Patents

Literature

97results about How to "Avoid drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

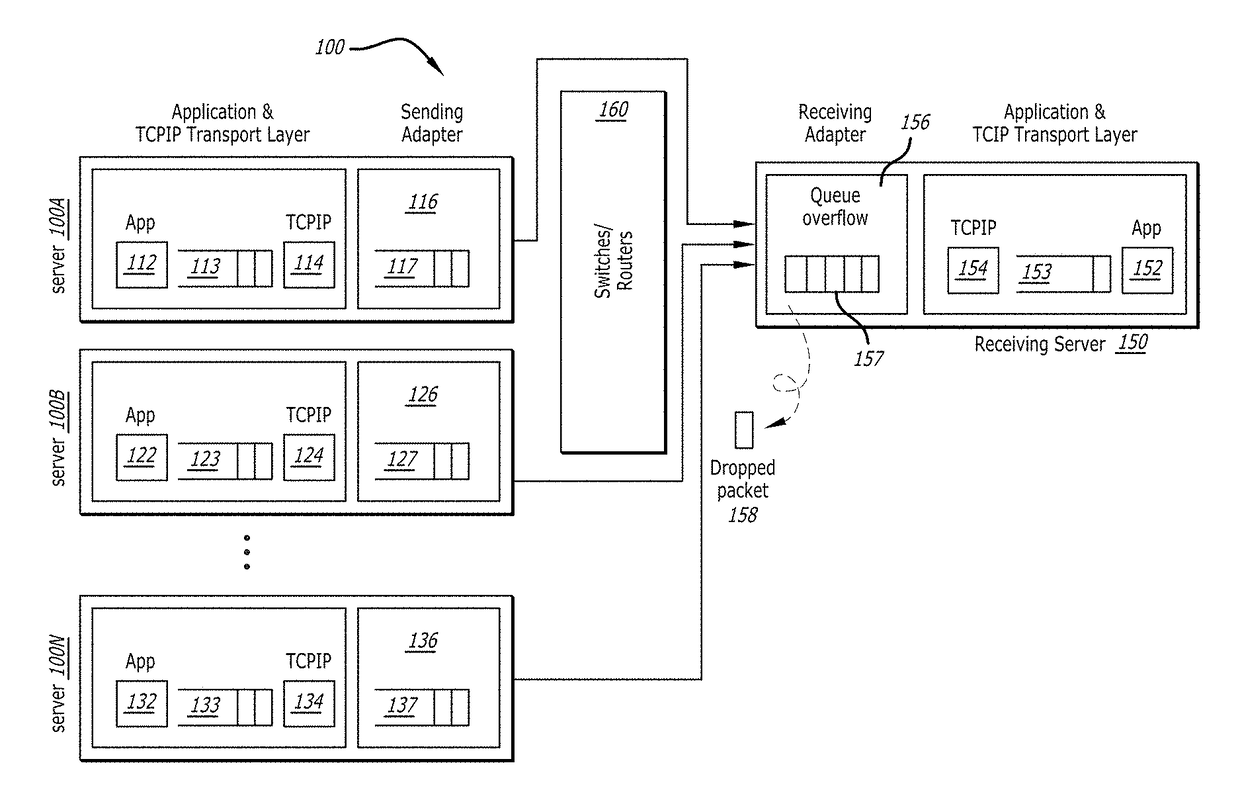

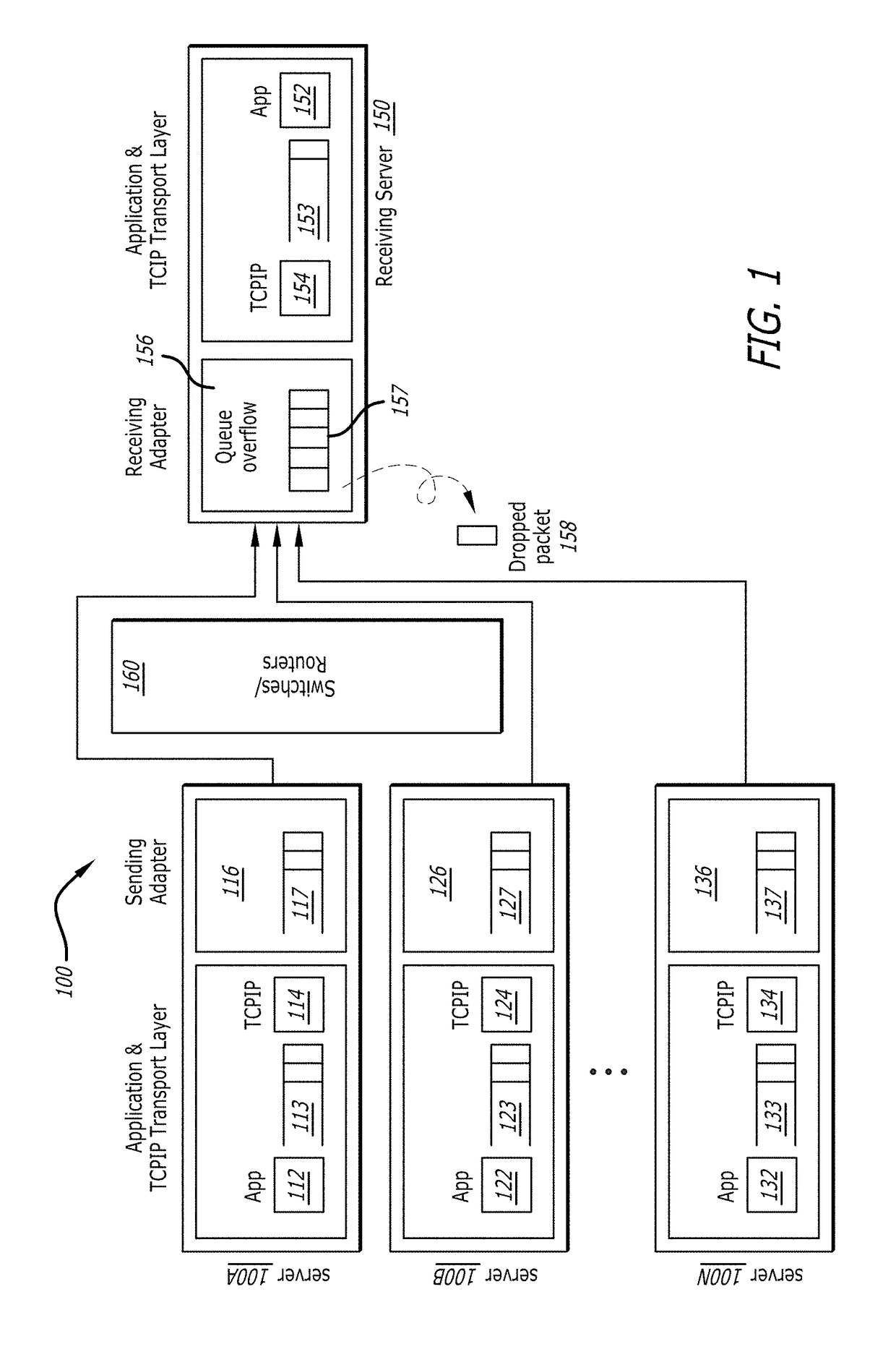

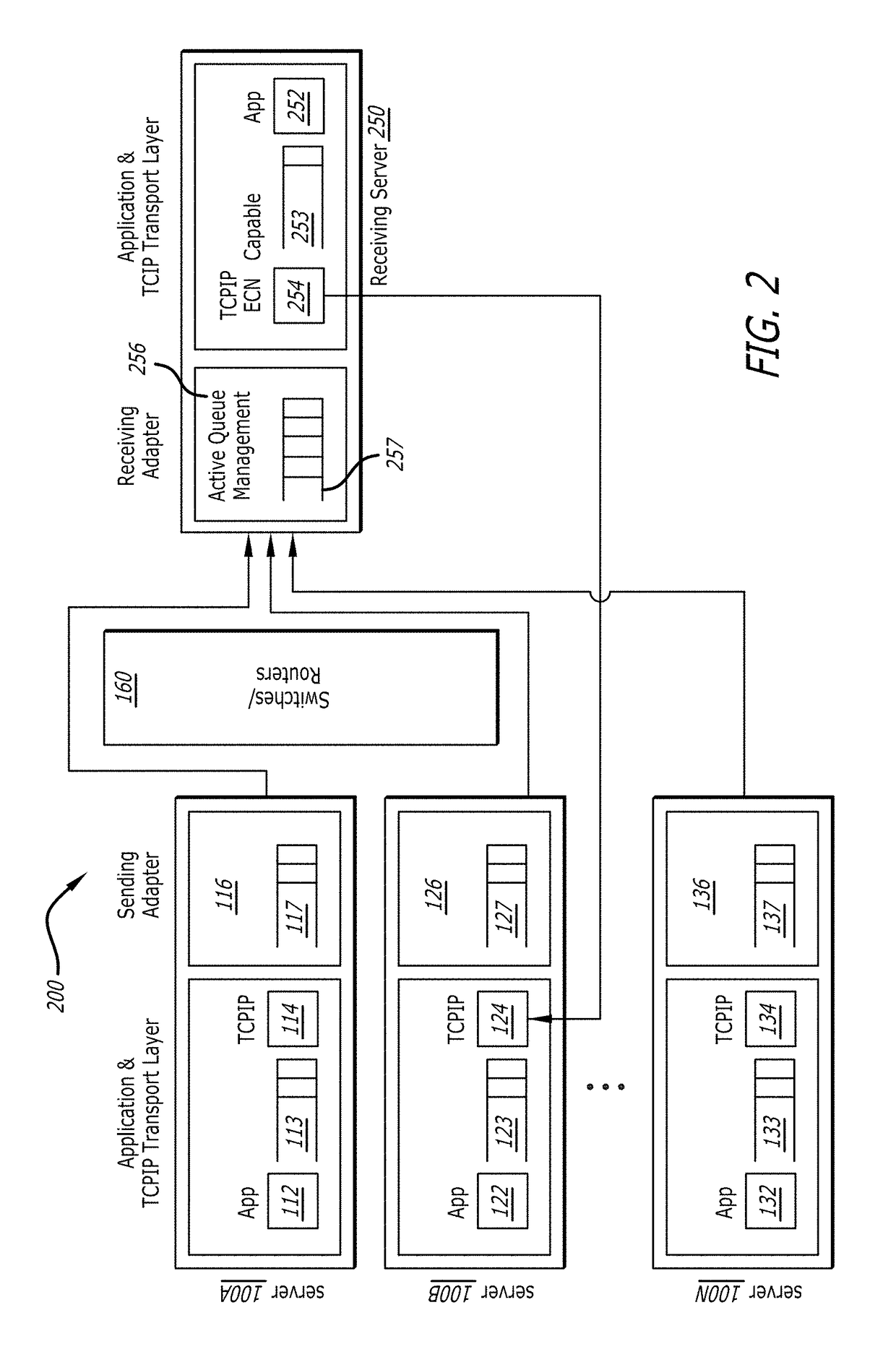

Avoiding dropped data packets on a network transmission

ActiveUS20170180261A1Avoid dropAdd depthSignal allocationData switching networksData bufferMartian packet

A method, system, and apparatus are provided to avoid dropping data packets between computers coupled on a network. In one example, the system receives a plurality of data packets from one or more sending servers into a receive queue of a first network interface device (e.g., Fibre Channel host bus adapter) in a receiving server. The receive queue includes addresses to data buffers to store a predetermined number of data packets. The system monitors the number of data packets stored in the data buffers waiting for read out by a software application. The system detects a potential overflow of the receive queue in response to a number of unused data buffers of the receive queue. In response to detecting the potential overflow, the system performs preemptive actions to avoid dropping at least one of the plurality of data packets.

