Safe, energy-saving and consumption-reducing double-layer hollow filmed structural glass

A double-layer hollow and safe technology, which is applied in the field of architectural glass, can solve the problems of people's injury, weak adhesion of glass surface, and splashing of glass fragments, etc., and achieve the effect of enhancing strength, reducing energy consumption of deep processing industry, and enhancing safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

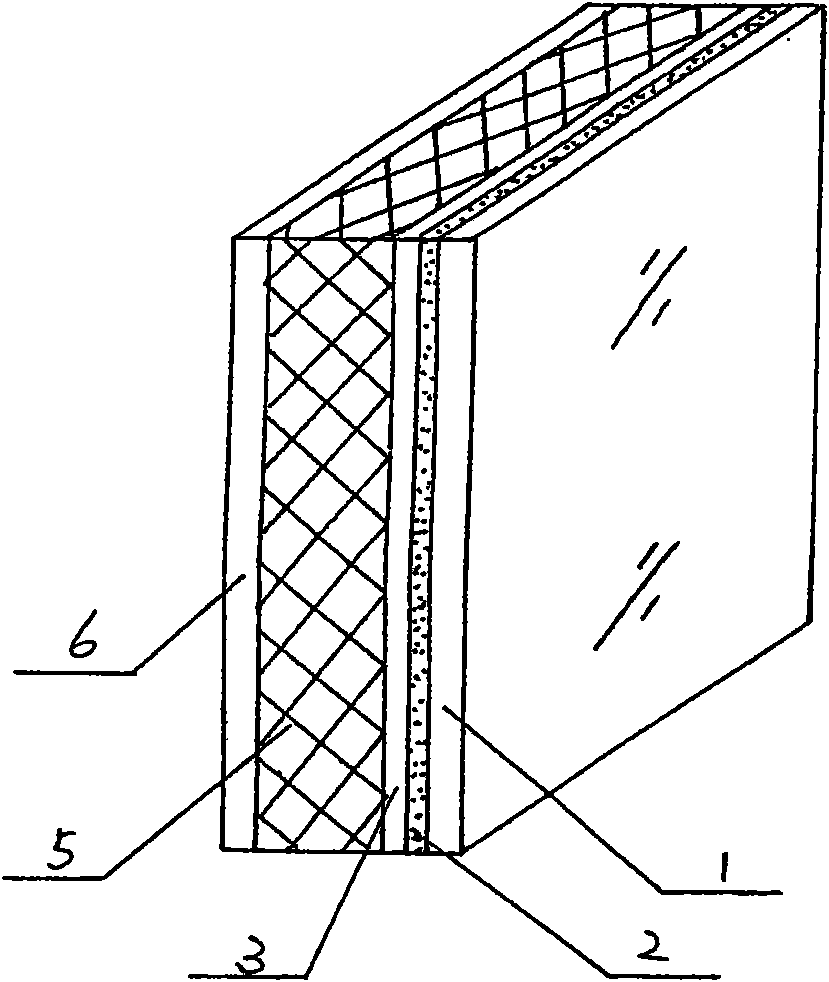

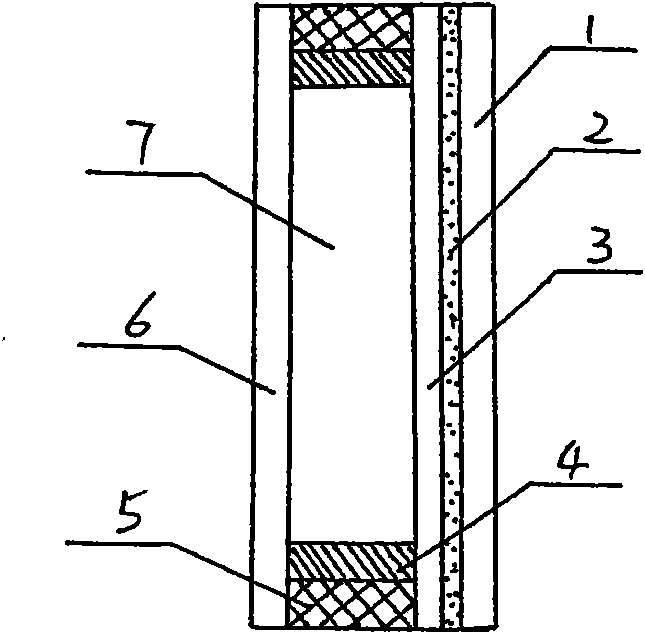

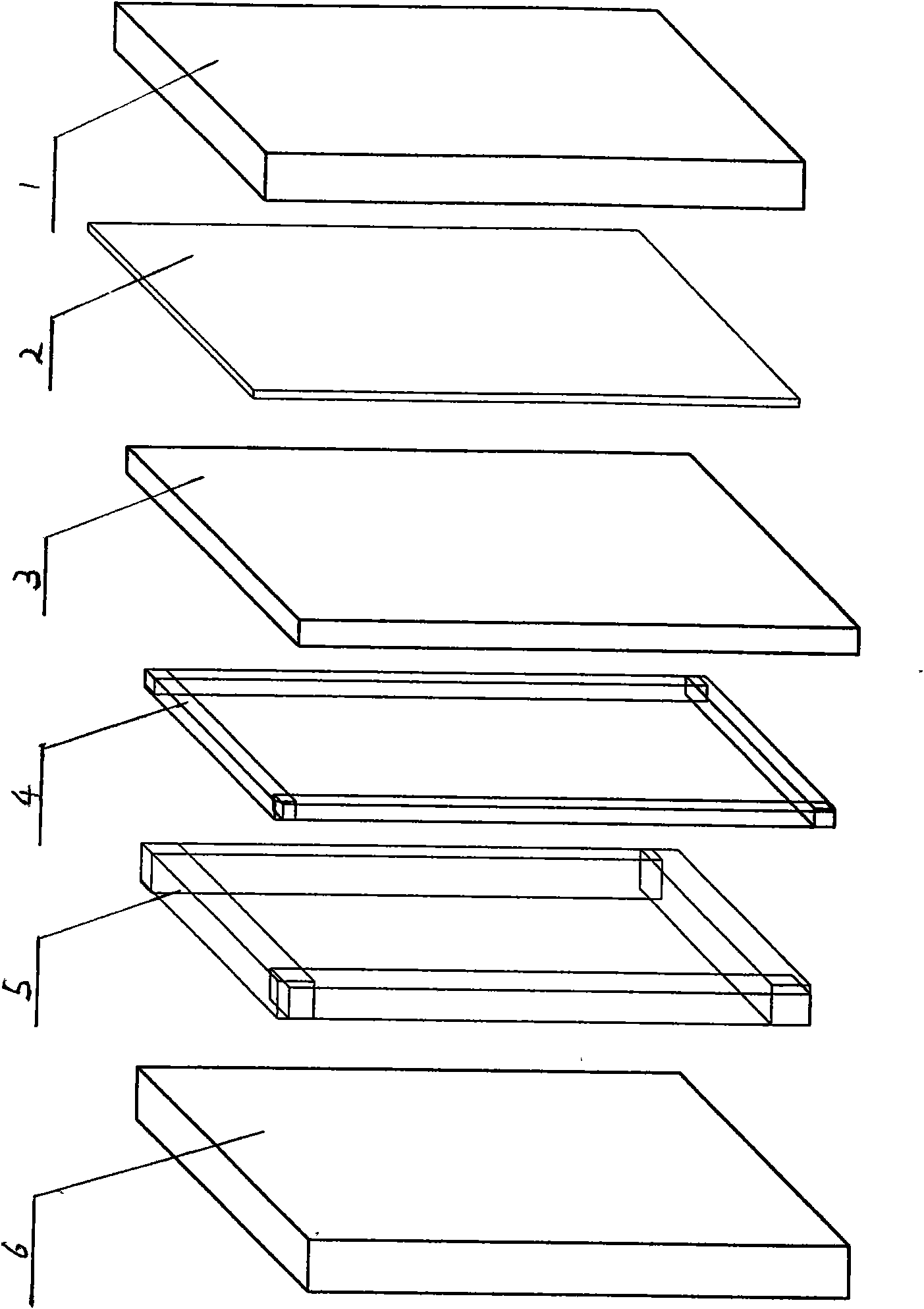

[0011] Examples 1-3: see figure 1 , The double-layer hollow film-adhered glass of safe energy-saving and consumption-reducing buildings of the present invention is mainly composed of an inner glass 1, an outer glass 6, a film layer 3 and a pressure frame 4.

[0012] The film layer 3 is tightly combined with the surface of the inner glass 1 on the outside of the room through the adhesive layer 2 to form a film-coated glass.

[0013] The press frame 4 is tightly sandwiched between the inner glass 1 and the outer glass 6 after the film is pasted, and the cavity surrounded by the inner periphery of the press frame 4 and the inner glass 1 and the outer glass 6 after the film is formed The hollow part 7, the cavity part formed between the outer periphery of the pressure frame 4, the inner glass 1 and the outer glass 6 after filming are filled with sealant to form the sealant frame 5, and the hollow part 7 is sealed externally.

[0014] The press frame 4 generally adopts an aluminum...

Embodiment 2

[0016] The difference between embodiment 2 and embodiment 1 is that the film layer 3 is tightly compounded on the surface of the inner side of the outer glass 6 through the adhesive layer 2, and the rest are the same as embodiment 1.

Embodiment 3

[0018] The difference between embodiment 3 and embodiment 1 is that the film layer 3 is tightly combined with the surface of the inner glass 1 on the outside side of the interior glass 1 and the surface of the outer glass 6 on the inside side of the room through the glue layer 2, and the rest are implemented in the same way example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com