Method of manufacturing a semiconductor sensor device and semiconductor sensor device obtained with such method

A sensor device, semiconductor technology, applied in the direction of semiconductor devices, measuring devices, instruments, etc., can solve the problems of damage, high risk, easy damage, etc., and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

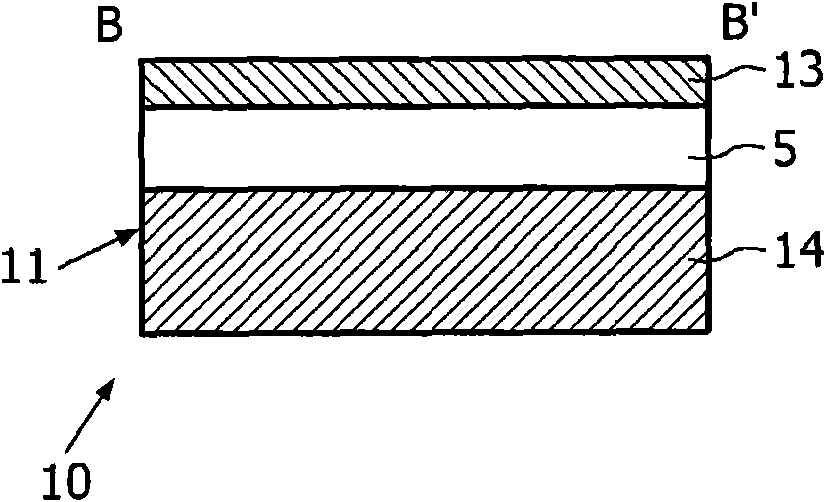

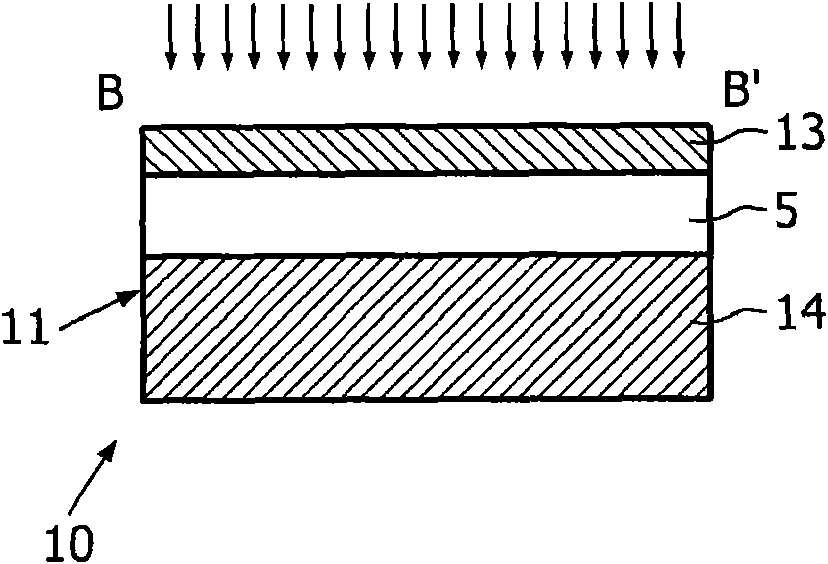

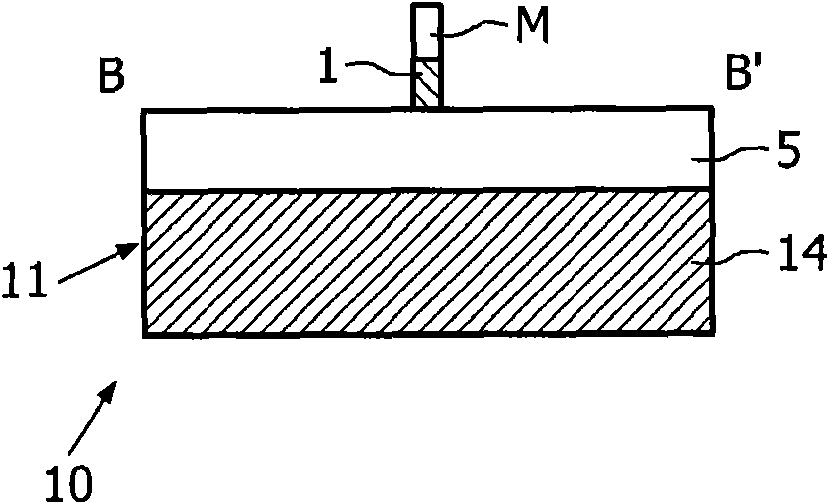

[0026] The figures are diagrammatic and not drawn to scale, the dimensions in the thickness direction being particularly exaggerated for clarity. Corresponding parts are generally given the same reference symbols and the same shading in different figures.

[0027] Where the term "particle" is used in the present invention, it may refer to, for example, chemical, biochemical or biological particles to be detected, such as but not limited to cells, organelles, membranes, bacteria, viruses, chromosomes, DNA, RNA, small Organic molecules, metabolites, proteins including enzymes, peptides, nucleic acid fragments, spores, microorganisms and their fragments or products, polymers, metal ions, toxins, illegal drugs, explosives, etc. Particles, especially smaller particles such as some DNA, RNA, nucleic acid fragments, etc., can also be coupled to larger particles. These particles can be biological cells.

[0028] Figures 1 to 9It is a cross-sectional view or a top view of a semicond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com