Boosting mechanism for sealing device of gas tank

A technology of sealing device and booster mechanism, which is applied in the field of mechanical engineering, can solve problems such as production shutdown and the failure of maintenance of the booster mechanism, and achieve the effect of solving production shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

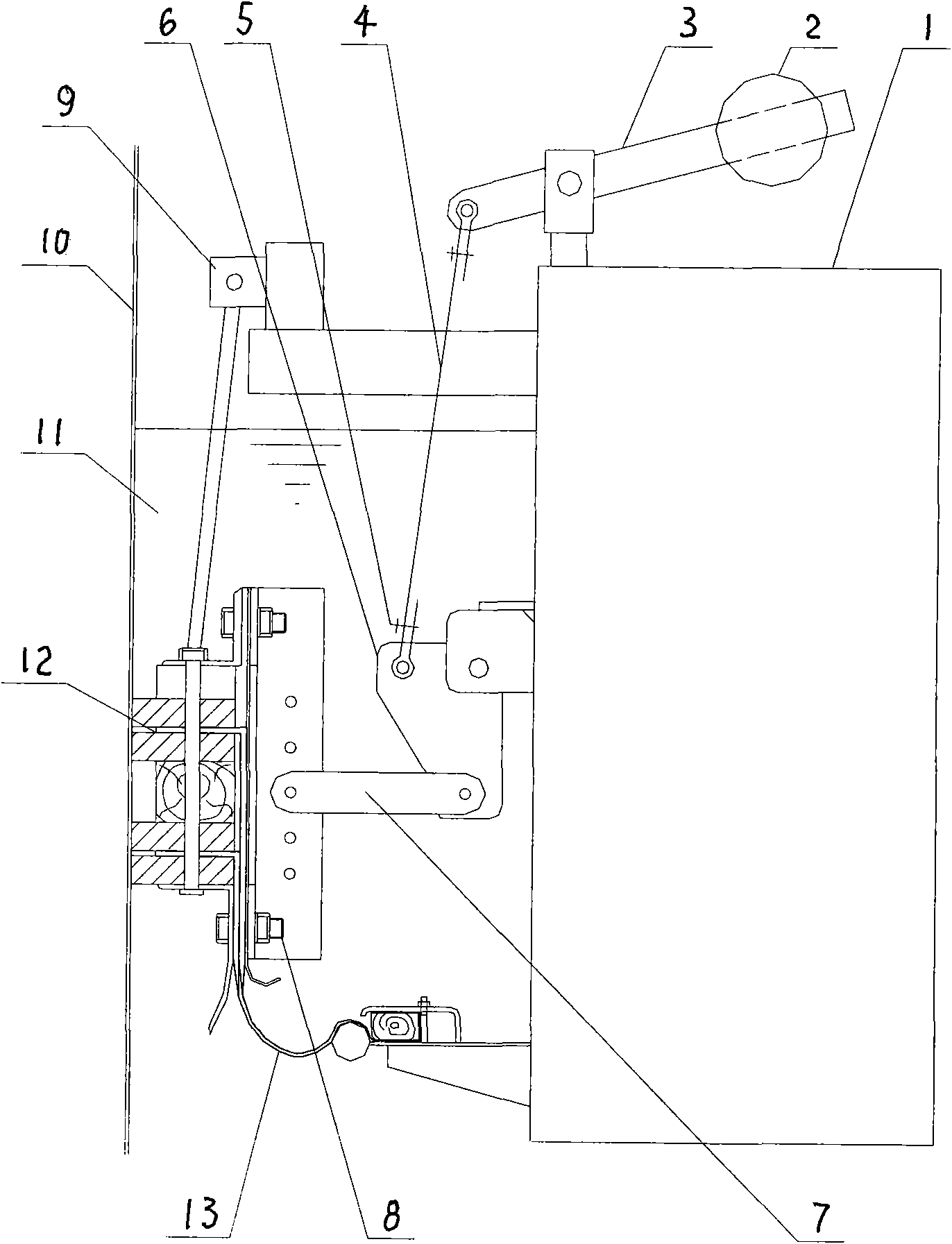

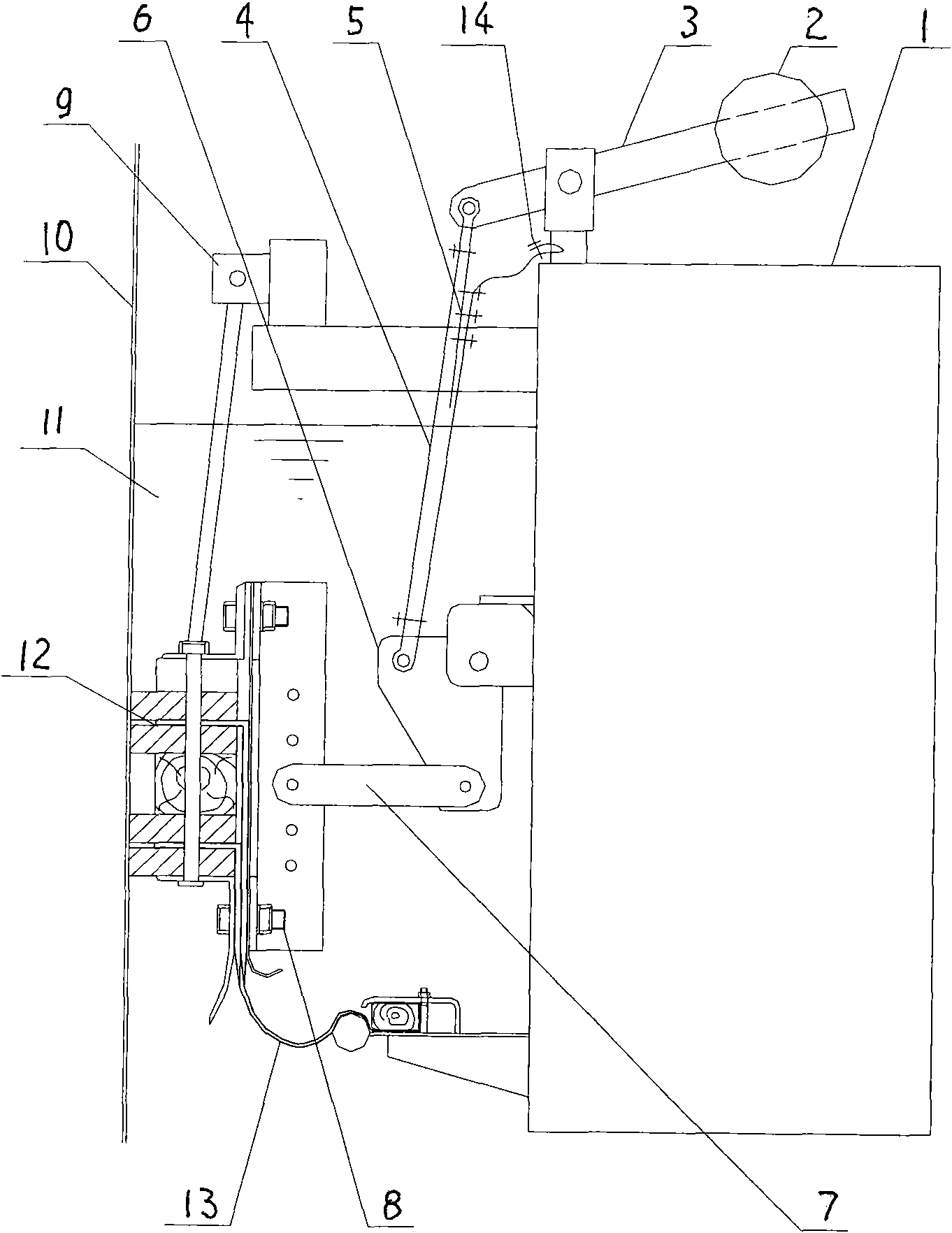

[0009] Attached below figure 2 The present invention is described further:

[0010] In the piston oil groove between the piston structure 1 and the cylinder side plate 10, a sealing device composed of sealing rubber 12, canvas 13 and all other parts is installed and the sealing oil 11 is kept with a certain liquid injection height to seal the gas. The several layers of sealing rubber 12 arranged along the perimeter of the gas cabinet are kept integral by the rubber clamping device 8; and are suspended on the piston structure 1 by thousands of groups of hanging mechanisms 9 arranged along the perimeter of the gas cabinet; the extended steel wire rope 4. It is fixed by a plurality of steel wire rope clips 5 and 14 on the piston structure above the piston oil groove. The steel wire ropes are double ropes, and the force is small. The horizontal force mechanism composed of weight 2, lever 3, steel wire rope 4, spring plate 6 and pressure bar 7 compresses the sealing rubber 12 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com