Novel belt pulley

A pulley, a new type of technology, applied in the direction of belt/chain/gear, components with teeth, portable lifting devices, etc., can solve the problems of complex structure and process, easy to enter the mud, and drop the belt, so as to simplify the structure and process, Eliminates maintenance and prevents belt drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

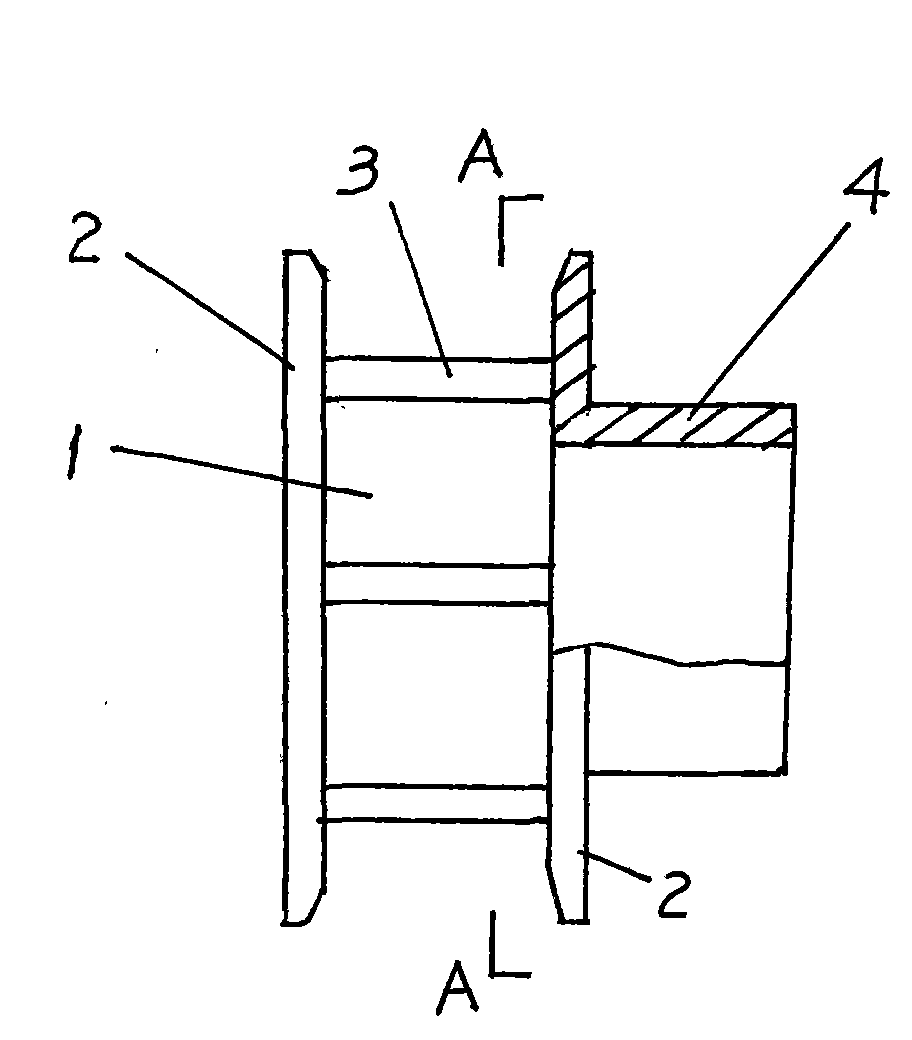

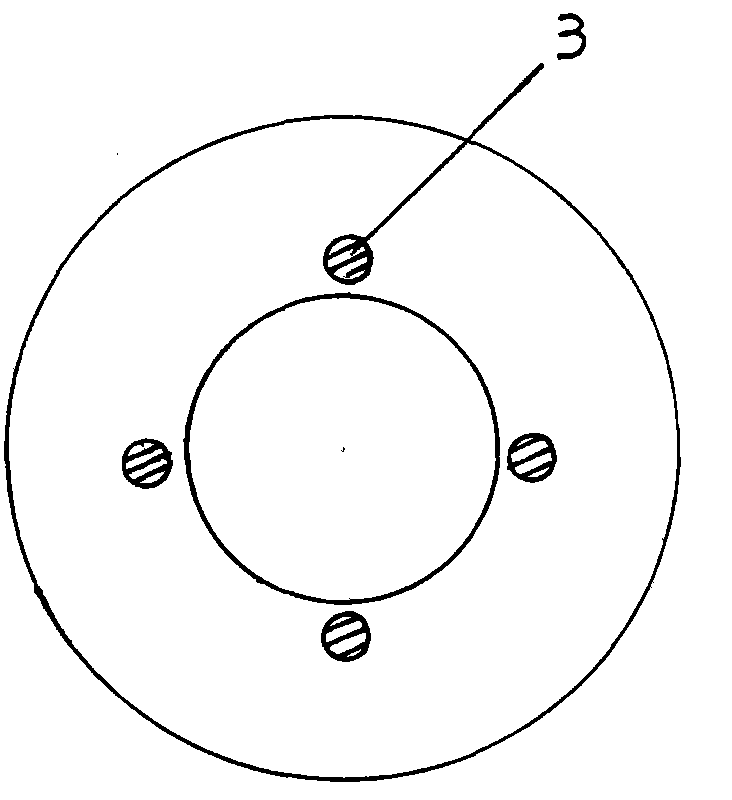

[0014] See figure 1 , 2 , The structure of Embodiment 1 of the present invention is as follows: the main body of the sheave is provided with two wheel pieces 2 with a central hole, and the connecting ribs 3 of 3-4 steel bars are welded evenly along the circumferential direction between the two wheel pieces 2 . Leakage holes 1 are formed between the connecting ribs 3, and the two wheel pieces 2 and the evenly distributed connecting ribs 3 form notches. The earth or sundries that enter the notch of the drive sheave during operation leak out from the leakage hole 1 to prevent the belt from falling off. One side of the main body of the sheave is connected with the bearing sleeve 4 . The production can also be done by casting process.

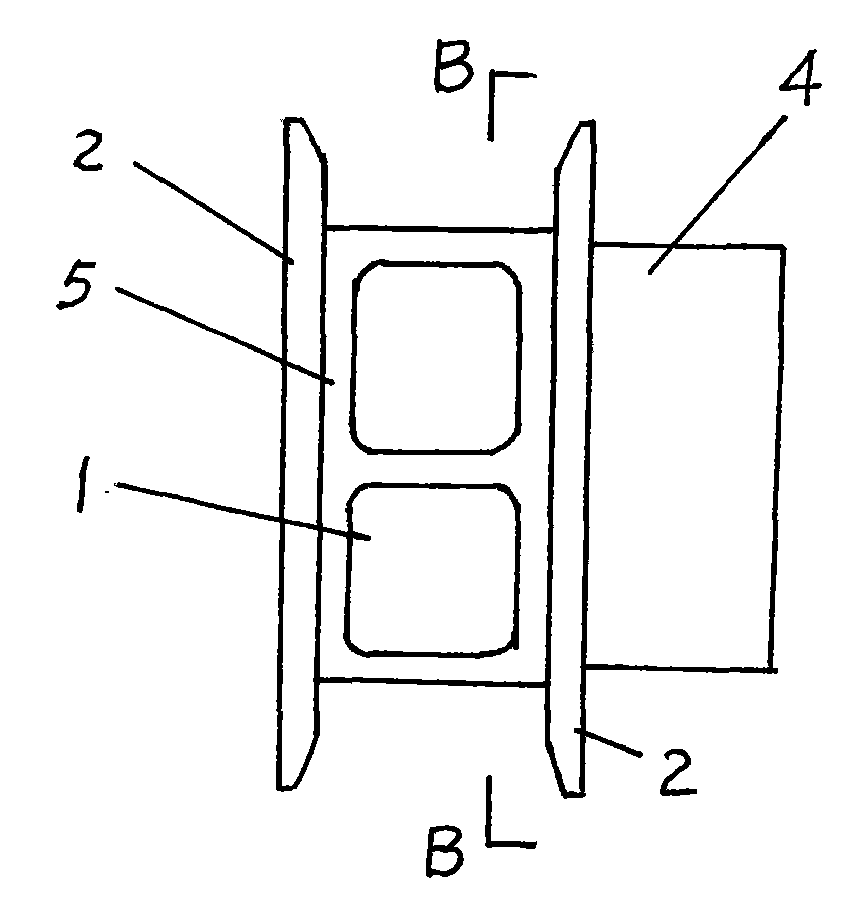

[0015] See image 3 , 4 , The structure of Embodiment 2 of the present invention is as follows: the main body of the sheave is provided with two wheel pieces 2 with a central hole, and a connecting plate 5 with a leakage hole welded between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com