Heating device

A technology for heating devices and terminals, which is applied in the direction of lighting devices, lighting and heating equipment, parts of lighting devices, etc., to achieve the effect of inhibiting the movement of the tube axis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

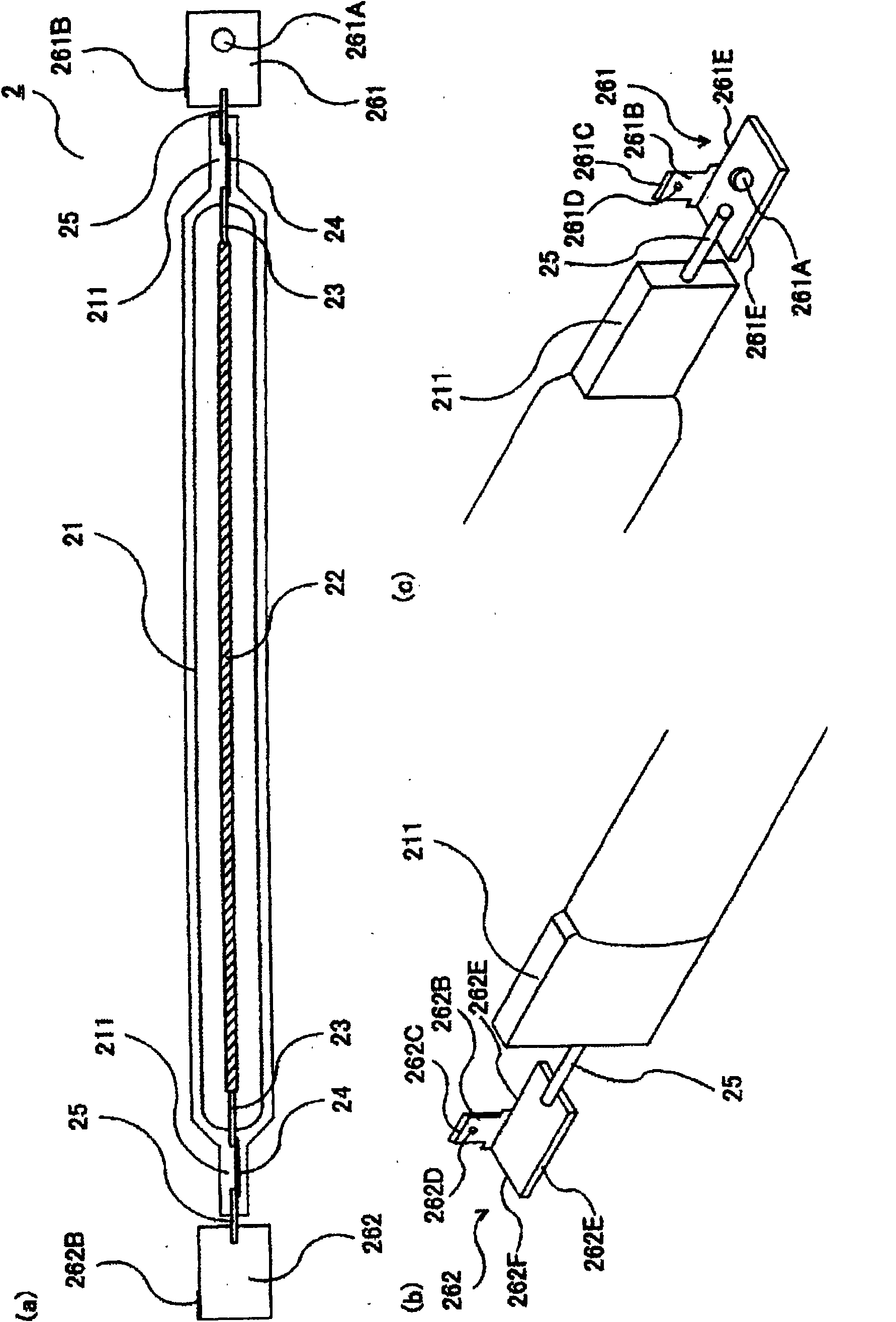

[0057] The heating device of the present invention is characterized in that, in order to position the tubular incandescent lamp at a desired position, the screw is not directly fixed on the other terminal, and in order to restrict the direction of the other terminal to be perpendicular to the axial direction of the tubular incandescent lamp direction movement, the other terminal is arranged on the other lamp holding part, and the movement of the tubular incandescent lamp in the axial direction is restricted.

