Robot control method capable of avoiding generation of singular points

A control method and robot technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve problems such as inaccurate positioning of steel coils, and achieve the effects of saving costs, preventing unknowable pauses, and avoiding singular points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

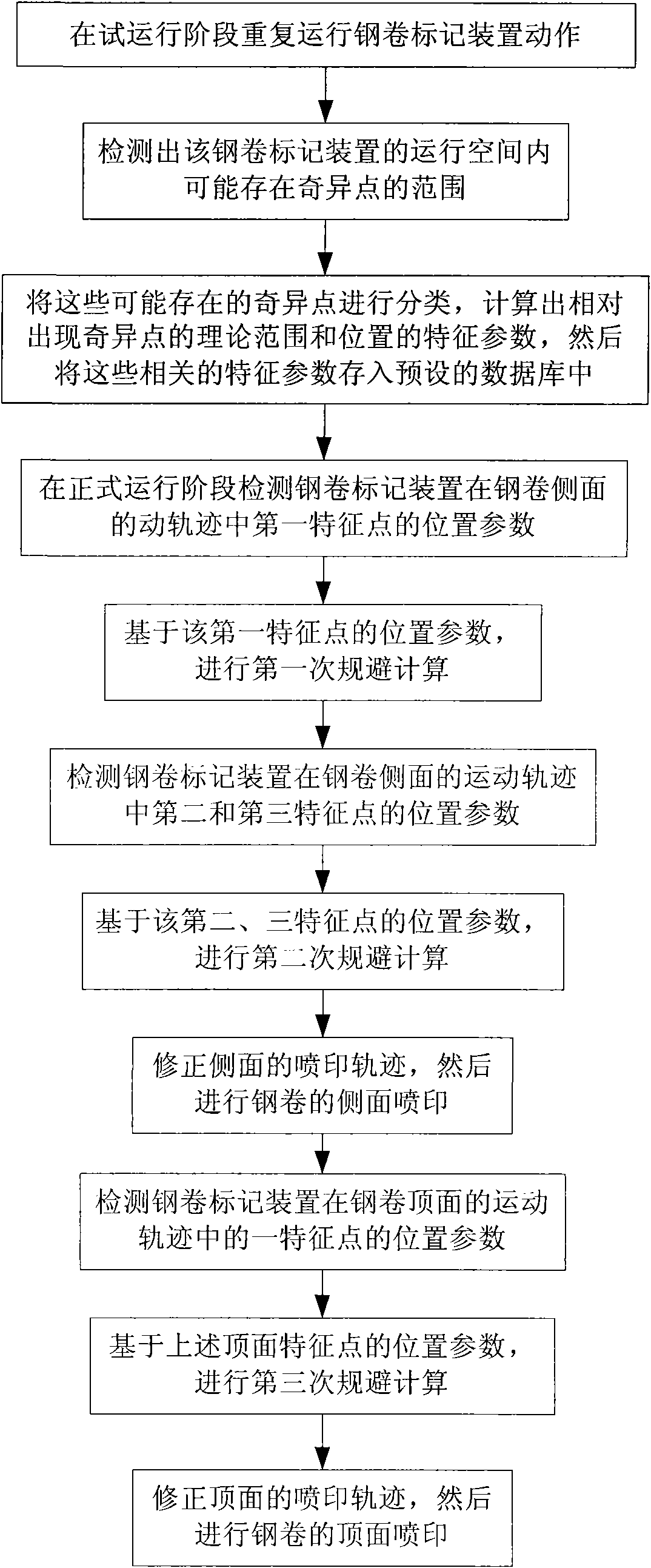

[0040] Such as figure 1 As shown, for the steel coil marking device that needs to be used in metallurgical enterprises, the following methods can be used to control it in order to avoid the occurrence of singularity:

[0041] The first stage is the trial operation stage, in which the following specific operations are performed:

[0042] First, repeat the operation of the coil marking device;

[0043] The second step is to detect the range of possible singular points in the operating space of the steel coil marking device;

[0044] The third step is to classify these possible singular points, calculate the characteristic parameters of the relative theoretical range and corresponding position of the singular points, and then store these related characteristic parameters in the preset database for correction of steel coils The action of marking the official operation of the device. Here, the characteristic parameters refer to the six-dimensional coordinates used and the runnin...

