Phase change memory dynamic resistance test and manufacturing methods

A technology of phase change and storage unit, which is applied in the direction of static memory, digital memory information, information storage, etc., and can solve the problems of smaller active area and lower current value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The features, objectives and advantages of the present invention can be fully understood through the following description of the attached drawings, embodiments and claims.

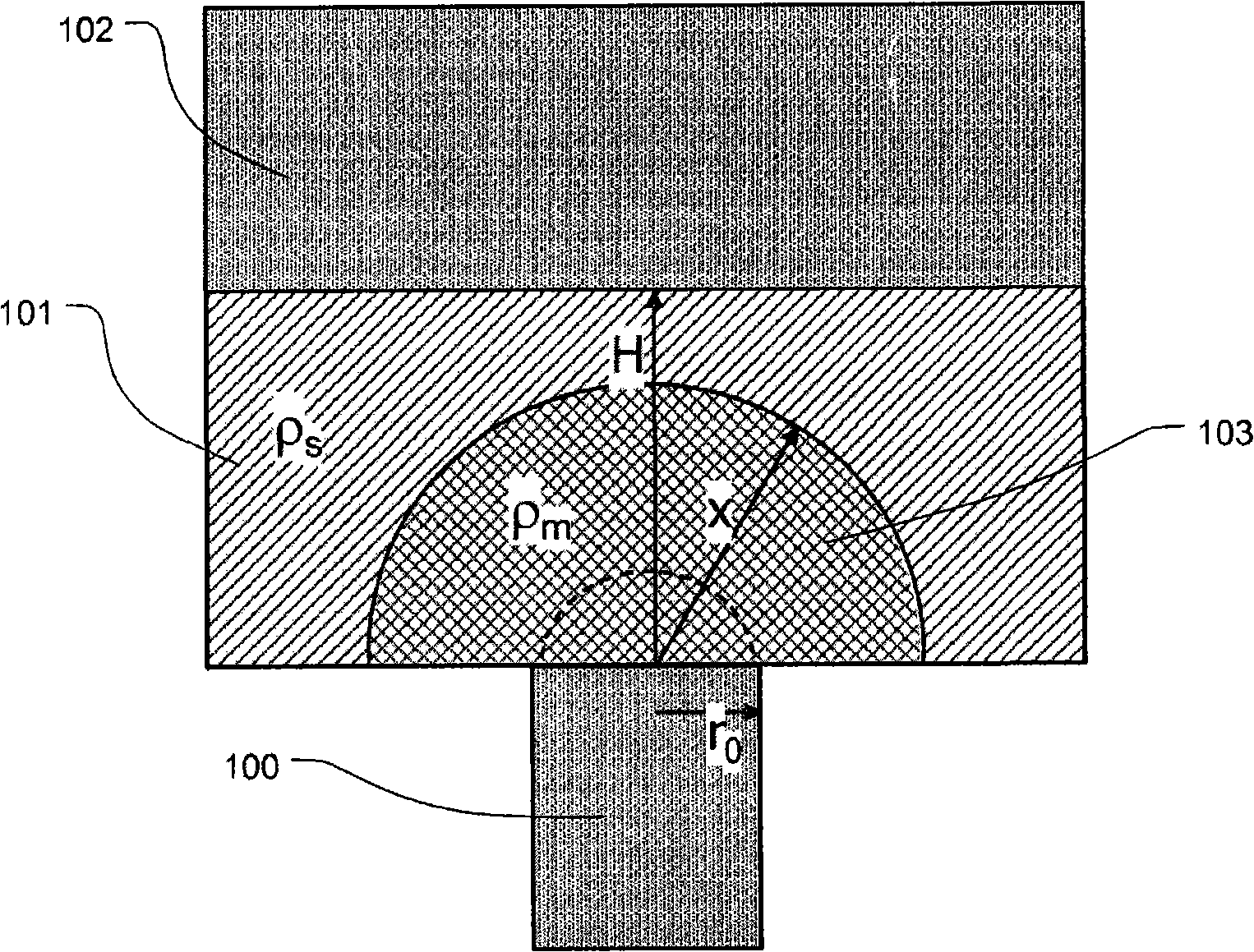

[0046] Subsequent descriptions of the invention will refer to Figure 1 to Figure 8 . figure 1 A simple diagram of a mushroom-shaped phase change memory cell comprising a bottom electrode 