Owner:AVAGO TECH INT SALES PTE LTD

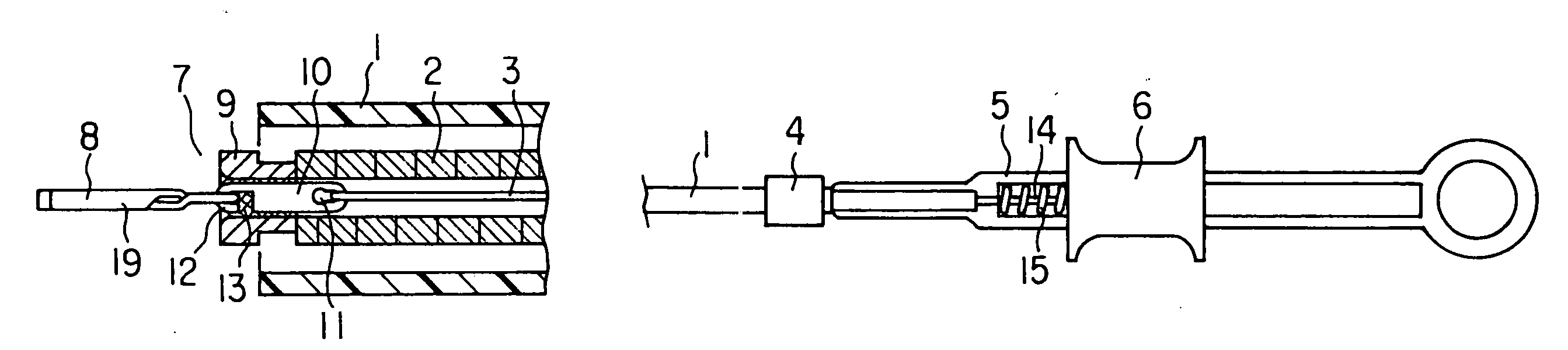

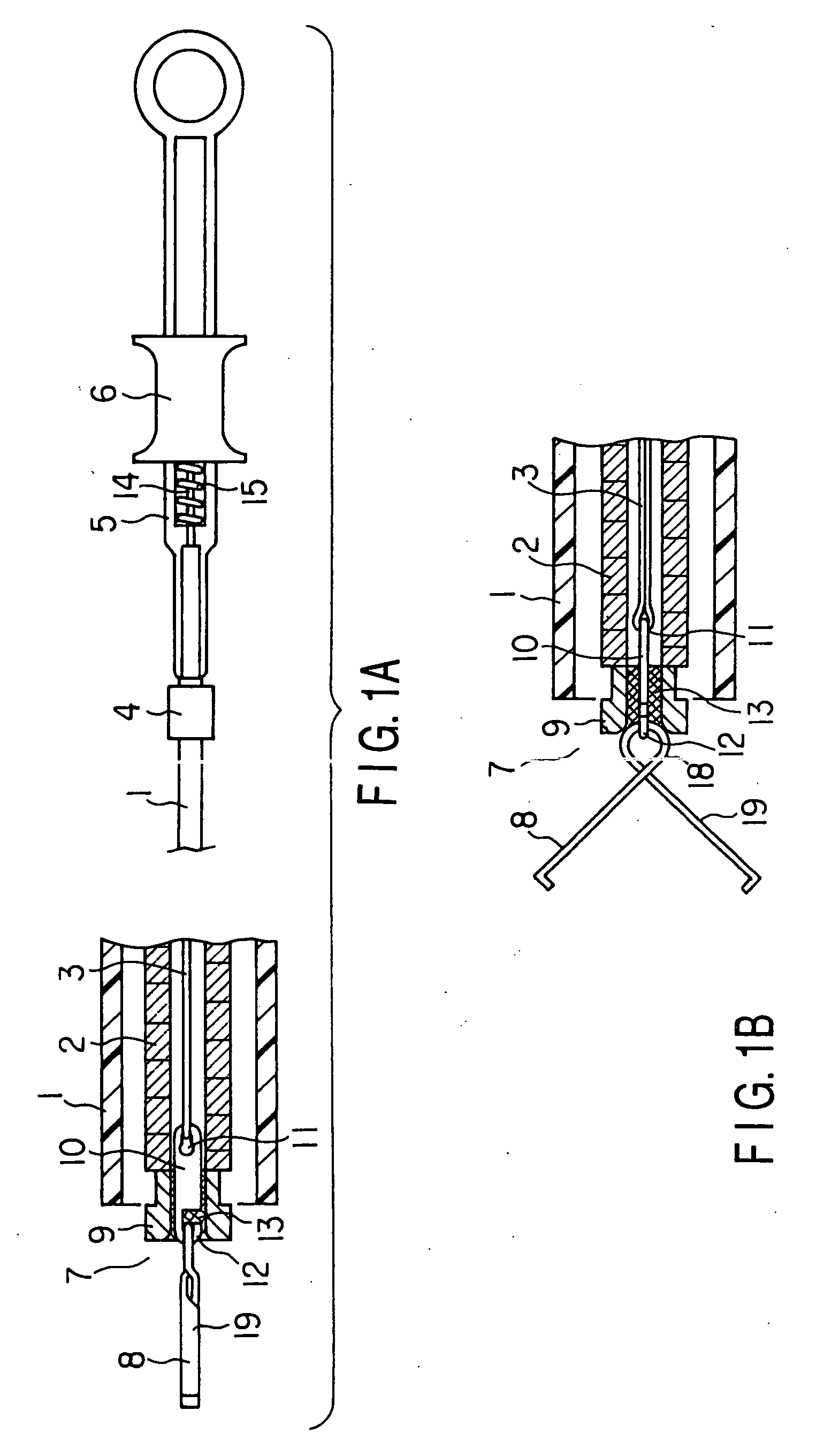

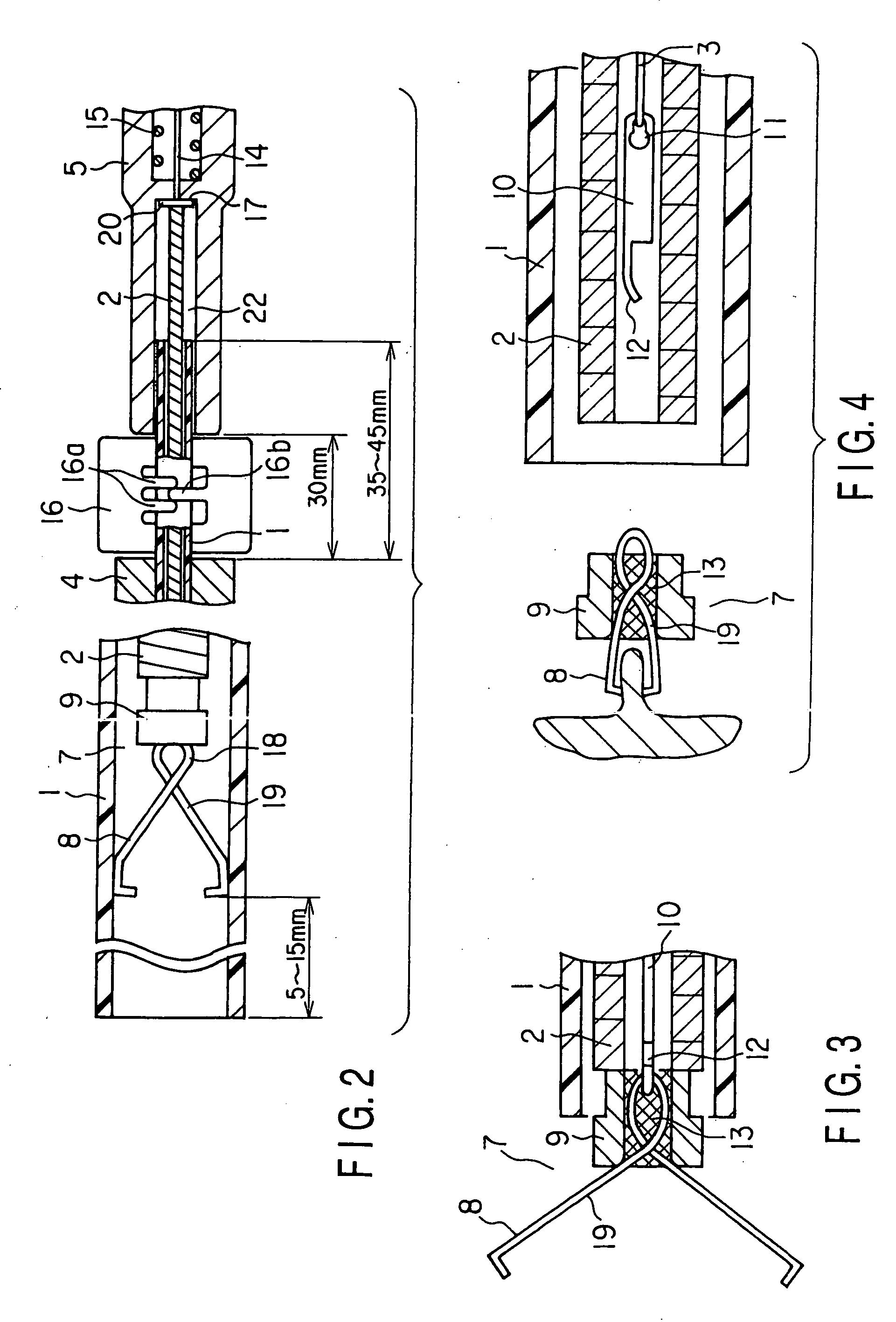

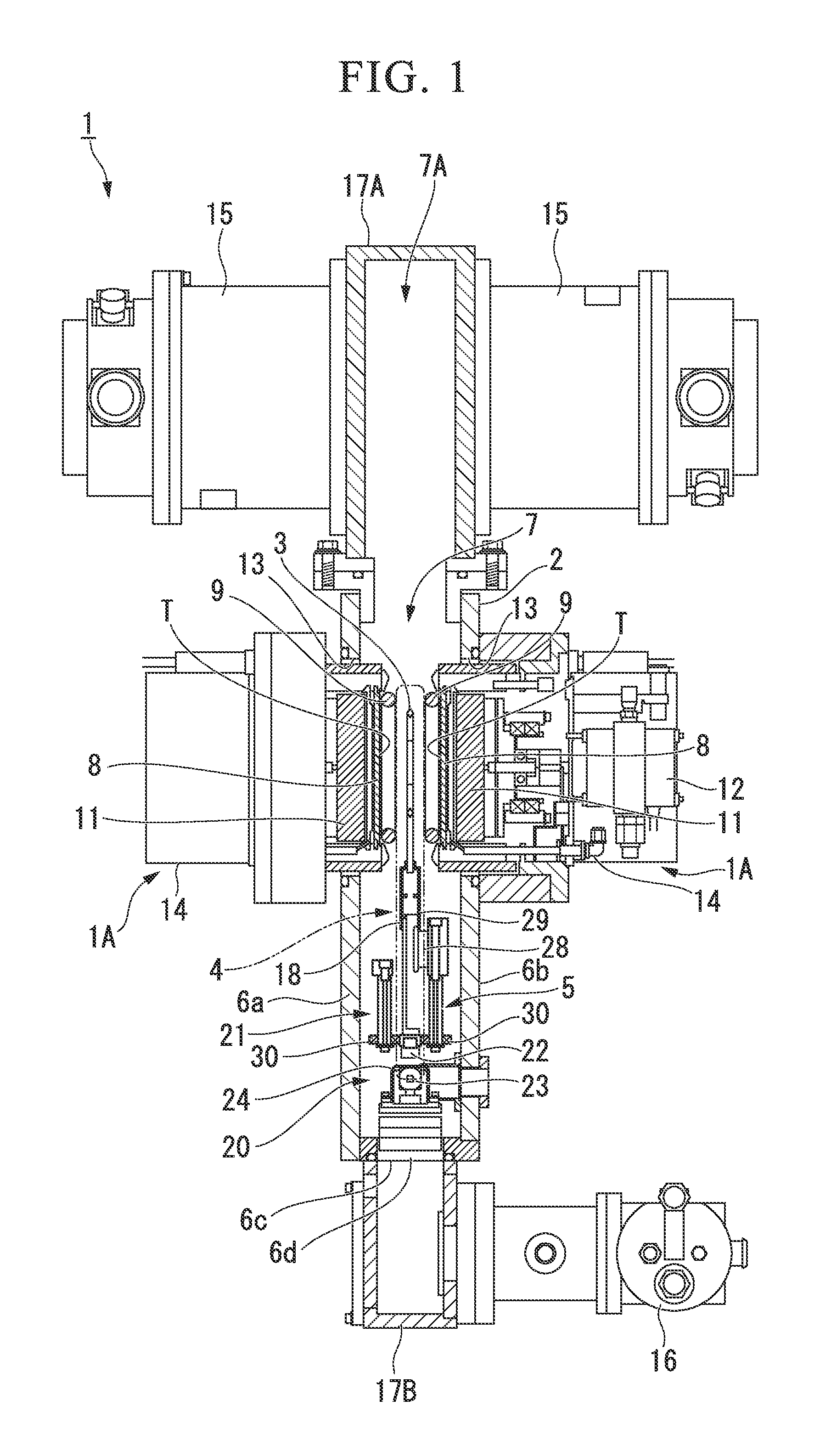

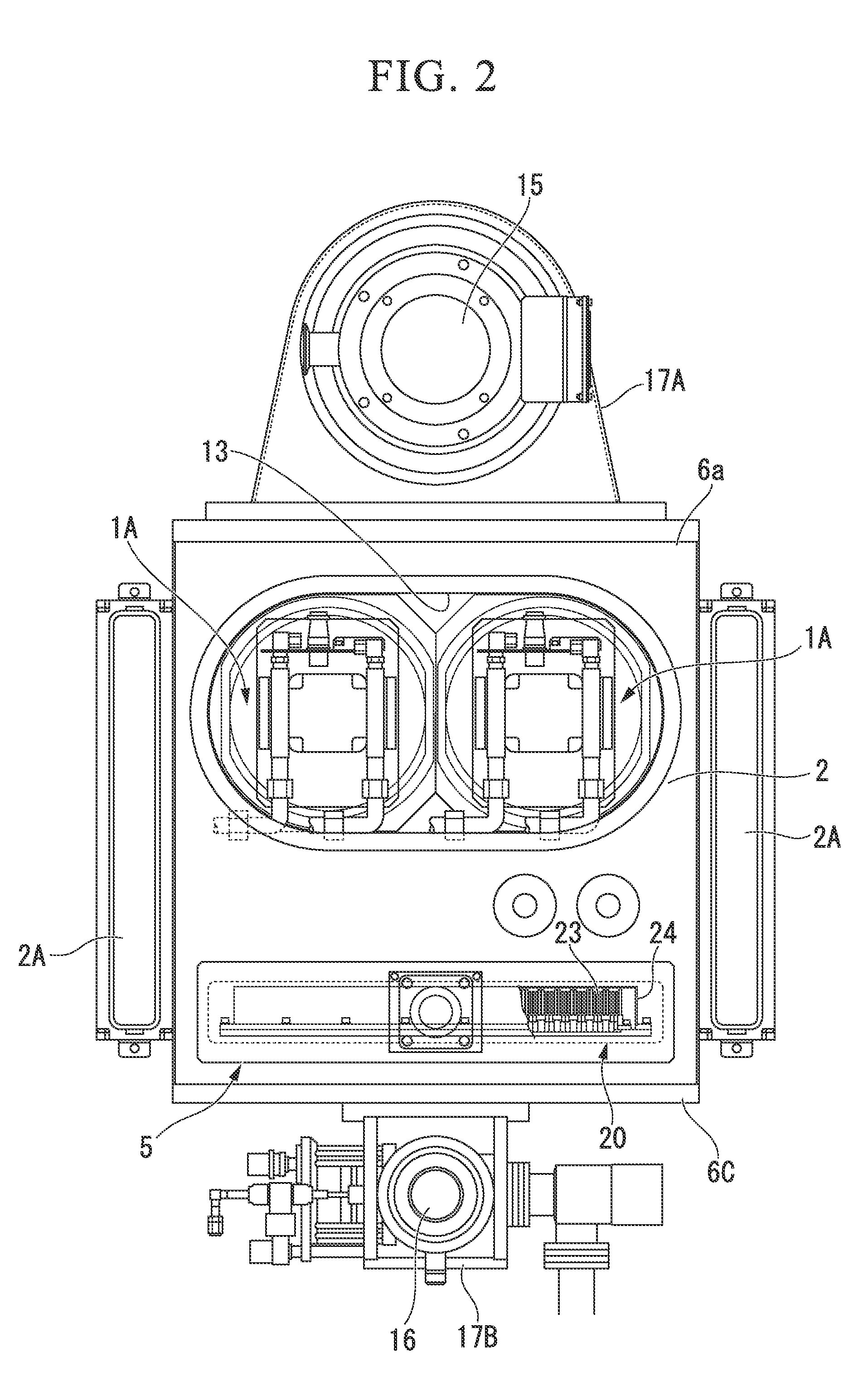

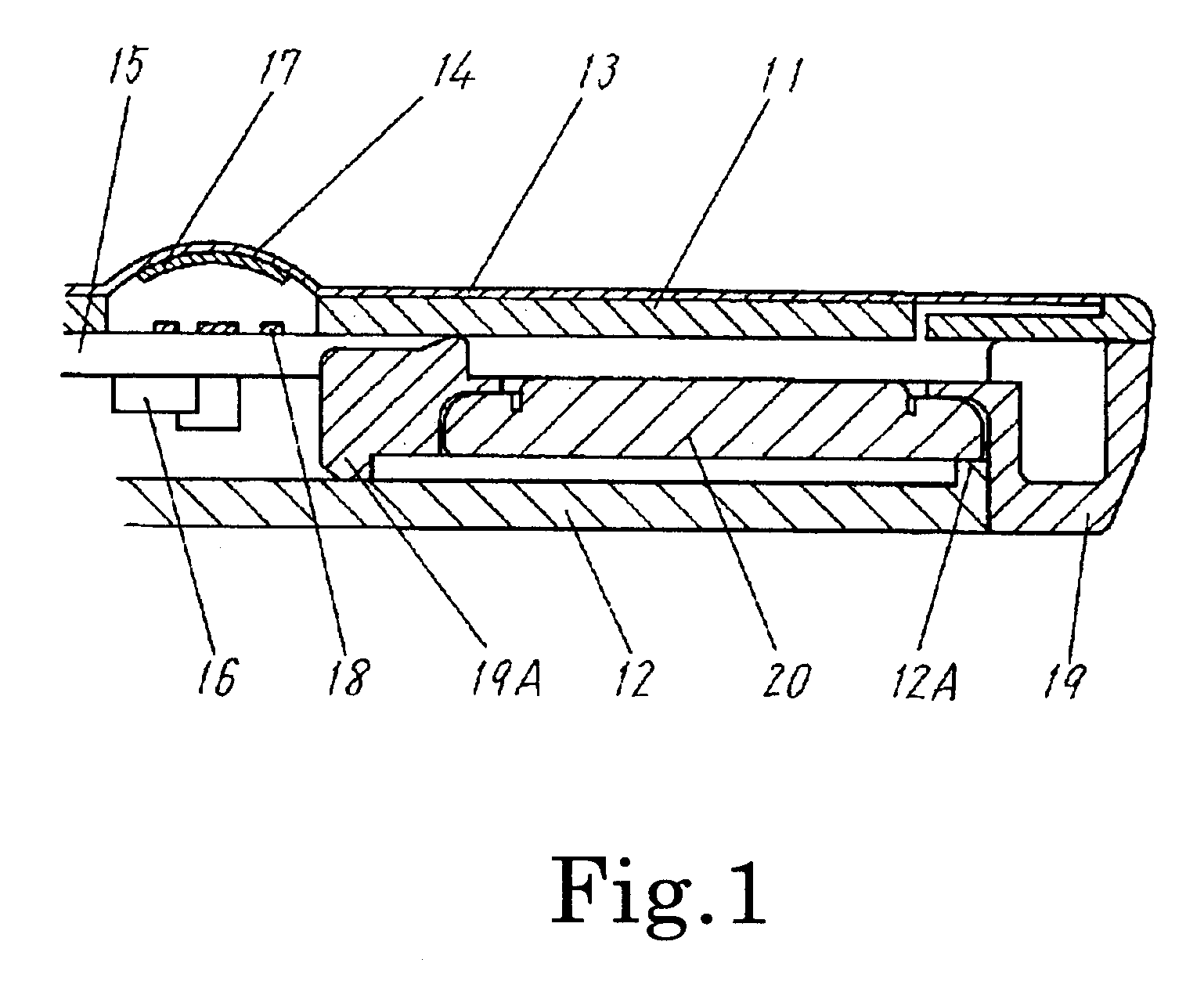

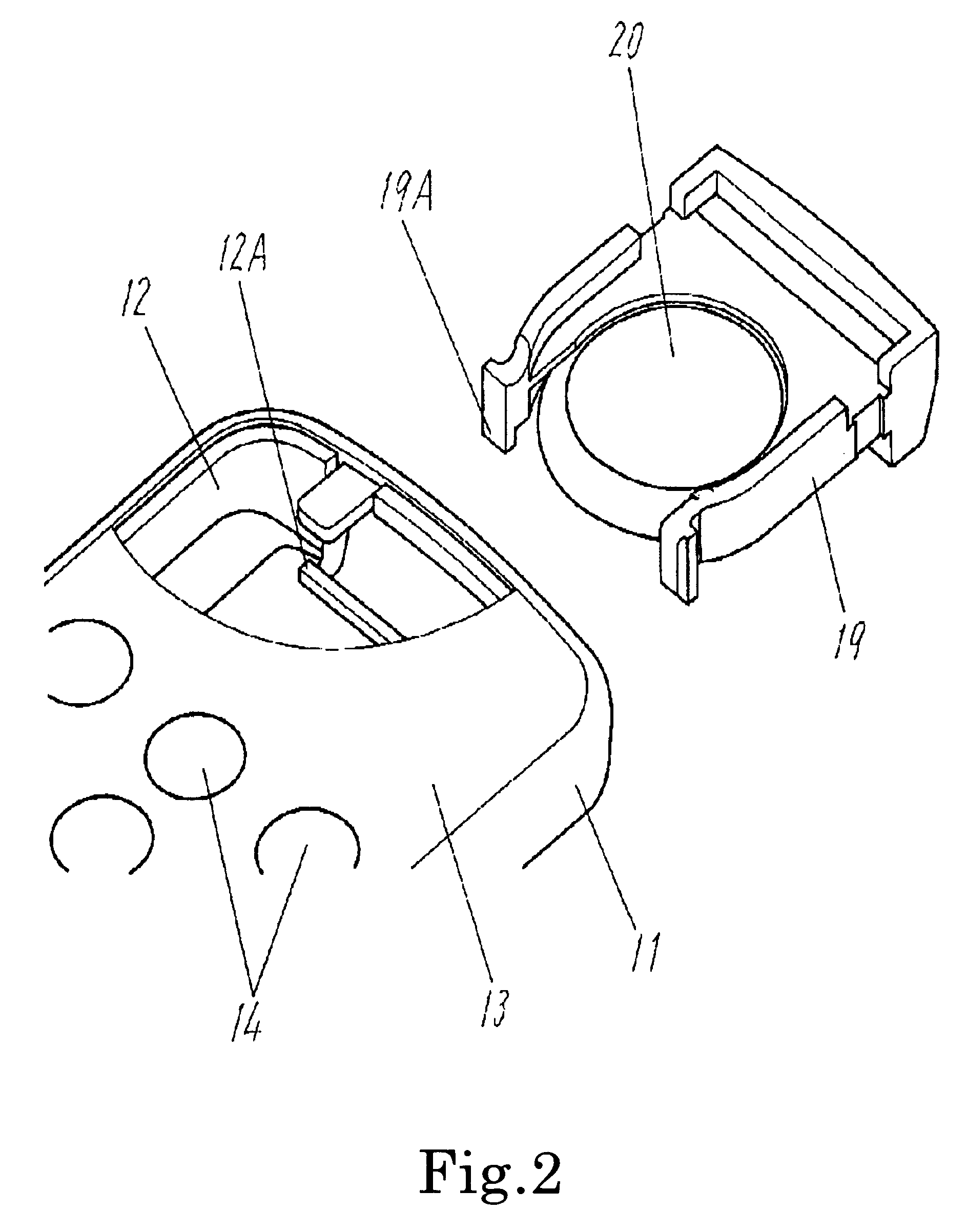

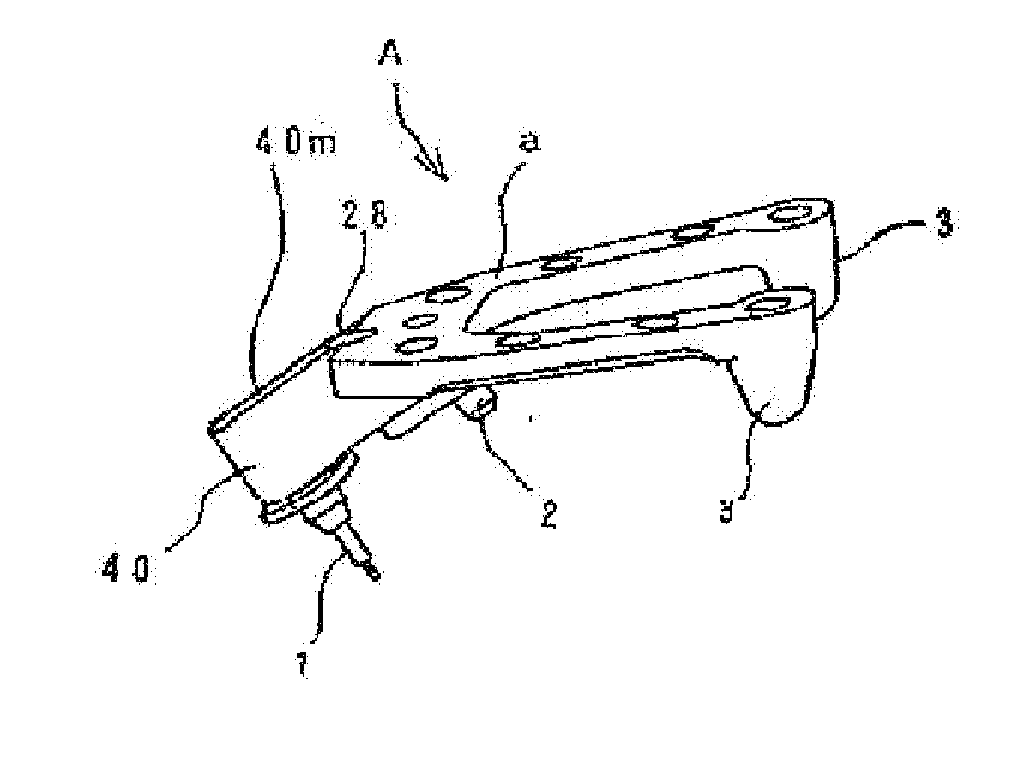

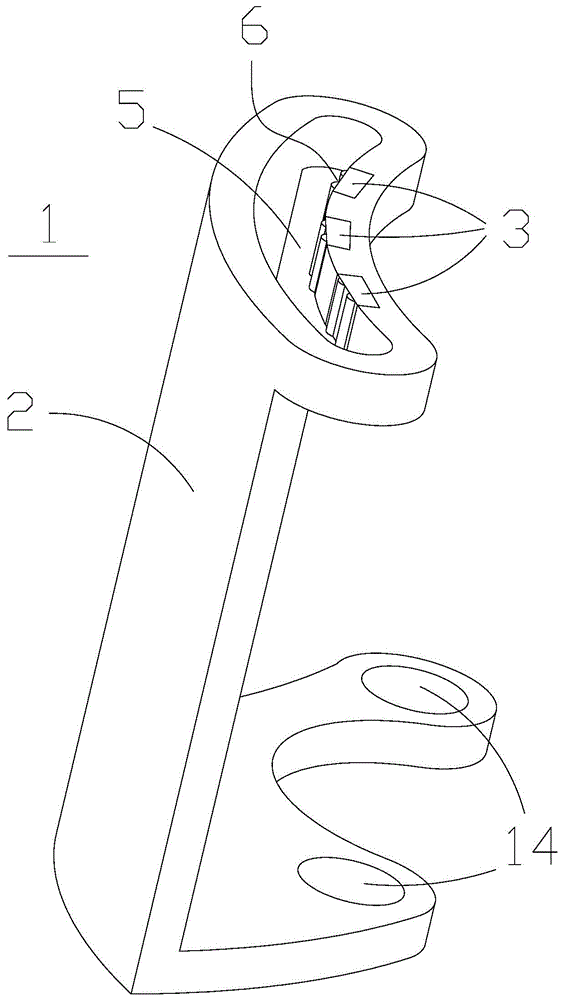

Clipping device

ActiveUS20060190015A1Prevent fallingGood insertion effectStaplesNailsBiomedical engineeringBody cavity

The present invention provides a clipping device having a coil sheath inserted into an insertion tube in a back / forth movable way to allow it to be inserted into a body cavity, an operation wire inserted into the coil sheath in a back / forth movable way, and a clip directly connected to a distal end of the operation wire to allow it to clip a living tissue.

Owner:OLYMPUS CORP

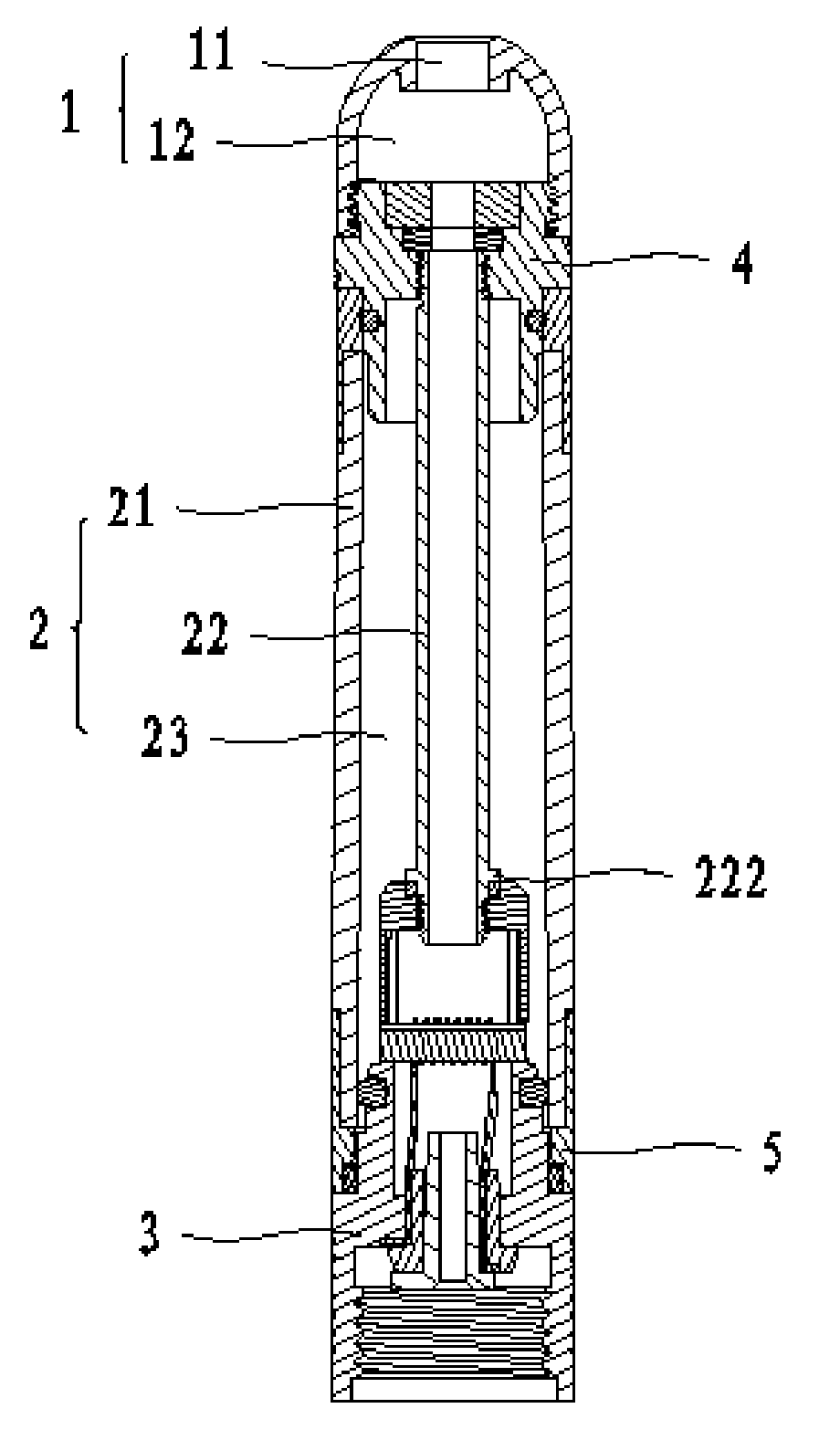

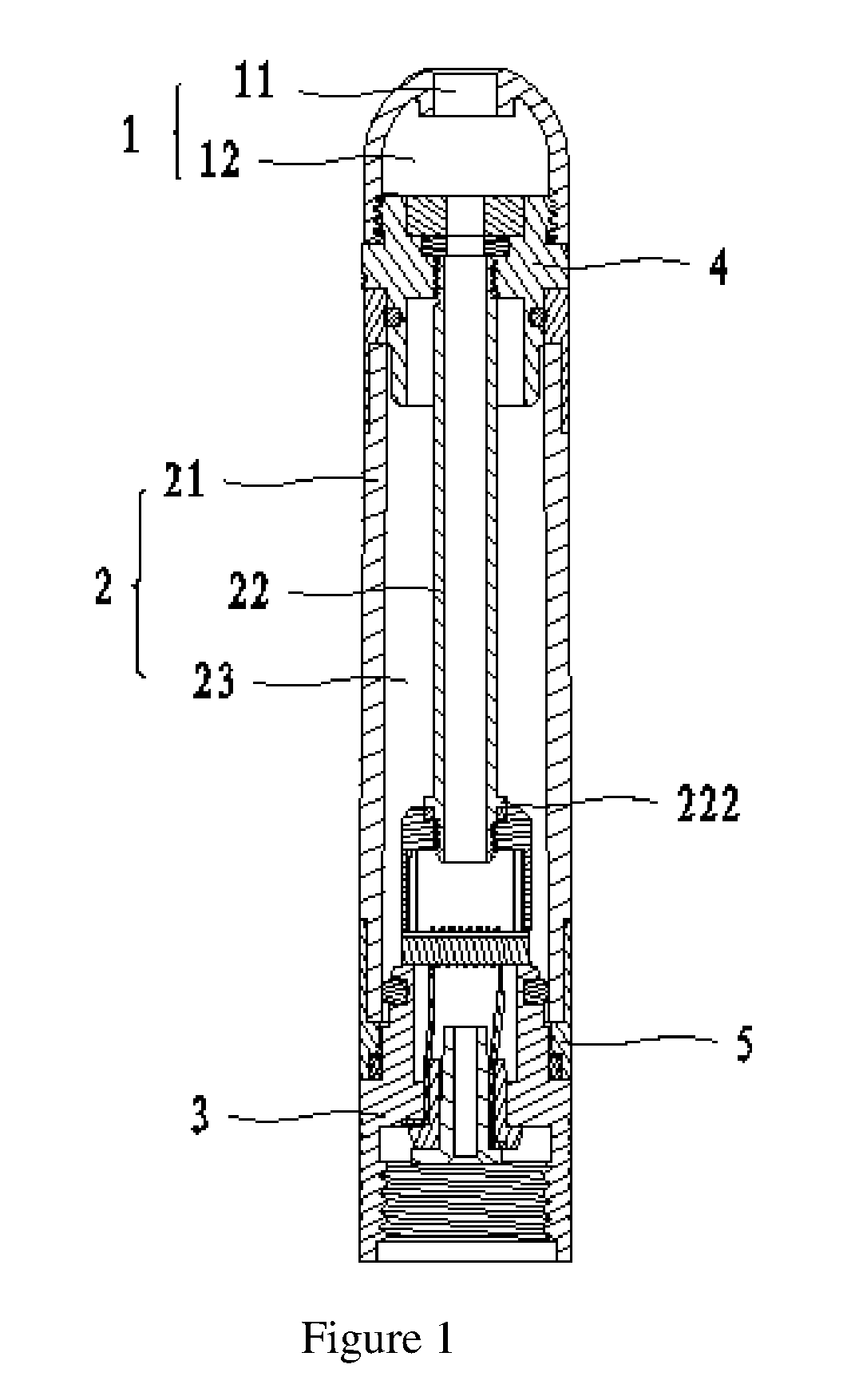

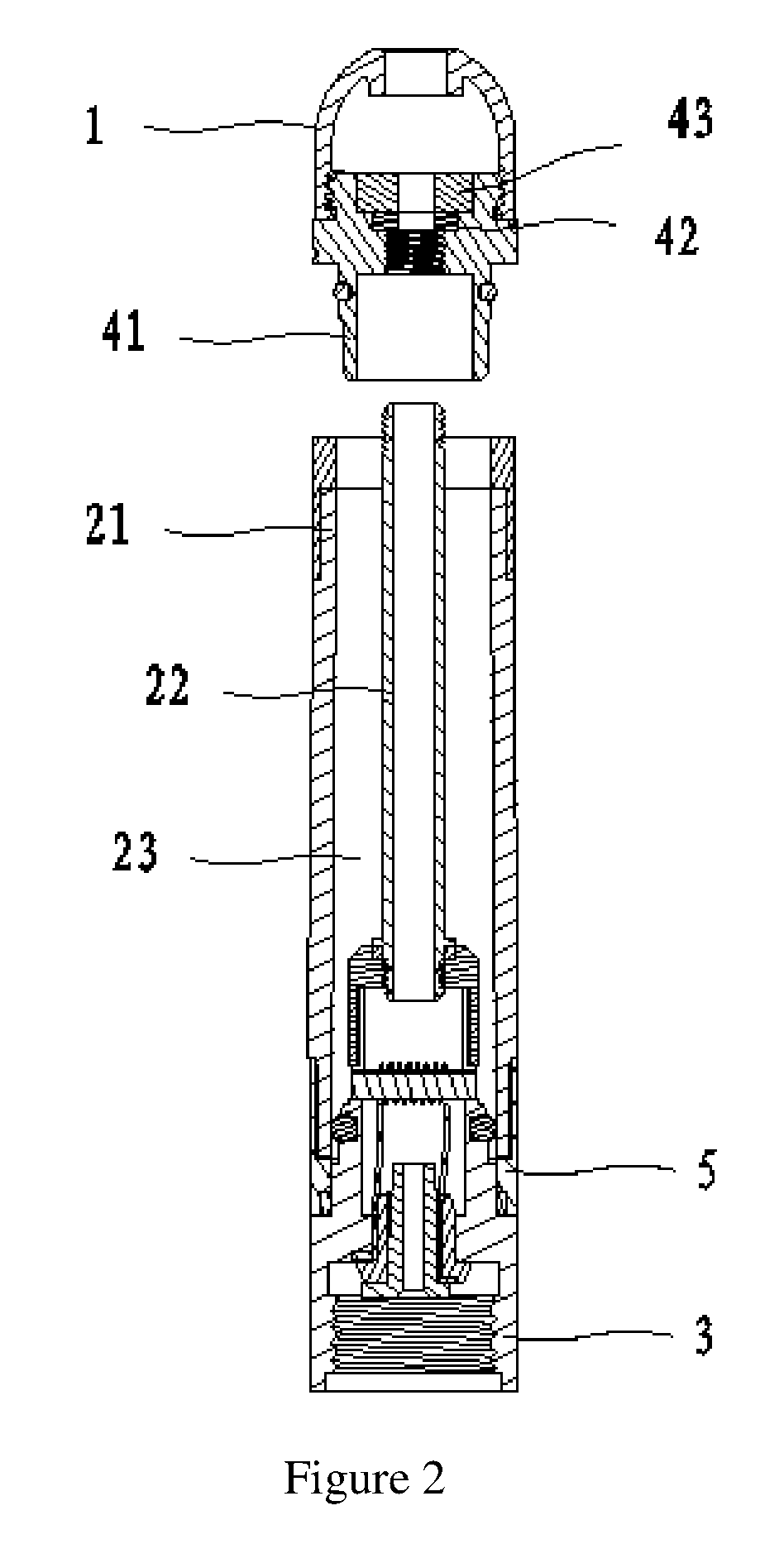

Atomizing component and electronic cigarette

ActiveUS20170359858A1Prevent splashEasy to replaceElectric heatingTobacco pipesVentilation tubeStructural engineering

The present application is disclosed an atomizing component and an electronic cigarette. The atomizing component comprises a light-permeable e-liquid storage sleeve. An atomizing core is detachably connected to an end of the e-liquid storage sleeve. A fastening element for restricting radial expansion of the e-liquid storage sleeve is sleeved at where the e-liquid storage sleeve is insertedly connected to the atomizing core. An end of a ventilation pipe opposite to the atomizing core is a smoke emitting outlet in communication with a suction nozzle. An e-liquid filler hole is extended from the end of the ventilation pipe provided with the smoke emitting outlet. The smoke emitting outlet and the e-liquid filler hole are located on planes of different heights; while e-liquid is being added, the outer circumferential wall of the ventilation pipe blocks the e-liquid splashed accidentally, thus preventing the e-liquid from being splashed into the ventilation pipe.

