Active suspension assembly for a vehicle

A suspension component and active suspension technology, applied to vehicle components, upper structure of trucks, suspension, etc., can solve problems such as uncomfortable driving performance and undesired needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

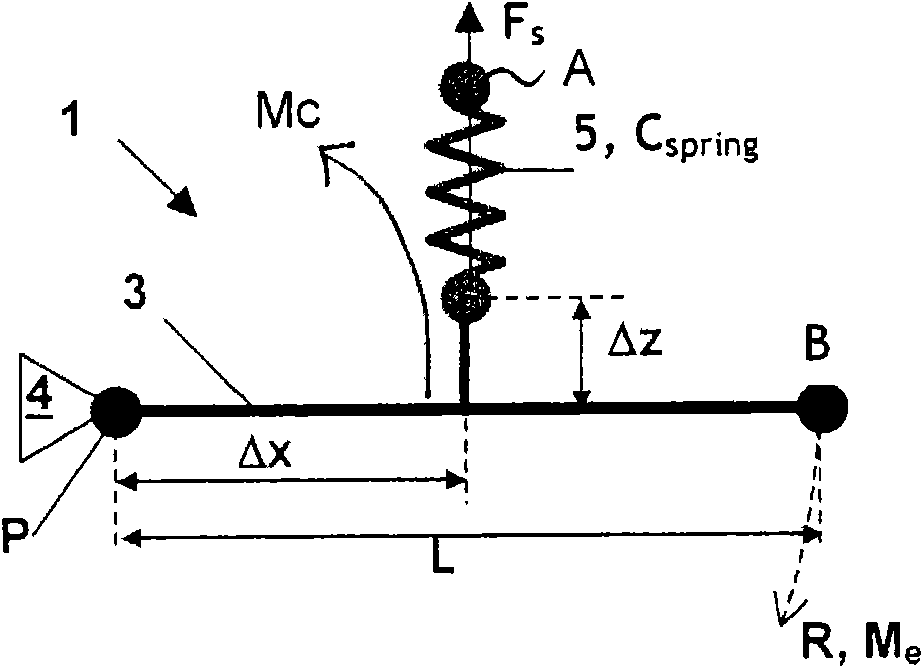

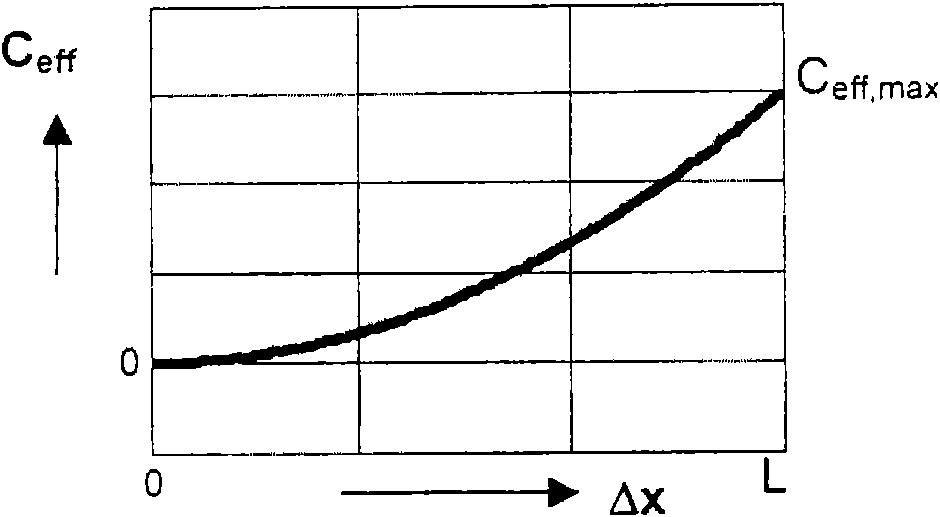

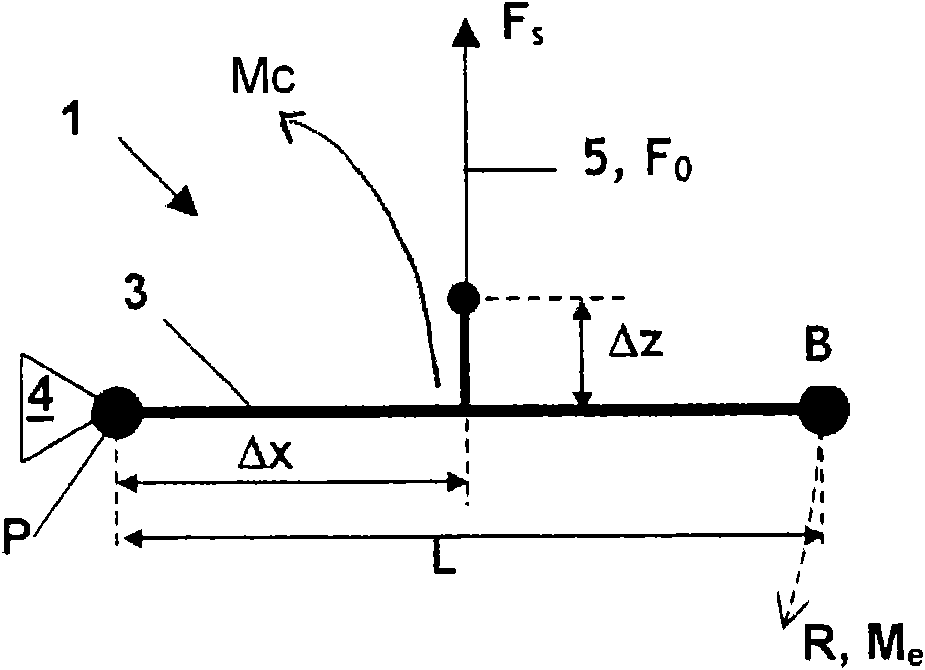

[0026] first refer to Figure 1A , Figure 1B as well as image 3 The relatively simple two-dimensional suspension assembly 1 shown in FIG. 1 illustrates the basic inventive principles of the present invention. The suspension assembly 1 comprises a support arm 3 and a spring device 5 . The support arm 3 has a length L and is pivotally connected to the chassis 4 about a pivot axis P at one end. The other end links with for example wheel or compartment 6 (as Figure 8 shown). The spring device 5 exerts a spring force F on the support arm 3 s , the elastic force F can be moved toward the pivot axis P or away from the pivot axis P along the support arm 3 (X-axis direction) s , in order to pass the elastic force F s Decrease and increase the moment M applied on the support arm 3 respectively c . Therefore, the torque M can be adjusted c To counteract the external moment M that can act on the support arm 3 in use e . Force F s The displacement of will affect the effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com