Ball valve

A ball valve and hemisphere technology, applied in the field of ball valves, to achieve the effects of long service life, convenient installation and maintenance, and easy switching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

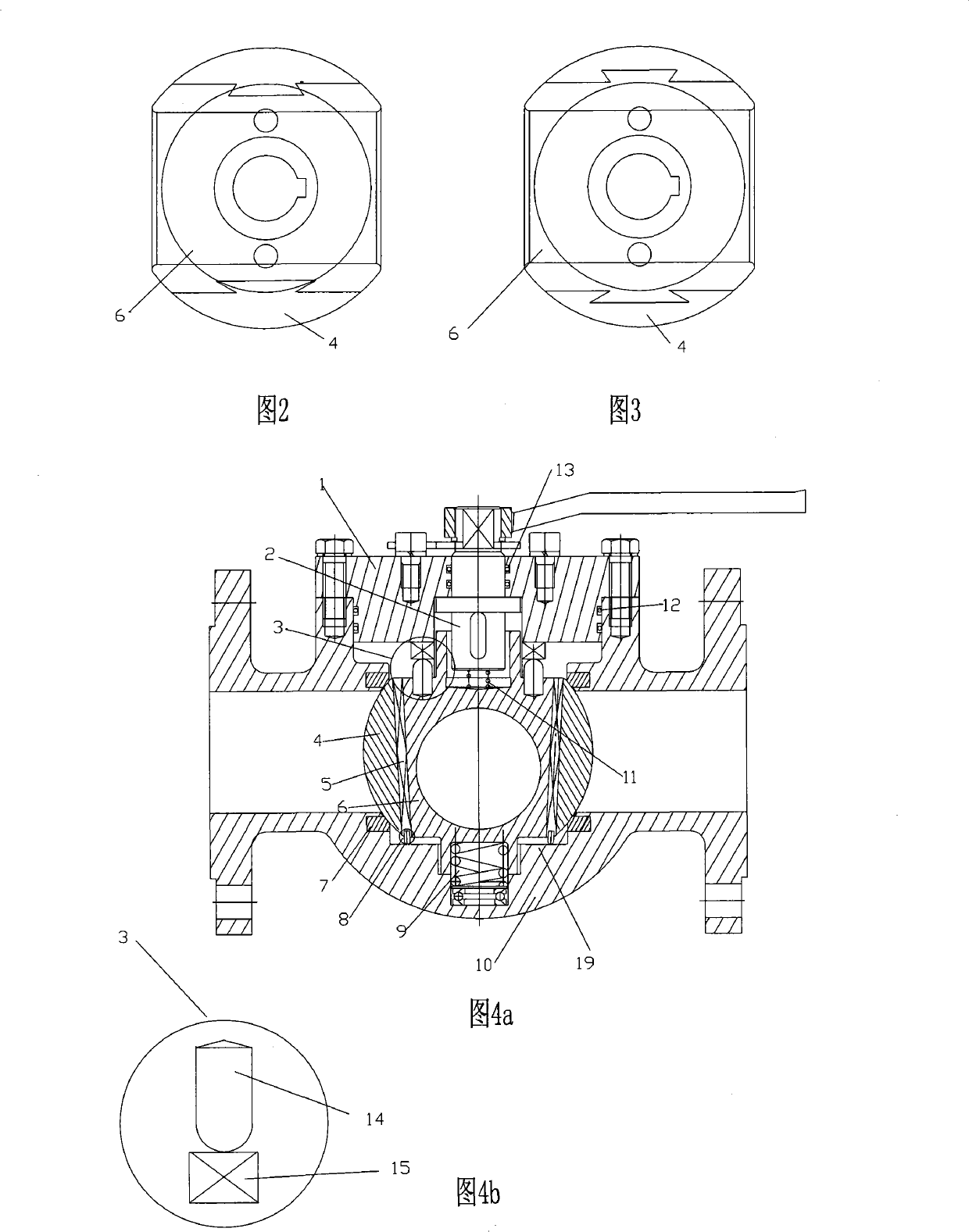

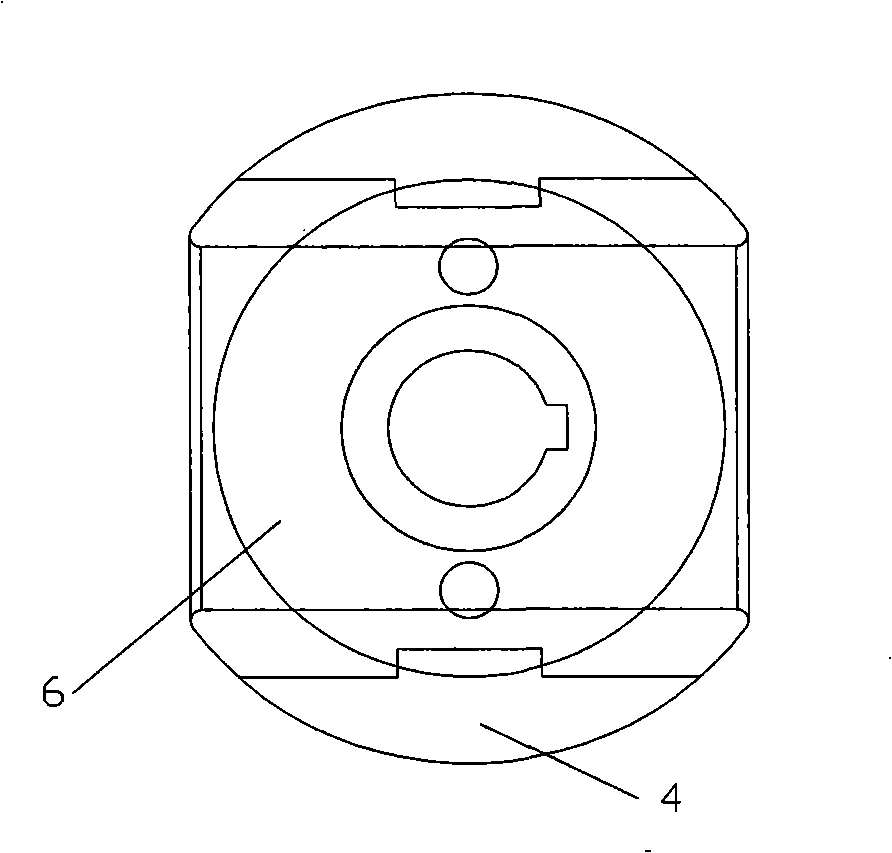

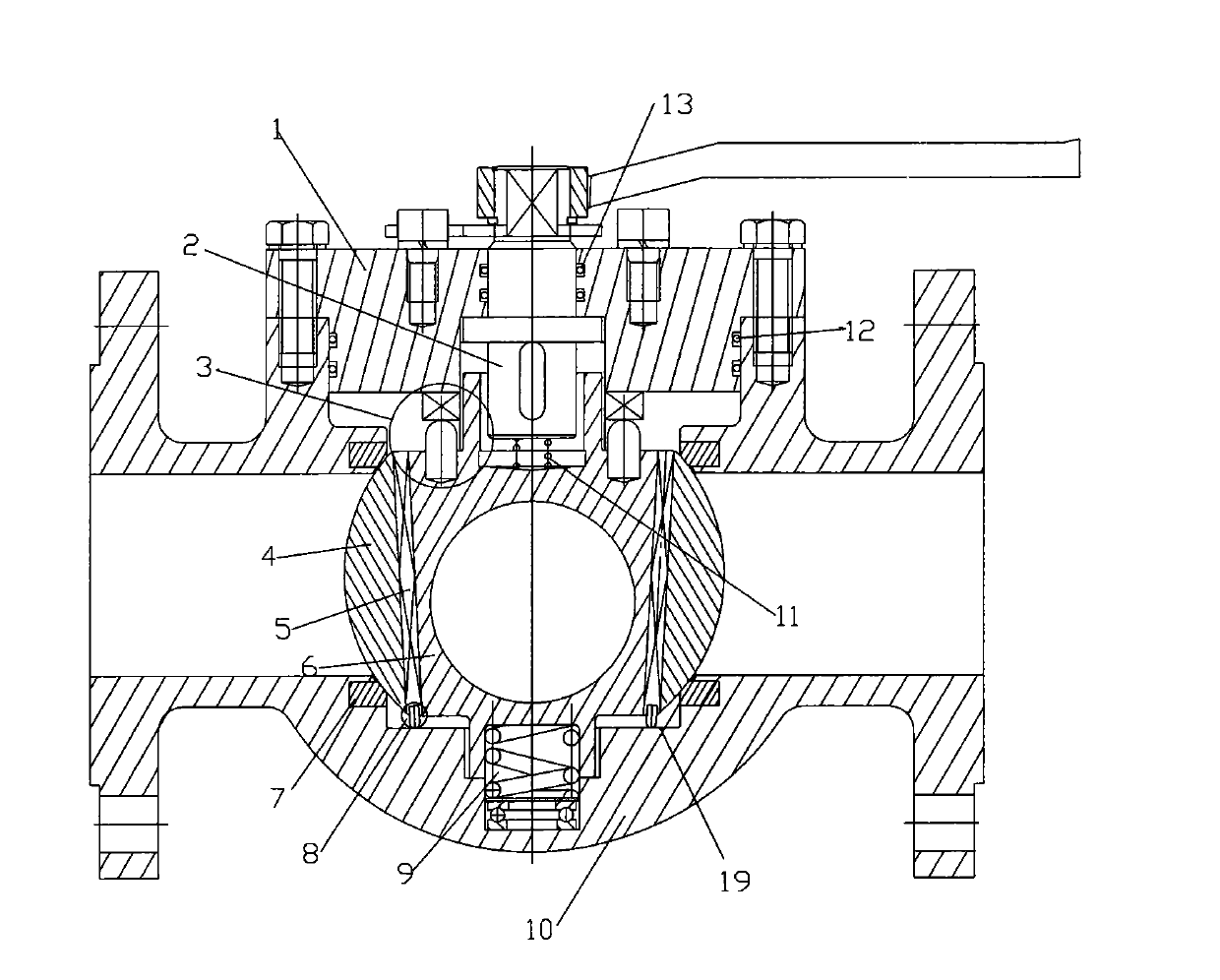

[0032] Such as Figure 1a , 1b , 2, 3 shown: the upper gland 1 is fixed on the valve body by bolts, and a sealing element 12 is installed between the upper gland 1 and the valve body to realize liquid sealing. The upper end of the rotary shaft 2 is connected to the handle, and the lower end passes through the upper gland 1 and is inserted into the hole at the upper end of the wedge-shaped ball core 6. The hole is an oblong hole, a square hole, a rectangular hole, and a circular hole with keys for fixing the positions of the two. Or other