Reflection grating

A reflective grating and reflective plate technology, applied in the field of optical imaging, can solve the problems of low transmittance of incident light of cylindrical grating, poor resistance to external light interference, complex production process, etc. , the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

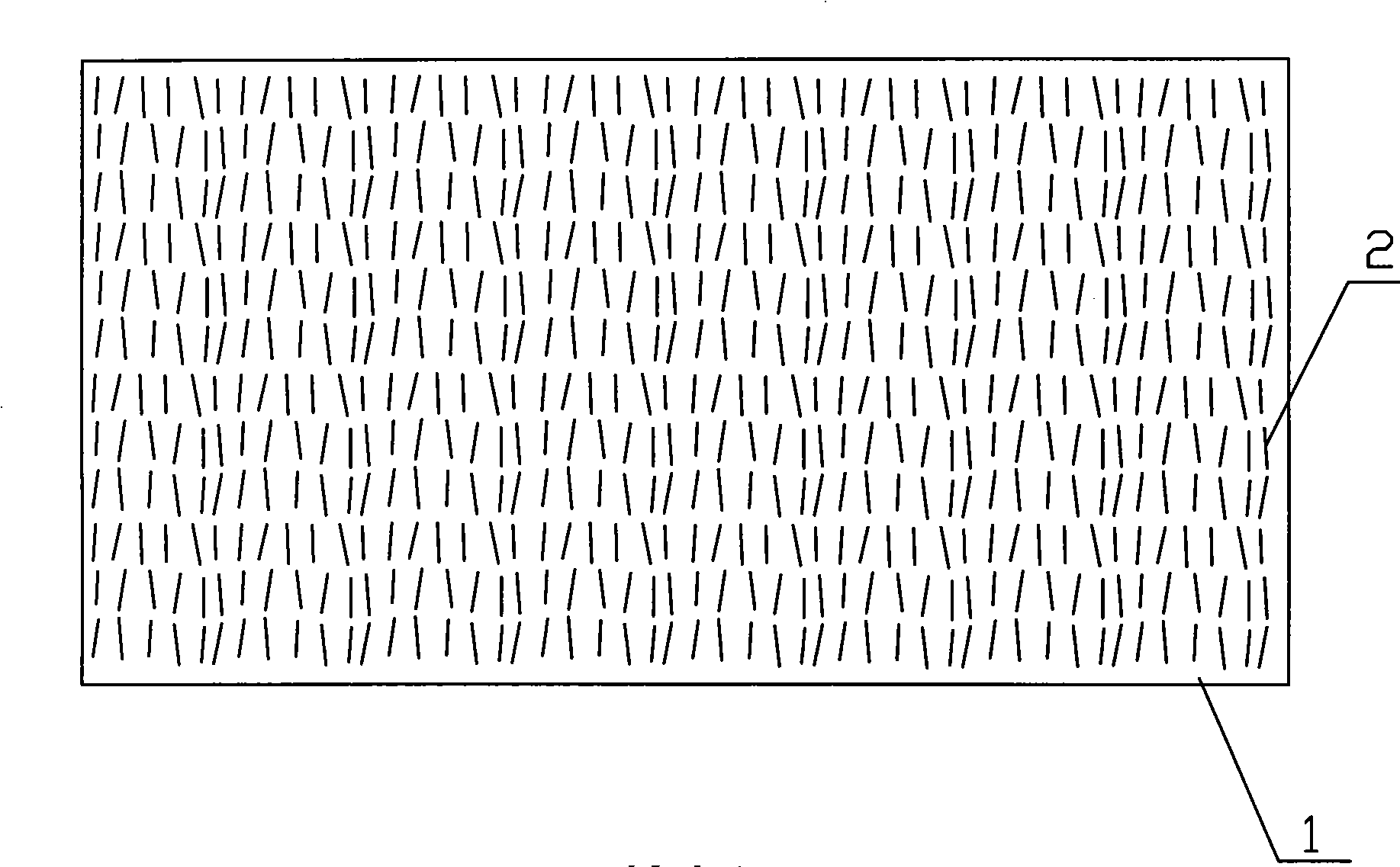

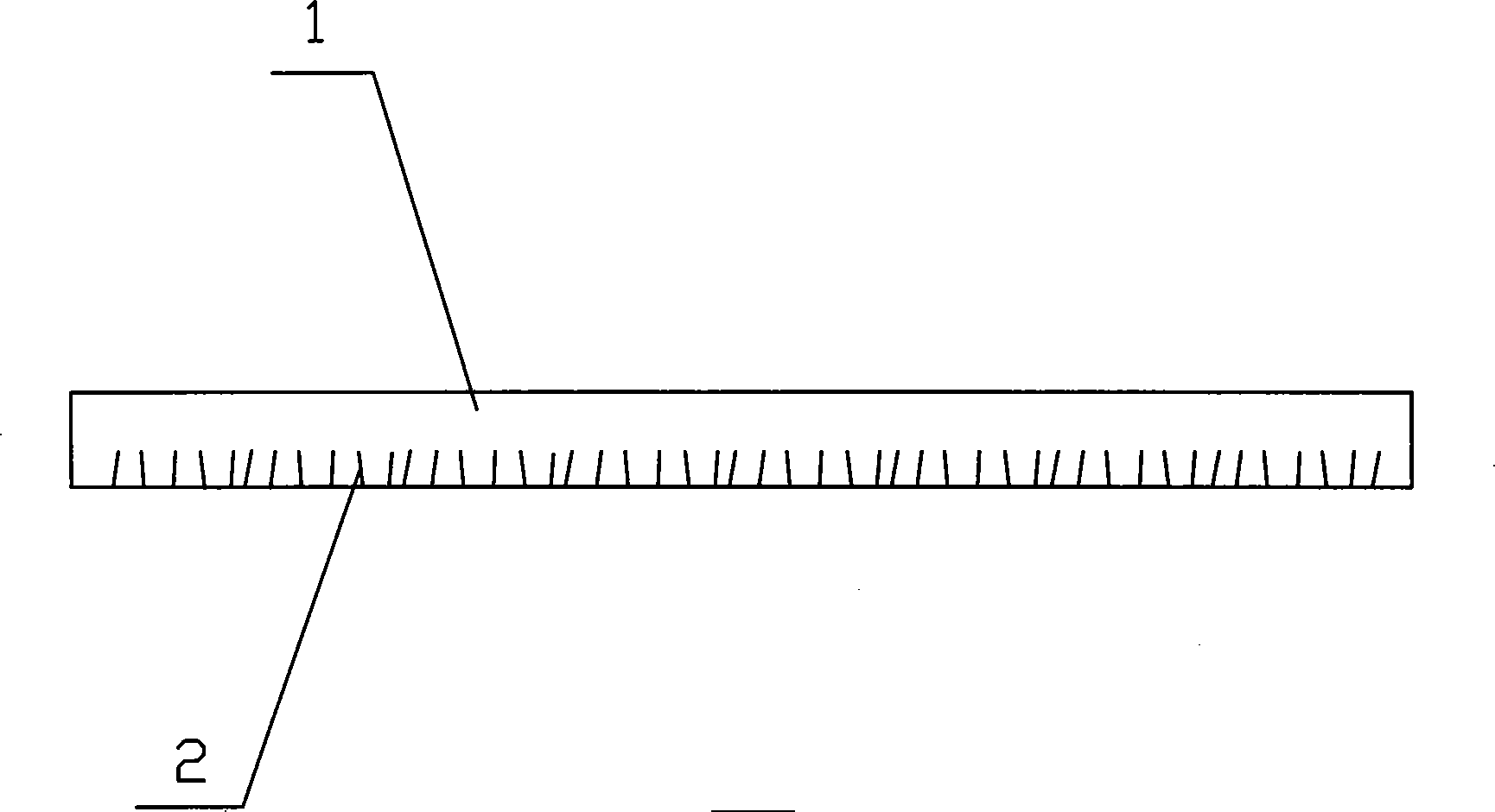

[0020] Such as Figure 1-3 As shown, a reflective grating is implanted with a black reflective plate 2 on a transparent plastic substrate 1 , and the reflective plate 2 is evenly distributed on the substrate 1 and forms an angle of 75° to 105° with the substrate 1 .

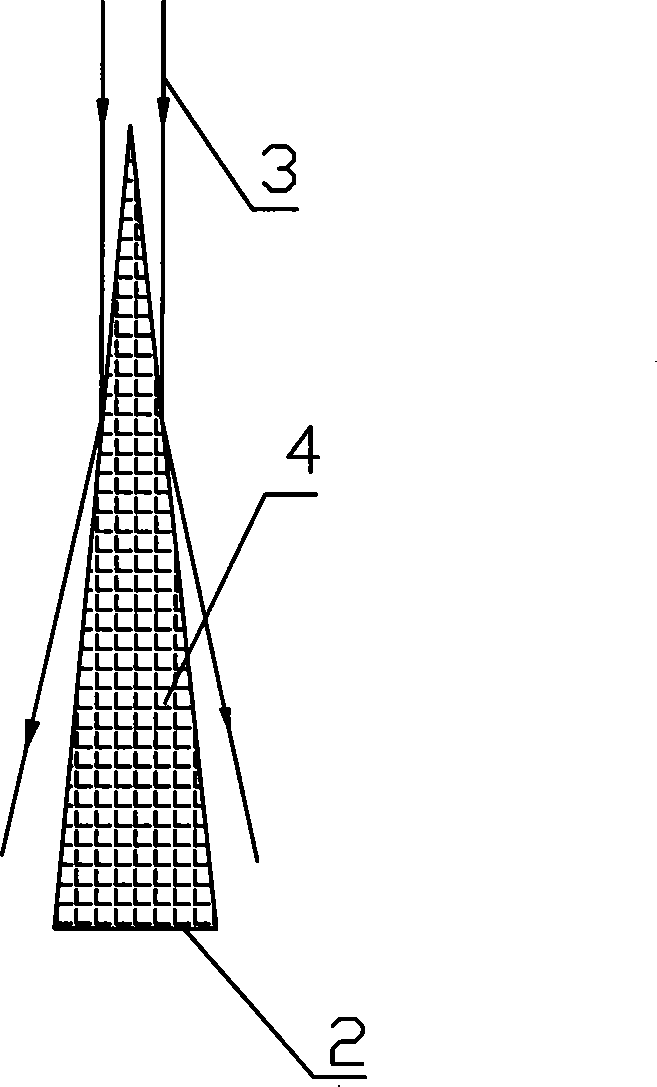

[0021] Substrate 1 is made of relatively optically dense material such as a polystyrene plate, with a refractive index n=1.59, and the reflector 2 is made of optically thin material, such as fluoroplastics, with a refractive index n=1.36 or other materials with a refractive index n less than 1.36. The plate 2 is filled with black carbon particles 4 and has a black appearance.

[0022] The thickness of the substrate 1 is 0.2-3mm, which is determined by the size of the substrate 1 and the requirements for mechanical rigidity. The thickness of the reflection plate 2 is less than 0.02mm, and the distance between the reflection plates 2 is 10 times of the thickness of the plate.

[0023] Such as Figure 4 As shown:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com