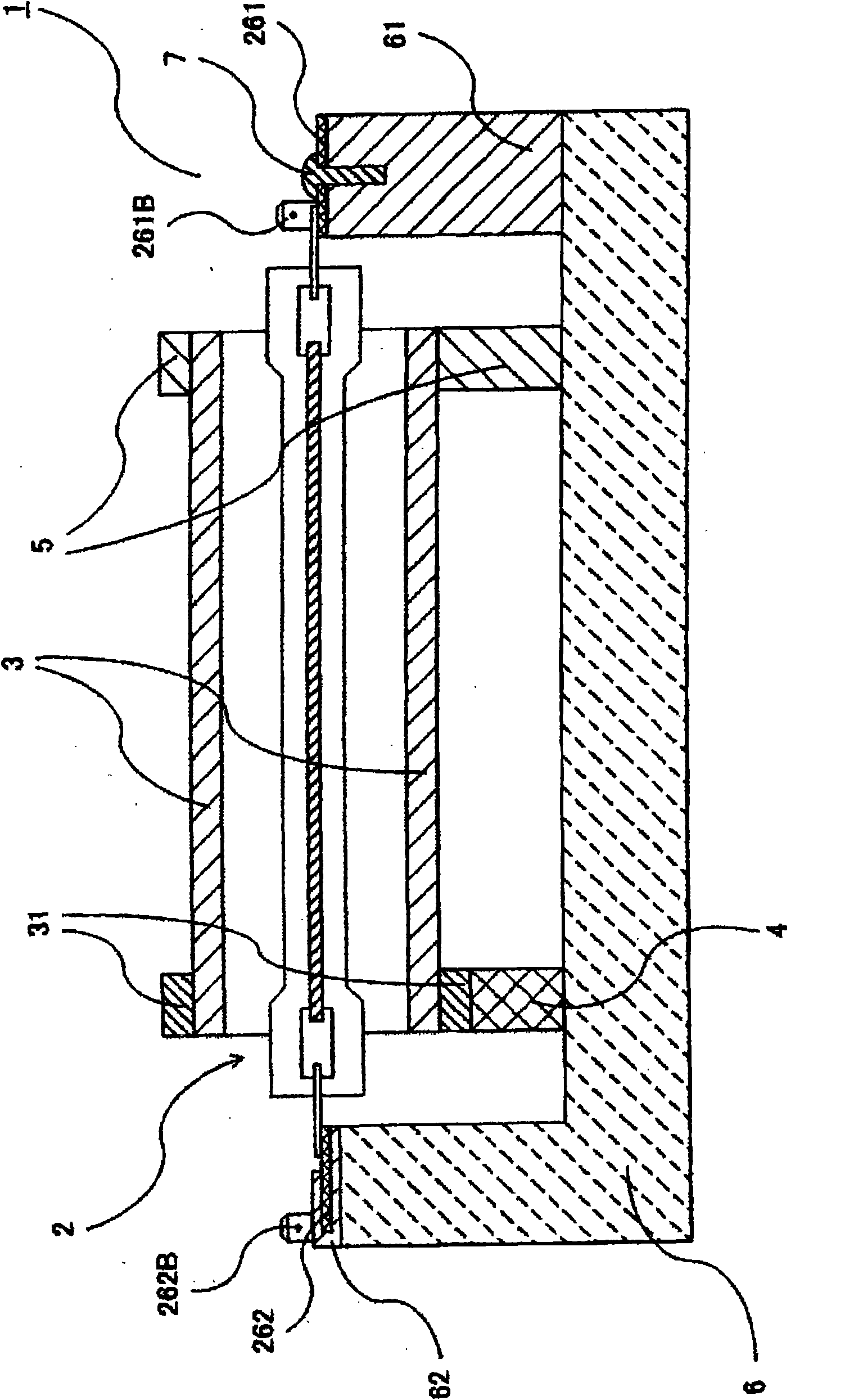

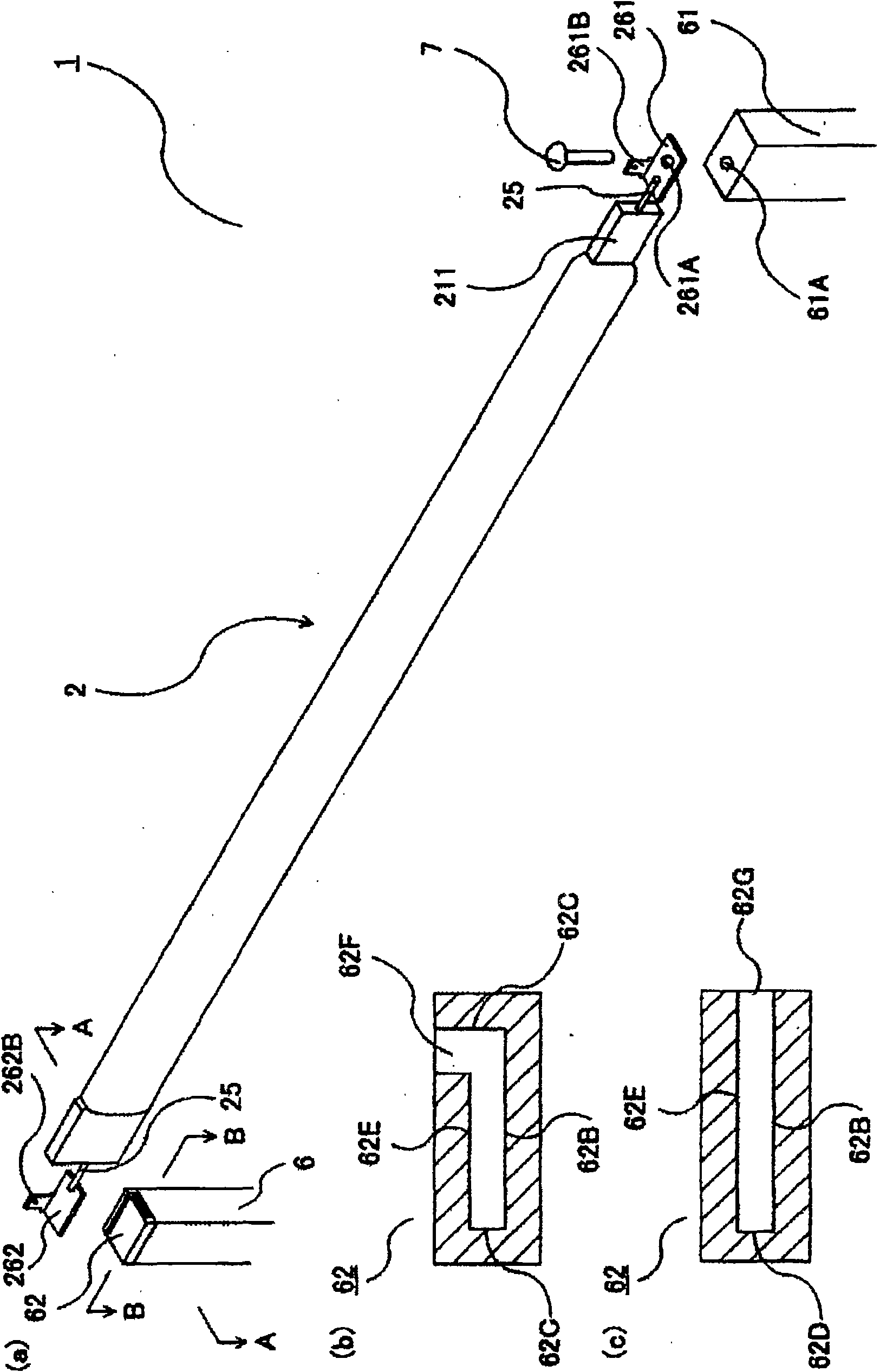

[0058] First, as a first embodiment of the heating device 1 of the present invention, refer to Figure 1 ~ Figure 3 The heating device 1 in which one terminal of a tubular incandescent lamp is fixed to a lamp holder will be described.

[0059] figure 1 It is an explanatory diagram of the heating device 1 according to the first embodiment, and is a cross-sectional view along the tube axis direction of the cylindrical roller 3 constituting the heating device 1 . figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com