devices that can prevent the relative rotation of the two during rotation. The shaft head at the lower end of the rotary shaft 2 corresponds to the hole at the upper end of the wedge-shaped ball core 6, and a seal 13 is installed between the rotary shaft 2 and the upper gland 1 to realize a liquid seal.

[0033] A thrust mechanism 3 is installed between the lower end of the upper gland and the wedge-shaped spherical core. During the rotation...

Embodiment 2

[0038] Such as Figure 4a , 4b As shown: the thrust mechanism 3 is composed of a plane cam 15 and a movable plug 14, wherein the plane cam 15 is installed on the wedge-shaped ball core 6, and the movable plug 14 is installed on the lower surface of the upper gland 1. The head of the movable plug 14 abuts on the plane cam 15, and the wedge-shaped ball core 6 drives the movable plug 14 to move along the surface of the plane cam 15 when the wedge-shaped ball core 6 rotates. Driven by the thrust mechanism 3, the wedge-shaped ball core 6 can move up and down relative to the sealed hemisphere 4.

[0039] The loose plug 14 in Embodiments 1 and 2 can also be directly processed on the wedge-shaped ball core 6 or the lower surface of the upper gland 1 .

Embodiment 3

[0041] Such as Figure 5a , 5b As shown: the thrust mechanism 3 can also be made up of two plane cams 15, the upper plane cam 15 is installed on the lower surface of the upper gland 1, the lower plane cam 15 is installed on the top of the wedge-shaped ball core 6, and the two plane cams 15 surface in contact. When the rotary shaft 2 drives the wedge-shaped ball core 6 to rotate, the two planar cams 15 also rotate relatively. Driven by the two flat cams 15, the wedge-shaped ball core 6 can move up and down relative to the sealing hemisphere 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com