Method for checking and detecting sealing surface of stop valves and regulating valves after online grinding

A control valve and globe valve technology, which is applied in the field of acceptance testing of sealing surfaces after on-line grinding of globe valves and control valves, can solve the problems of reducing work efficiency, increasing acceptance testing time, low reliability, etc., so as to prevent internal leakage and improve acceptance. Accuracy and the effect of ensuring reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

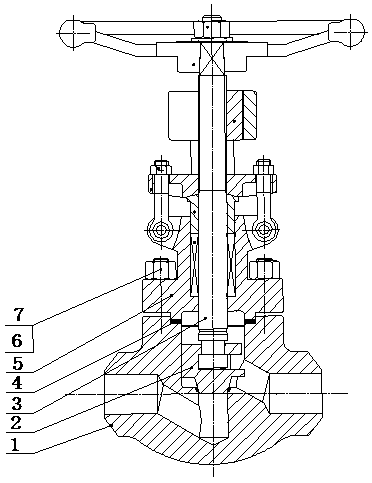

[0019] A method for inspection and detection of sealing surfaces of globe valves and control valves after on-line grinding. The method comprises: a valve seat 1, which is characterized in that: a valve stem 3 is installed inside the valve seat, and the valve stem The bottom is connected to the valve flap 2, the sealing surface of the valve flap is attached to the sealing surface of the valve seat, a valve cover gasket 4 is installed at the seam above the valve seat, and the valve cover has a valve cover The gasket is attached to the lower seam of the valve cover 5, and the valve seat and the valve cover are connected by stud bolts 6 and fixed by nuts 7;

[0020] The method for acceptance detection of the sealing surface of the shut-off valve and the regulating valve after online grinding, the method includes the following steps:

[0021] First, connect and fix the valve disc with the valve stem, then install the connected valve disc, valve stem and bonnet together so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com