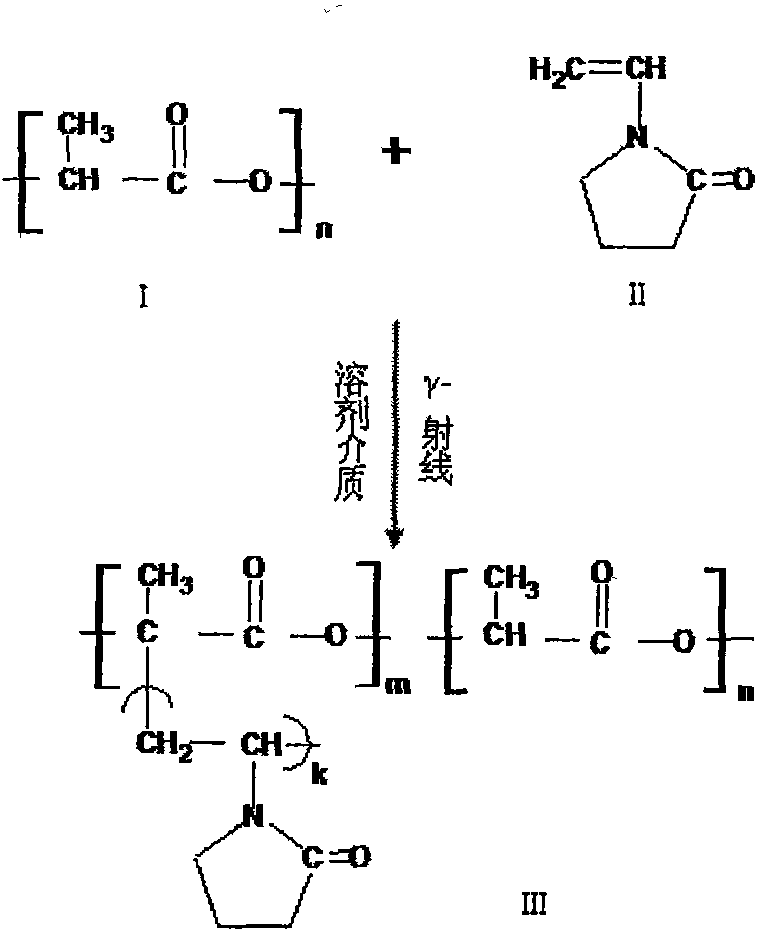

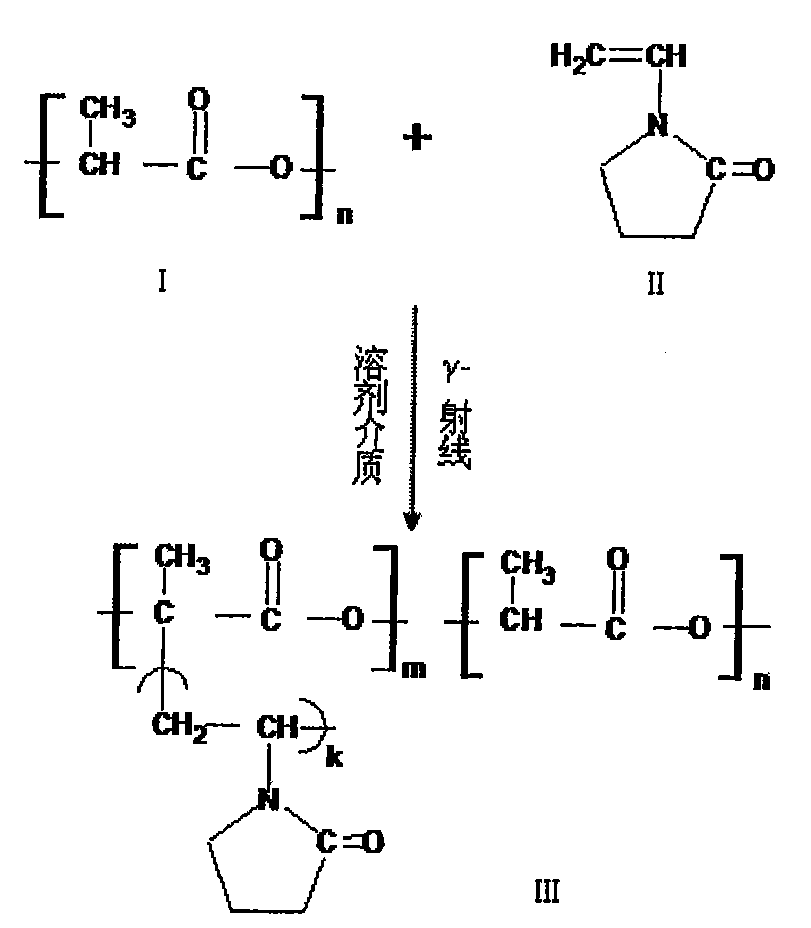

A method for preparing radiation graft copolymer of polylactic acid and N-vinyl pyrrolidone

A technology of vinylpyrrolidone and radiation grafting, applied in the field of biomedical materials, can solve the problems of complex purification process of graft copolymers, difficult control of graft ratio of graft copolymers, complex reaction process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Distill the N-vinylpyrrolidone under reduced pressure to remove the polymerization inhibitor, the vacuum degree is -0.065MPa, seal the N-vinylpyrrolidone from which the polymerization inhibitor has been removed, and place it in a refrigerator for use. Store at 0°C.

[0028] Weigh 3 g of N-vinylpyrrolidone from which the polymerization inhibitor was removed, and dissolve it in 30 g of methanol to form a solution. Measure 18 ml of the methanol solution of N-vinylpyrrolidone, pour it into an ampule bottle, then weigh 0.5 g of polylactic acid, put it into the ampule bottle, and make it completely immersed in the methanol solution of N-vinylpyrrolidone. Vacuumize and fill with nitrogen repeatedly for 5 times, and finally seal the tube with nitrogen. The sealed tube sample is sent to the irradiation field to 60 Co-γ was irradiated at room temperature, the absorbed dose was 1.0kGy, and the dose rate was 5kGy / h.

[0029] The irradiated sample was taken out, immersed in disti...

Embodiment 2

[0032] Distill the N-vinylpyrrolidone under reduced pressure to remove the polymerization inhibitor, the vacuum degree is -0.098MPa, seal the N-vinylpyrrolidone from which the polymerization inhibitor has been removed, and place it in a refrigerator for use. Store at 0°C.

