Face shovel spadework device provided with movement redundancy and capable of optimizing spading force

A motion, redundant technology, applied in mechanically driven excavators/dredgers, etc., can solve the problems of single structure, high energy consumption, small driving force arm, etc., achieve good flexibility, optimize digging force, driving force big arm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

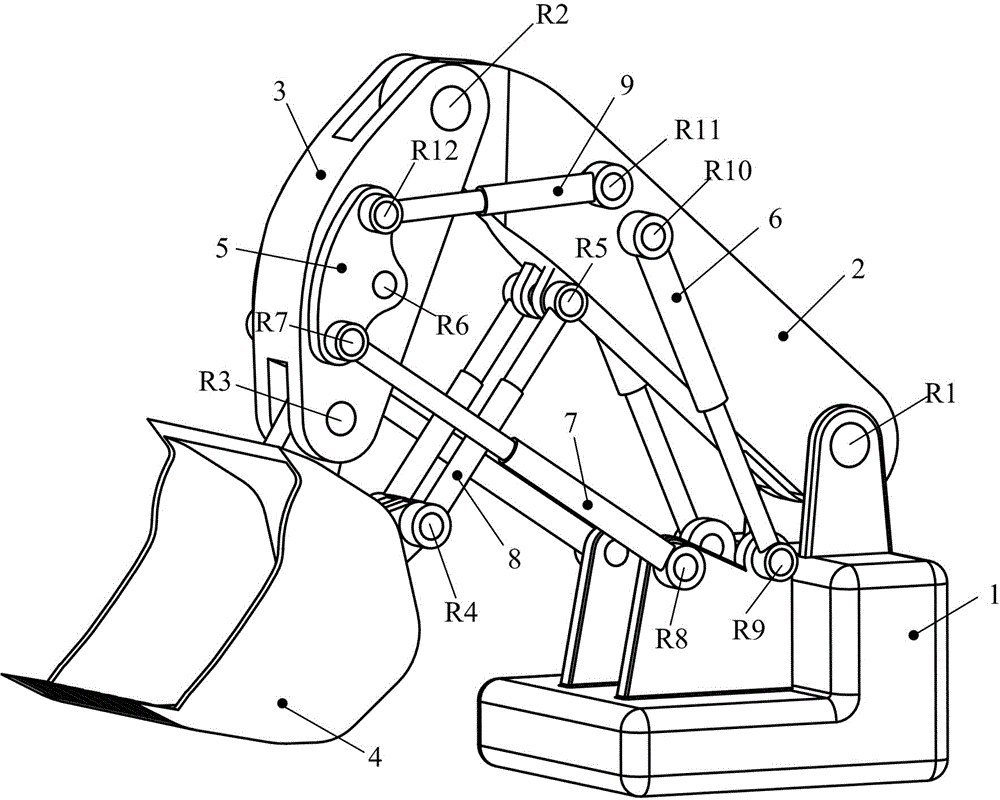

[0018] exist figure 1 In the three-dimensional schematic diagram of a mobile redundant front shovel excavation device that can optimize digging force, one end of the frame 1 is connected to the lower end of the boom 2 through the hinge R1, and the upper end of the boom 2 is connected through the hinge R2 It is connected to one end of the arm 3, and the other end of the arm 3 is hinged to a part of the bucket 4 through a hinge R3. A pair of powerful triangles 5 are symmetrically hinged on both sides of the middle part of the above-mentioned arm 3 through hinges R6, and the pair of powerful triangles 5 are respectively connected to the piston rod ends of a pair of arm hydraulic cylinders 7 through hinges R7. The pair of powerful cams 5 are respectively hinged to the ends of the piston rods of the pair of stick hydraulic cylinders 9 through the hinge R12; the ends of the cylinder liners of the above pair of stick hydraulic cylinders 1 are respectively connected to the other end o...

