Porcelain insulator cementing maintenance device

A porcelain insulator and glue-mounted technology, which is applied in the field of porcelain insulators, can solve the problems of slow working speed, low work efficiency, time-consuming and laborious work of glue-mounted lines, and achieve the effect of low cost, high work efficiency and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

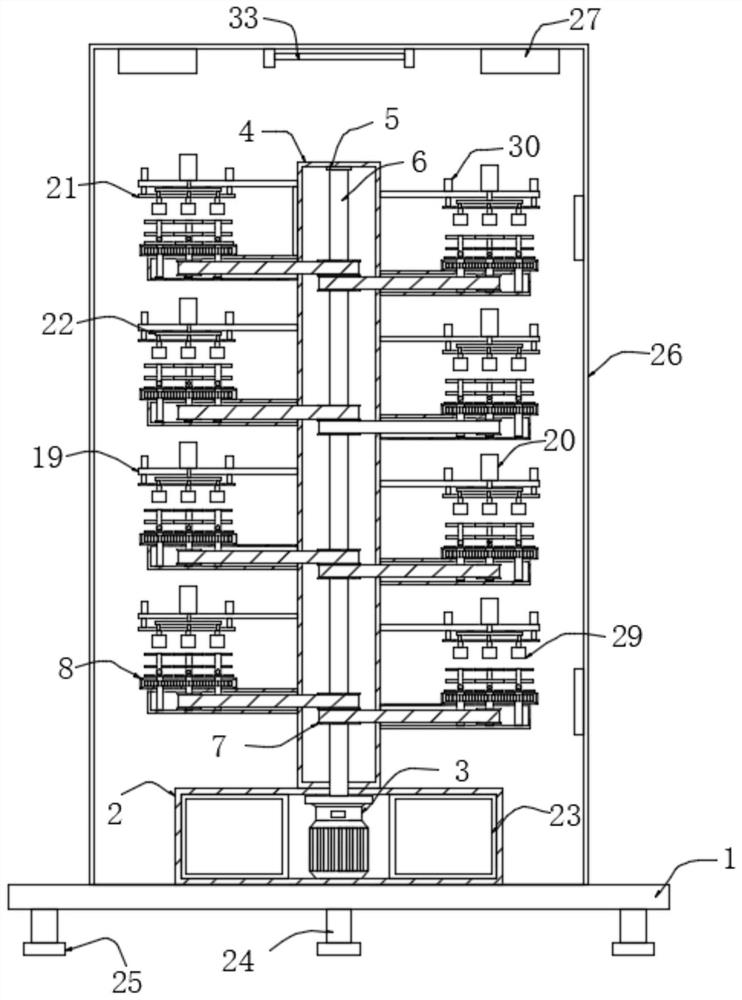

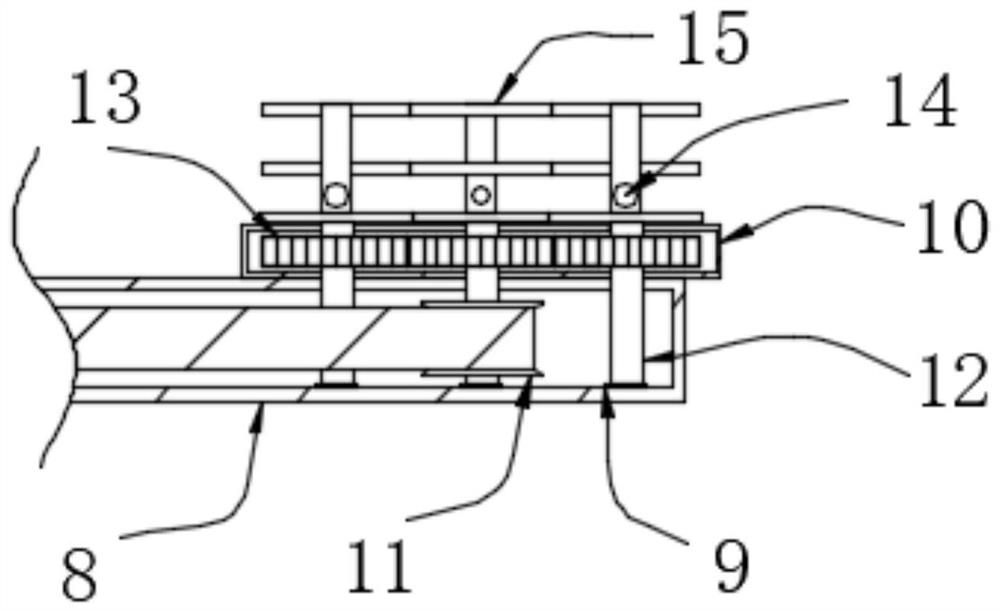

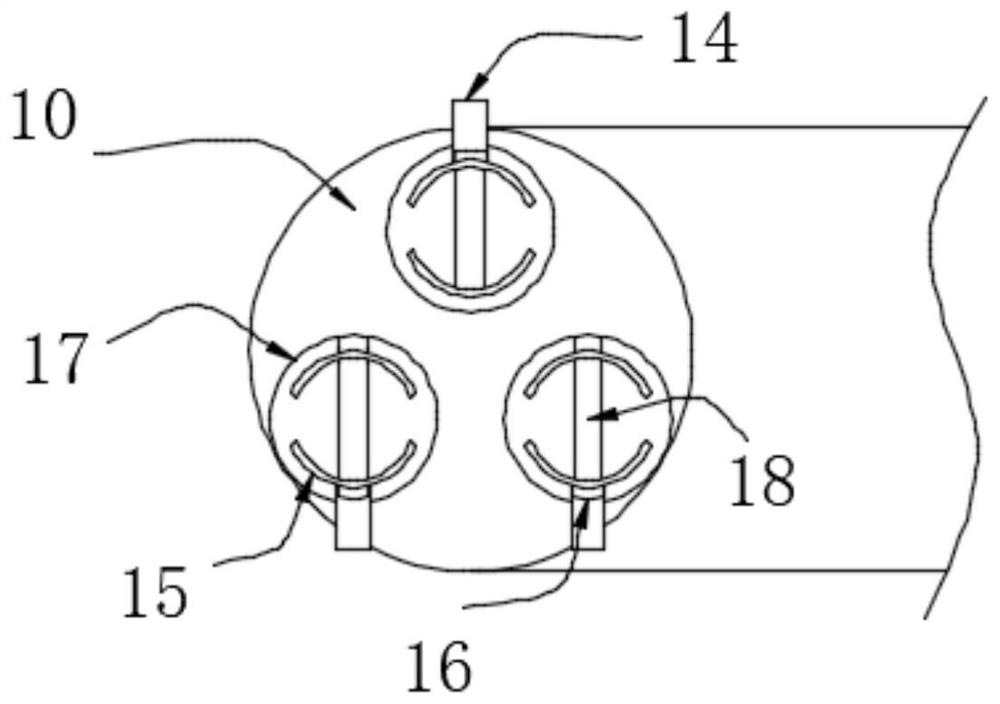

[0026] see Figure 1-5 , the present invention provides a technical solution: a porcelain insulator adhesive maintenance device, including a bottom plate 1, the upper surface of the bottom plate 1 is fixedly connected with a first box body 2, and the inner bottom wall of the first box body 2 is installed with a motor 3, The output shaft of the motor 3 runs through the inner side wall of the first box body 2, the upper surface of the first box body 2 is fixedly connected with the first casing 4, and the inner top wall of the first casing 4 is connected with the first The connecting rod 6, the output shaft of the motor 3 is fixedly connected to one end of the first connecting rod 6, the outer wall of the first housing 4 is uniformly and fixedly connected with the second housing 8, and the inner bottom wall of the second housing 8 passes through the second The bearing 9 is rotatably connected with four second connecting rods 12, the upper surface of the second housing 8 is thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com