Fiber grating osmotic pressure sensor with low measuring range

A technology of osmotic pressure sensor and optical fiber grating, which is applied in the direction of displaying liquid level indicator through pressure measurement, fluid pressure measurement using optical method, etc., which can solve the problems of low resolution, linearity of large detection, and inability to detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

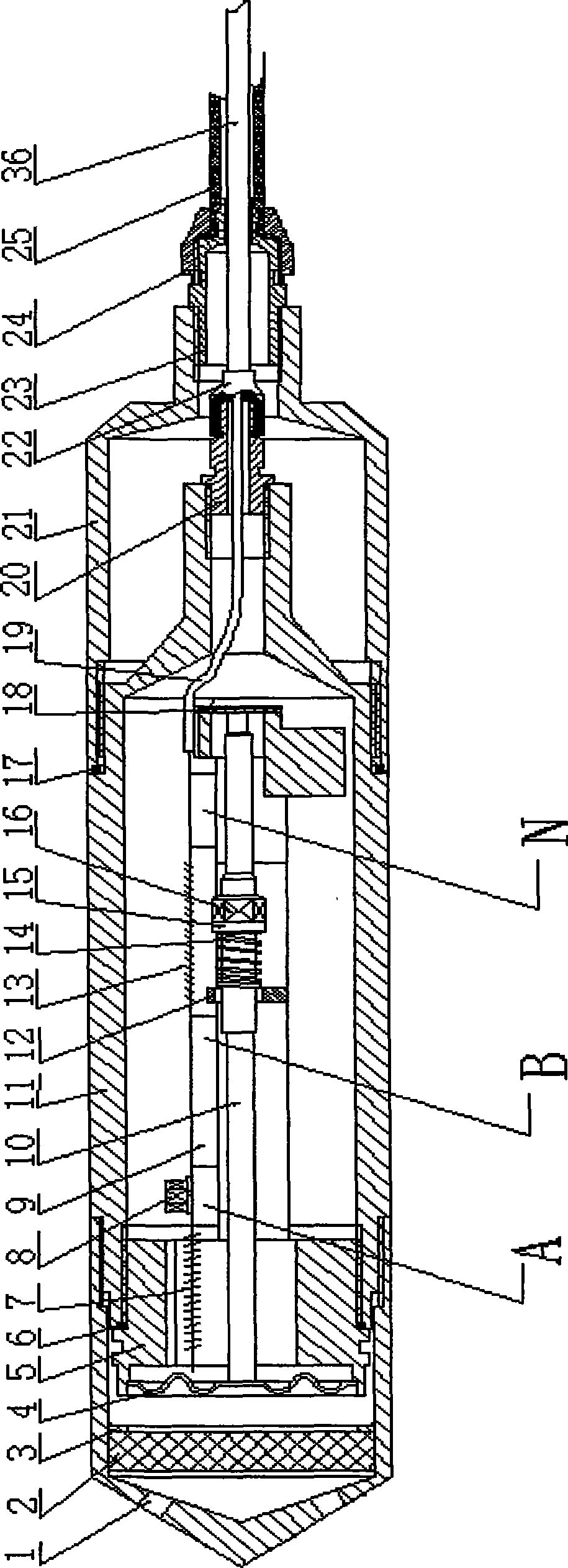

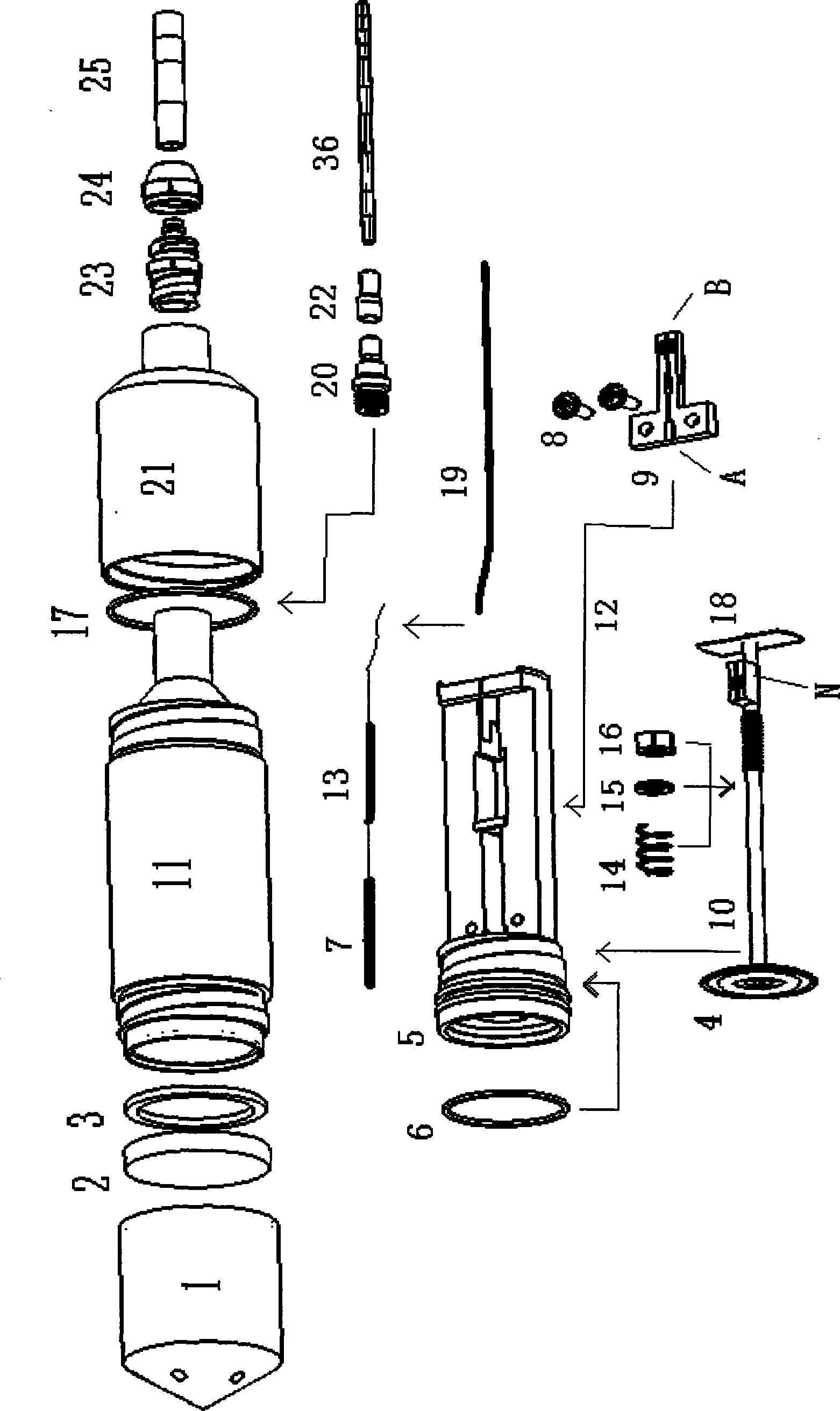

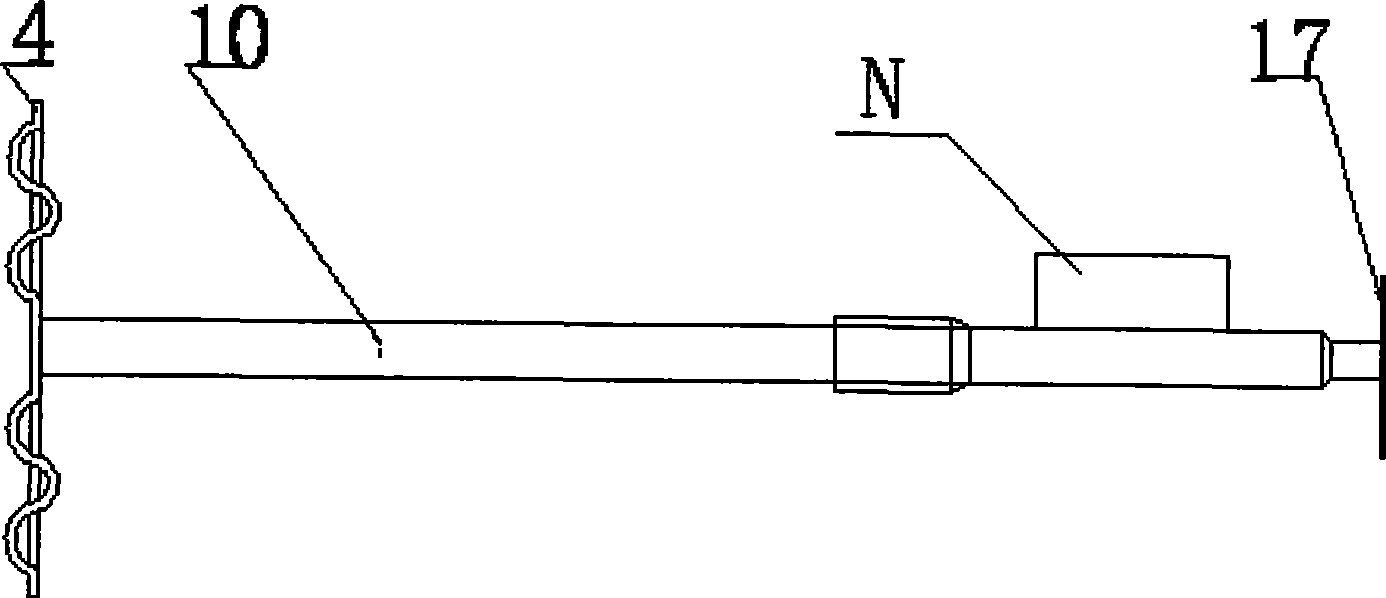

[0026] Such as figure 1 As shown, a fiber Bragg grating small-range osmotic pressure sensor includes a tubular support 5 and a water-tight casing 11, as well as a first fiber Bragg grating 7 and a second fiber Bragg grating 13 connected in series, and the edges are fixedly arranged The circular corrugated diaphragm 4 and the special-shaped diaphragm 18 at both ends of the tubular support 5, the centers of the circular corrugated diaphragm 4 and the special-shaped diaphragm 18 are fixedly arranged at the two ends of the connecting rod 10 respectively, and the connected The rod 10 is provided with a platform N, the joint of the circular corrugated diaphragm 4 and the special diaphragm 18 and the tubular support 5 is watertight, the joint of the tubular support 5 and the shell 11 is watertight, and the tubular support 5 is also provided with an adjustable frame 9 that supports the connection between the first Fiber Bragg Grating 7 and the second Fiber Bragg Grating 13 at one end...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap