Paint composition

A composition and coating technology, applied in the direction of polyester coatings, coatings, etc., can solve the problems of poor adhesion, limited color, difficult to achieve mass production, etc., to achieve excellent flexibility and adhesion, exquisite coating appearance, The effect of working fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

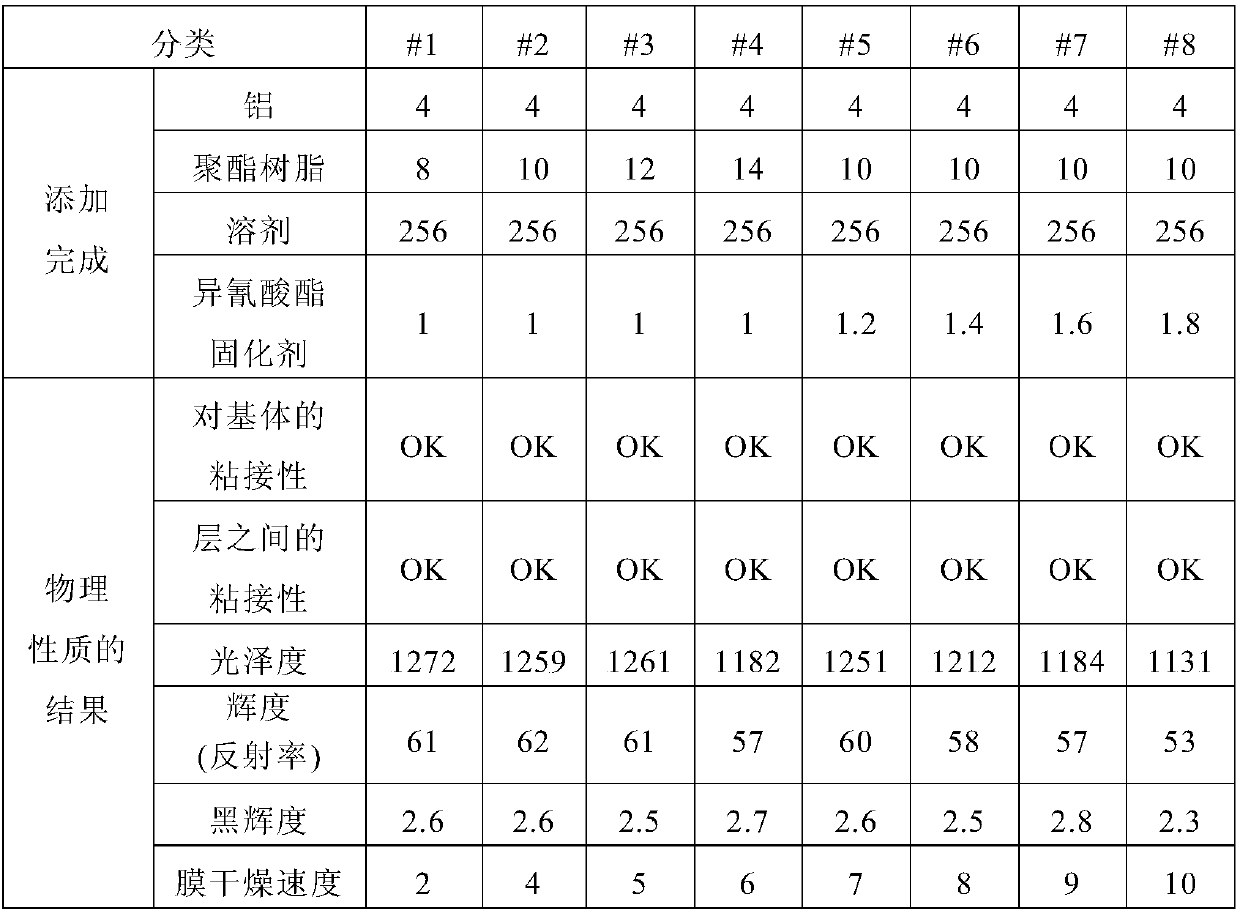

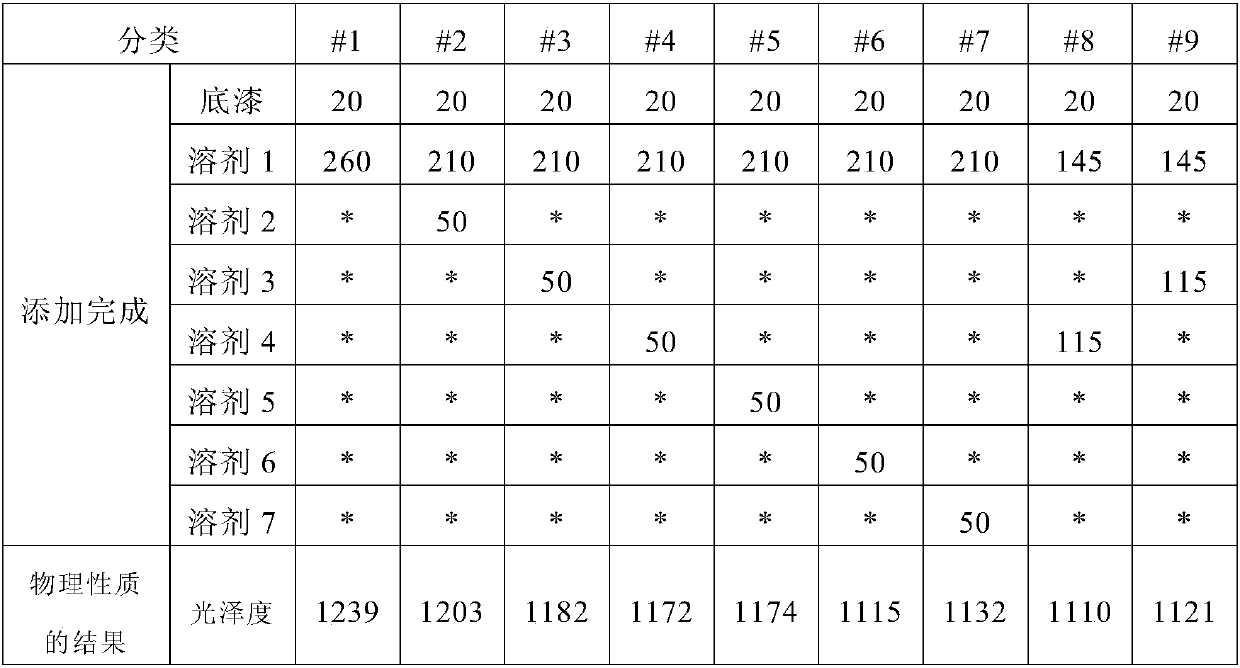

[0050] The coating composition was prepared according to the composition shown in Table 1. The prepared coating composition sample was sprayed onto the substrate (material: PET / polyurethane substrate), then dried to form a coating film, and the following physical properties of the formed coating film were measured. The measurement results of physical properties are shown in Table 1.

[0051] Adhesion to the substrate

[0052] The adhesion to the substrate was measured by the cross cut (ASTM, ISO standard) method.

[0053] Adhesion between layers

[0054] The adhesion between the layers was measured by the cross cut (ASTM, ISO standard) method.

[0055] Gloss

[0056] The gloss is measured by a gloss meter.

[0057] Brightness (reflectivity)

[0058] The brightness is measured by the CM-2500 meter.

[0059] Black brightness

[0060] The black brightness is measured by the CM-2500 meter.

[0061] Film drying speed (relative value)

[0062] After the coating film is formed on the OHP fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com