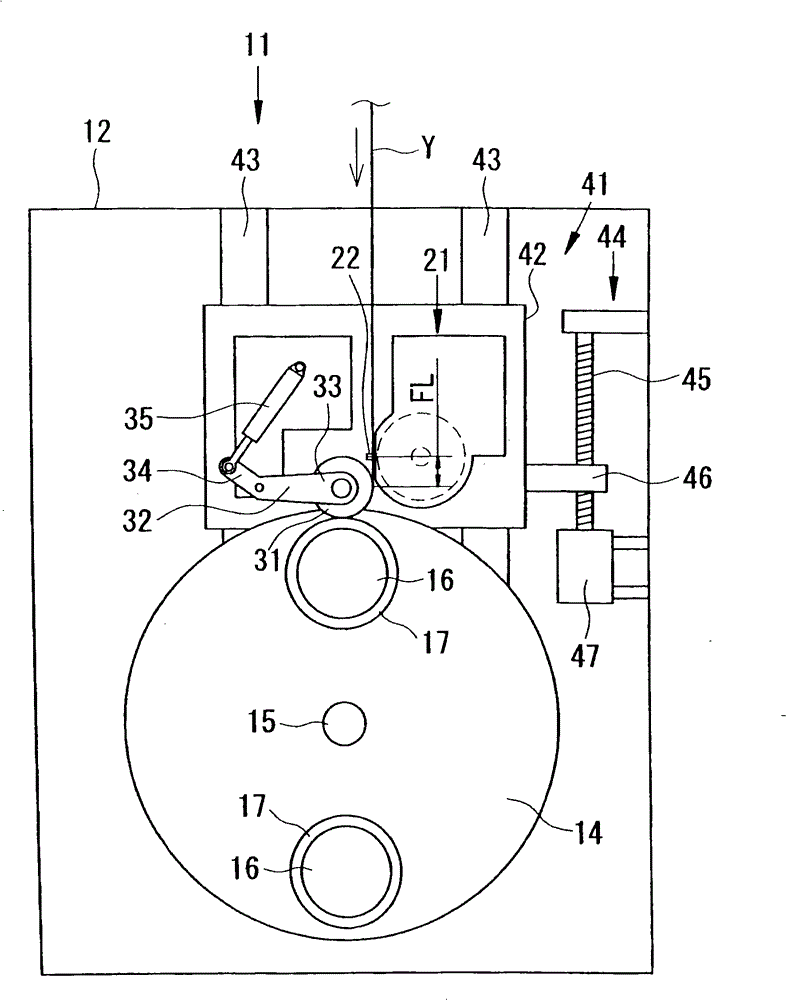

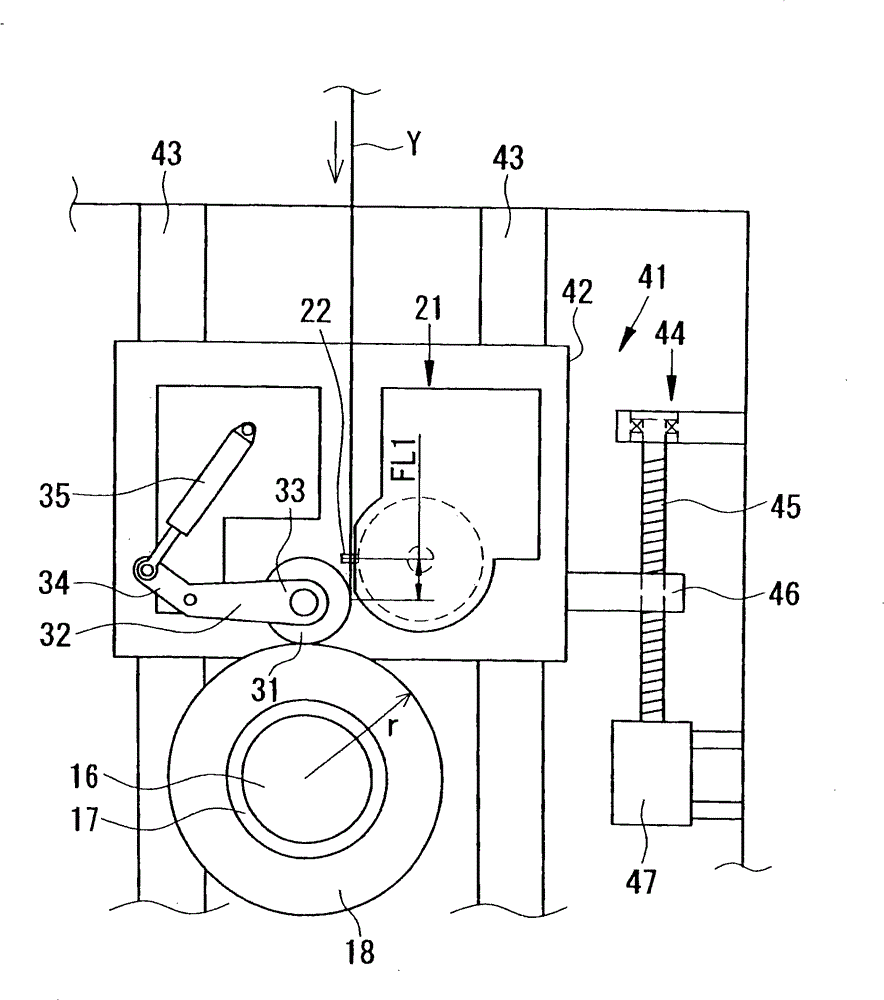

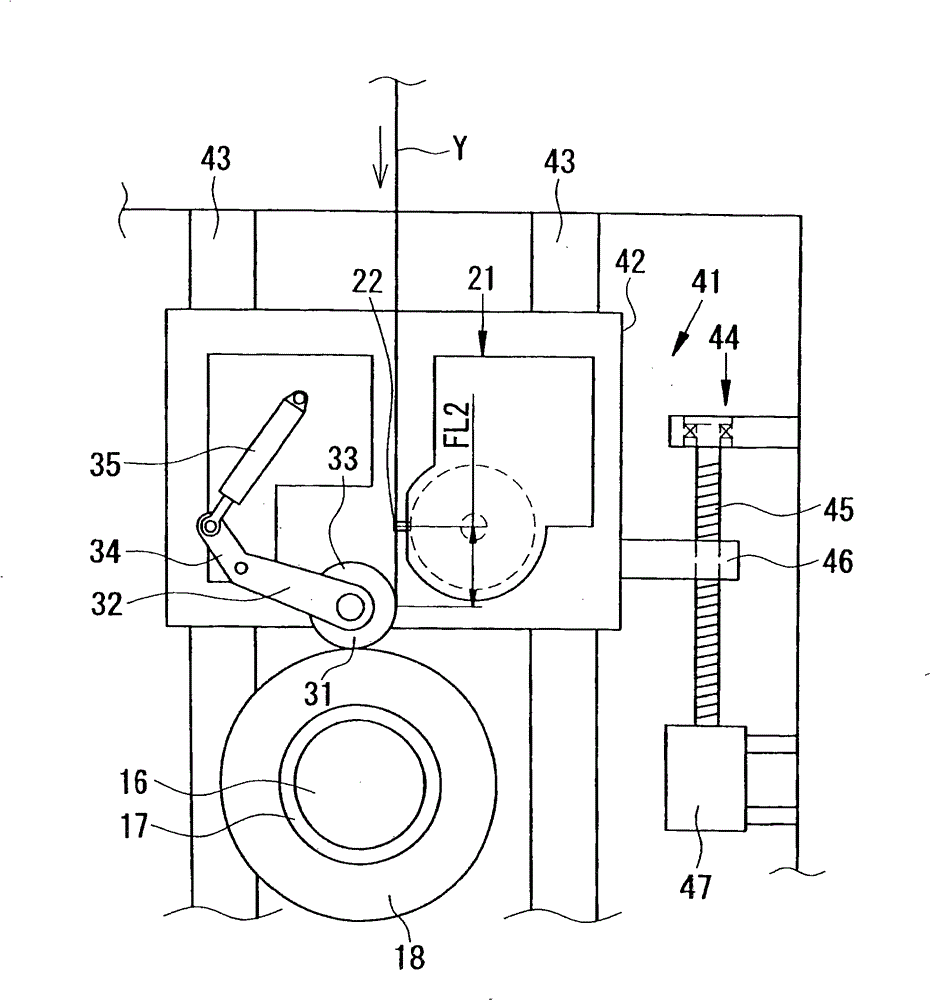

[0037] like figure 1 As shown, the winder 11 includes a body frame 12 on which a slide box 42 that can be raised and lowered relative to the body frame 12 and a turntable plate 14 that is rotatable relative to the body frame 12 are provided. The turntable plate 14 can rotate around the rotating shaft 15 under the drive of a rotating drive device (not shown in the figure). Two bobbin holders (bobbin holders) 16 to which bobbins 17 are attached protrude from positions symmetrical to the rotation axis 15 of the turntable plate 14 . By reversing the turret plate 14 with the rotary drive unit, the positions of the two bobbin holders 16 can be exchanged so that one of the bobbin holders 16 is located at the upper winding position and the other is located at the lower standby position.

[0038] like Figure 4 As shown, two bobbin holders 16 provided on the turret plate 14 are respectively connected to bobbin holder drive motors 19 so as to be rotatable. Each bobbin holder drive m...

Embodiment 2

[0064] The knurling suppression mechanism is a well-known mechanism in the prior art, and is to eliminate the knurling of the package 18 like Figure 9 This is a mechanism for gradually changing the diagonal weave angle in the early stage P2 and the late stage P3 of the package forming period P1 as shown. The twill angle at this time is the reference twill angle A1 determined by upper factors such as the type of synthetic fiber yarn Y. Therefore, the burr suppression mechanism is a mechanism for changing the reference diagonal angle A1. In the early stage P2 of the package forming period P1, the convex edge suppression mechanism starts winding from a small reference twill angle A1, gradually increases the reference twill angle A1, and gradually decreases to a small reference twill angle A1 in the later stage P3 until the end of winding . The knuckle suppression mechanism is a mechanism that changes the density of the package 18 from high density to low density in the early s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com