100 , comprising a phase change material element 101 , and a top electrode 102 . The bottom electrode 100 in the described embodiment is a 0 The columnar shape, and the interface between the phase change material element 101 and the bottom electrode 100 has a contact area of about πr 0 2 . The area where the top electrode 102 is connected to the phase change material element 101 is substantially larger than the contact area between the bottom electrode 100 and the phase change material element 101 .

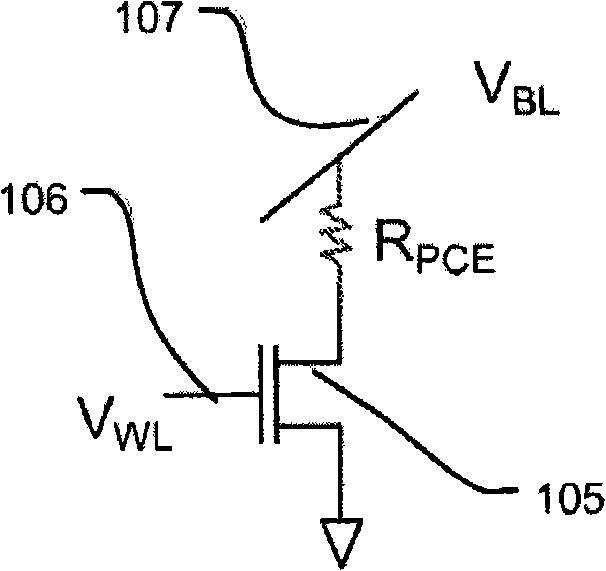

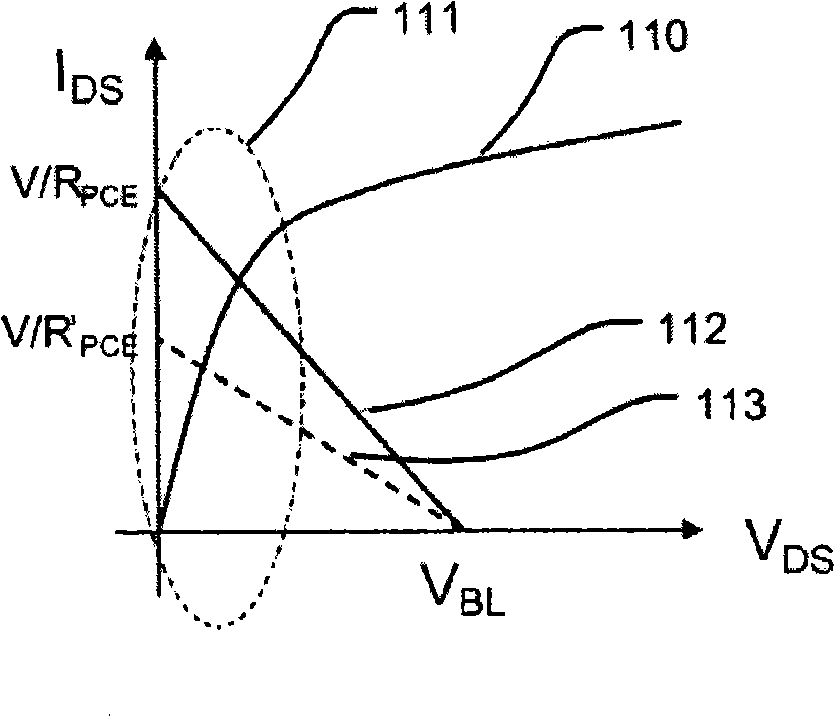

[0047] In operation, the bias circuit (for example see Figure 5 A bias circuit voltage and current source...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap