Propeller hub

A technology for propellers and propeller hubs, which is applied in the field of propeller hubs for ships. It can solve the problems of large differences in the force bearing area of pistons, inconvenient installation, and small structural torsion transmission, so as to increase the torque transmission capacity and reduce the use of The effect of increasing the number and the force-bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

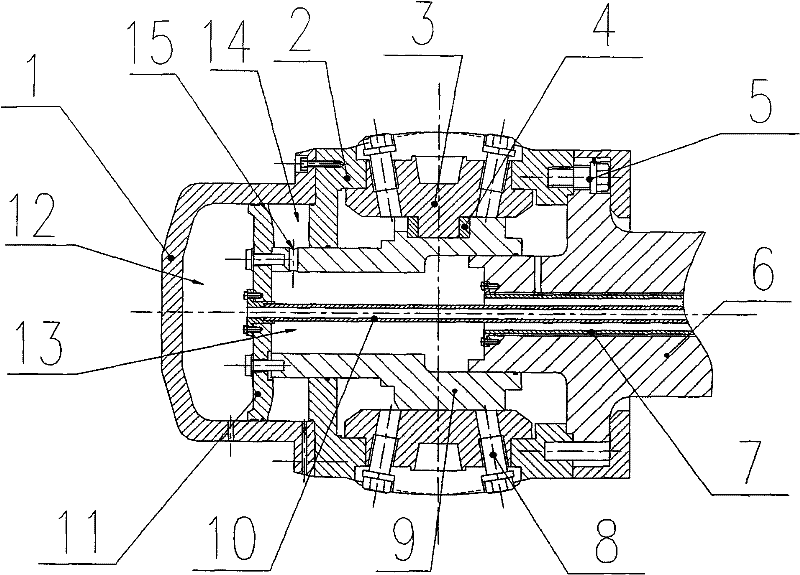

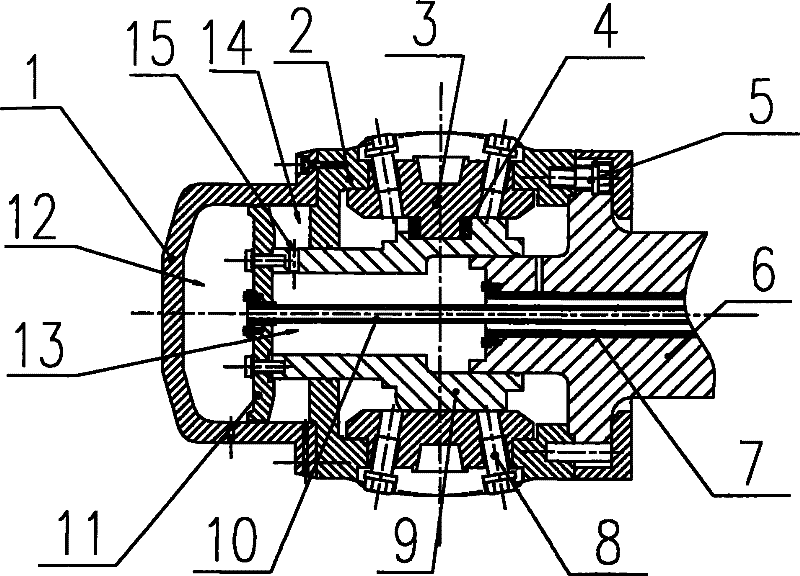

[0016] The accompanying drawings disclose the specific structure of the present invention without limitation, and the present invention will be further described below in conjunction with the accompanying drawings.

[0017] Depend on figure 1 It can be seen that the present invention includes: oil cylinder block 1, propeller hub 2, piston 11, blade packing 3, slider 4, guide frame 9, blade root screw 8, stern shaft 6 with inner oil pipe 10 and outer oil pipe 7, oil cylinder The body 1 is connected with the propeller hub 2, the piston 11 is located in the oil cylinder body 1, the outer wall of the guide frame 9 is slidingly connected with the inner edge of the center hole of the propeller hub 2, and the propeller hub 2 is connected with the stern shaft 6 through the flange screw 5. Among them: the piston 11 is installed on the end of the guide frame 9 inside the propeller hub through screws, and the cavity between the front end of the piston 11 and the inner wall of the oil cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com