Embodiment 2

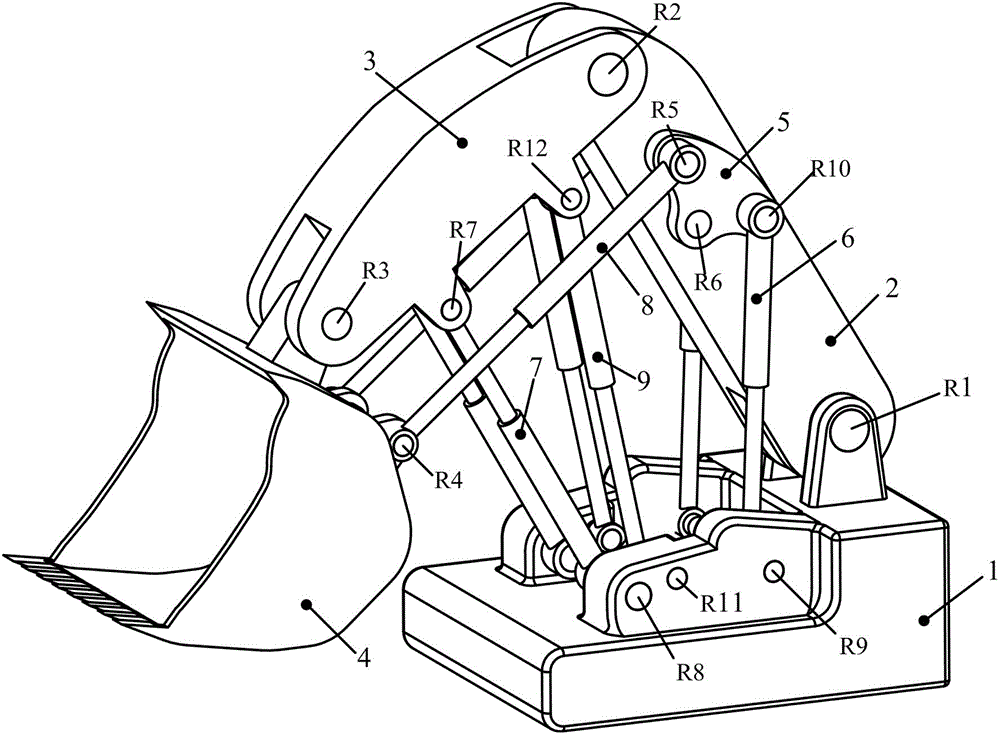

[0020] exist figure 2 In the three-dimensional schematic diagram of a mobile redundant front shovel excavation device that can optimize digging force, one end of the frame 1 is connected to the lower end of the boom 2 through the hinge R1, and the upper end of the boom 2 is connected through the hinge R2 One end of the arm 3 is connected, and the other end of the arm 3 is connected to a part of the bucket 4 through a hinge R3. A pair of powerful triangles 5 are respectively symmetrically connected to both sides of the middle part of the above-mentioned boom 2 through a hinge R6. The cylinder liner ends of a pair of bucket hydraulic cylinders 8 are respectively connected to the above-mentioned strong triangle 5 through hinge R5, and the piston rod ends of the pair of bucket hydraulic cylinders 8 are respectively connected to a part of the above-mentioned bucket 4 through hinge R4; The above-mentioned pair of powerful triangles 5 are respectively connected to the cylinder line...

Embodiment 3

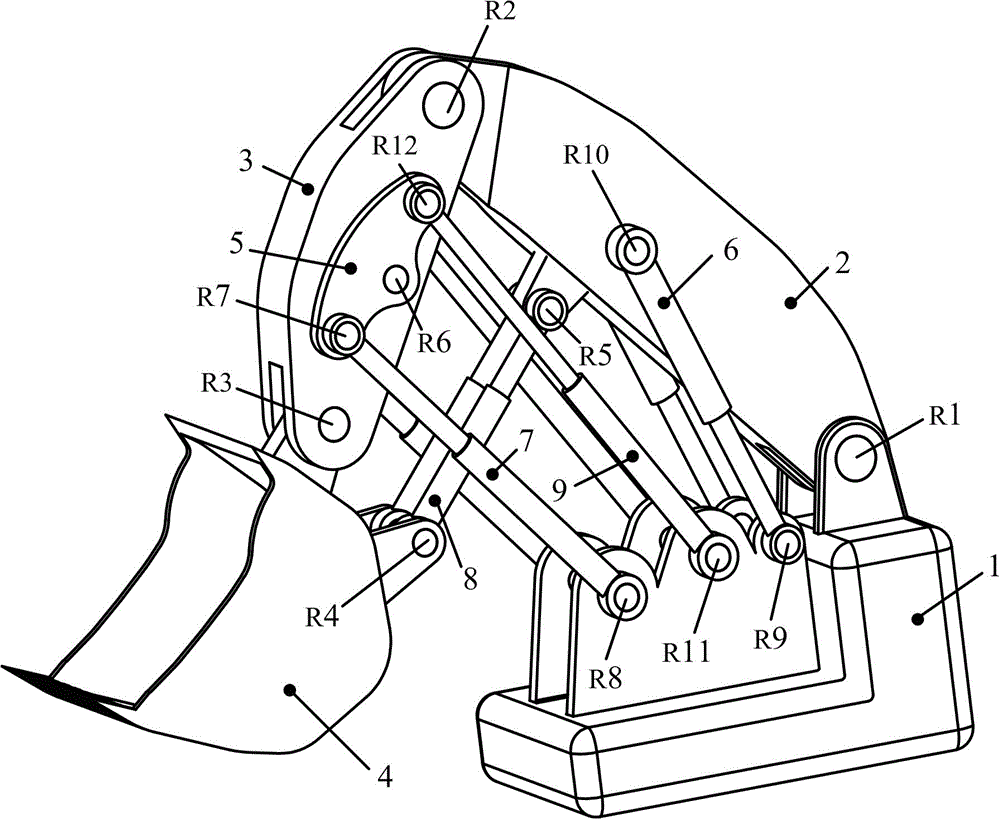

[0022] exist image 3 A perspective schematic diagram of a mobile redundant front shovel excavation device that can optimize digging force is shown , One end of the frame 1 is connected to the lower end of the boom 2 through the hinge R1, the upper end of the boom 2 is connected to one end of the arm 3 through the hinge R2, and the other end of the arm 3 is connected to a part of the bucket 4 through the hinge R3. connect. A pair of powerful triangles 5 are symmetrically hinged on both sides of the middle part of the above-mentioned arm 3 through hinges R6, and the pair of powerful triangles 5 are respectively connected to the piston rod ends of a pair of arm hydraulic cylinders-7 through hinges R7; The ends of the cylinder liners of the pair of stick hydraulic cylinders 1 and 7 are respectively connected to another part of the frame 1 through hinge R8; The cylinder liner ends of the pair of stick hydraulic cylinders 2 are respectively connected to the above-mentioned frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com