Owner:SHENZHEN KIMSEN TECH CO LTD

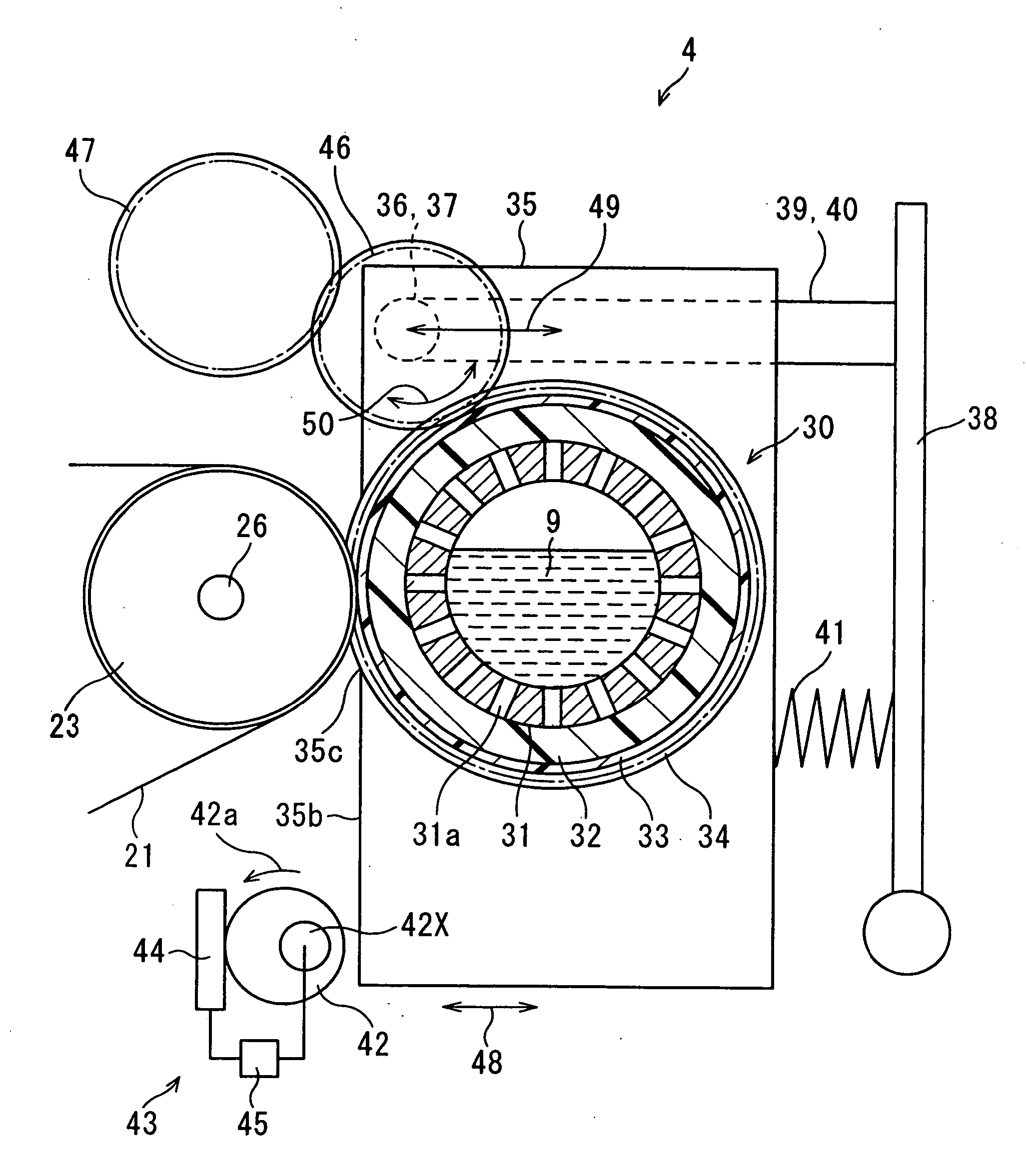

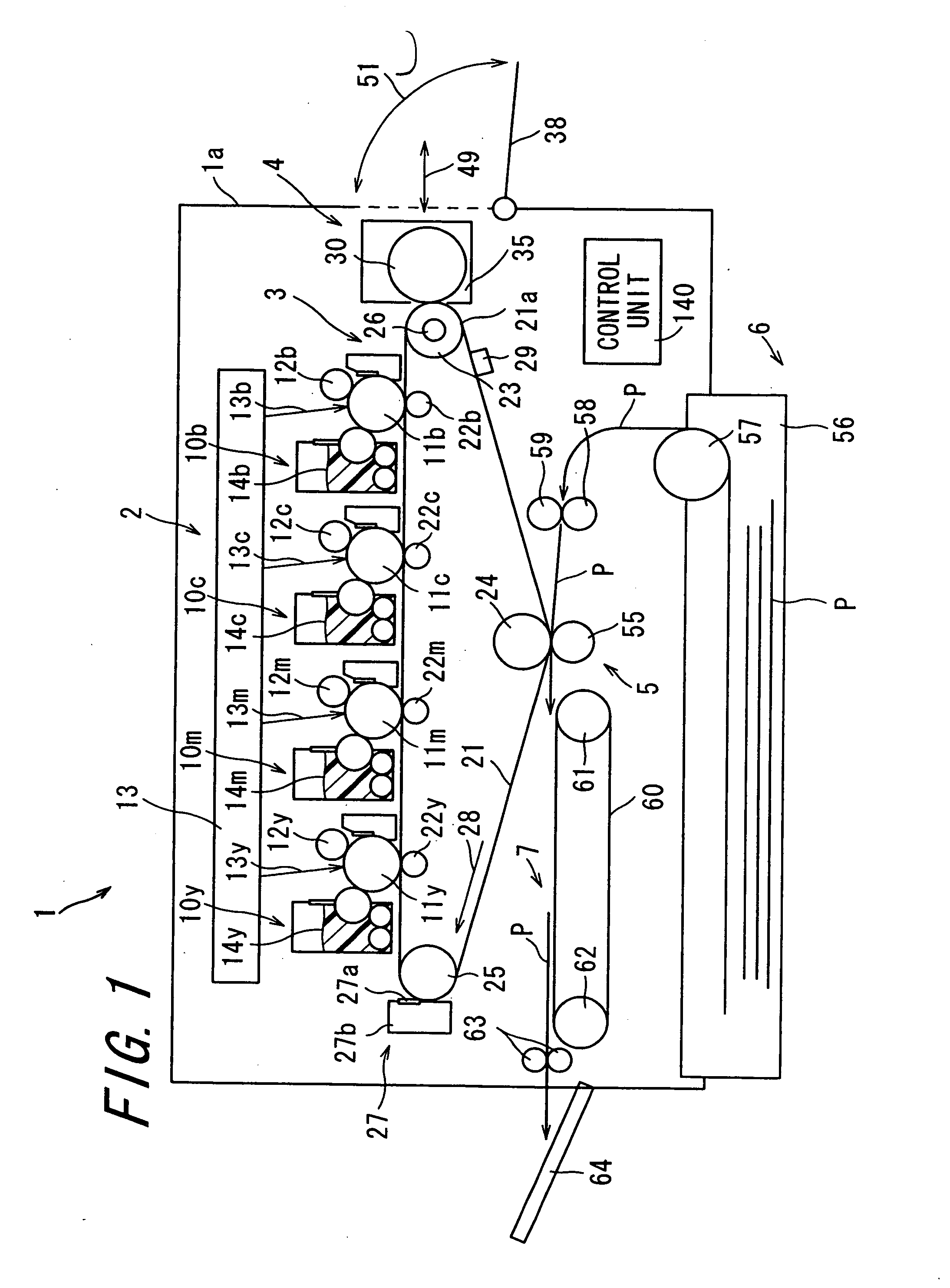

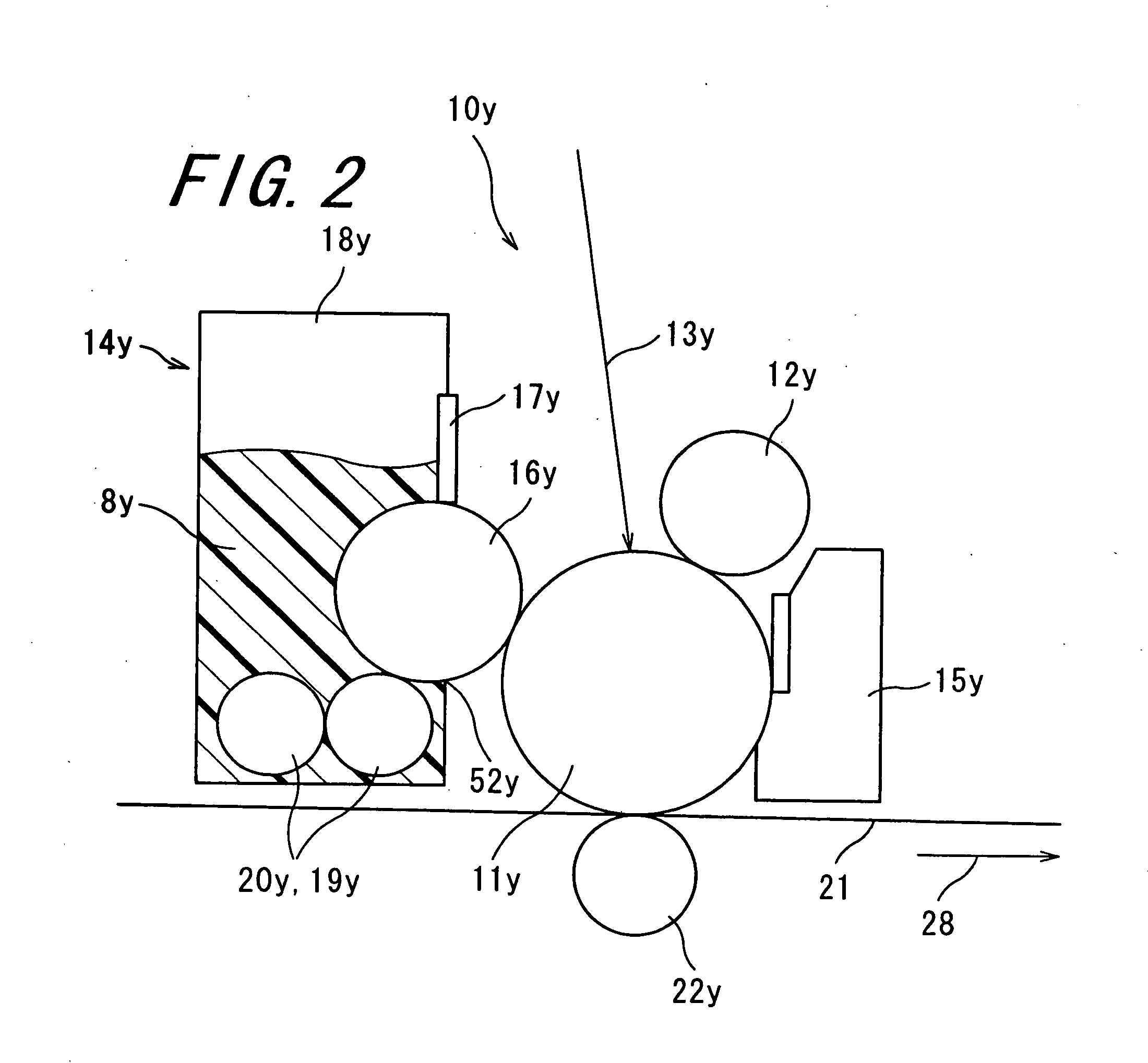

Image forming apparatus

InactiveUS20070212128A1Prevent splashAvoid dropElectrographic process apparatusImage formationEngineering

An image forming apparatus includes a toner-image forming section, an intermediary transfer section including an intermediary transfer belt, a fixing-fluid applying section, a transferring and fixing section, a recording-medium supply section, and an ejection section. The fixing-fluid applying section includes a coating roller, an eccentric cam for moving the coating roller approachably and separably with respect to the intermediary transfer belt, a contact and release detecting section for detecting whether the coating roller is contacted by or away from the intermediary transfer belt, a rotational driving section for rotatably driving the coating roller, and a control unit for controlling the eccentric cam and the rotational driving section.

Owner:SHARP KK

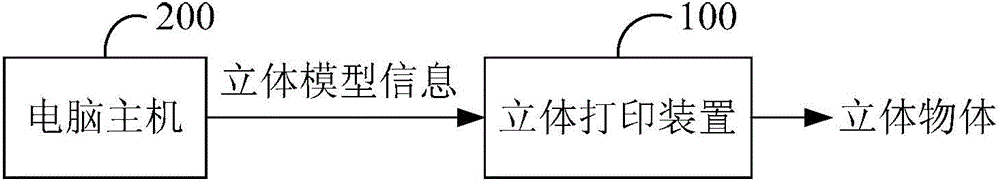

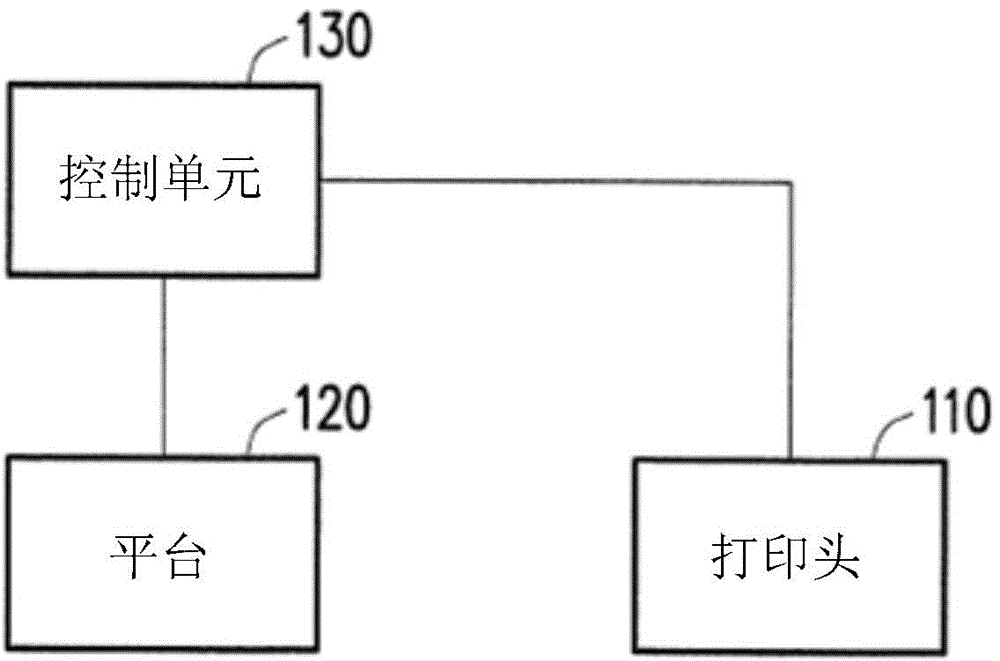

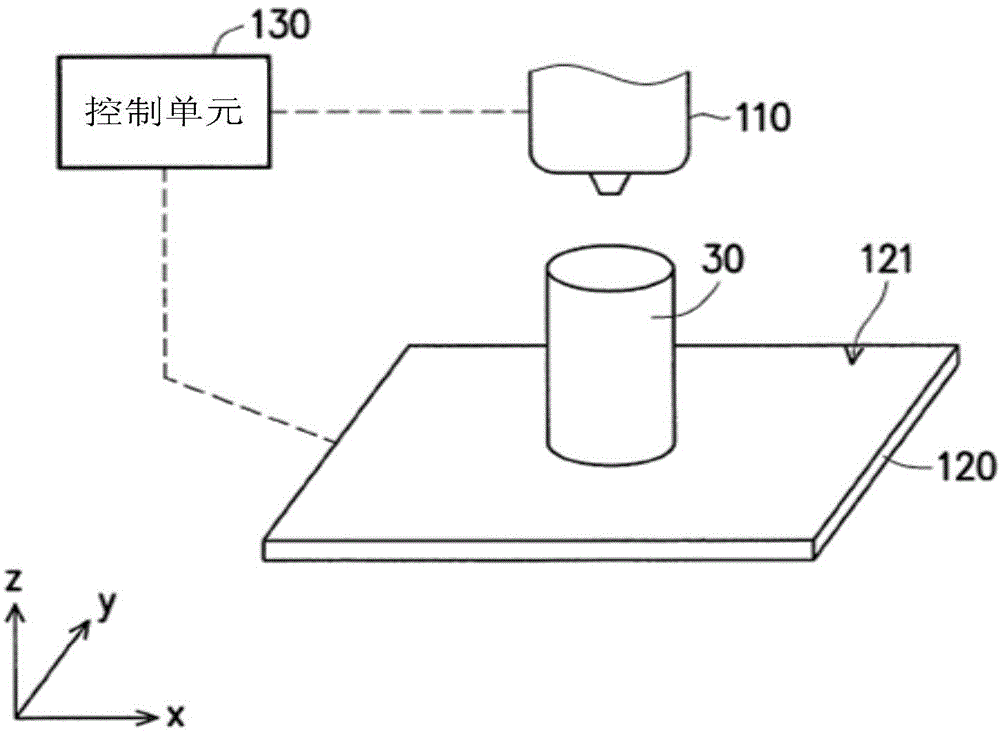

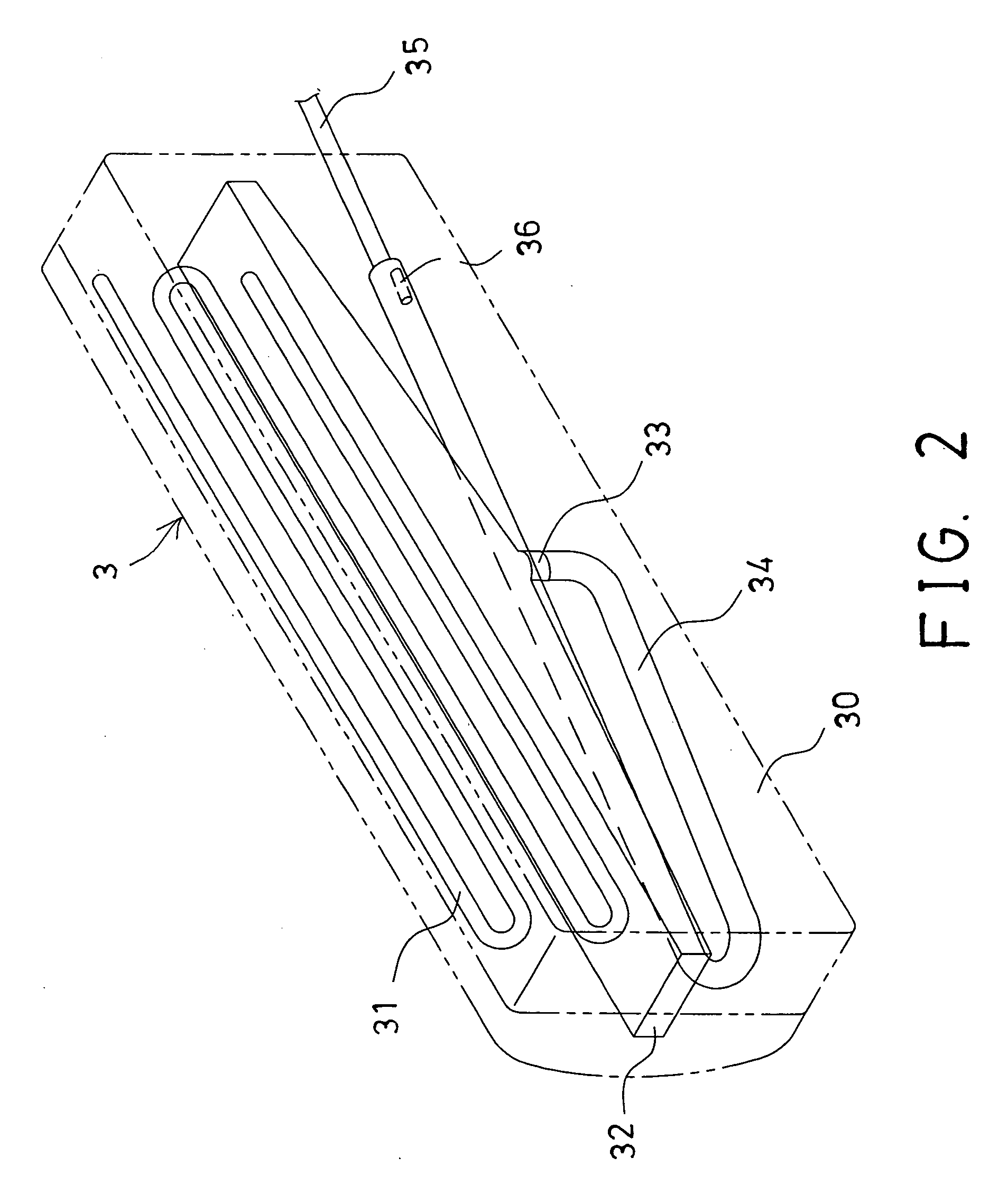

Three dimensional printing apparatus and method for controlling printing head thereof

InactiveCN104890233AAvoid layering on top of each otherAvoid dropAdditive manufacturing apparatusAdditive manufacturing with liquidsEngineeringSmall range

A three-dimensional printing apparatus and a method for controlling printing head thereof are provided. The method is used for controlling a moving path of a printing head of the three-dimensional printing apparatus and the method includes following steps. The printing head is controlled to form a layer object on a carrying surface according to three-dimensional model information. It is determined whether a cross-section parameter of the layer object is match to a small range condition. If the cross-section parameter of the layer object is match to the small range condition, the printing head is controlled to move toward a first direction far away from layer object according to position information of the layer object. The printing head is controlled to move toward a second direction close to the layer object.

