Hydraulically based continuously variable inertial capacity

A variable, inertial-capacity technology, used in transmissions, friction transmissions, flywheels, etc., can solve problems such as inability to adjust inertia, and achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

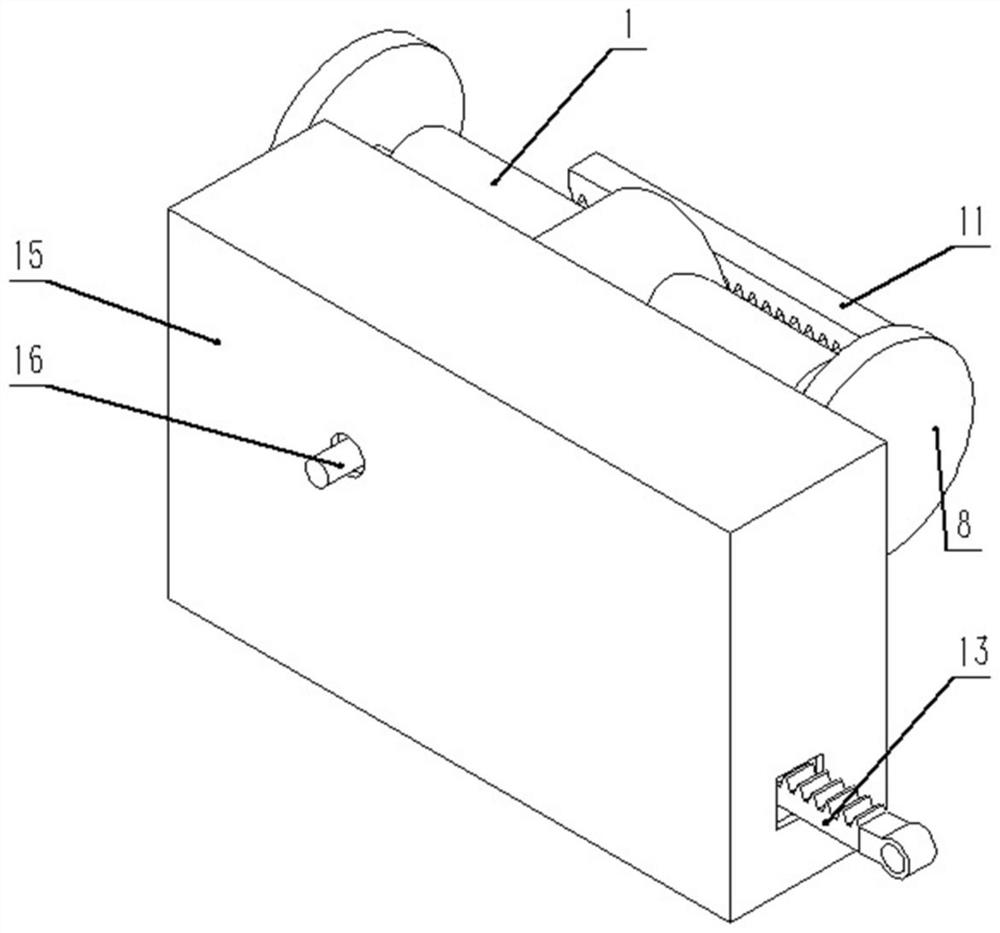

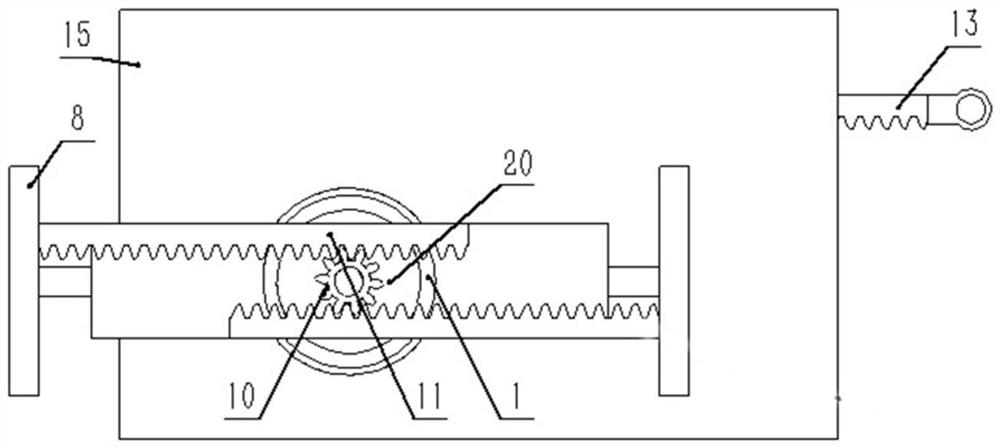

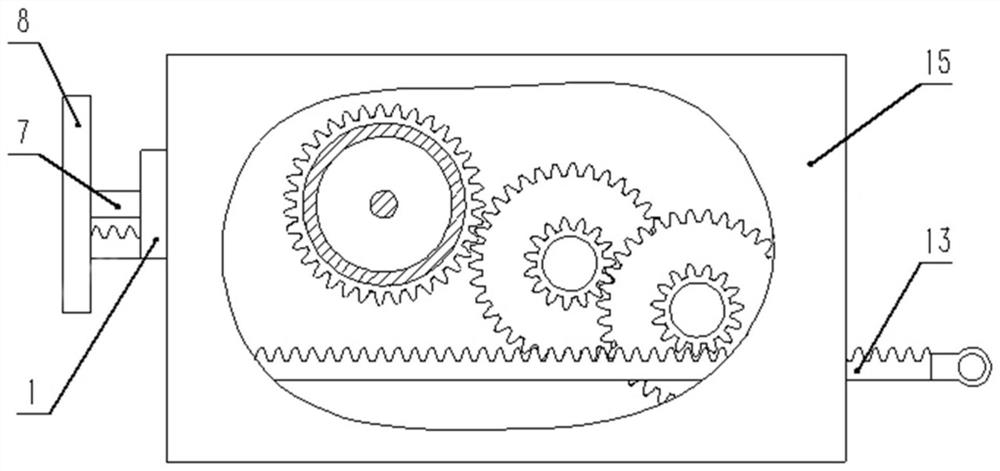

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] to combine Figure 1 to Figure 6 , the hydraulic-based continuously variable inertial capacity described in the present invention includes a flywheel assembly, a first rack and pinion mechanism, a second rack and pinion mechanism and a housing 15, and the flywheel assembly includes a T-shaped flywheel tube 1, a first piston assembly and two second piston assemblies, the T-shaped flywheel tube 1 includes a first round tube and two second round tubes, the bottom of the first round tube has an end cap, and the two second round tubes are symmetrically arranged at the bottom of the first round tube The two sides of the outer wall of the T-shaped flywheel jointly constitute a T-shaped flywheel tube 1. One end of the two second piston assemblies extends into the second circular pipe, the other end extends into the second circular pipe, and one end of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com