Optimal design method for structural parameters of cylindrical linear motors

A technology of structural parameters and linear motors, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as optimization difficulties and inaccurate calculations, achieve clear thinking, reduce the number of calculations, and avoid inaccurate calculations of centralized parameters accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

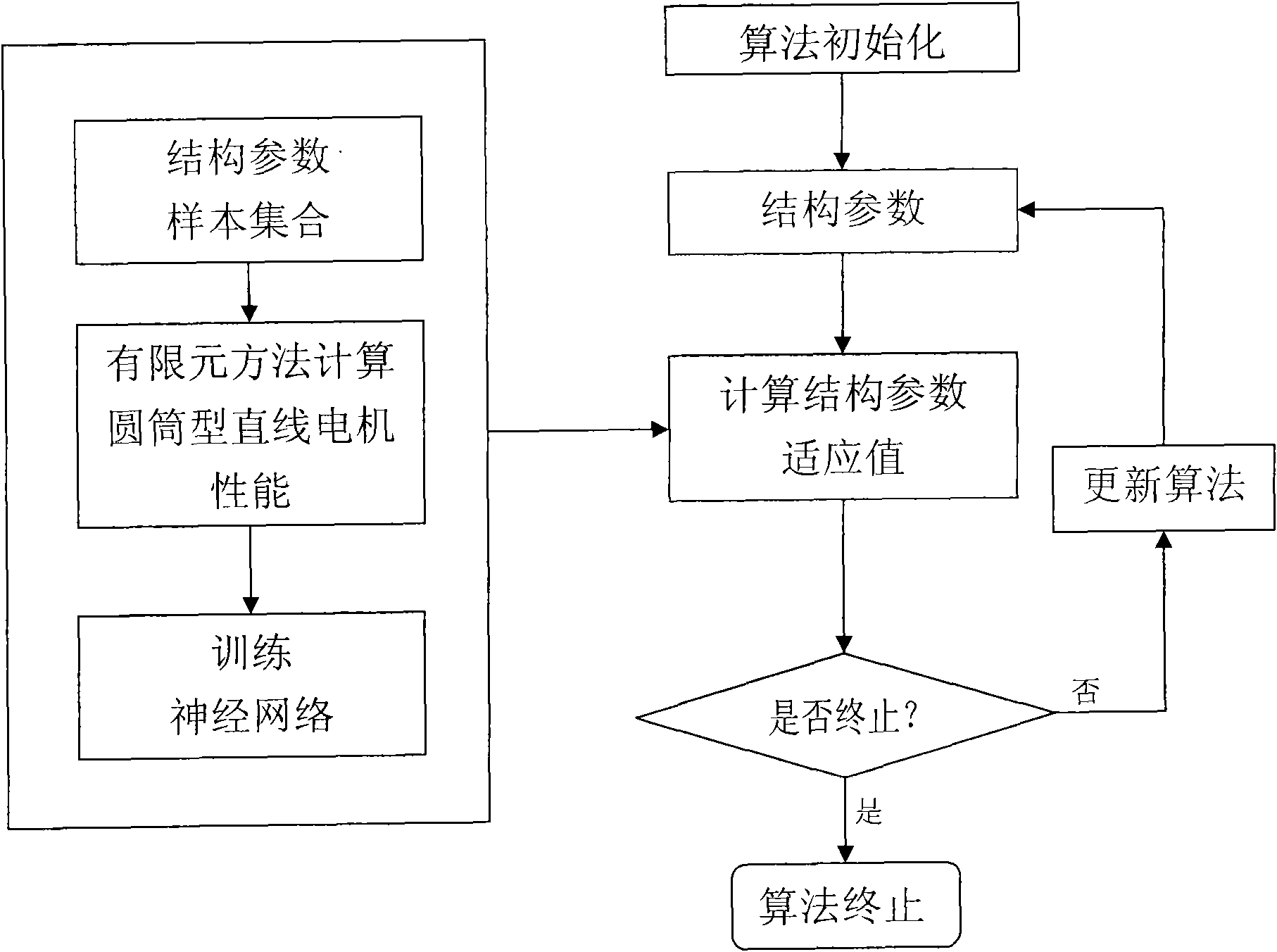

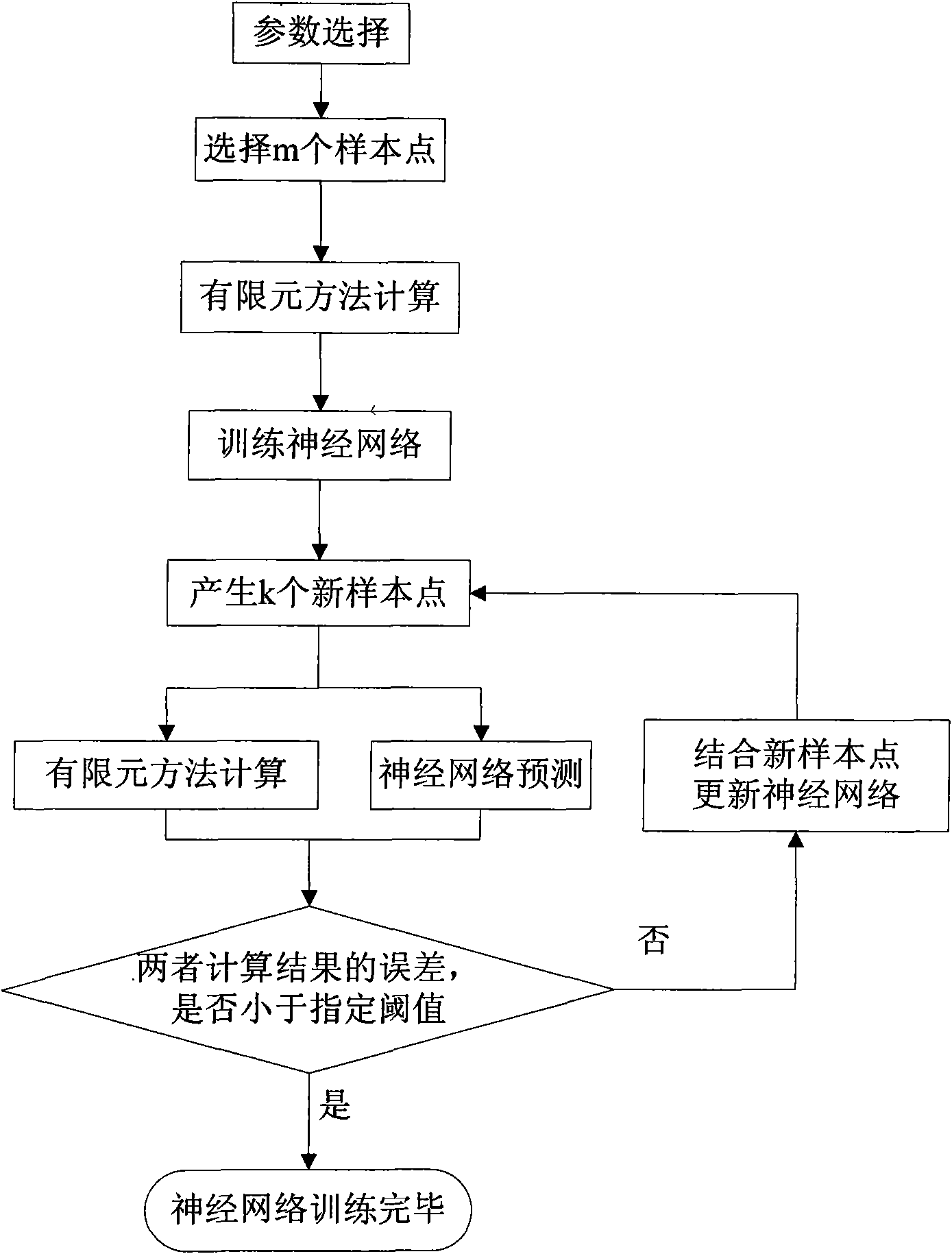

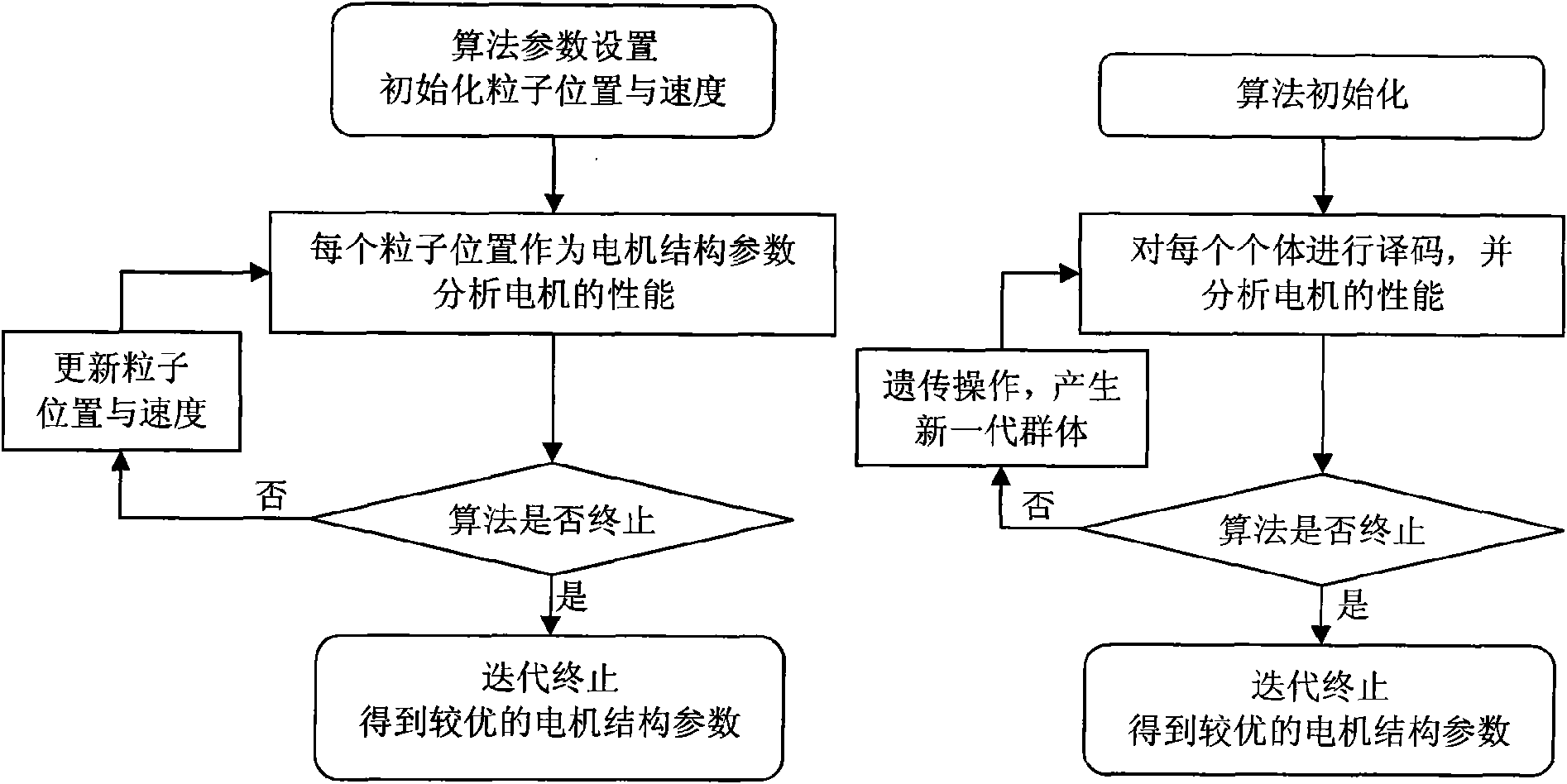

Method used

Image

Examples

Embodiment

[0035] First determine the type of motor. According to the specific engineering requirements of this embodiment, three-phase windings are used, and single-phase single-layer windings are embedded in each slot. In order to make the motor run smoothly, the number of three-phase windings used should be an integer multiple of 6, and the number of slots is also an integer of 6. At the same time, the permanent magnet adopts radial magnetization and alternate distribution, so that the direction of the magnetic field is alternately distributed inside and outside along the running direction of the motor. Then, according to the actual engineering needs of this embodiment and combined with the finite element method, a brief analysis is made to determine the winding distribution of the linear motor. Figure 5 As shown, some parameters are shown in Table 2: the winding adopts full-pitch distributed winding, and the "Y" connection method is adopted. The phase order of the winding current in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com