Heating power expansion valve

A thermal expansion valve and valve stem technology, applied in the field of thermal expansion valves, can solve problems such as internal leakage, achieve the effect of preventing the deviation of superheat and eliminating internal leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

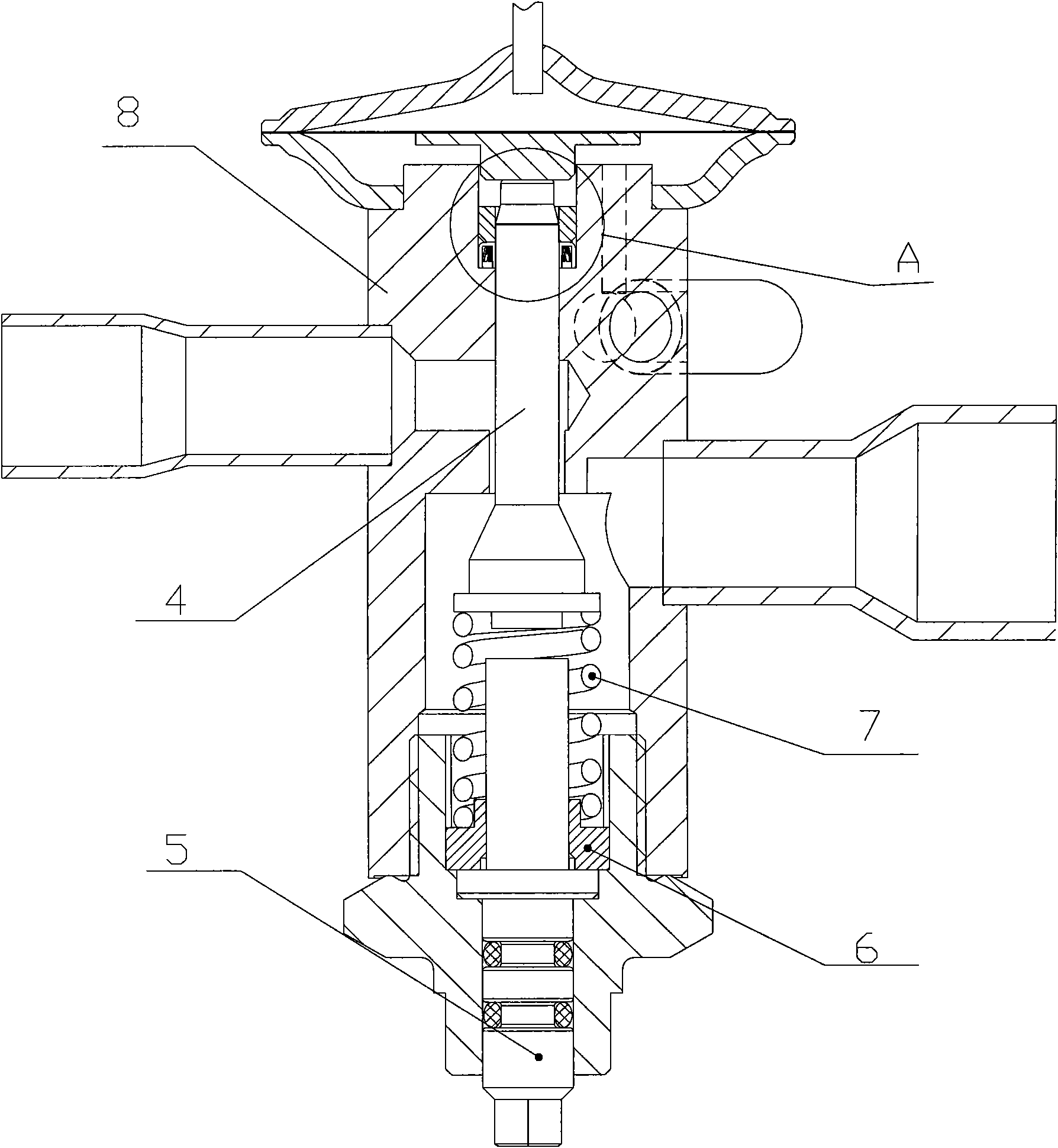

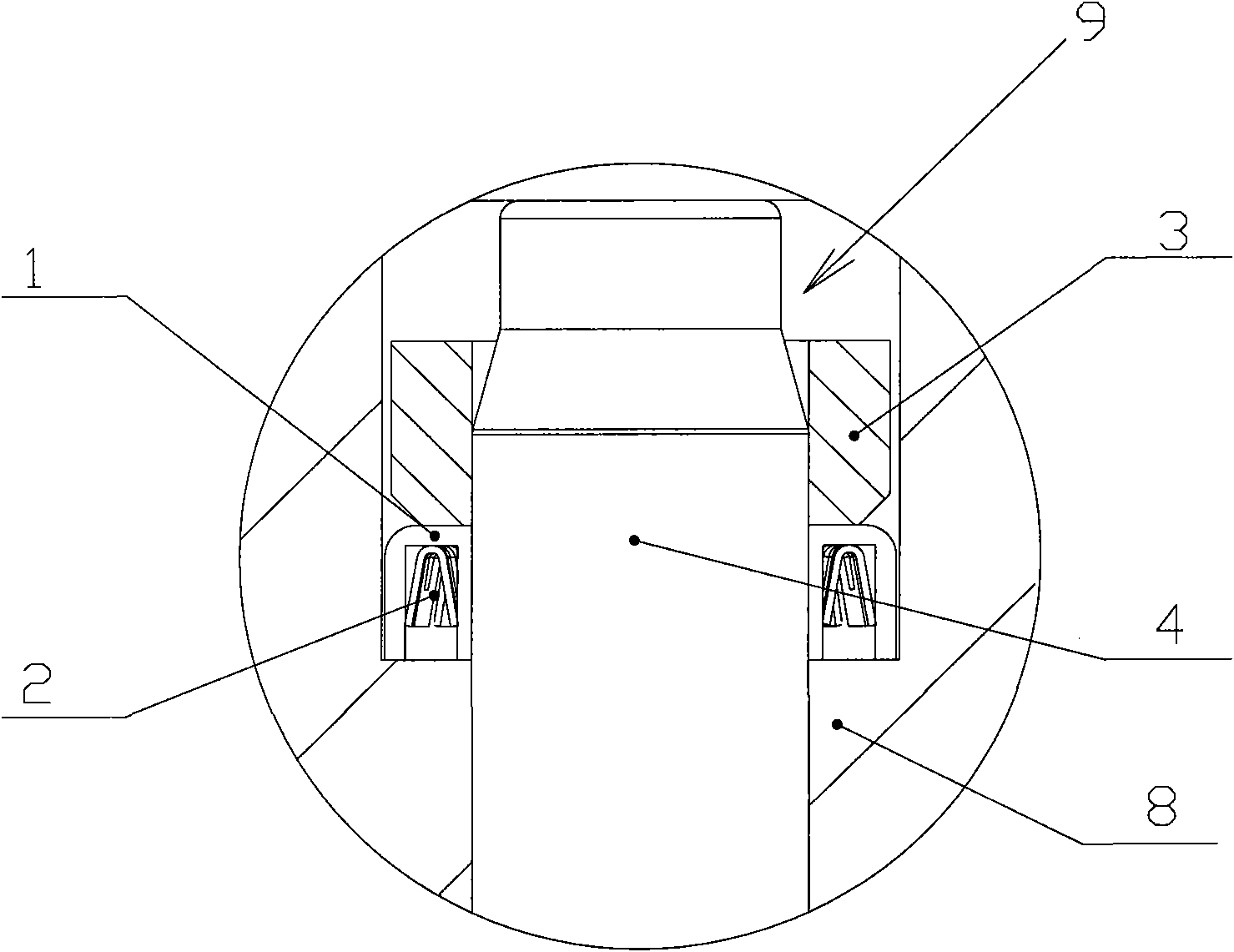

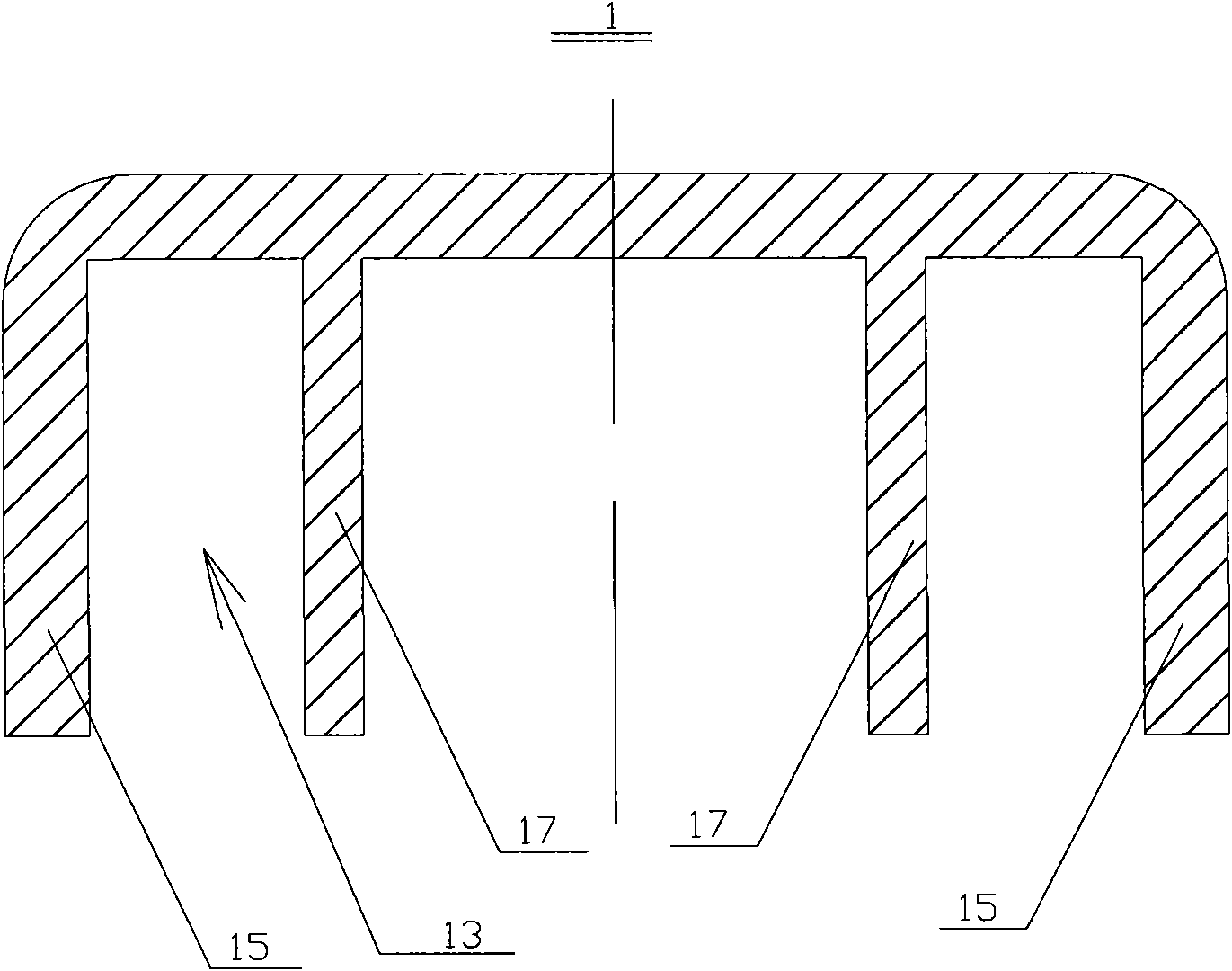

[0019] figure 1 Schematically shows the structure of a thermal expansion valve according to an embodiment of the present invention; figure 2 schematically shows figure 1 The local enlarged structure at A. Such as figure 1 and figure 2 As shown, a thermal expansion valve includes: a valve body 8 with a transmission hole 9 inside; a valve stem 4 pierced in the transmission hole 9; a sealing ring 1 slidably sleeved outside the valve stem 4 and It is located between the transmission hole 9 and the valve stem 4; the pressure block 3 is sleeved on the outside of the valve stem 4 and pressed on the sealing ring. The pressing block 3 can prevent the displacement of the sealing ring 1 during the working process, avoiding the leakage caused by the displacement of the sealing ring 1 .

[0020] The sealing ring 1 can be made of rubber an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com