Wire winding profiler

A technology of relying on molds and winding wires is applied in the field of auxiliary tools for the production of energy-saving lamps, which can solve the problems of high scrap rate, different winding strength, and no quality assurance, so as to reduce production costs, ensure winding quality, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

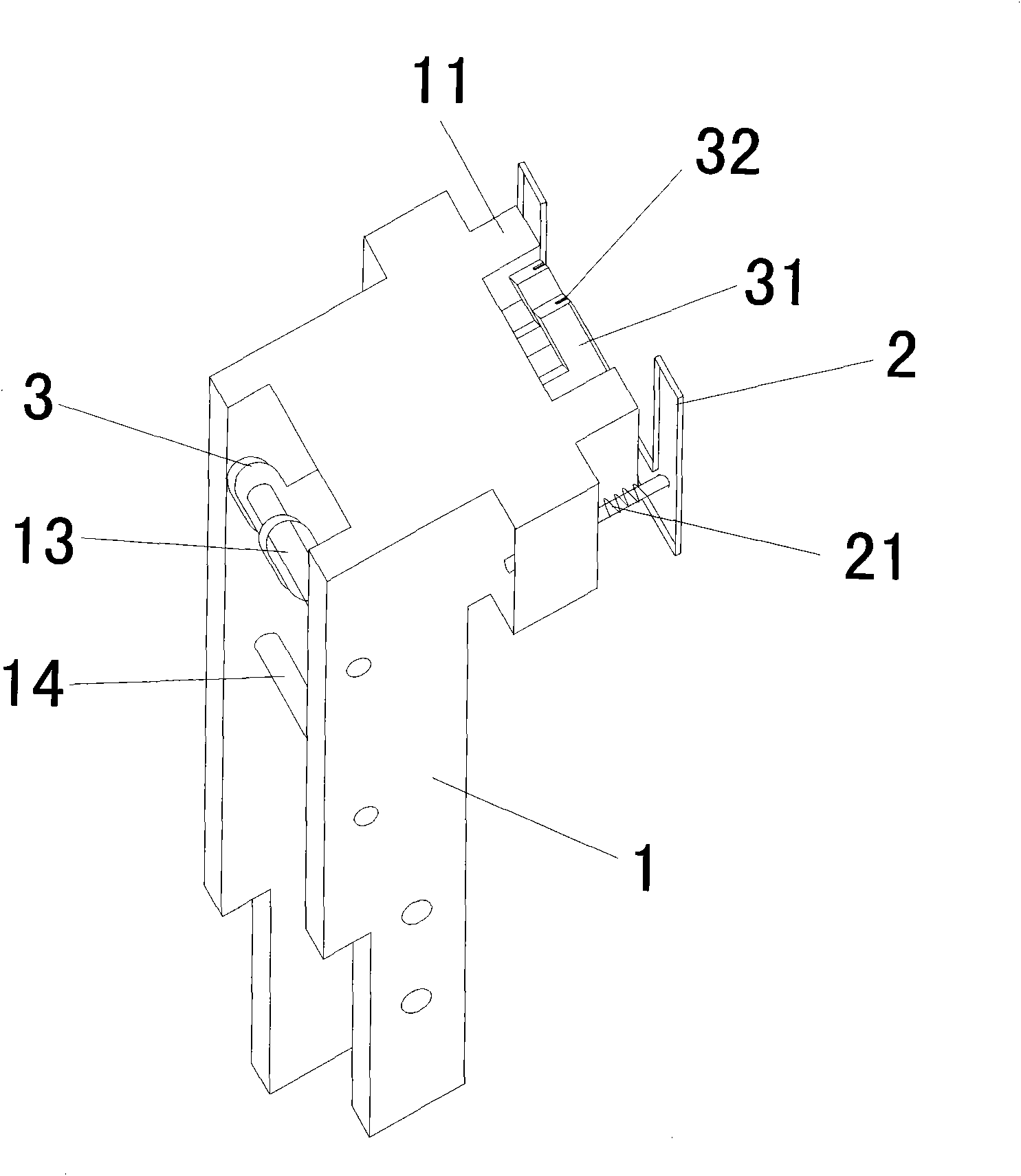

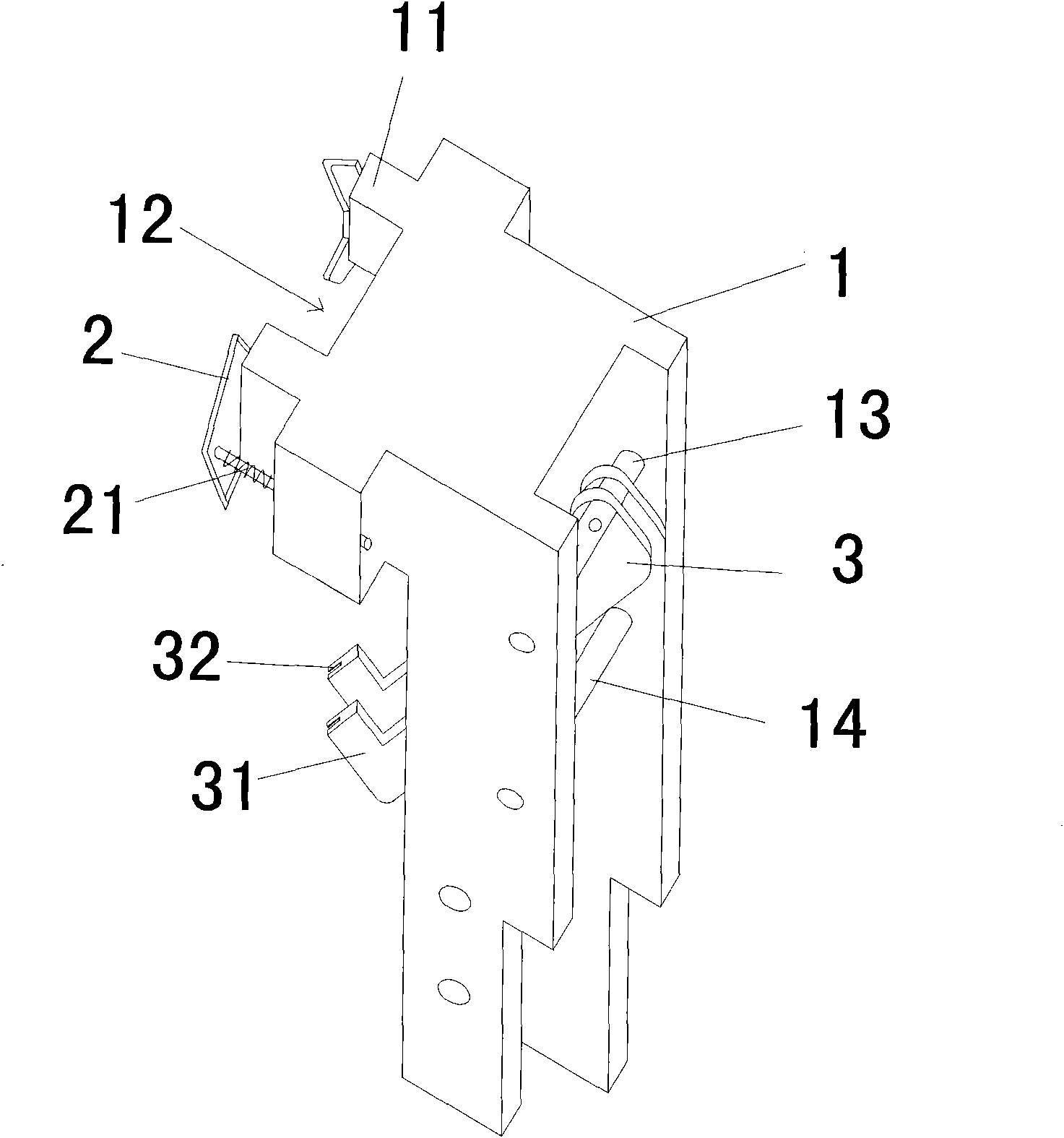

[0015] see figure 1 , figure 2 , the wire-winding profiler of the present invention is used to assist in winding the electric wires of the lamp tube to the terminals of the circuit board. It comprises a profiling bracket 1, a profiling door 2 and a profiling rocker 3. The former bracket 1 is an integral structural member formed by connecting a top plate and two side plates. The top plate protrudes forward and is provided with two door frames 11 protruding forward at its front end, forming a concave hole between the two door frames. The groove 12 is connected with a positioning pin 13 and a reverse pin 14 between the two side plates. The counter pin 14 is located below the positioning pin 13, and the distance between it and the positioning pin is less than the length of the rocking arm of the master model. Model door 2 is an L-shaped plate structure, and totally two pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com