Middle rack mounted on camber beam of motorcycle

A technology of motorcycles and curved beams, which is applied in the field of load racks, and can solve problems such as the limitation of unsteady loading volume, affecting the driver's riding and driving, and the inability to load objects with a larger volume or area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

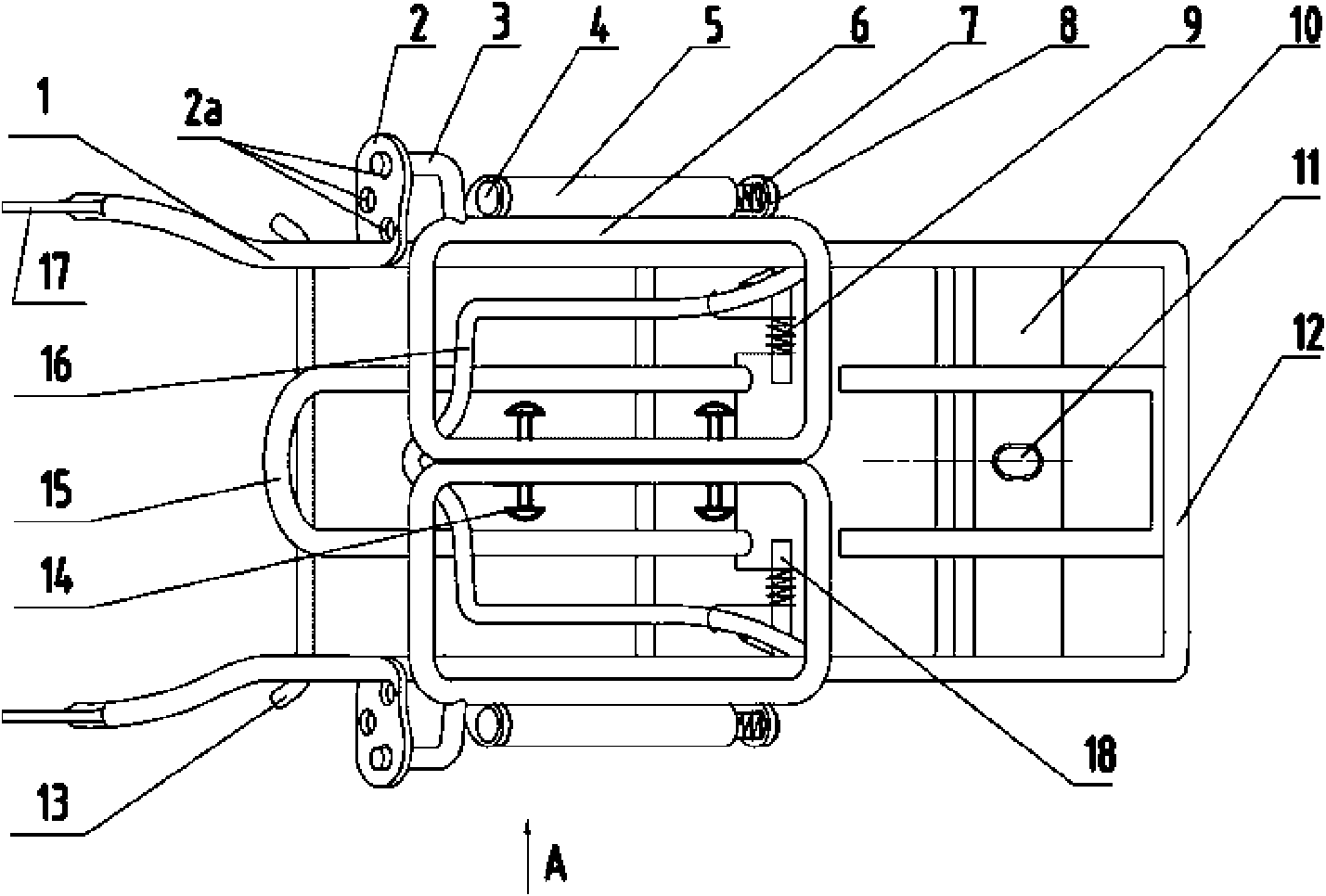

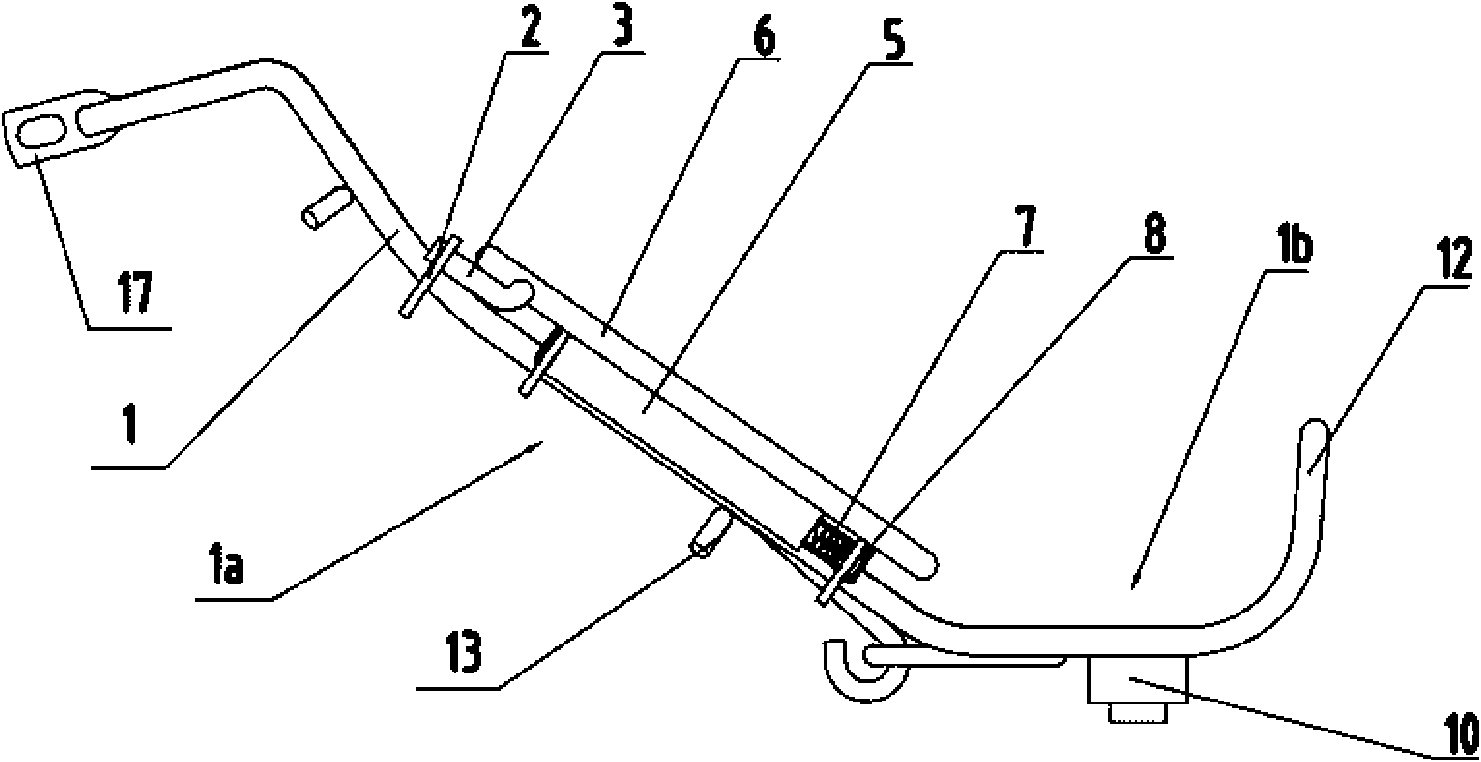

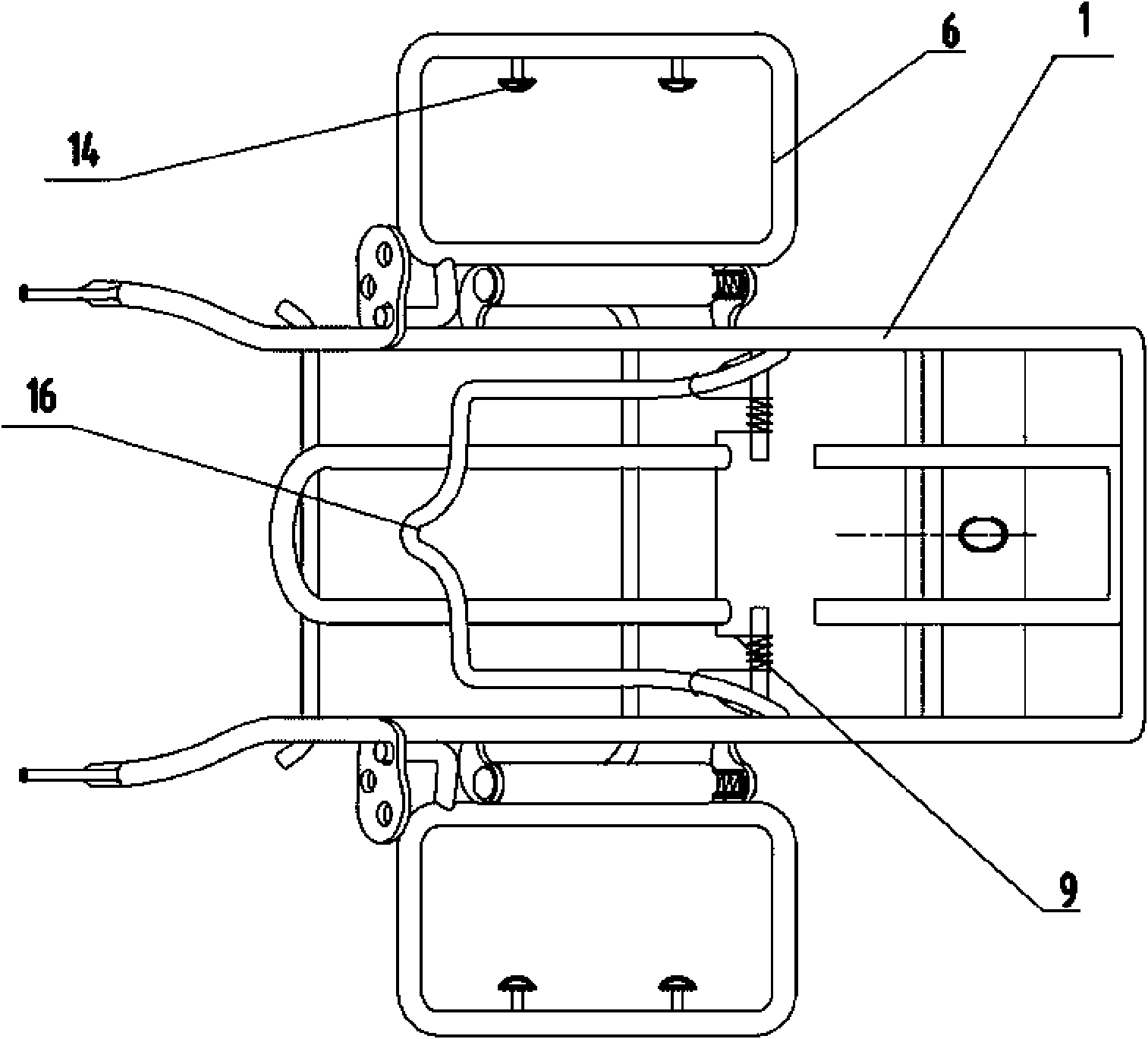

[0020] Figure 1 to Figure 5 , Including a main frame 1 formed by bending an inclined front loading portion 1a and a horizontal rear loading portion 1b. The front end of the front load portion 1a of the main frame 1 is provided with two mounting supports 17, and the mounting supports 17 are provided with mounting holes, which can be fixed to the curved beam by bolts. The lower part of the front load portion 1a is horizontally provided with support ribs 13 , It is used to clamp the curved beam of the motorcycle to support the middle shelf. U-shaped ribs 15 are longitudinally arranged on the front load portion 1a to enhance the strength of the middle shelf. The rear loading portion 1b is provided with a mounting hole 11, which is set on the mounting plate 10 welded to the rear loading portion 1b. The mounting hole 11 is a flat hole that can fine-tune the position during installation and fixation. The rear end of the part 1b is provided with an upward guardrail 12, and the carried ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com