Automobile rear floor frame assembly

A rear floor and assembly technology, applied to upper structure sub-assembly, vehicle components, upper structure, etc., to achieve the effects of reducing maintenance costs, improving torsional rigidity, and mature and stable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

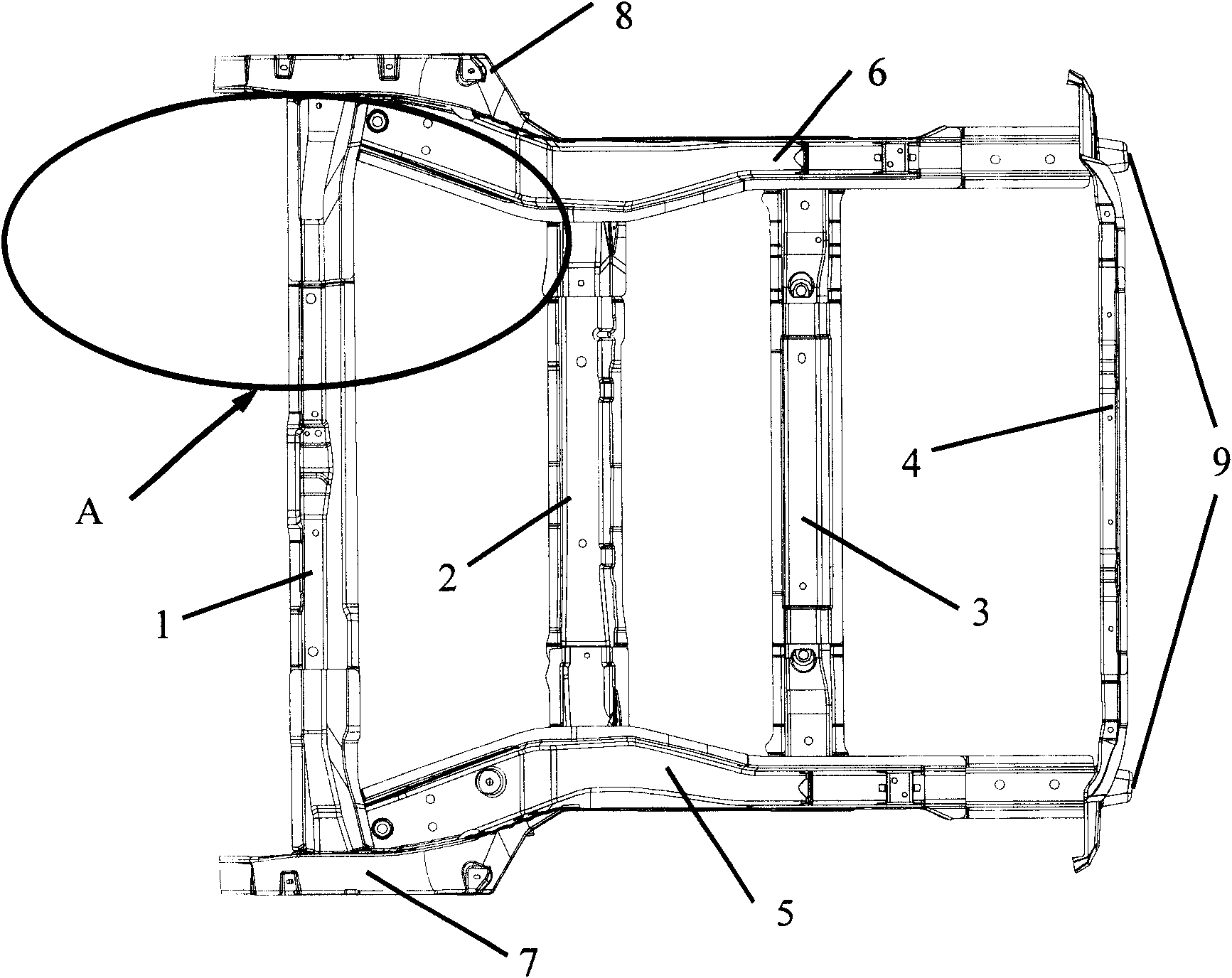

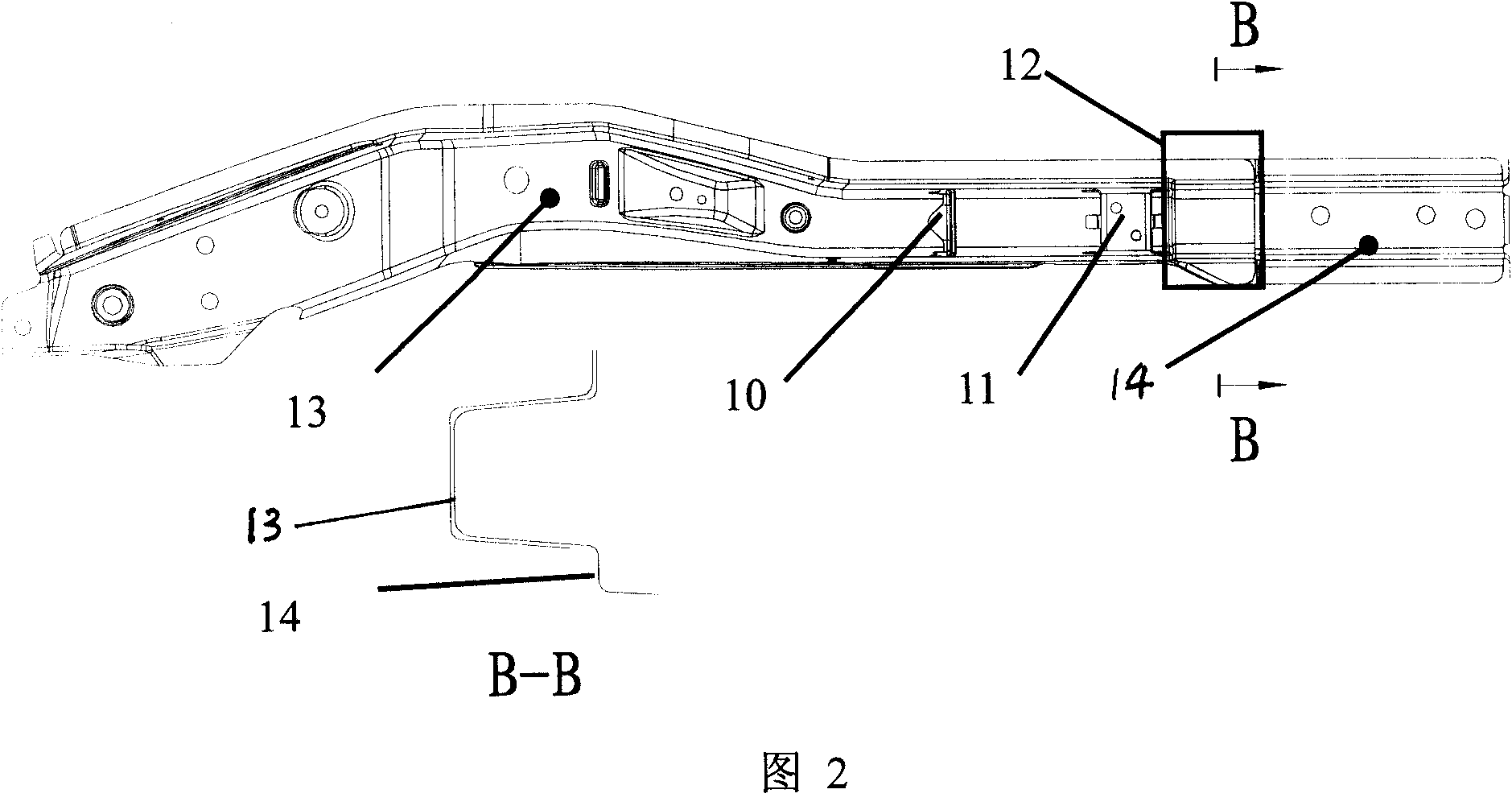

[0020] Both the left side of the rear floor side beam assembly and the right side of the rear floor side beam assembly adopt the form of welding combination of front and rear parts, such as figure 2 and figure 2 As shown in A, the front part 13 of the rear floor sill and the rear part 14 of the rear floor sill are welded at the region 