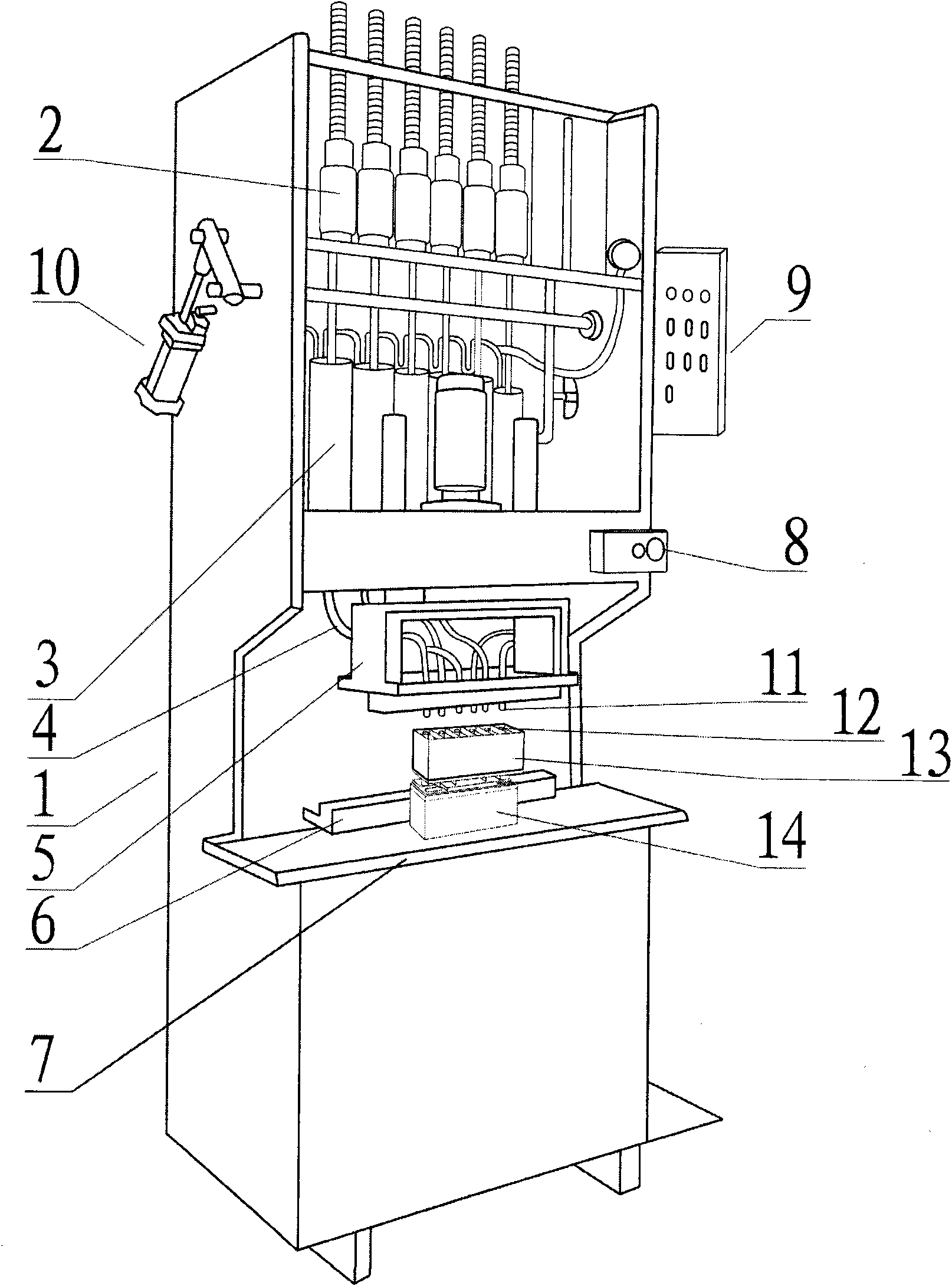

Formation liquid storage tank of quantitative acid dosing and charging of battery

A liquid storage tank and battery technology, which is applied in the direction of secondary battery charging/discharging, lead-acid batteries, battery pack components, etc., can solve the problems of wasting acid, failing to meet the requirements of acid addition, and affecting the quality of acid filling, etc. , to achieve the effect of improving quality, fast working speed and accurate quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