Embodiment 2

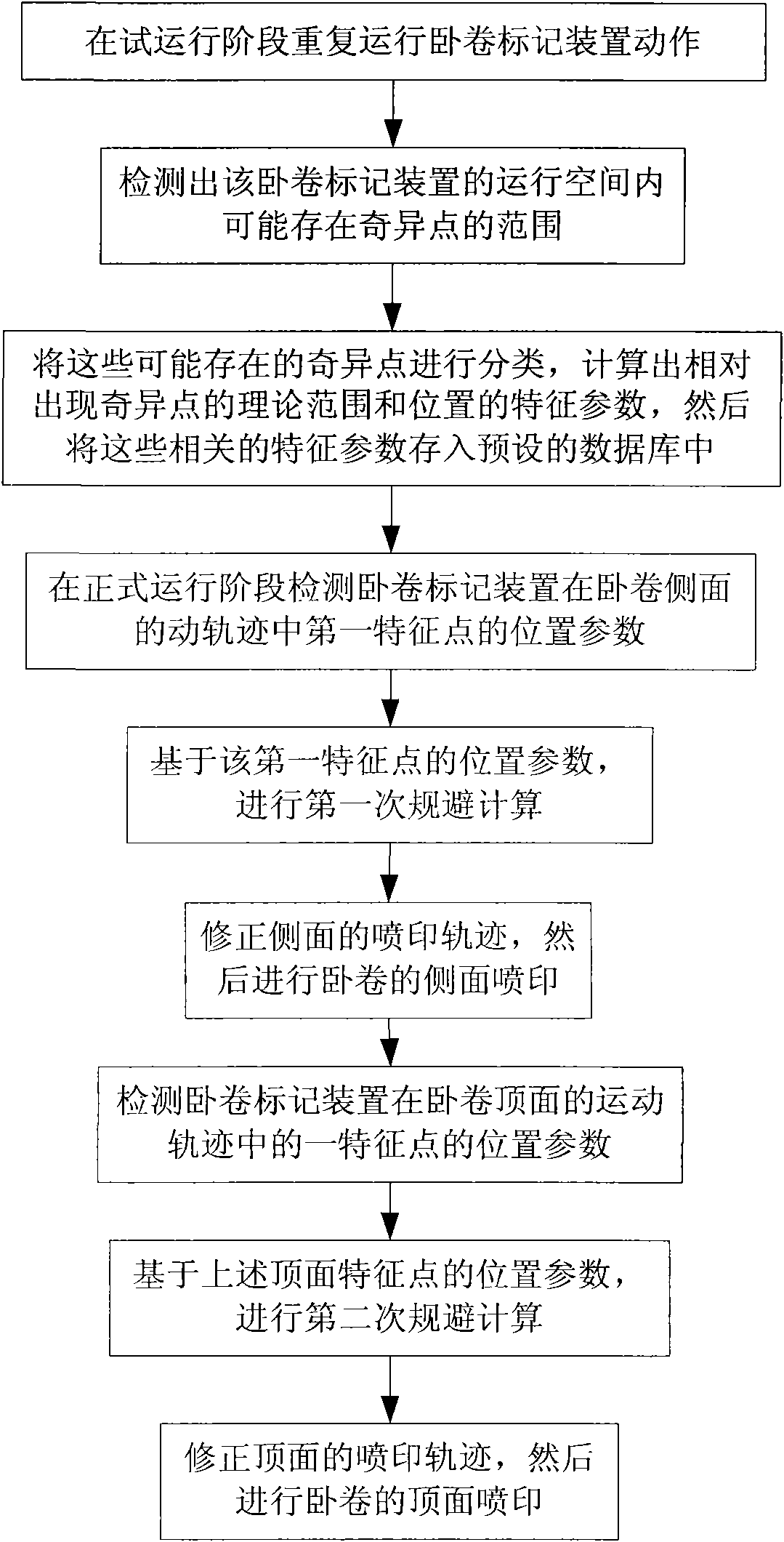

[0055] Such as figure 2 As shown, for the steel coil horizontal coil marking device that needs to be used in metallurgical enterprises, since the position of the parallel line of its axis is fixed, according to the present invention, the following methods can be used to control it to avoid the occurrence of singularity the goal of:

[0056] The first stage is the trial operation stage, in which the following operations are performed:

[0057] First, repeat the action of the horizontal coil marking device for steel coils;

[0058] The second step is to detect the range of singular points that may exist in the operating space of the horizontal coil marking device for steel coils;

[0059] The third step is to classify these possible singular points, calculate the characteristic parameters of the relative theoretical range and corresponding position of the singular points, and then store these related characteristic parameters in the preset database for correction of steel coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com