Owner:XYZPRINTING +2

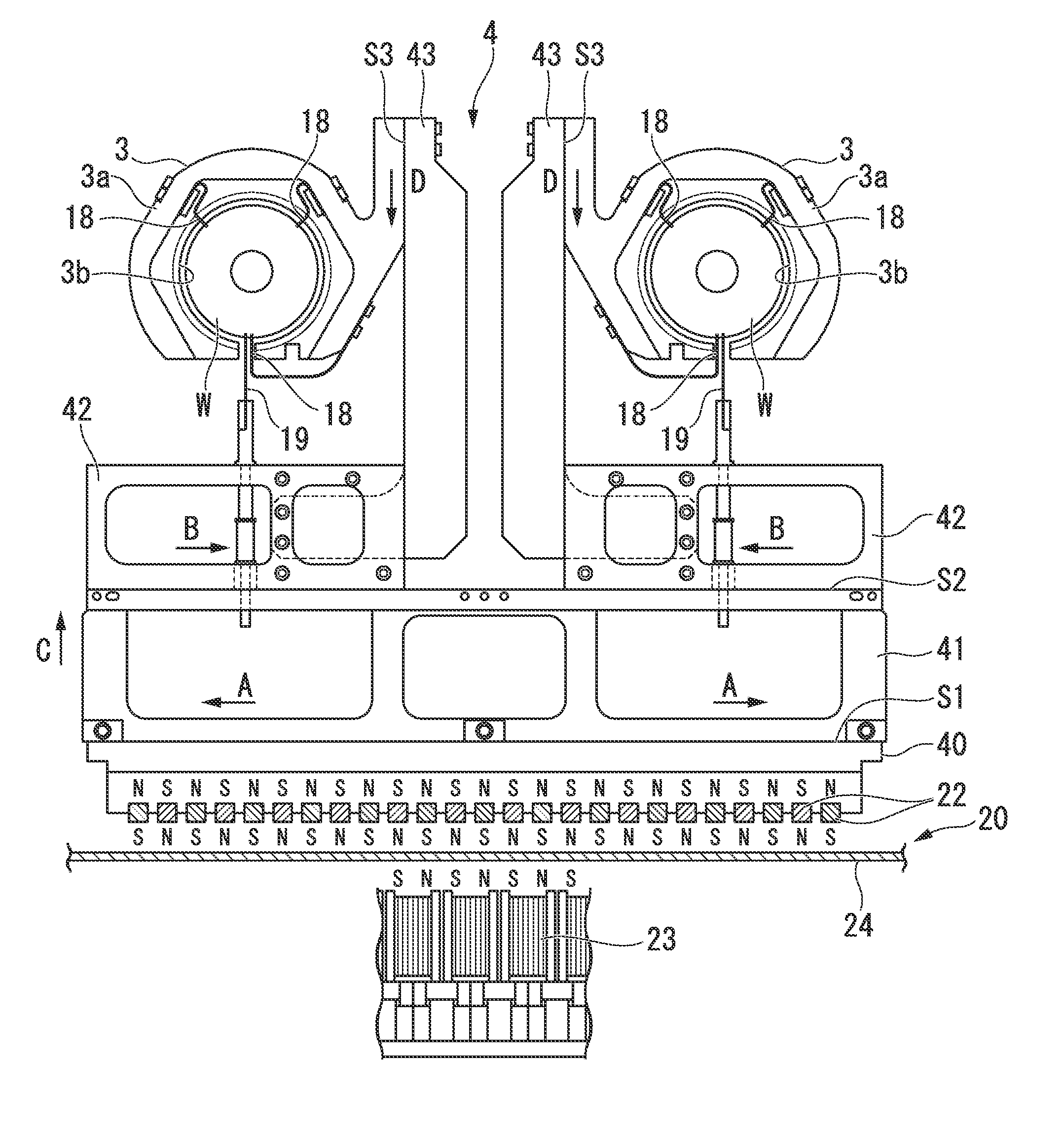

In-line type film forming apparatus and method for manufacturing magnetic recording medium

ActiveUS20120231158A1Increase productionIncrease productivityVacuum evaporation coatingSemiconductor/solid-state device manufacturingThermal expansionMechanical engineering

There is provided an in-line type film-forming apparatus that can prevent a substrate from being dropped out of a carrier and convey the carrier at high speed. A first supporting member (41) is supported to be displaceable in a direction along an attaching face (S1) of the support base (40) in accordance with the growth of the first supporting member (41) due to thermal expansion in a horizontal direction, a second supporting member (42) is supported to be displaceable in a direction negating the growth of the first supporting member (41) due to thermal expansion in the horizontal direction along an attaching face (S2) of the first supporting member (42) in accordance with the growth of the second supporting member (42) due to thermal expansion in the horizontal direction, and a holder (3) is supported to be displaceable in a direction negating the growth of the first and second supporting members (41) and (42) due to thermal expansion in the vertical direction along an attaching face (S3) of the third supporting member (43) in accordance with the growth of the holder (3) due to thermal expansion in the vertical direction.

