Connecting device for flexible gas tube

A technology for connecting devices and gas pipes, which is applied in the directions of hose connecting devices, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of troublesome connection of flexible gas pipes, etc., and achieve the effect of easy connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

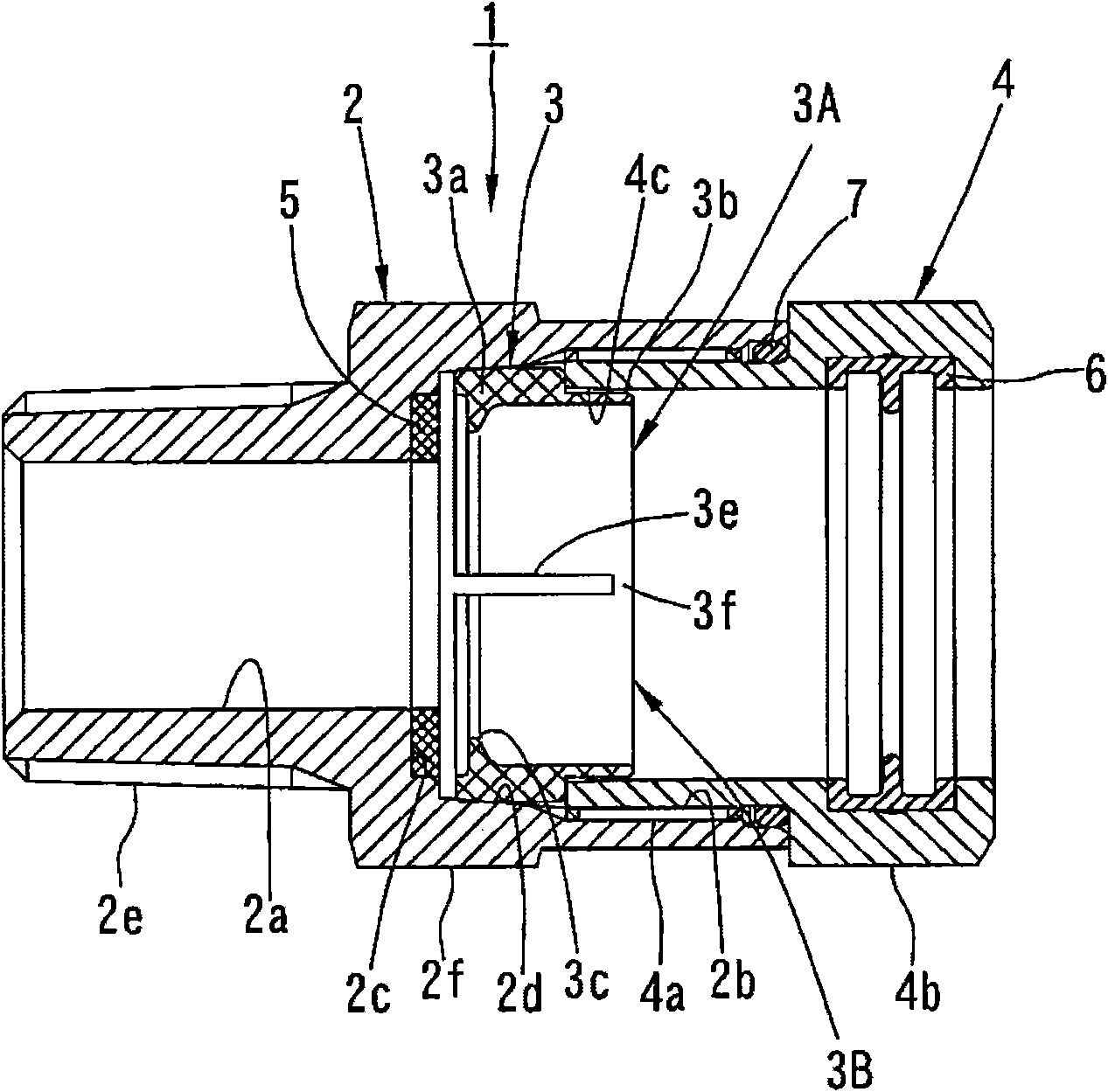

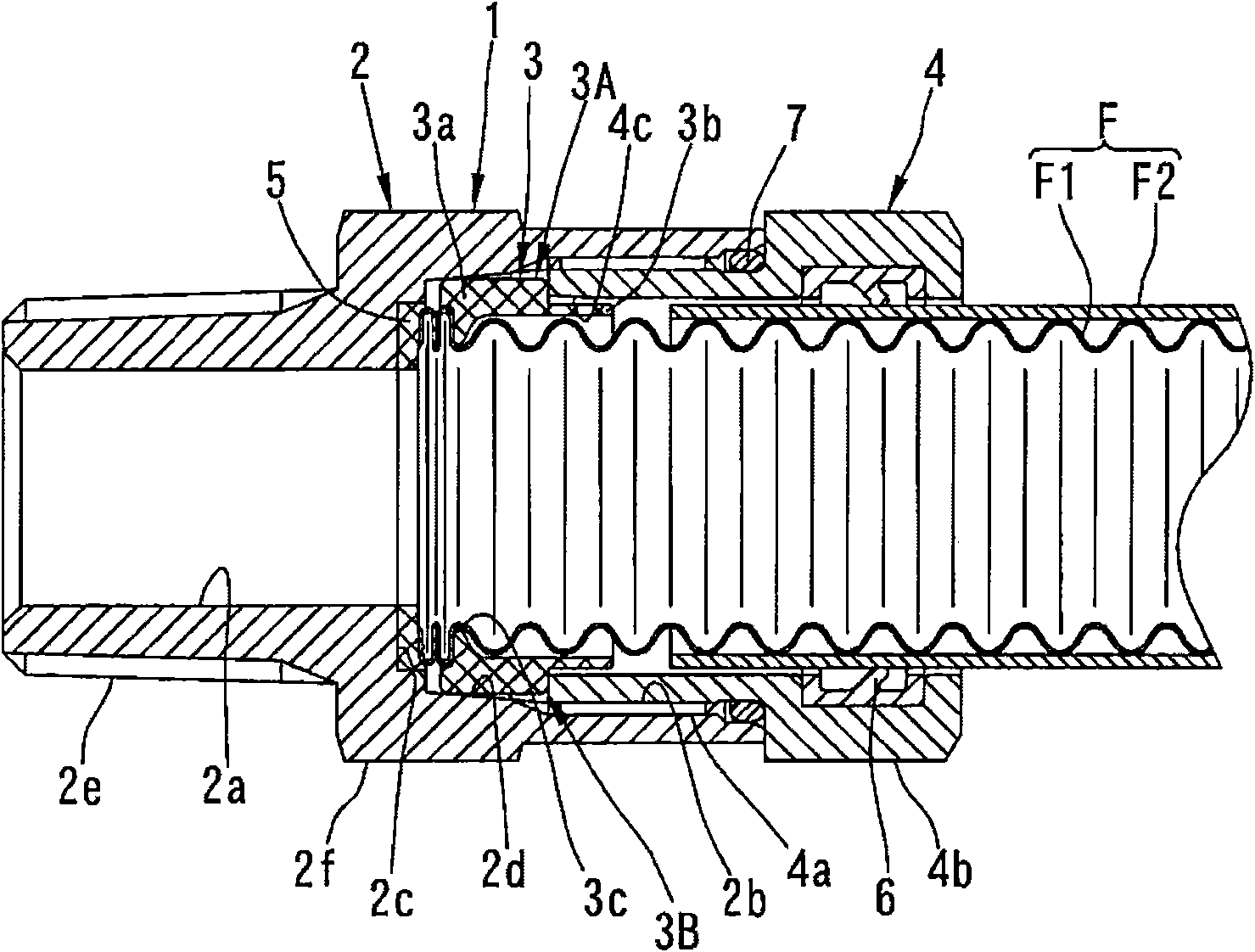

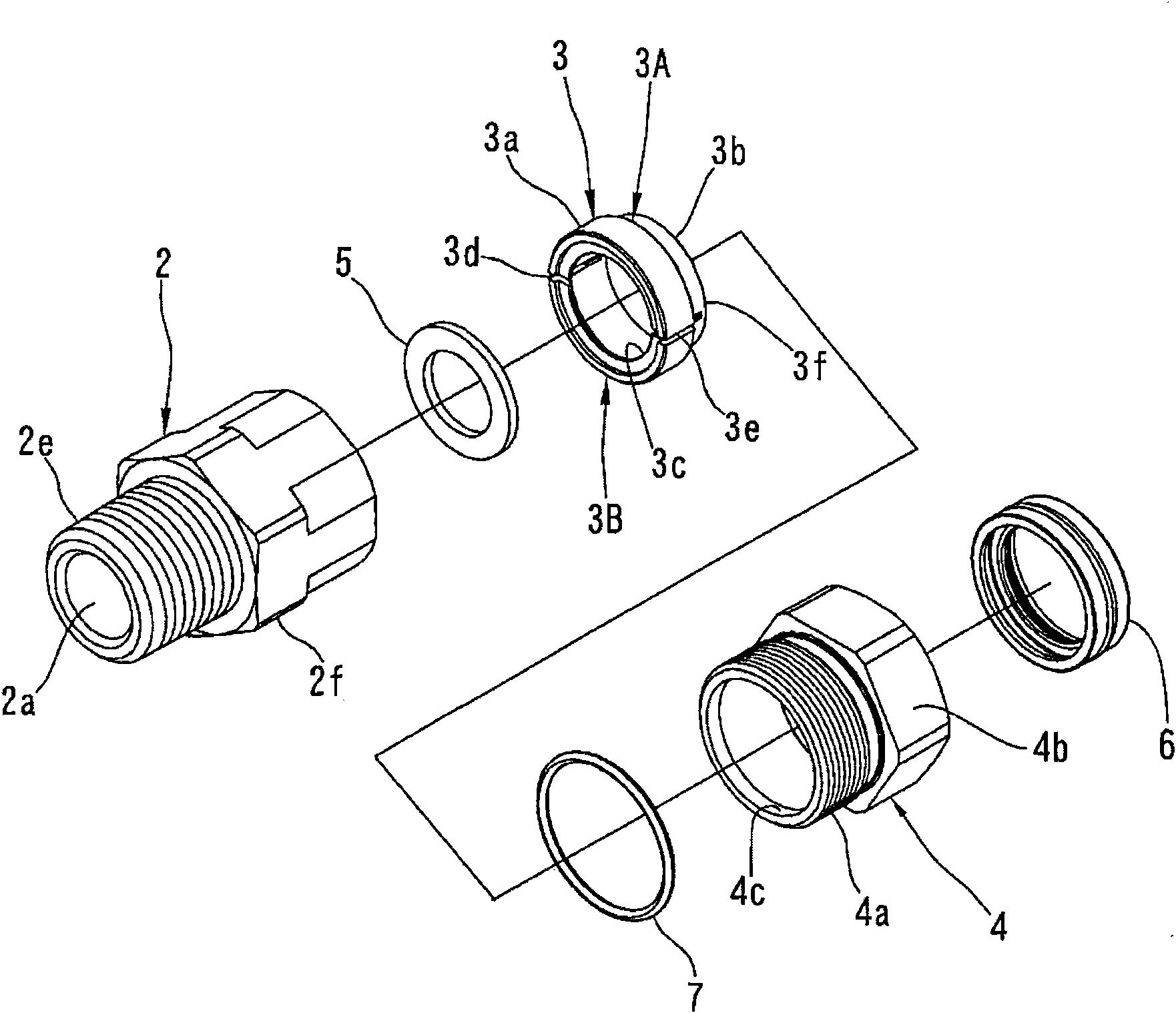

[0040] Hereinafter, the best embodiment for carrying out the present invention will be described with reference to the accompanying drawings.

[0041] First, the flexible gas pipe F as the connecting object of the connecting device for flexible gas pipe according to the present invention will be described. Covering tube F2 constitutes. When the flexible gas pipe is connected to a gas machine, the front end of the cladding pipe F2 is cut off so that a predetermined number of peaks (for example, five peaks) are exposed from the front end of the bellows F1.

[0042] Next, a connecting device for a flexible gas pipe according to the present invention for connecting the above-mentioned flexible gas pipe F to gas equipment will be described. Figure 1 ~ Figure 3 A first embodiment of the present invention is shown. The flexible gas pipe connection device 1 of this embodiment has a device body 2 , a retainer 3 and a screw member 4 as main components.

[0043] A connection hole 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com