Steel tube ultrasonic inspection method capable of simultaneously realizing three functions in one channel

An ultrasonic flaw detection and channel technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, instruments, alarms, etc., can solve the problems of cost increase and equipment volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

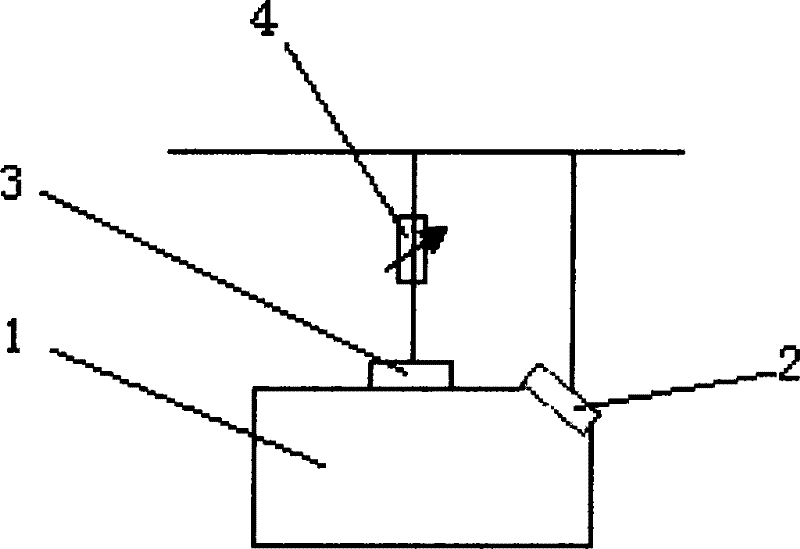

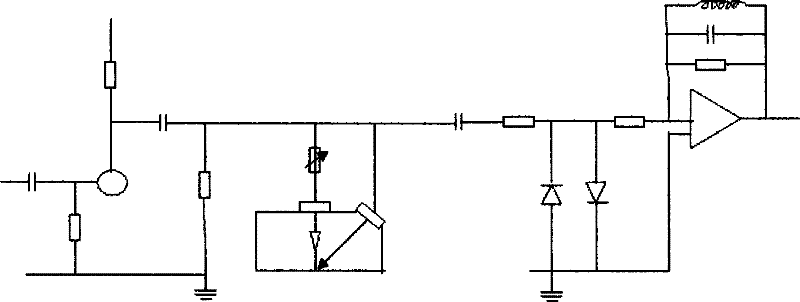

[0020] This embodiment provides a steel pipe ultrasonic flaw detection method with one channel simultaneously realizing three functions. Ceramic sheet 1 2, piezoelectric ceramic sheet 2 3, variable resistor 4;

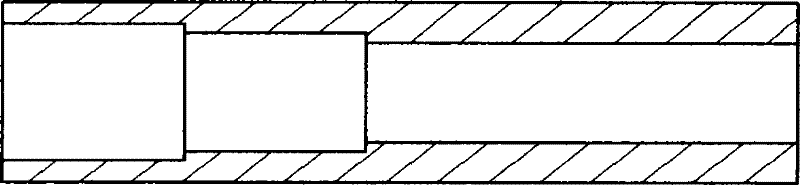

[0021] The basic structure is based on the general angle probe, adding a piezoelectric ceramic piece 2 3, the function of the piezoelectric ceramic piece 2 is the same as that of the piezoelectric ceramic piece in the ordinary angle probe, and it emits longitudinal waves to the wedge 1 , enters the tube wall after refraction, and has been converted into a transverse wave at this time. If a defect is encountered when the transverse wave propagates forward, it will return to the original path after being reflected by the defect and return to the piezoelectric ceramic piece 1 2, forming a damage echo; piezoelectric ceramic piece 2 3 and the wedge form a straight probe with a delay block, and the piezoelectric ceramic sheet 2 3 emits longitudinal waves to the steel pipe wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com