Owner:SHOWA DENKO KK

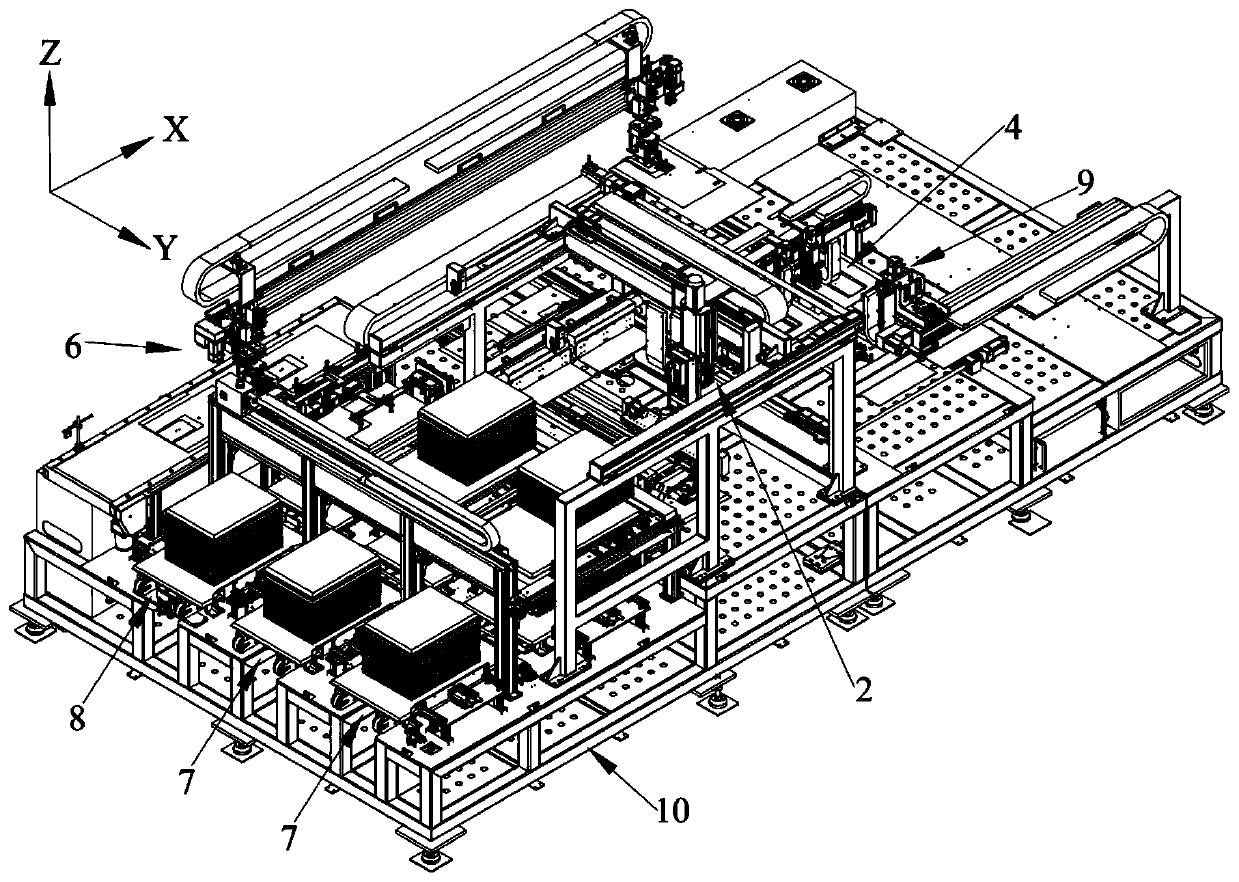

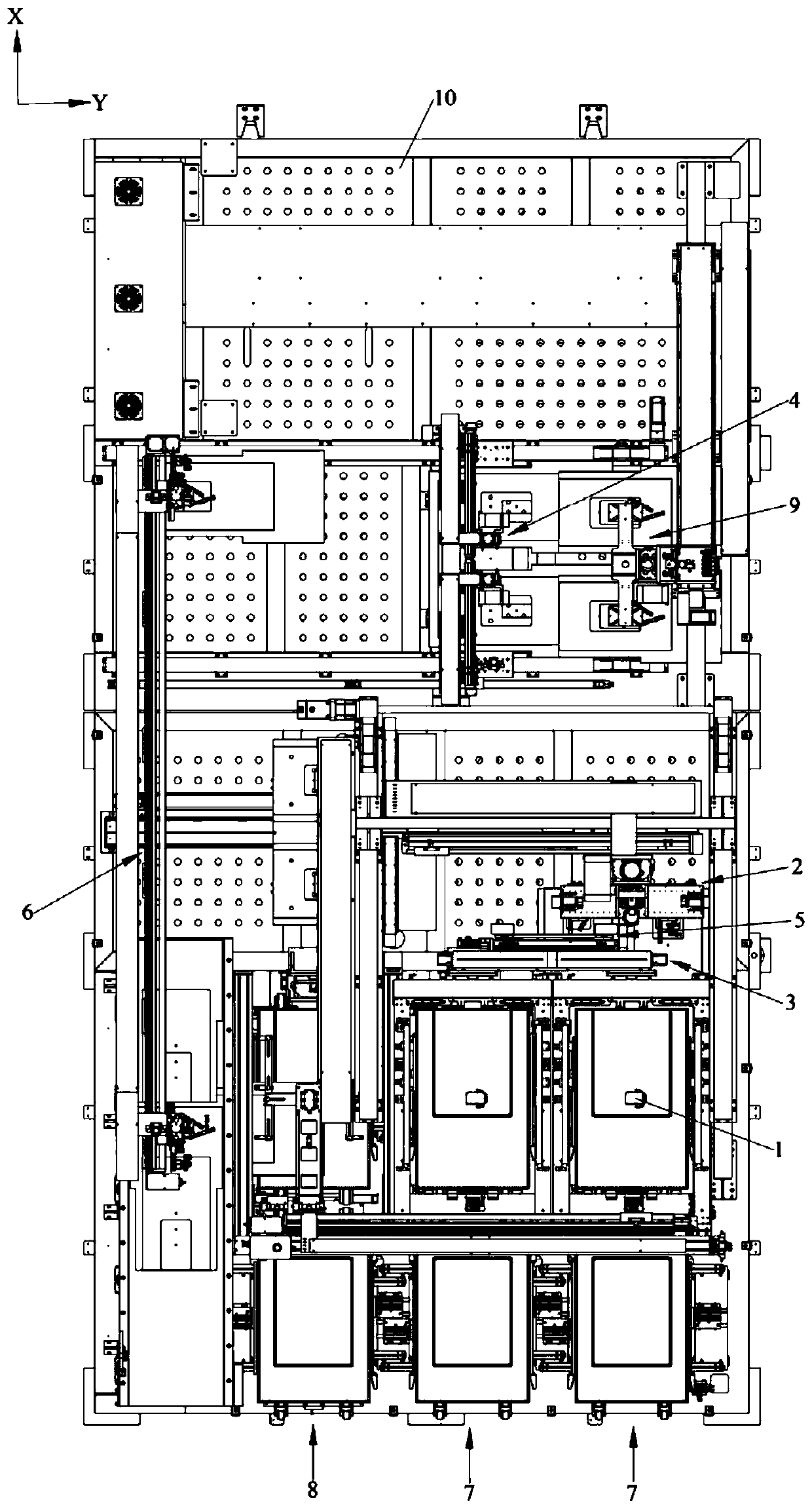

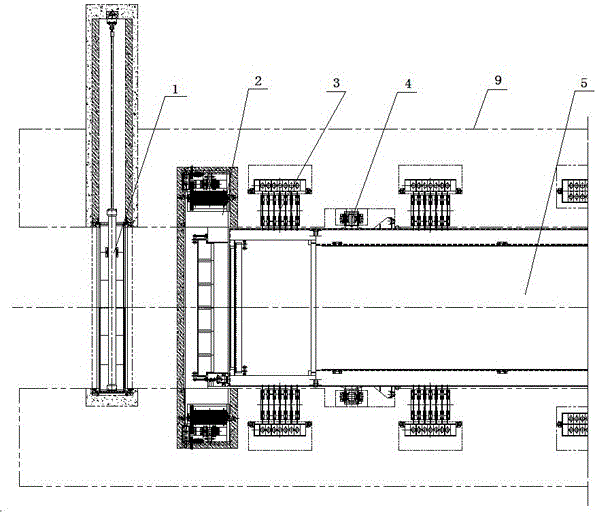

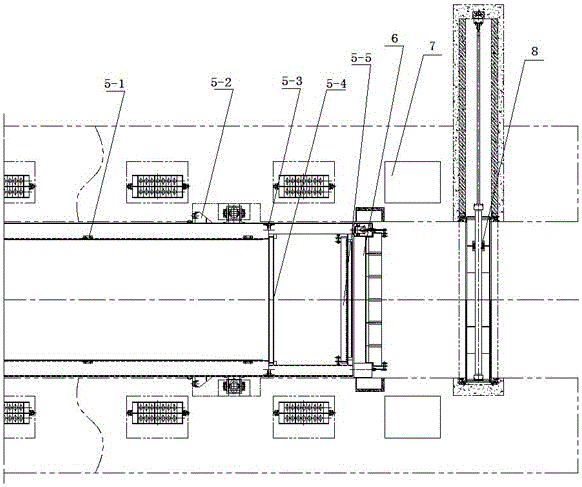

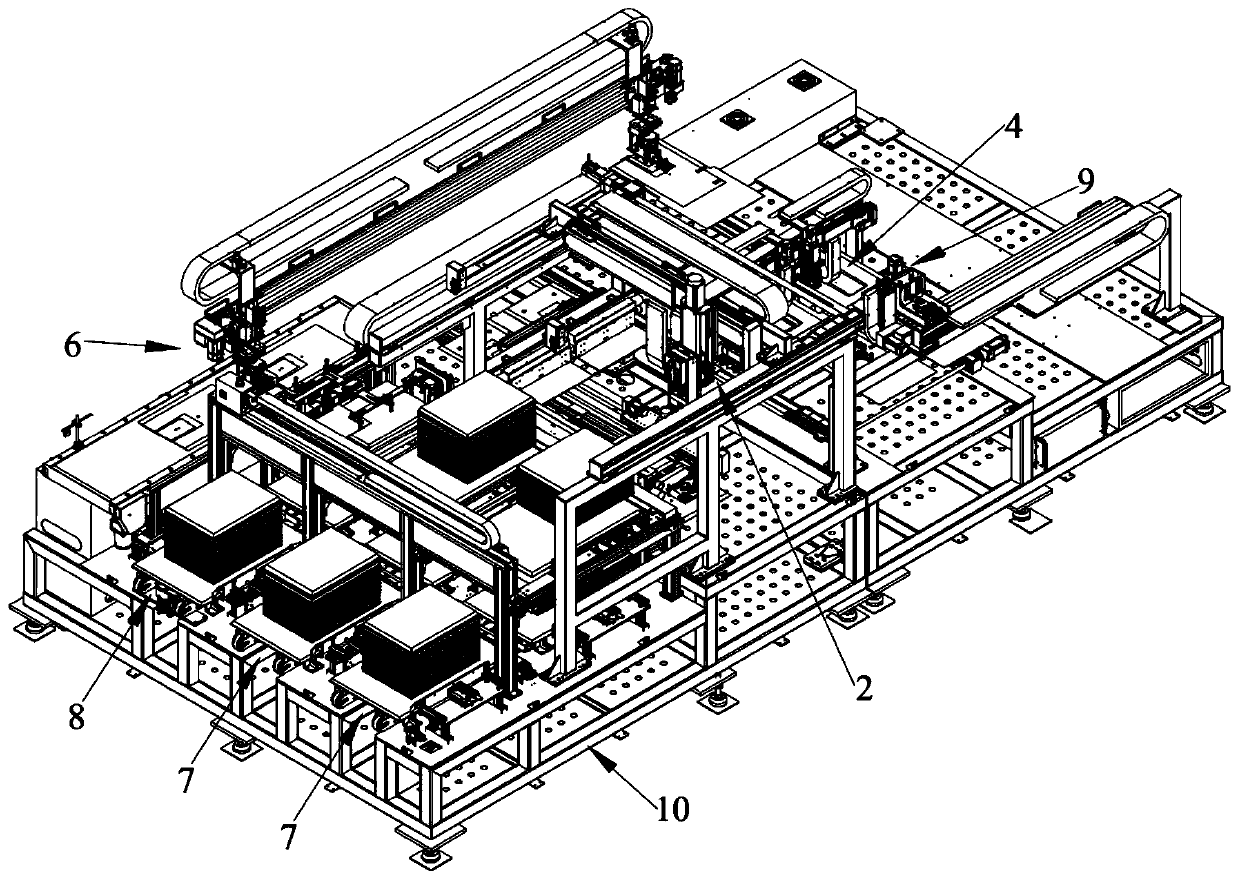

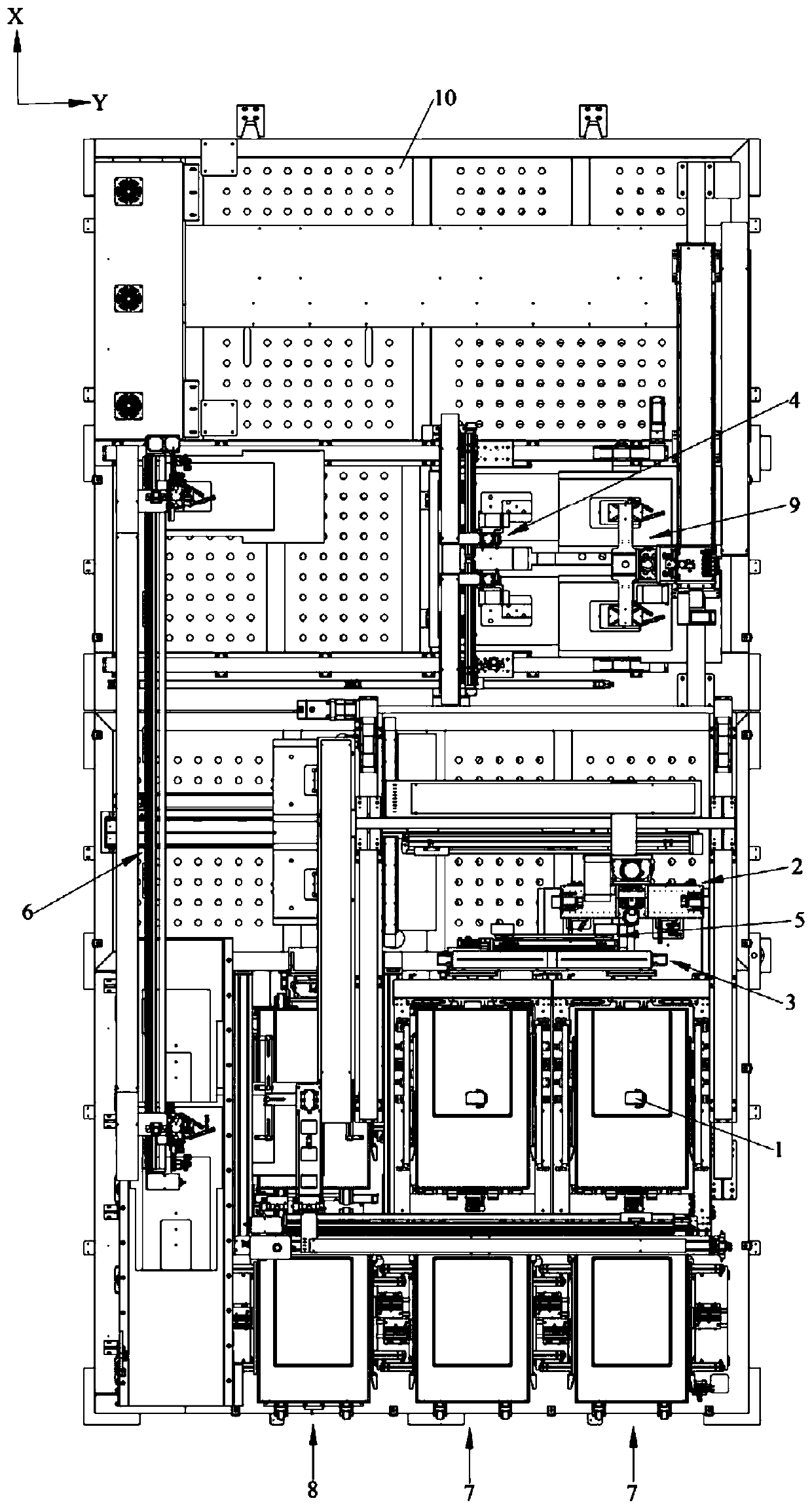

Production line

InactiveCN110255180AHighly integratedIncrease productivityArticle unpackingCleaning using liquidsProduction lineTransfer mechanism

The invention relates to the technical field of automatic production equipment and discloses a production line. According to the production line, on one hand, by arranging a large-view detecting mechanism, a feeding and transferring mechanism, a washing mechanism and a film tearing mechanism, products can be grabbed, moved, washed and subjected to film tearing treatment, and the integration level and the production efficiency of the production line are improved greatly; on the other hand, by means of cooperation of the large-view detecting mechanism and the feeding and transferring mechanism, the grabbing angle and the grabbing position can be adjusted accurately, thus it is ensured that the products at different positions and angles can be grabbed stably, the grabbing success rate and the grabbing efficiency can be increased and improved remarkably, and the situation that due to unstable grabbing, the products are thrown off in the moving process can be effectively avoided.

Owner:SUZHOU JINGLAI OPTO CO LTD

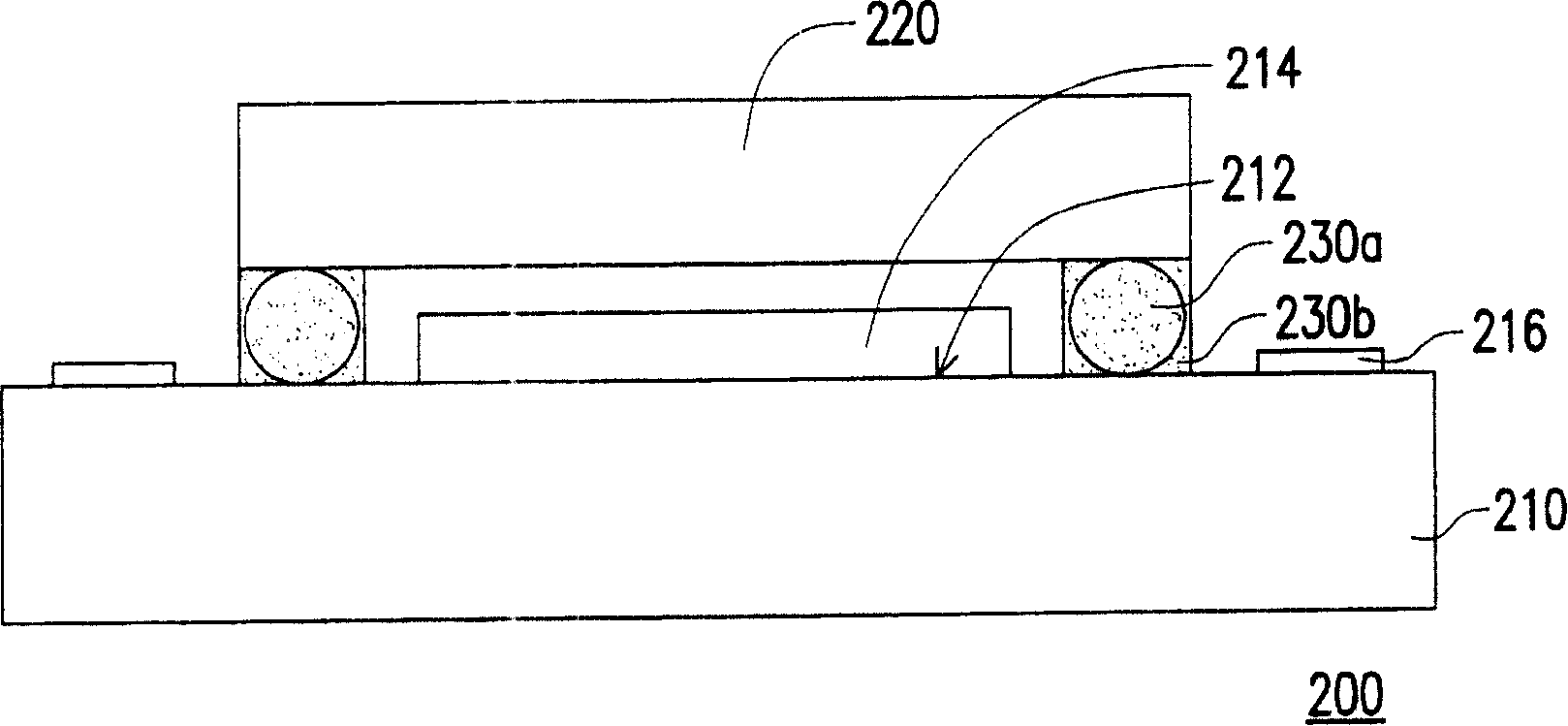

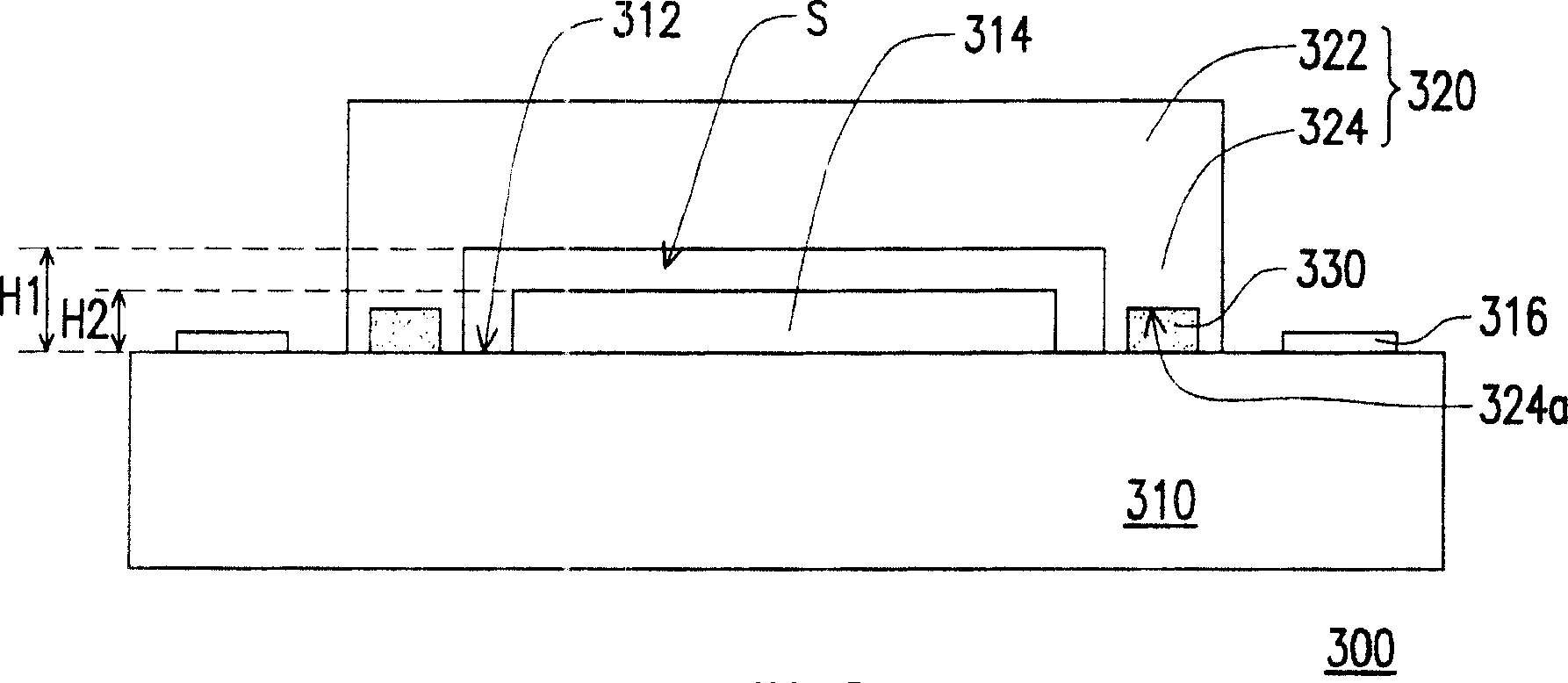

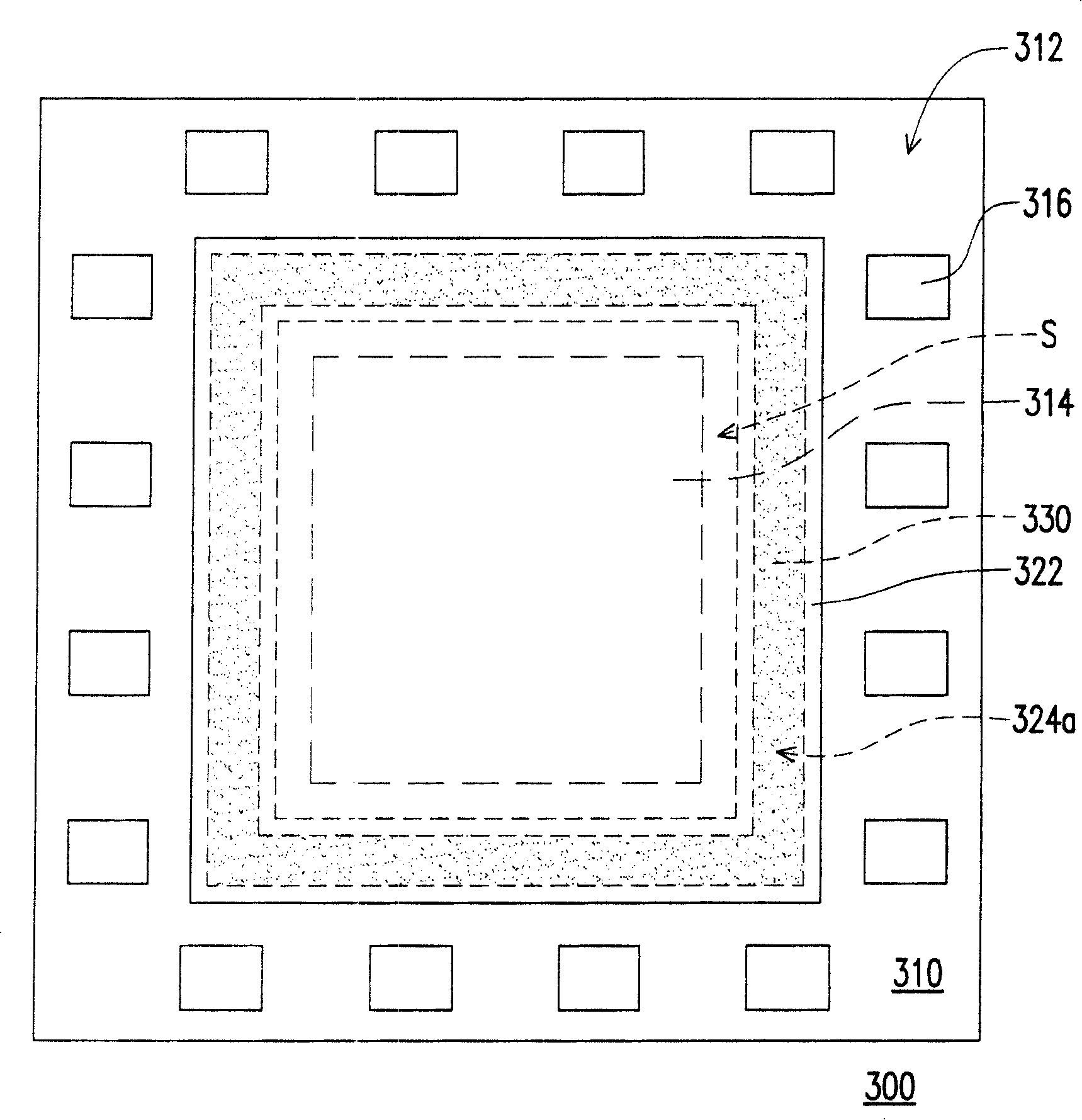

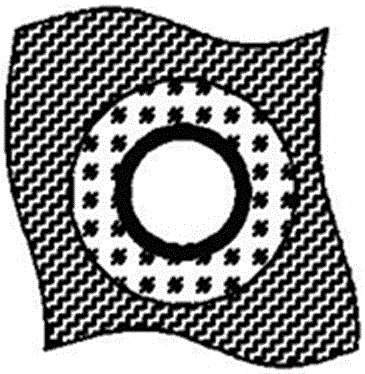

Packaging cover board, chip packaging structure and manufacturing method thereof

InactiveCN101162711AImprove process yieldGood light penetrationSemiconductor/solid-state device detailsSolid-state devicesHigh rateEngineering

A chip package structure comprises a chip, a package cover board and a bound layer, wherein, the chip is provided with a drive surface which is provided with an image sensing element and a plurality of connection cushions positioned on the periphery of the sensing element. In addition, the package cover board is arranged above the drive surface and comprises a baseplate and a support part positioned on the baseplate, wherein, a holding room is left on the baseplate by the support part, the support part contacts with the drive surface of the chip to ensure the image sensing element on the drive surface arranged in the holding room. Besides, the bound layer is arranged between the support part and the drive surface. The chip package structure of the invention has the advantages of high rate of finished products of technique, low cost of production and good optical penetrating power.

Owner:UNITED MICRODISPLAY OPTRONICS CORP

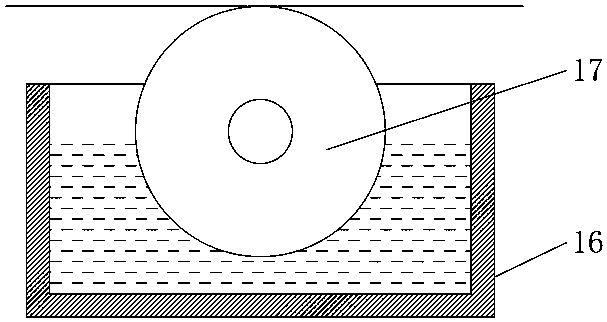

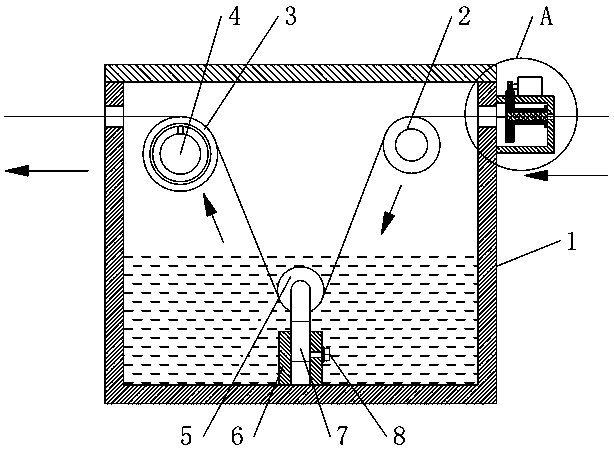

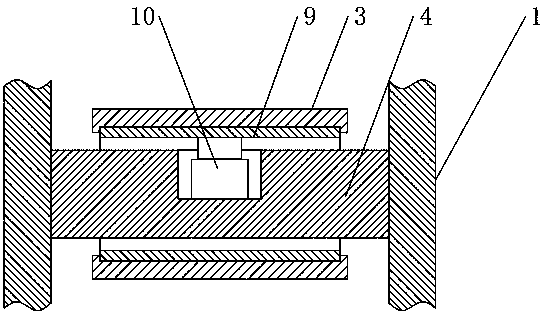

Oiling device of spinning elasticizer

ActiveCN109825969AEvenly distributed oilOil evenlyMechanical cleaningPressure cleaningFuel tankTextile

The invention discloses an oiling device of a spinning elasticizer, and belongs to the technical field of textile machinery. The oiling device comprises an oil tank. Thread passing holes are formed inthe top ends of the two sides of the oil tank respectively. A thread inlet roller, a steering roller and a vibrating roller distributed in a triangular shape are rotationally connected with the innerwall of the oil tank. The thread inlet roller and the vibrating roller correspond to the two thread passing holes respectively. A fixed rod is fixedly connected into the oil tank. The vibrating roller comprises a connecting cylinder, a rotating cylinder and a vibrator. An installation groove is formed in the side wall of the fixed rod. The vibrator is fixedly connected into the installation groove. The connecting cylinder sleeves the fixed rod. A gap is formed between the inner wall of the connecting cylinder and the outer wall of the fixed rod. The inner wall of the connecting cylinder is fixedly connected with the vibration end of the vibrator. The rotating cylinder rotationally sleeves the connecting cylinder. Silk threads can be oiled evenly, and it is avoided that residual oil dropsinto a workshop and contaminates the working environment.

