A kind of semiconductor graphene and its preparation method and field effect tube

A graphene and semiconductor technology, applied in the field of semiconductor graphene and its preparation, can solve the problems of unfavorable device integration due to crystal domain area, limited application, growth of semiconducting graphene with large crystal domain, etc., and achieves wide application value, simplification Production steps, the effect of large crystal domain area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

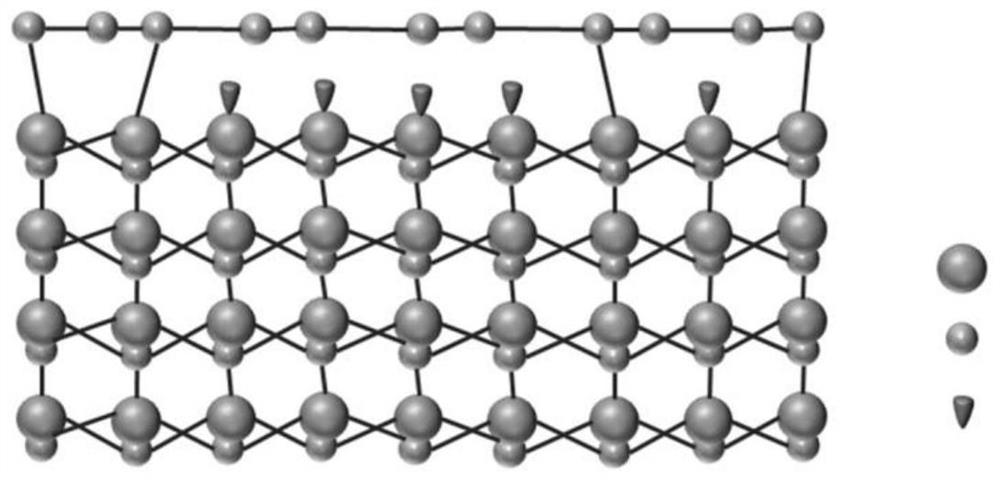

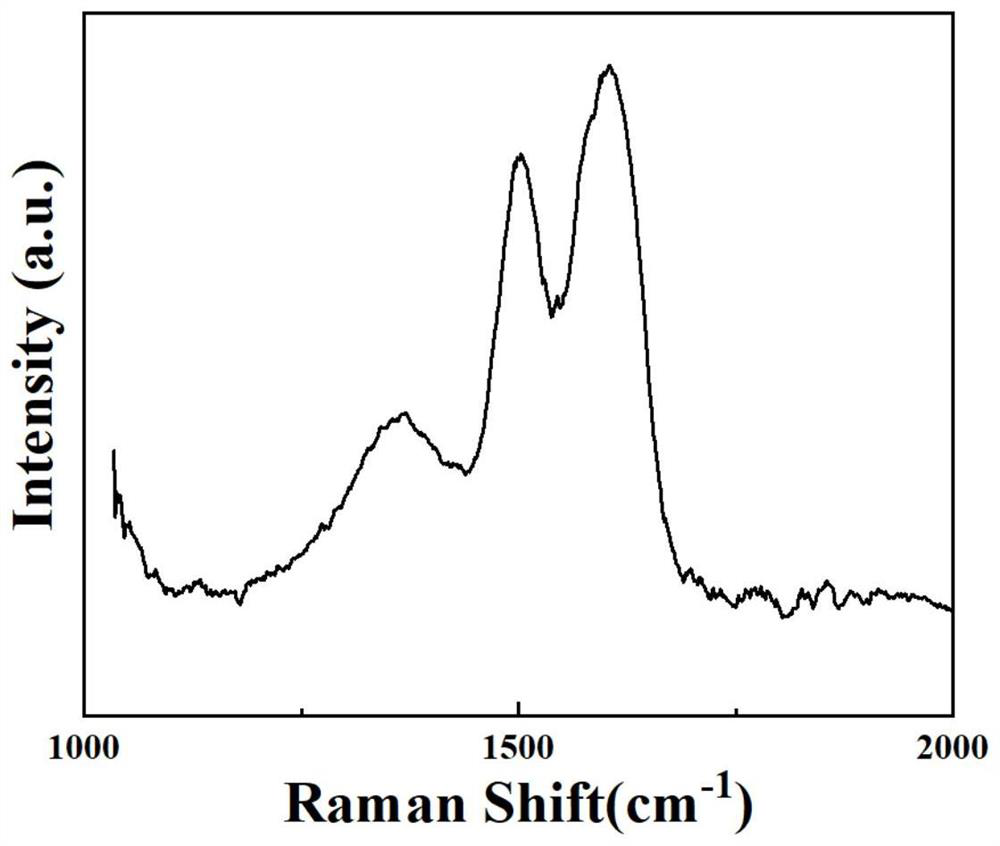

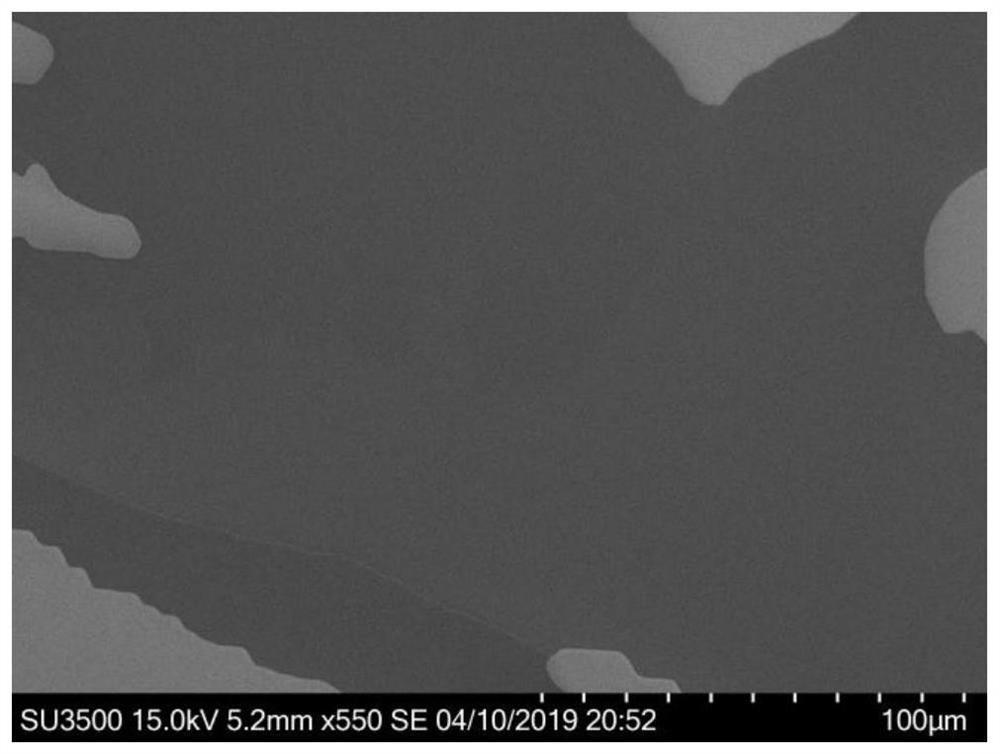

[0036] The semiconductor graphene buffer layer is directly grown on the Si surface of the silicon carbide substrate, and the specific steps are as follows:

[0037] (1) Select two 6H-type silicon carbide wafers, respectively called silicon carbide wafer A and silicon carbide wafer B; perform mechanical chemical polishing (CMP) on silicon carbide wafer A and silicon carbide wafer B, remove paraffin and thoroughly clean ;

[0038] (2) ultrasonically sonicate silicon carbide wafer A and silicon carbide wafer B in acetone, absolute ethanol, and deionized water for 15-30 min each, and use N 2 blow dry;

[0039] (3) 10nm thick AZ photoresist is spin-coated on silicon carbide wafer A, and silicon carbide wafer B is not coated with photoresist;

[0040] (4) Put the silicon carbide wafer A and the silicon carbide wafer B coated with the photoresist into the graphite crucible, and place them in the form of "face-to-face"; specifically, the silicon carbide wafer A is below and the sili...

Embodiment 2

[0046] The semiconductor graphene buffer layer is directly grown on the Si surface of the silicon carbide substrate by the method of Example 1, the difference is only that the temperature in step (7) is 1650° C. for 90 minutes.

Embodiment 3

[0048]The semiconductor graphene buffer layer is directly grown on the Si surface of the silicon carbide substrate by the method of Example 1, and the difference is only that the 4H-type silicon carbide wafer is selected as the silicon carbide wafer A, and the 6H-type silicon carbide wafer is selected as the silicon carbide wafer B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com