[0033] Weigh 10 g of N-vinylpyrrolidone from which the polymerization inhibitor was removed, and dissolve it in 23 g of methanol to form a solution. Measure 18 ml of N-vinylpyrrolidone solution and pour it into an ampoule. Put 0.5g of polylactic acid into the ampoule and completely soak it in the solution of N-vinylpyrrolidone. Vacuumize and fill with nitrogen repeatedly for 5 times, and finally seal the tube with nitrogen. The sealed tube sample is sent to the irradiation field to 60 Co-γ radiation originates from irradiation at room temperature, the absorbed dose is 5kGy, and the dose rate is 2.5kGy / h.

[0034] The irradiated sample was taken out, immersed in distilled water at 30°C for 4 hours, then ...

Embodiment 3

[0036] Distill the N-vinylpyrrolidone under reduced pressure to remove the polymerization inhibitor, the vacuum degree is -0.085MPa, seal the N-vinylpyrrolidone from which the polymerization inhibitor has been removed, and place it in a refrigerator for use. Store at 0°C.

[0037] Weigh 40 g of methanol, 10 g of ethanol and 0.5 g of hydrochloric acid with a concentration of 36% (mass percentage concentration) respectively, and mix them to form a composite solvent. Weigh 6 g of N-vinylpyrrolidone from which the polymerization inhibitor has been removed, and dissolve it in a composite solvent of methanol and ethanol. Measure 15 ml of N-vinylpyrrolidone solution and pour it into an ampoule. Put 0.3g of polylactic acid into the ampoule and completely soak it in the solution of N-vinylpyrrolidone. Vacuumize and fill with nitrogen repeatedly for 5 times, and finally seal the tube with nitrogen. The sealed tube sample is sent to the irradiation field to 60 The Co-γ radiation sour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com