Air flotation conveying device

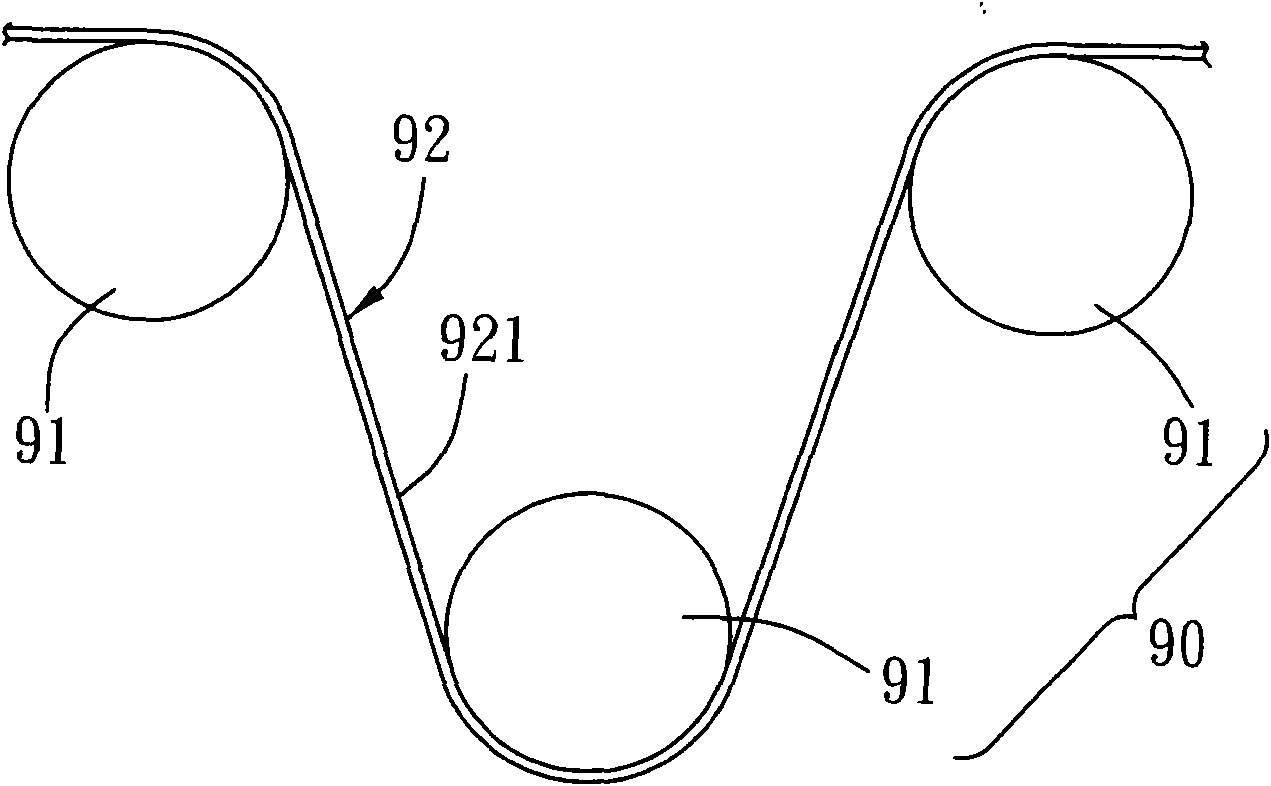

A conveying device and air flotation technology, applied in transportation and packaging, thin material handling, winding strips, etc., can solve problems such as difficult to control the tension and flatness of the flexible circuit board 92, circuit damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