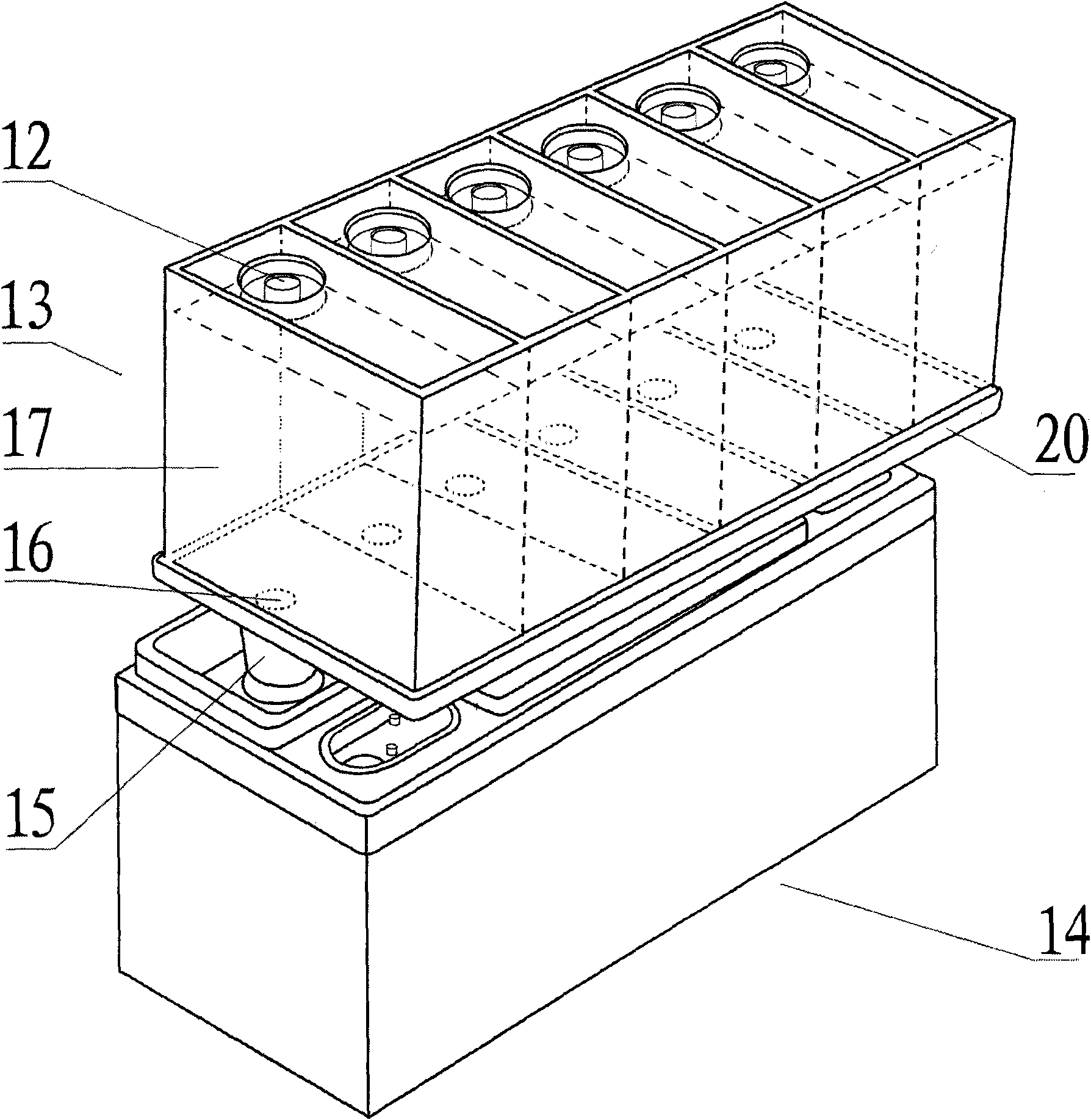

[0023] The liquid storage tank 13 is composed of a plurality of tank bodies 17. The tank bodies 17 are divided into "one" shapes and connected together. The upper end of the tank body 17 is provided with an acid inlet nozzle 12. The lower end of the portion is bonded and fixed to the upper end of the base 20. The acid inlet mouth 12 and the acid inlet hole 16 are in the same core position. Each of the acid inlet holes 16 is set at the bottommost position on the upper plane of the bottom platform 20 , so that the acid liquid can flow into the acid inlet holes 16 naturally. Four limit legs 19 are also provided on the lower part of the base 20 to support between the liquid storage tank 13 and the battery 14, so that the glue nozzle 15 can be normally stressed.

