Inertia variable engine

An engine and variable technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of economical decline, increased engine fuel consumption, etc., and achieve good environmental performance, fuel saving, and reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

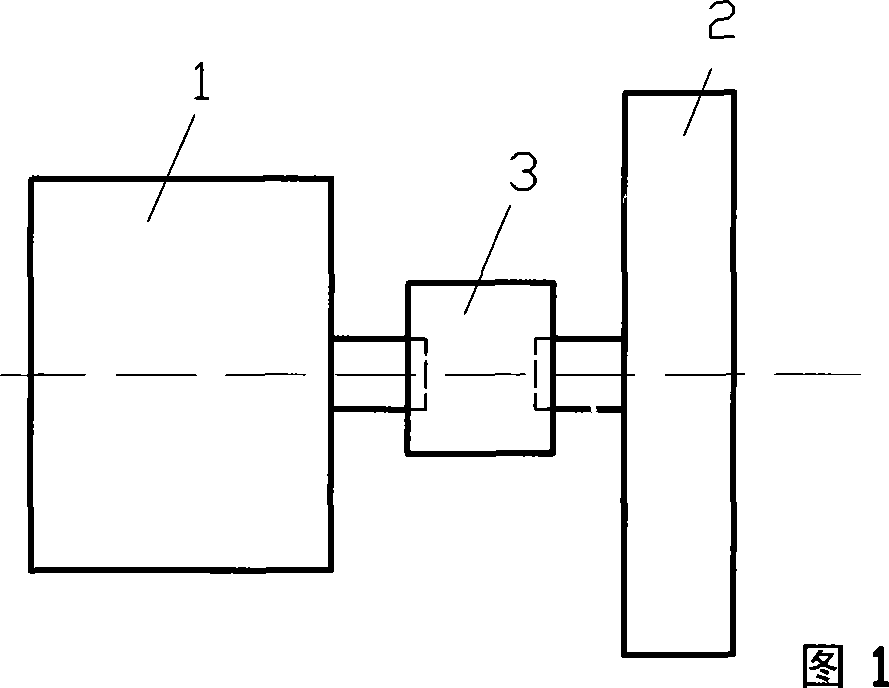

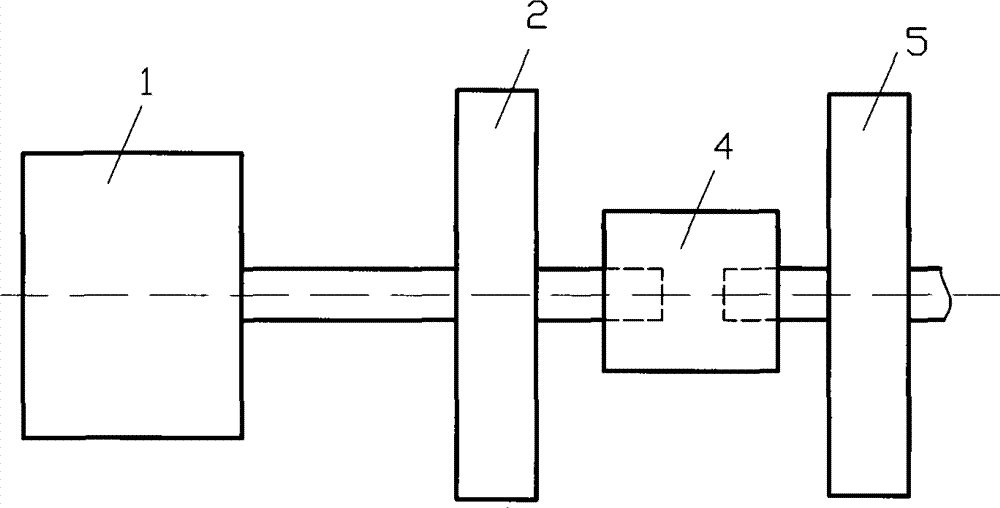

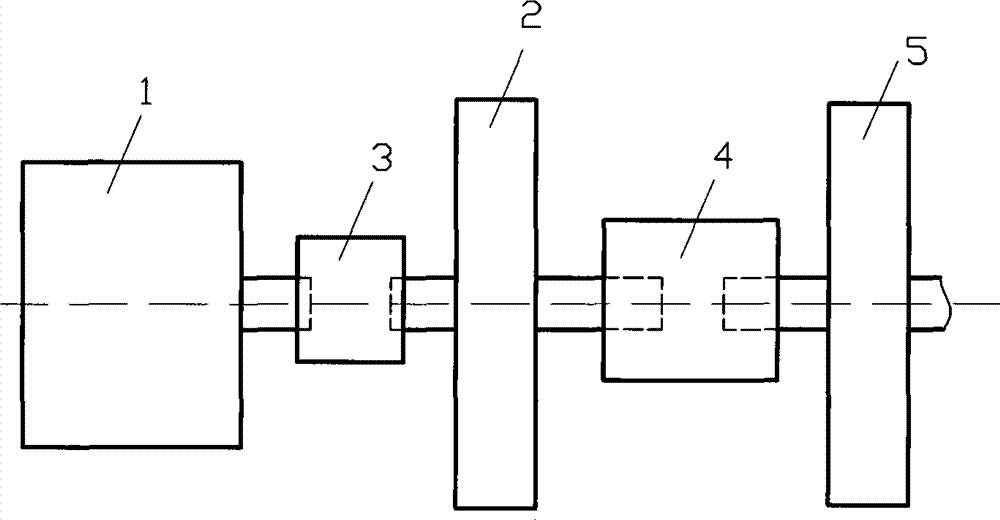

[0010] Figure number

[0011] 1. Engine 2. Flywheel 3. Transmission

[0012] 4. Clutch device 5. Inertia body

[0013] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0014] Please refer to figure 1 The variable inertia engine shown includes: an engine 1 and a flywheel 2, the crankshaft of the engine 1 is fixedly connected to the flywheel 2 via a speed change device 3, and the control device of the speed change device 3 is linked with the throttle of the engine.

[0015] Please refer to figure 2 As shown in the variable inertia engine, the crankshaft of the engine 1 is directly connected to the flywheel 2, and the flywheel 2 is connected to the inertia body 5 through a mechanical or electromagnetic clutch device 4, and the mechanical or electromagnetic clutch device The control device of 4 is linked with the accelerator of engine.

[0016] Please refer to image 3 As shown in the variable inertia eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com