Owner:苏州申久高新纤维有限公司

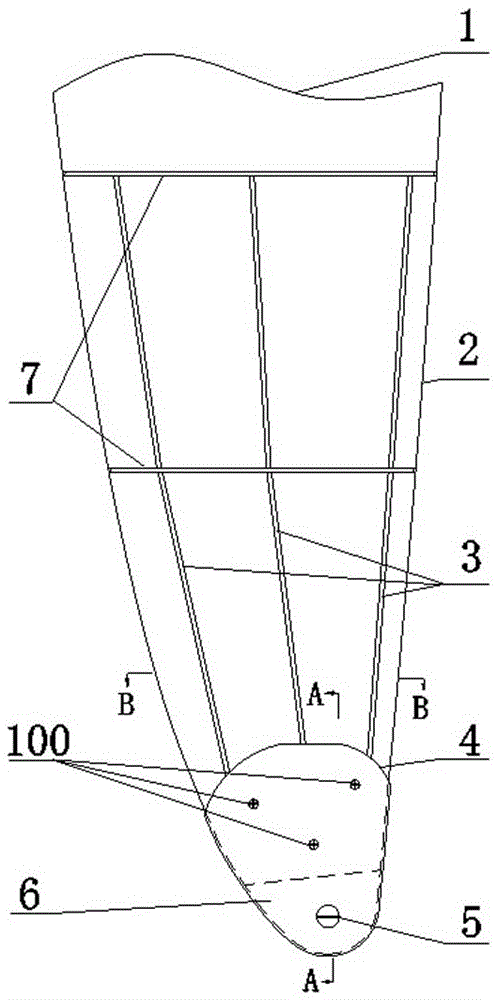

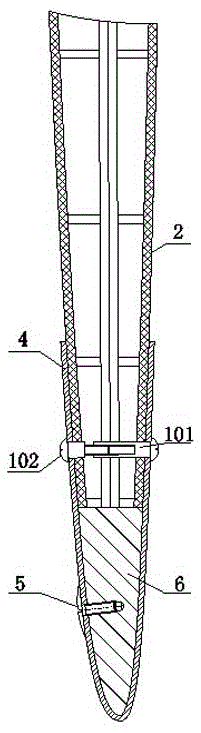

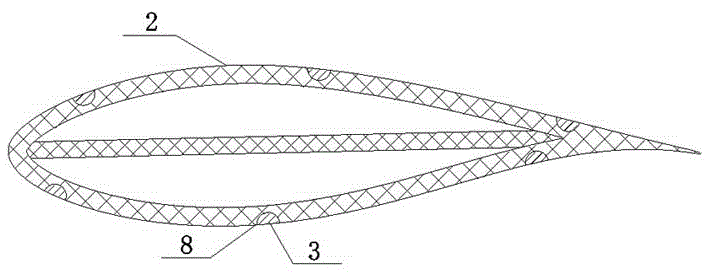

Wind driven generator blade lightning protection device with metal blade tip

PendingCN106762469AImprove the conductive effectReduced effectMachines/enginesEngine componentsWind drivenWind force

The invention relates to a wind driven generator blade lightning protection device, in particular to a wind driven generator blade lightning protection device with a metal blade tip. The device comprises a wind driven generator blade, the metal blade tip arranged on the blade tip part of the wind driven generator blade, and a metal protection sleeve arranged on the metal blade tip in a sleeving manner and connected with the metal blade tip in an electric conduction manner. At least two electric conduction belts are arranged on the upper arc curved face and the lower arc curved face of the opening end of the metal protection sleeve correspondingly in an extending manner. The electric conduction belts extend in the axial direction of the wind driven generator blade and are arranged at intervals in the radial direction. Electric conduction rings are arranged at the positions, at the rear portion of the opening end of the metal protection sleeve, of the blade tip part in a surrounding manner and are connected with the electric conduction belts in an electric conduction manner. The wind driven generator blade lightening protection device has the beneficial effects that compared with the prior art, the technical problem of lightning triggering of a blade tip end is solved effectively, the structure is simple, the cost is low, the dead load is small, the wind driven generator blade lightning protection device can be used for preassembling before the blade is delivered out of a factory and meanwhile can be used for additional installing and transforming of the wind driven generator blade in running.

Owner:张瑞佳

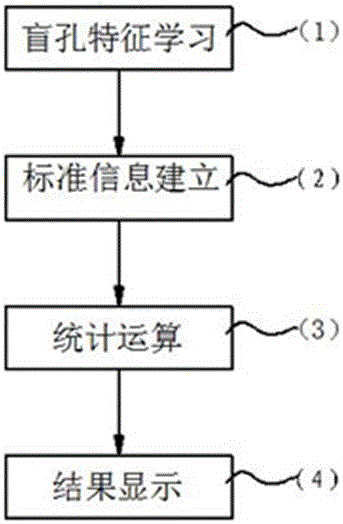

Detection method for blind holes on printed circuit board

ActiveCN106501706AAvoid dropImprove conveniencePrinted circuit testingPrinted circuit boardComputer science

The invention discloses a detection method for blind holes on printed circuit board, comprising the following steps: 1) making a sample board according to one real finished product of a printed circuit board; scanning any blind hole image of the plurality of blind holes on the sample board as a learning object; 2) on the basis of the step 1, obtaining the hole positions of the plurality of blind holes on the sample board; using at least one blind hole image characteristics of the sample board to establish the standard information; 3) when the step 2 is completed, scanning a to-be-detected board with the same manufacturing procedures as the sample board; obtaining the to-be-detected information of the plurality of blind holes on the to-be-detected board according to the method in the step 2; and 4) after the deviation statistic amount is calculated, displaying the deviation information in the form of images or charts. According to the invention, the detection method for blinding holes of printed circuit board can overcome the defects of designed data and can be conveniently used.