12 by spot welding, and the welded regions are superimposed to form a buffer structure region 12 with a difference in thickness.

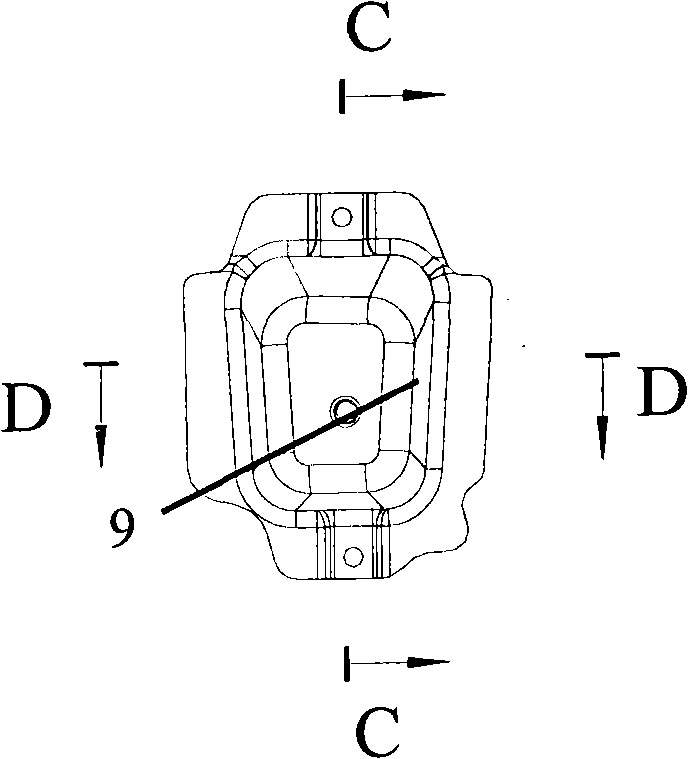

[0021] see image 3 , Figure 3A , Figure 3B , the rear end and the rear part and the rear skirt plate 4 joints are welded with a collision deformation box 9 at the rear end of the left side 5 of the back floor side beam assembly and the right side 6 of the back floor side beam assembly. F is the direction of force.

[0022] After adopting the structural design of the present invention, the main principle of the rear safety design of the vehicle body occurs in the following two situations when the vehicle colli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com