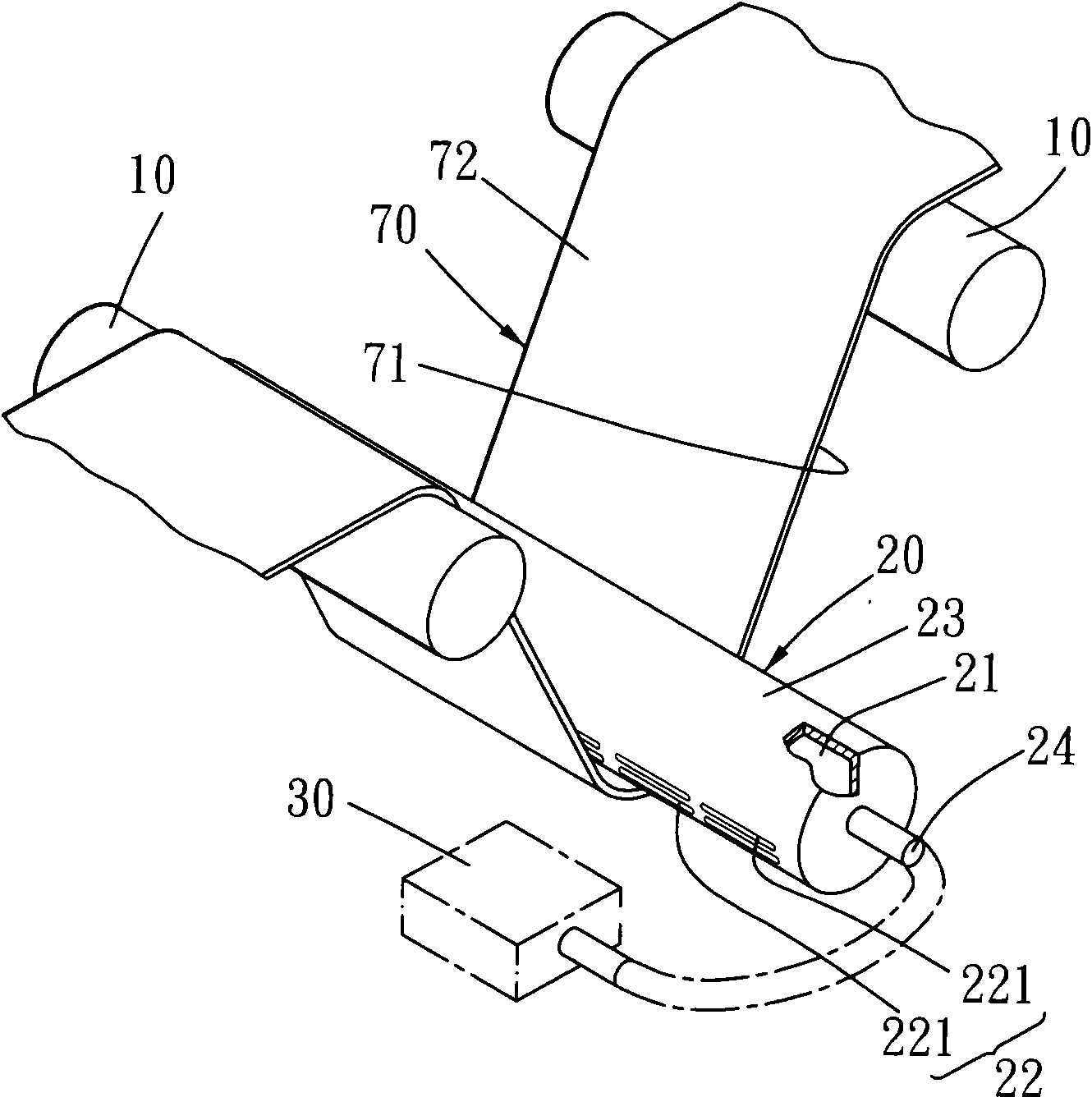

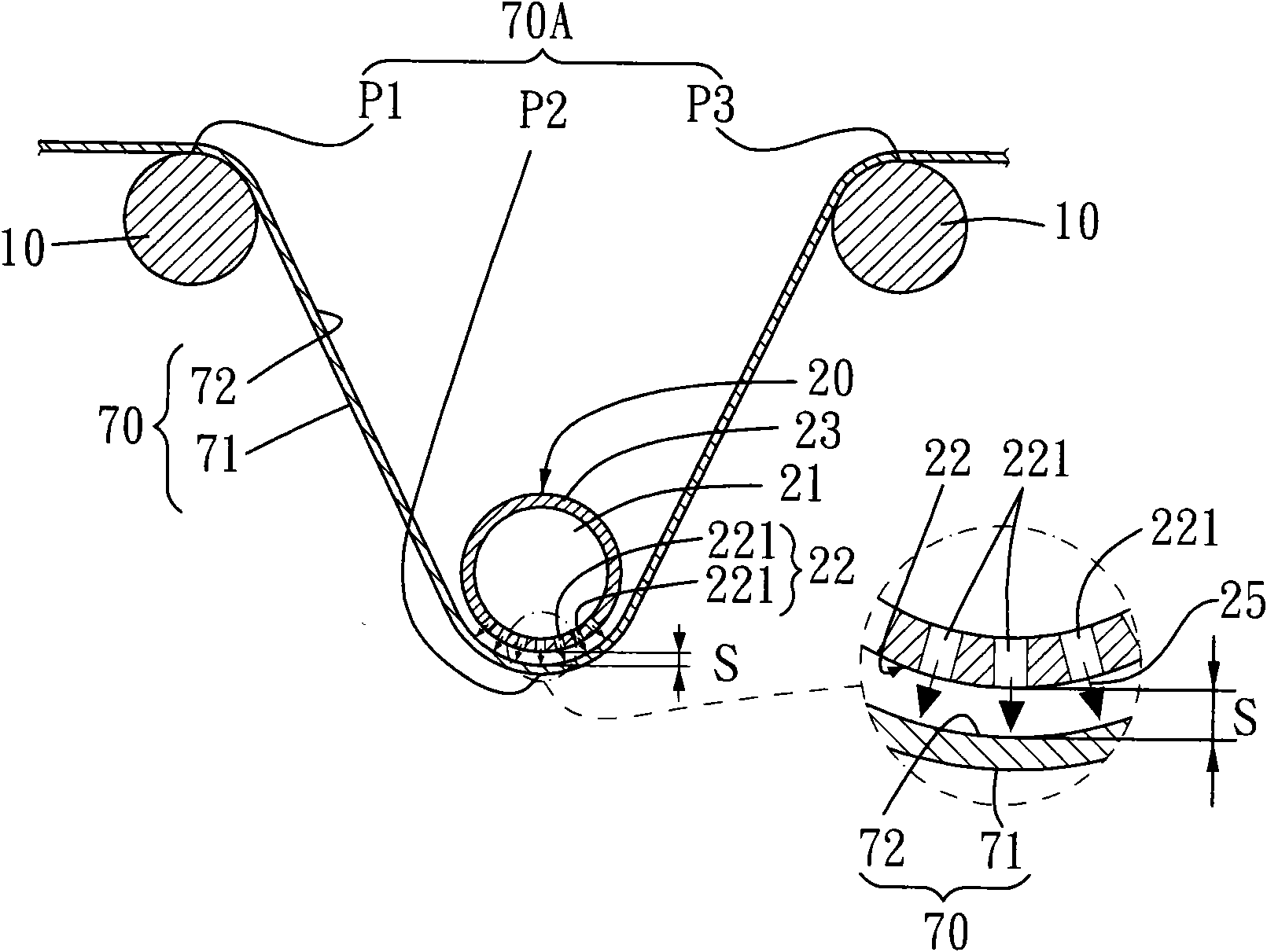

[0035] Such as figure 2 and image 3 As shown, the present invention is an air-floating conveying device, which includes at least two conveying shafts 10 and at least one air-floating conveying shaft 20, used to transport a curved and sheet-shaped object 70 to be tested to move;

[0036] The object to be tested 70 has a contact surface 71 and a working surface 72; the conveying shaft 10 is in contact with the contact surface 71 of the object to be measured 70, and the air bearing conveying shaft 20 is adjacent to but not in contact with the object to be measured 70 and, the object to be tested 70 is limited by the air bearing conveying shaft 20 to form a curved section 70A between the two conveying shafts 10 (such as image 3 As shown, the bending section 70A is a range formed by a first contact point P1, a limiting point P2 and a second contact point P3);

[0037] The air-floating conveying shaft 20 has a gas storage space 21, a working part 22, a non-working part 23 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com