High temperature-resisting anti-corrosion anti-abrasion self-lubricating coating material and preparation method thereof

An anti-corrosion and high-temperature technology, applied in anti-corrosion coatings, lubricating compositions, base materials, etc., can solve problems such as defects in anti-corrosion performance curing conditions, achieve mechanical strength and temperature resistance guarantee, avoid high energy consumption, heat resistance Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

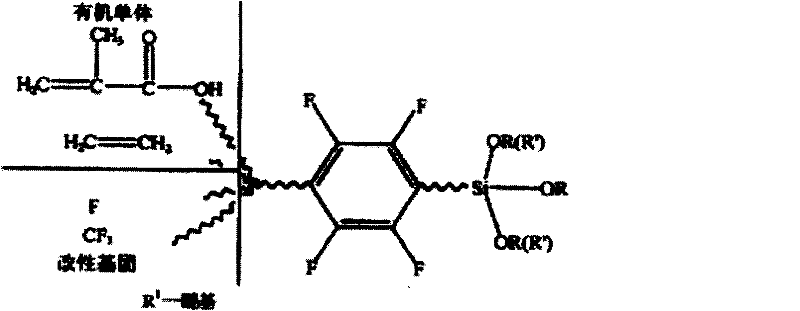

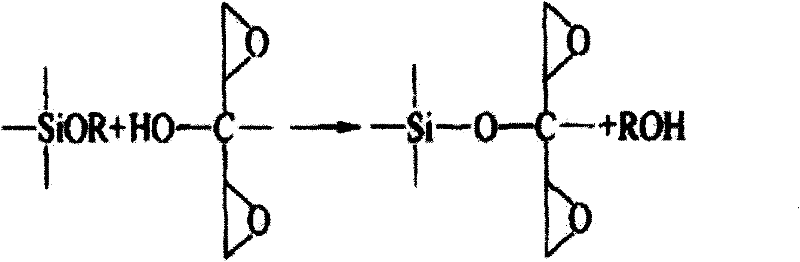

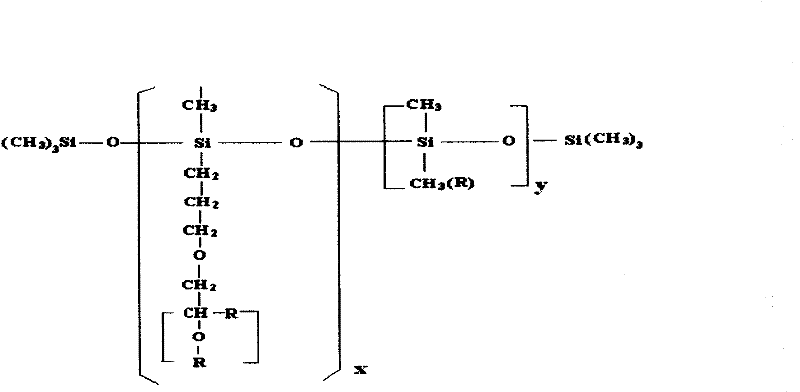

Method used

Image

Examples

Embodiment 1

[0046] A ceramic wear-resistant self-lubricating heavy-duty anti-corrosion coating, the coating comprises the following components and weight % content:

[0047] 35% ceramic binder, 30% composite ceramic powder, 10% composite solid lubricant, 3% blackening agent, 0.3% additive, 2% preservative, 3% bonding strength enhancer, and 16.7% composite organic solvent.

[0048] The preparation method of ceramic binder:

[0049] After mixing 10g of fluorine-containing alkylmethyl dichlorosilane and 23g of dihydrocarbyl chlorosilane evenly, add 0.4g of lead oxide, heat up to 85°C and keep it warm for 2 hours, then slowly raise the temperature to 140°C, then titrate and add 30% concentration of hydrochloric acid to make The acid value is below 5mgKOH / g, keep warm for 3 hours. Add 100g of epoxy resin (E44) to the product, heat to 150°C, and dealcoholize at this temperature, then add 7g of glycidyl allyl ether, raise the temperature to 200°C and keep the acid value below 5mgKOH / g. Cool do...

Embodiment 2

[0055] A ceramic wear-resistant self-lubricating heavy-duty anti-corrosion coating, the coating comprises the following components and weight % content:

[0056] 40% ceramic binder, 25% composite ceramic powder, 15% composite solid lubricant, 4% blackening agent, 0.4% additive, 3% preservative, 1% bonding strength enhancer, 11.6% mixed organic solvent.

[0057] The preparation method of ceramic binder:

[0058] After mixing 60g of fluorine-containing alkylmethyl dichlorosilane and 138g of dihydrocarbyl chlorosilane evenly, add 2g of barium oxide, heat up to 90°C and keep it for 2 hours, then slowly raise the temperature to 135°C, then titrate and add 30% concentration of hydrochloric acid to make the acid Value below 5mgKOH / g, keep warm for 3 hours. Add 600g of epoxy resin (E51) to the product, heat to 150°C, and dealcoholize at this temperature, then add 40g of glycidyl allyl ether, heat up to 200°C and keep the acid value below 5mgKOH / g. Cool down, add ethylene glycol ethe...

Embodiment 3

[0064] A ceramic wear-resistant self-lubricating heavy-duty anti-corrosion coating, the coating comprises the following components and weight % content:

[0065] 45% ceramic binder, 35% composite ceramic powder, 8% composite solid lubricant, 4.5% blackening agent, 0.2% additive, 1.5% preservative, 1.5% bonding strength enhancer, 4.3% mixed organic solvent.

[0066] The preparation method of ceramic binder:

[0067] After mixing 295g of fluorine-containing alkylmethyl dichlorosilane and 690g of dihydrocarbyl chlorosilane evenly, add 15g of lead oxide, heat up to 95°C and keep it for 2 hours, then slowly heat up to 130°C, then titrate and add 30% concentration of hydrochloric acid to make the acid Value below 5mgKOH / g, keep warm for 3 hours. Add 3.2kg of epoxy resin (E42), heat to 150°C, and dealcoholize at this temperature, then add 200g of glycidyl allyl ether, raise the temperature to 200°C and keep the acid value below 5mgKOH / g. Cool down, add ethylene glycol ether acetate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com