Opening degree control method of side guide plate of heavy plate mill

A control method and side guide technology, which are applied to the rolling mill control device, metal rolling, metal rolling, etc., can solve the problem that the side guide affects the rolling rhythm, etc., and achieve the improvement of rolling mill production capacity, reduction of production time, and reduction of opening adjustment. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

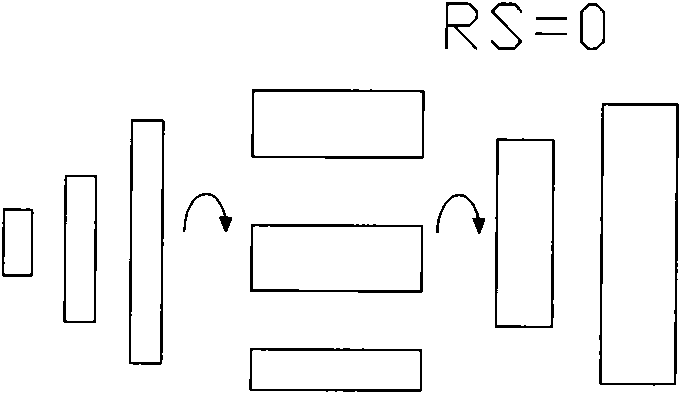

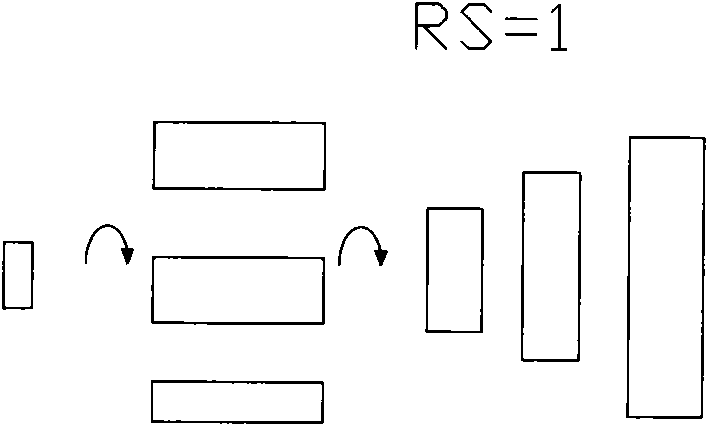

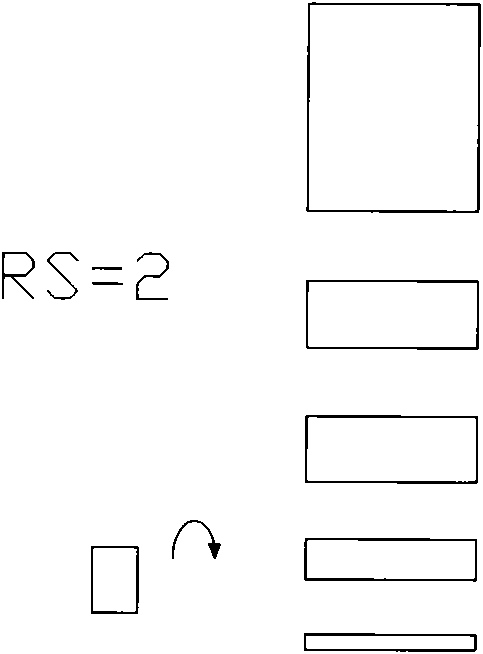

[0058] see image 3 , a schematic diagram of the method for controlling the opening of the side guide plate of a thick plate rolling mill according to the present invention. The method for controlling the opening of the side guide plate of the thick plate rolling mill of the present invention comprises the following steps:

[0059] Step 101, the rolling mill receives the rolling pass information of the next steel plate, and the side guide plate in front of the rolling mill is preset according to the RS code and the length and width of the slab;

[0060] Step 102, before the slab arrives at the rolling mill, stop on the transfer roller table, RS=1 or 2?

[0061] Step 103, if RS=1 or 2, the slab starts to be turned into steel, and the side guide plate is opened and closed after the steel turning is completed, and the two sides of the side guide plate touch the slab and then opened for 40-100mm, and the centering is completed;

[0062] In step 104, if RS≠1 or 2, the side guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com