Pipe beveling machine

A beveling machine and pipe technology, applied in metal processing machinery parts, clamping, support, etc., can solve the problems of low production efficiency, inconvenient operation, difficult implementation, etc., and achieve high production efficiency, easy operation, consistent and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

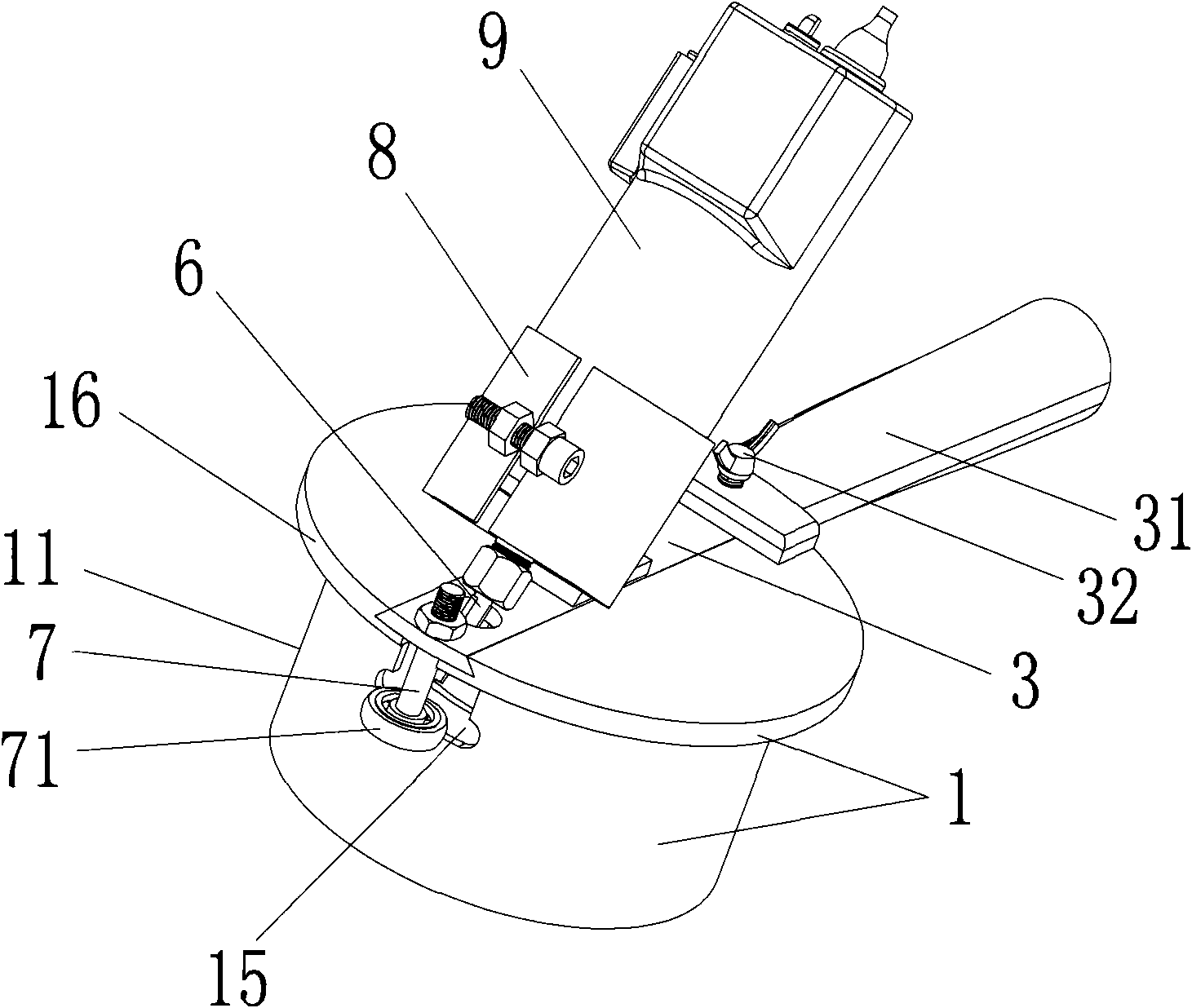

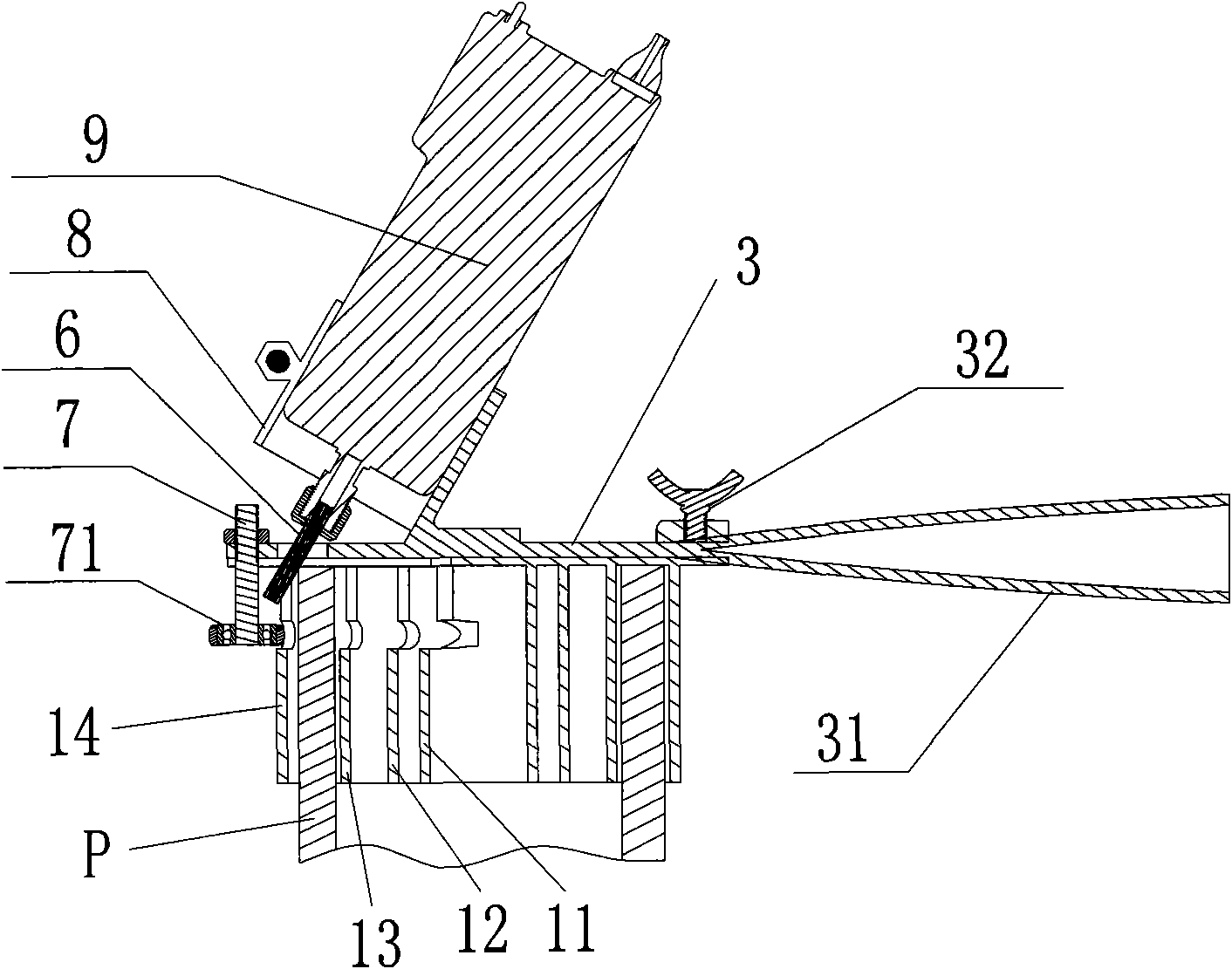

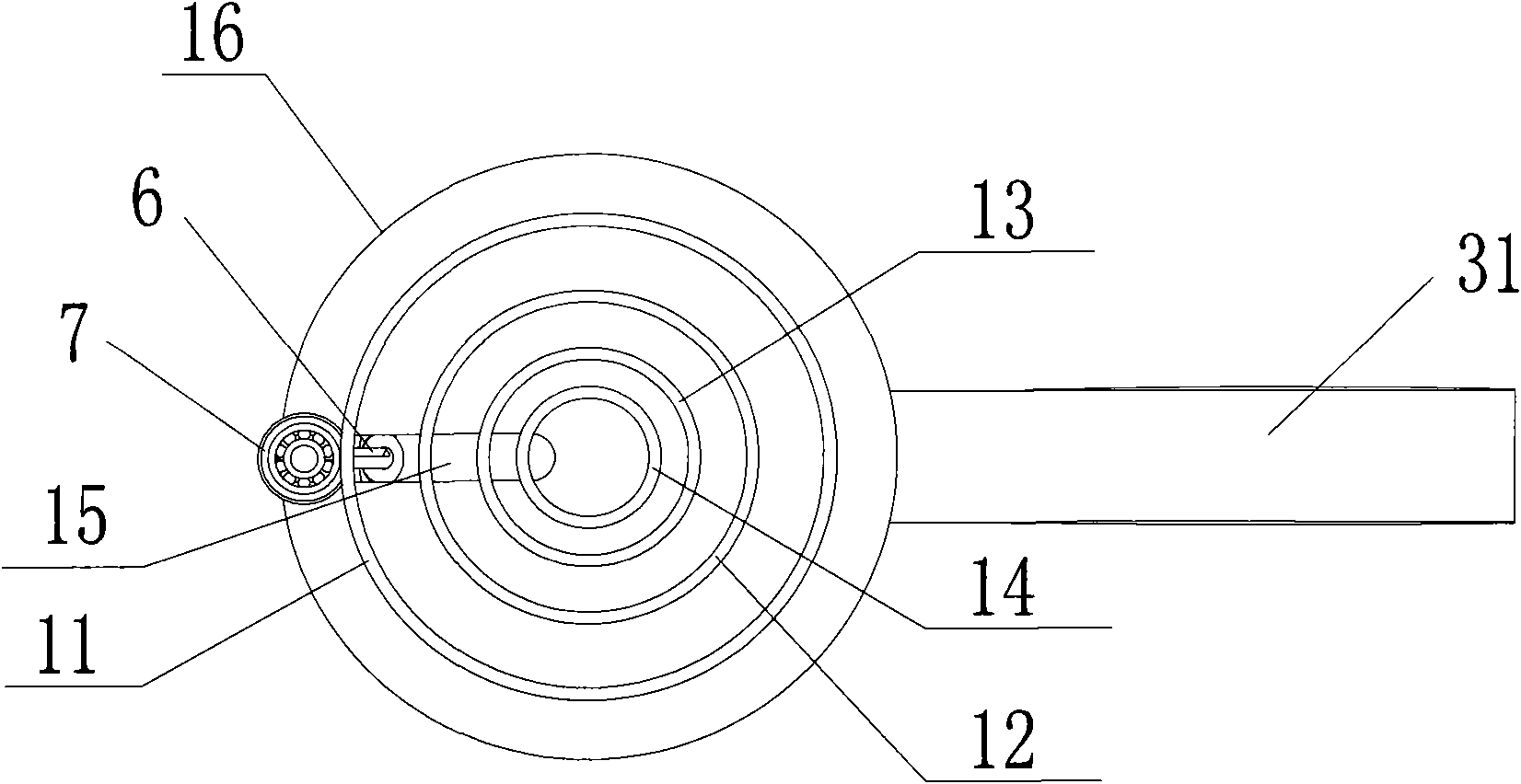

[0022] see Figure 1~3 , the present invention is provided with machine base 8, driving device 9, bevel knife 6, sleeve pipe base 1 and limit lever 7; Driving device 9 is located on the machine base 8, and driving device 9 is provided with motor and transmission part (motor and transmission Not shown in the parts figure), the output shaft of the motor is connected with the transmission part. A slide handle 3 with a handle 31 is provided at the bottom of the frame 8, and a slide groove is provided at the top of the sleeve base 1, and the slide handle 3 is embedded in the slide groove to be slidable. The sliding handle 3 is provided with a sliding handle locking part 32 for positioning the sliding handle 3 . The groove cutter 6 is connected with the transmission part of the driving device, the longitudinal section of the casing seat 1 is T-shaped, the top 16 of the casing seat 1 is disc-shaped, and the bottom of the casing seat 1 is 4 concentric circular tubes. Liner dies 11, ...

Embodiment 2

[0025] Similar to Embodiment 1, the difference is that the bottom of the machine base is connected to the sliding handle via a pivot pin, so that the machine base can rotate around the pin shaft. Therefore, it is easier to adjust the inclination angle of the machine base (that is, the inclination angle of the bevel knife), so as to better meet the bevel requirements of different inclination angles required by the pipe port to be processed.

Embodiment 3

[0027] Similar to Embodiment 1 or 2, the difference lies in that the grip part on the slider is screwed to the body of the slider, so that the slider can be moved by turning the grip part of the slider.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com