Embodiment 2

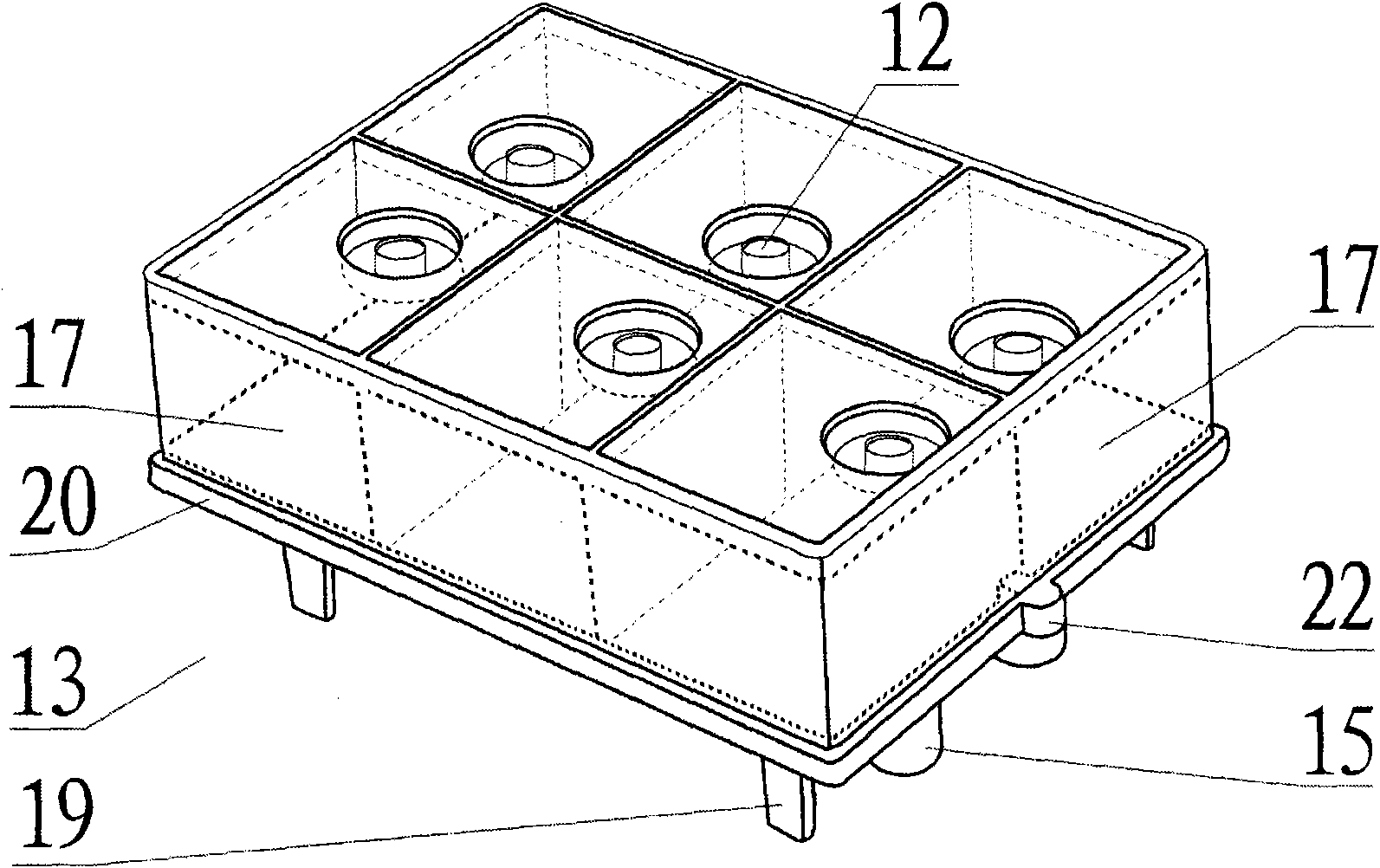

[0025] Liquid storage tank 13 is made up of a plurality of tank bodies 17, and described tank body 17 is arranged in two rows, and acid inlet nozzle 12 and glue nozzle mouth 18 are arranged on the inner side of each tank body 17, in order to make tank body 17 and bottom platform 20 is oriented in the direction of bonding, and an orientation platform 22 is arranged in the middle of one side of the bottom platform 20 . The acid inlet mouth 12 and the acid inlet hole 16 are in the same core position. Each of the acid inlet holes 16 is arranged at the bottom position of the upper plane of the bottom platform 20, so that the acid liquid can naturally flow into the acid inlet holes 16. Viewed from the back side of the bottom platform 20, because the acid inlet holes 16 are arranged on the bottom The bottommost position of the plane on the platform 20, so there is a funnel-shaped liquid leakage protrusion 21 at the bottom of the base platform 20, and the mouth of the liquid leakage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com