Owner:万润科技精机(昆山)有限公司

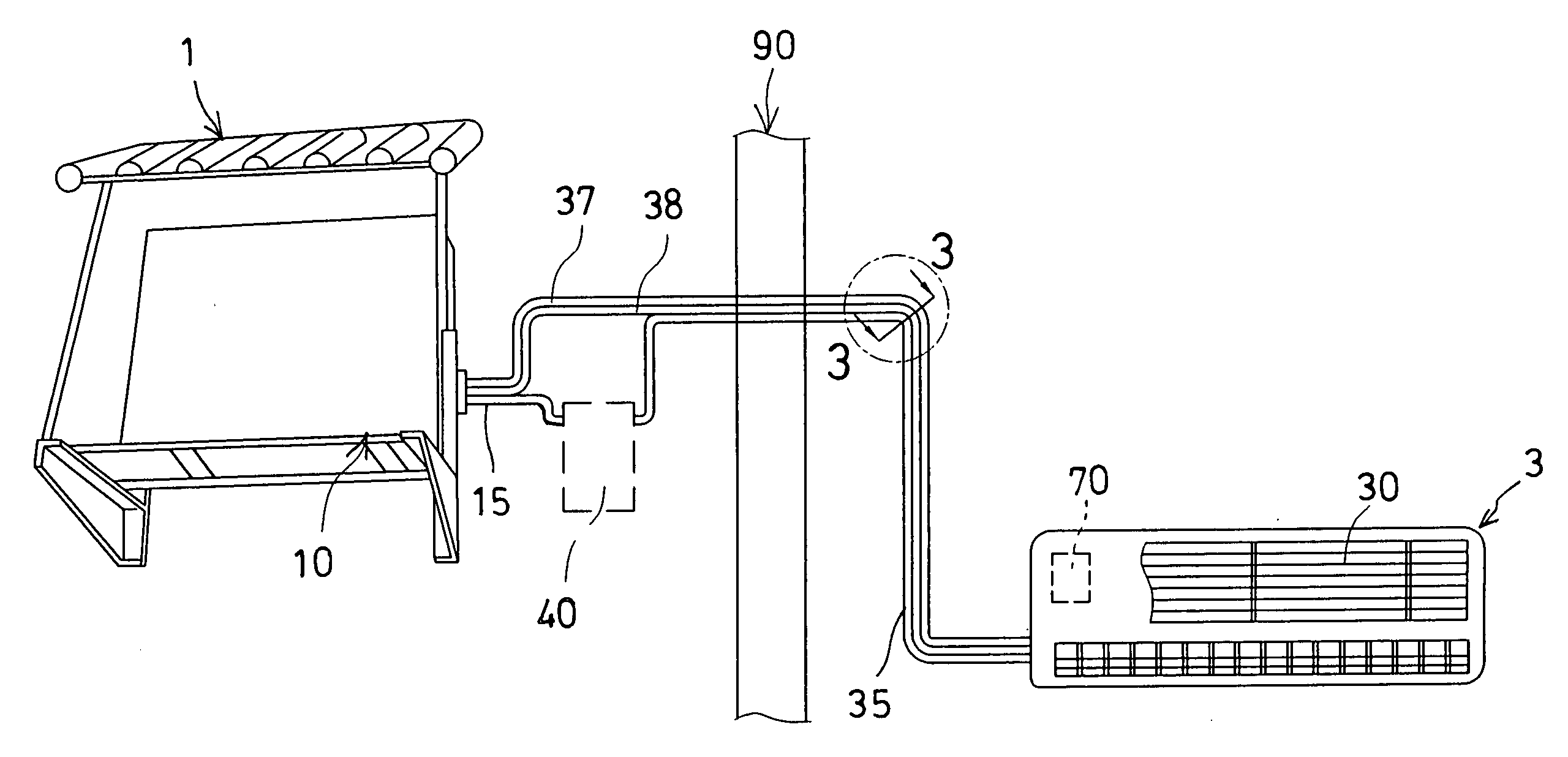

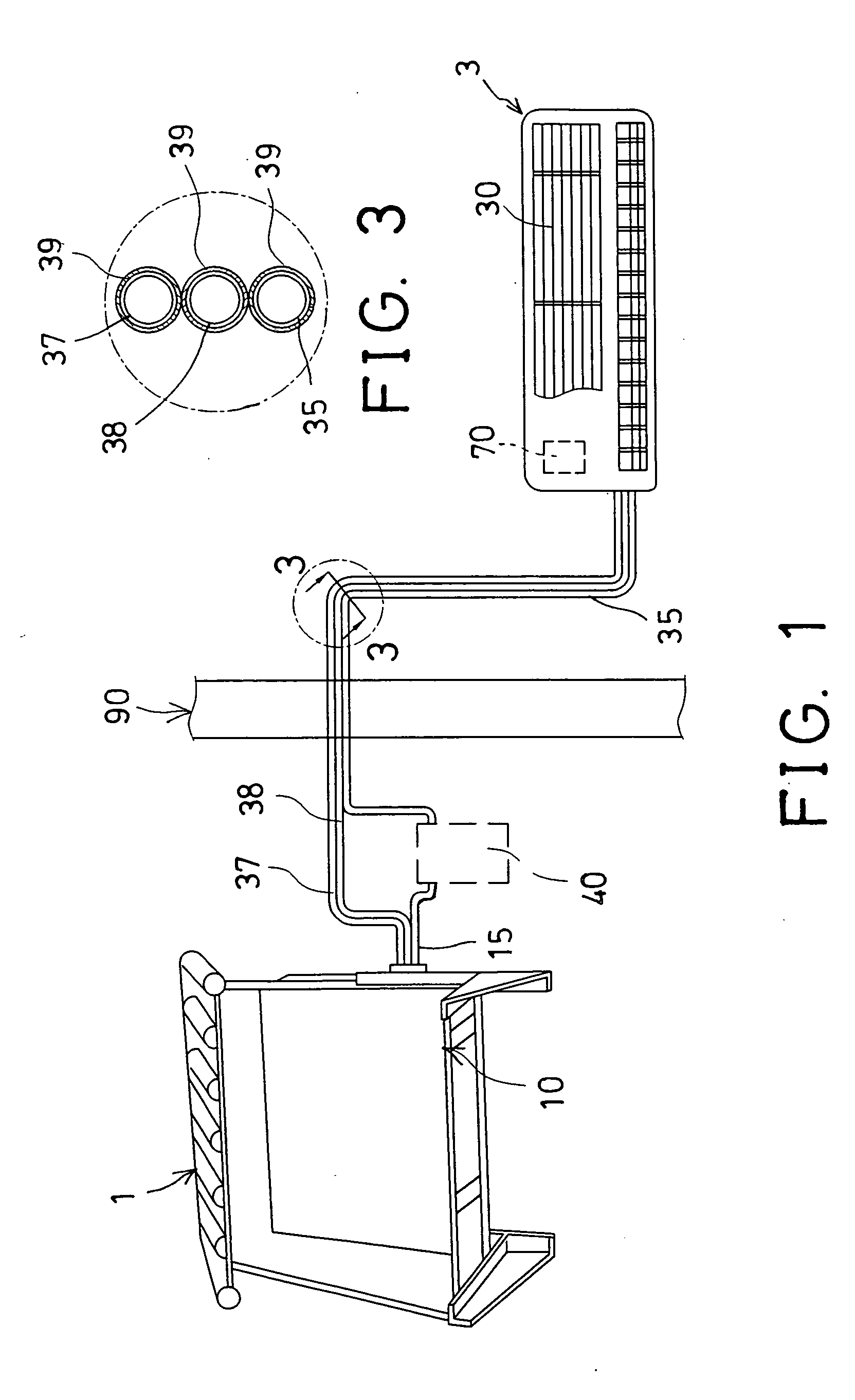

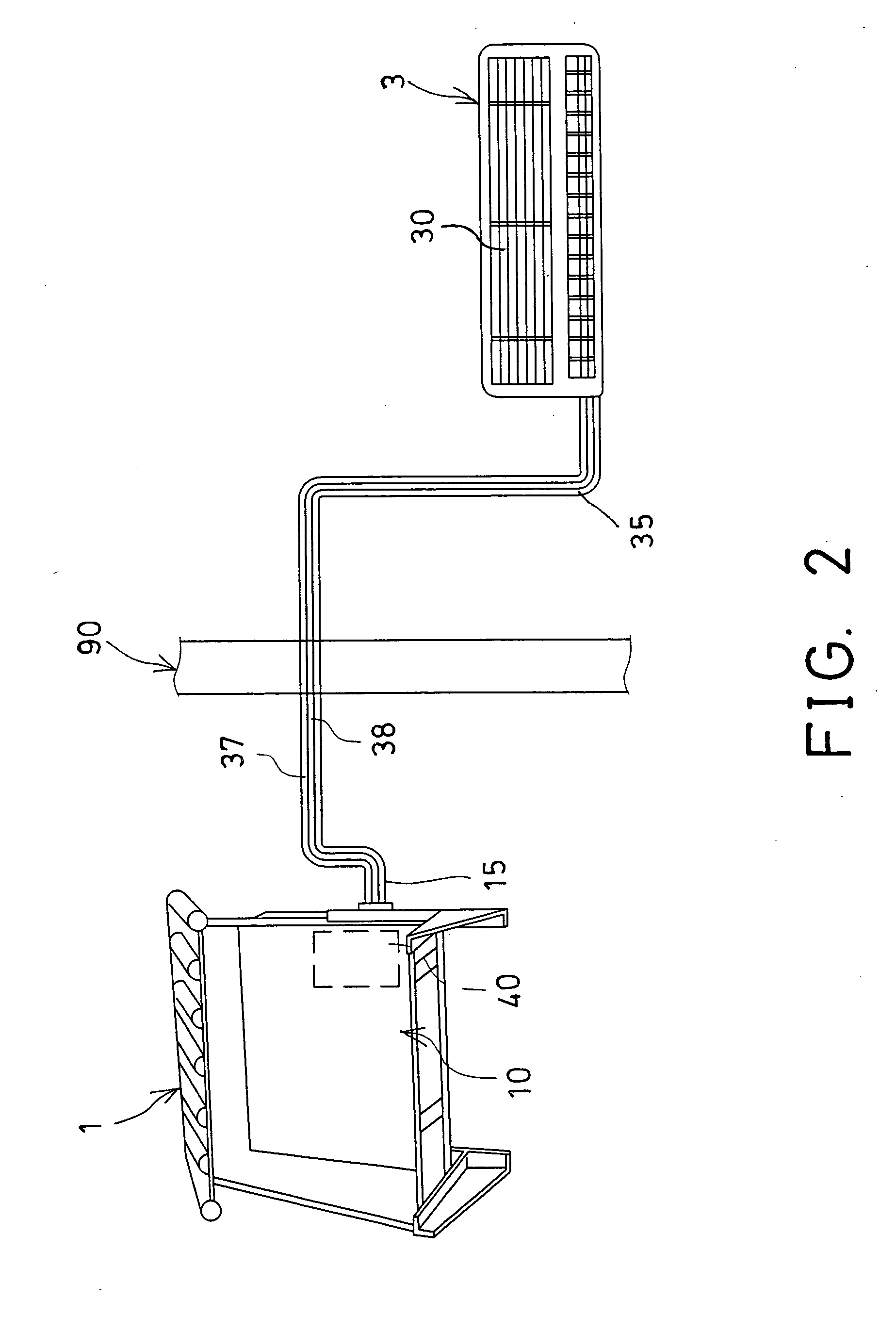

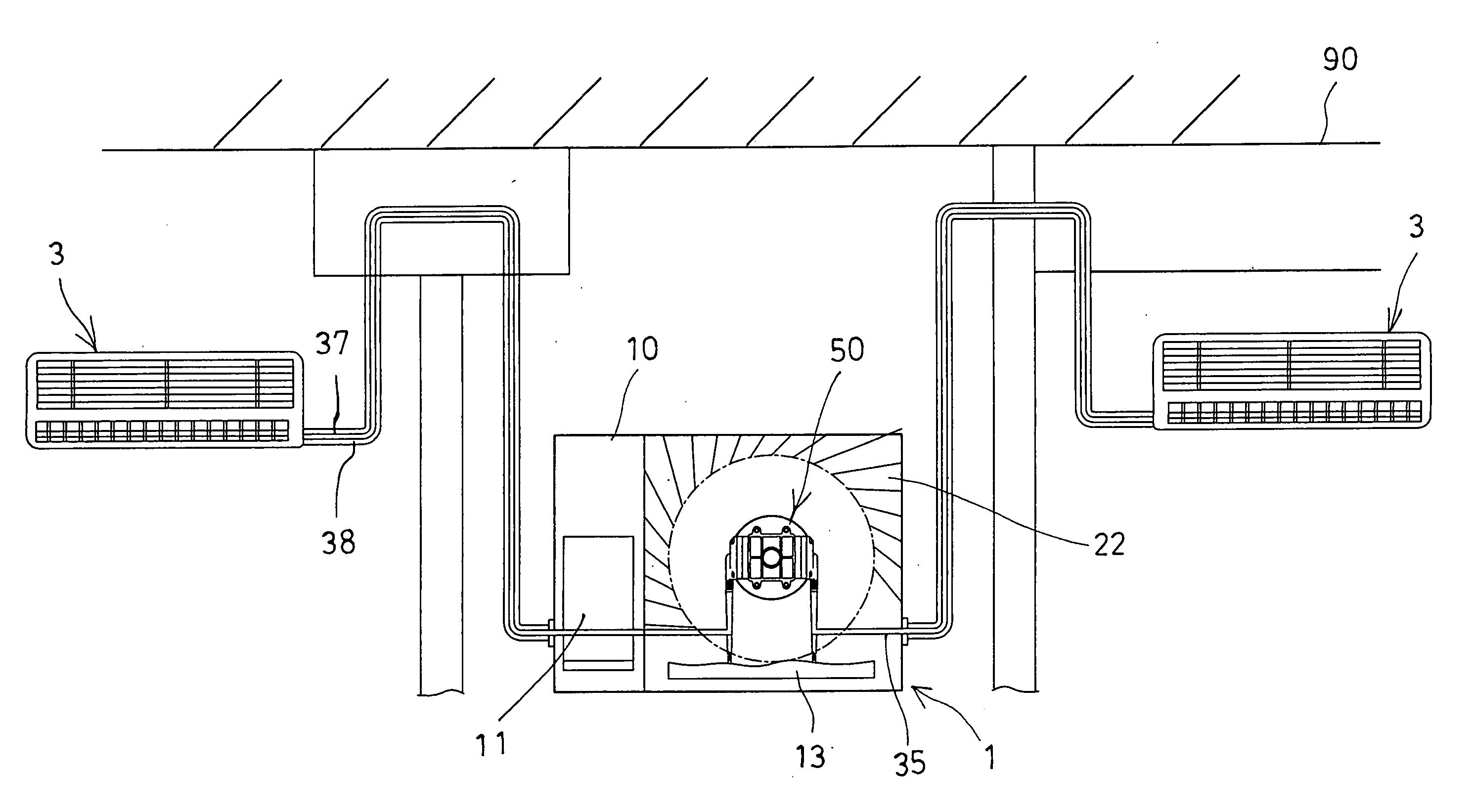

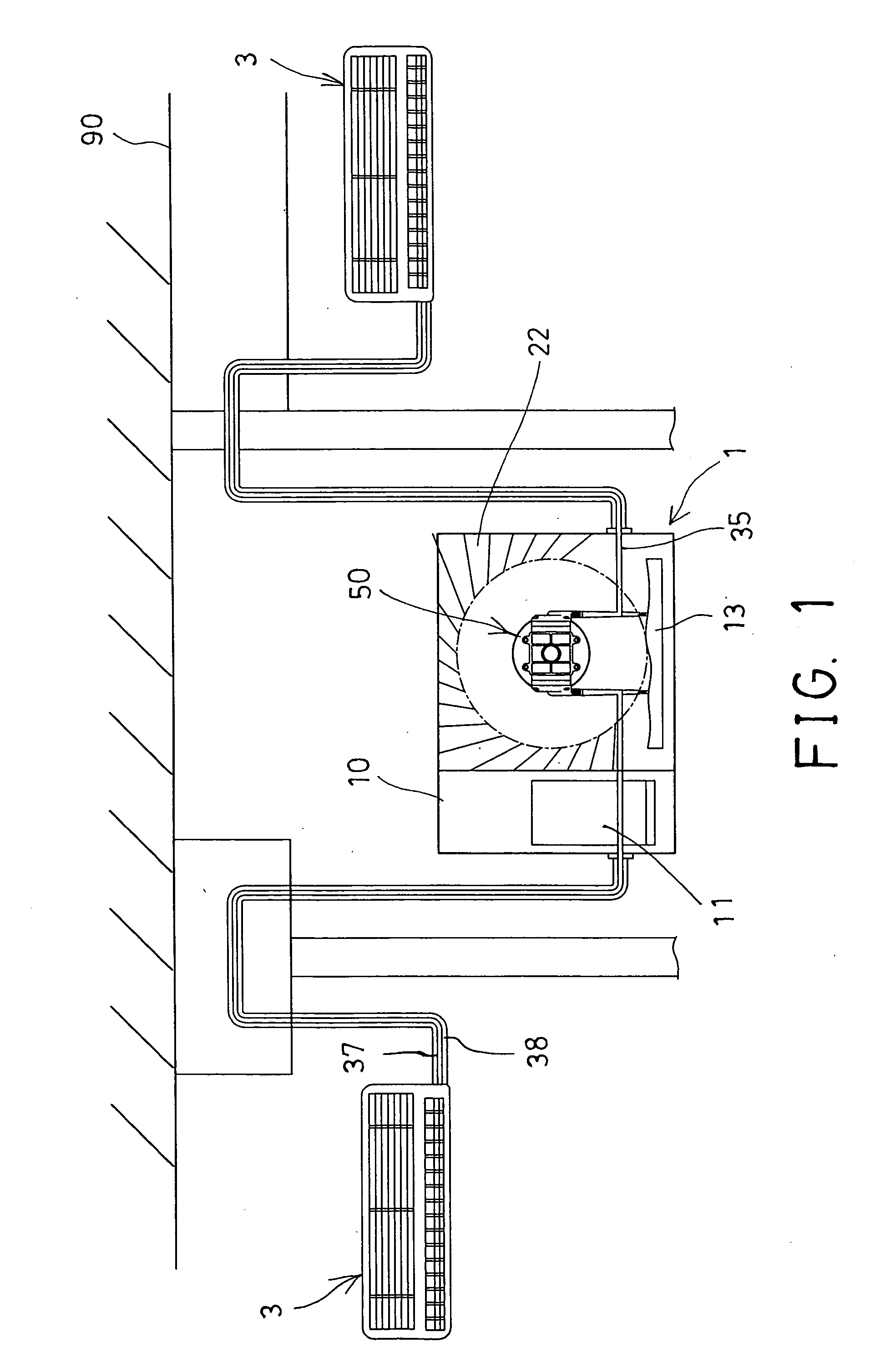

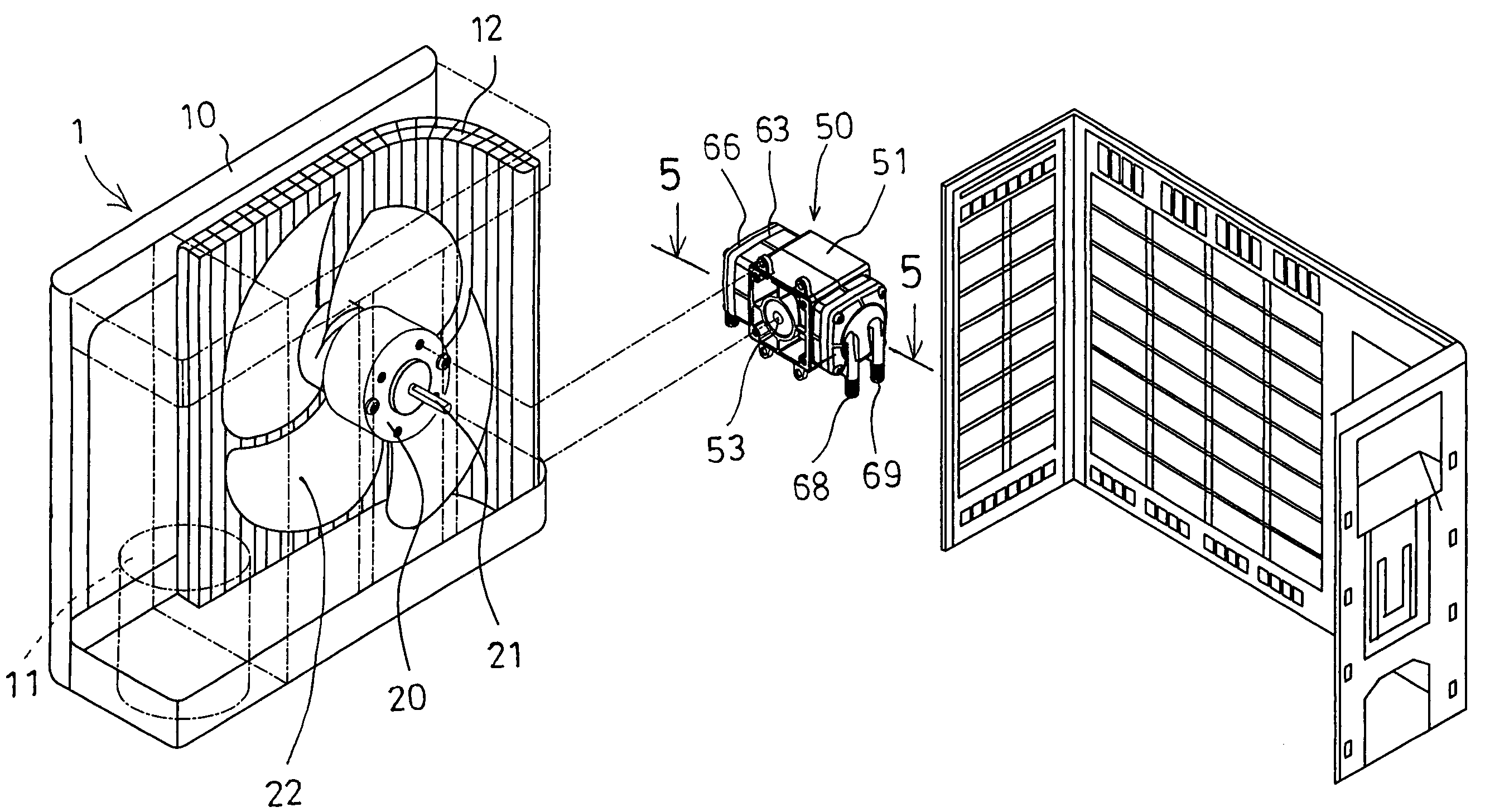

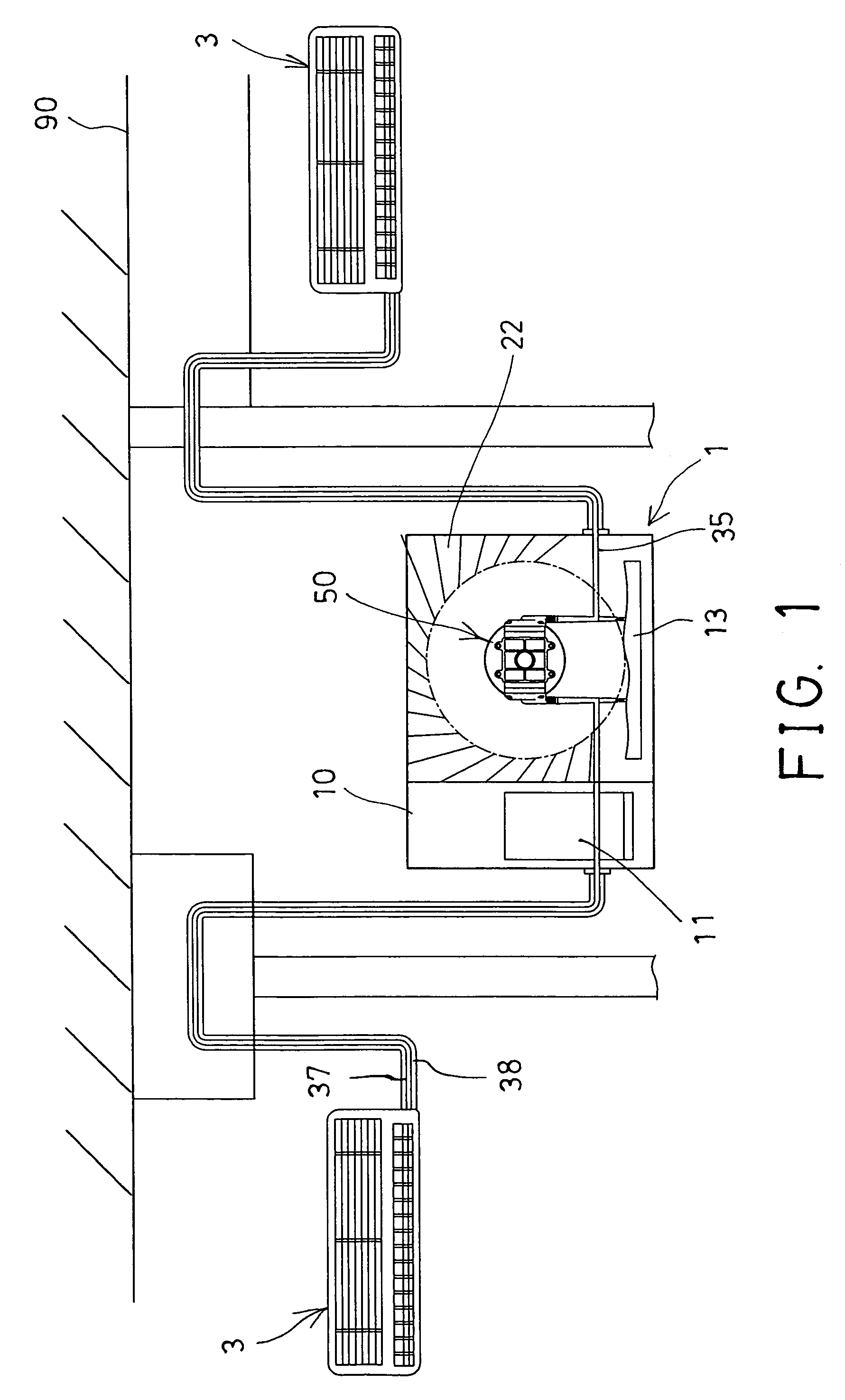

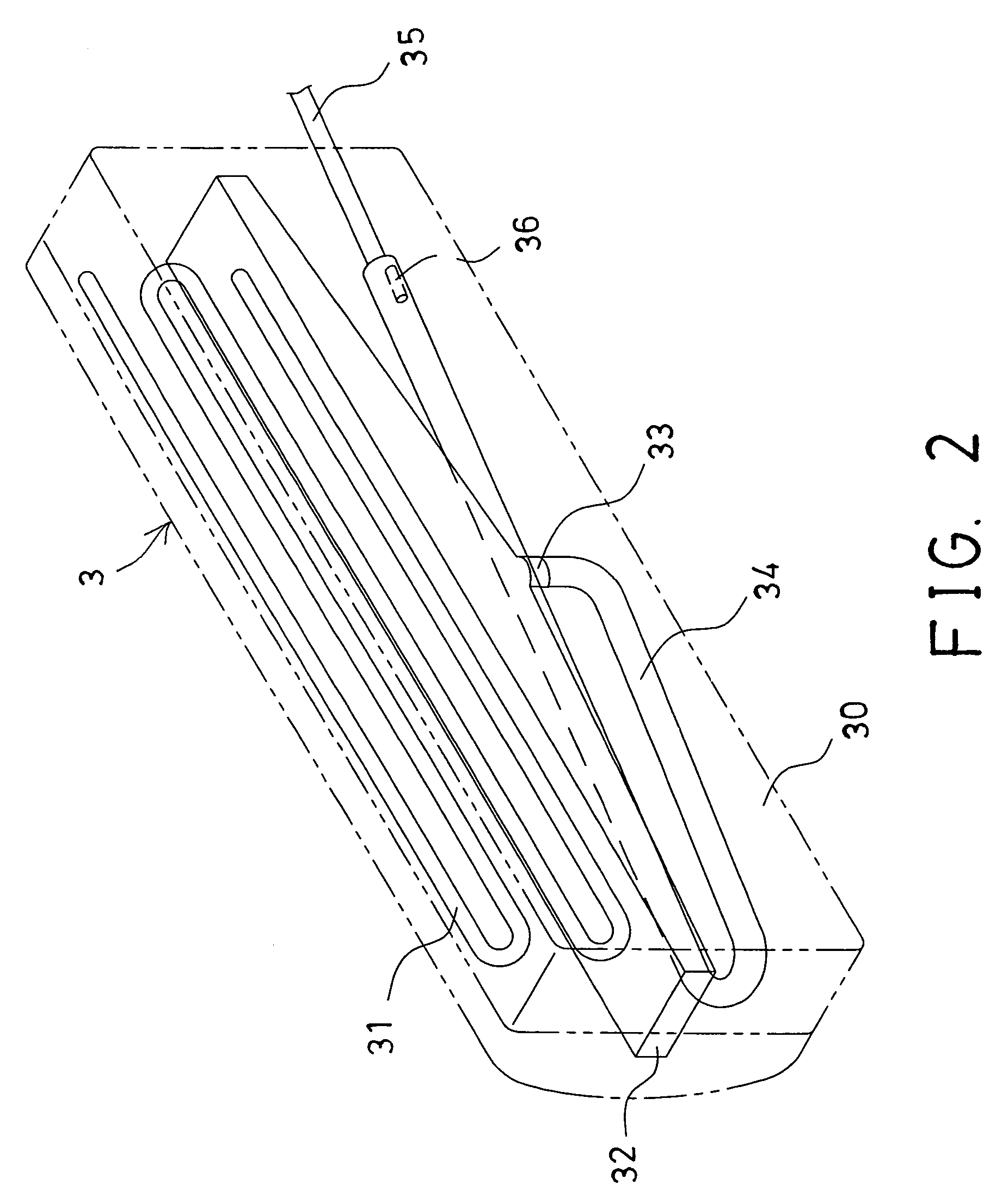

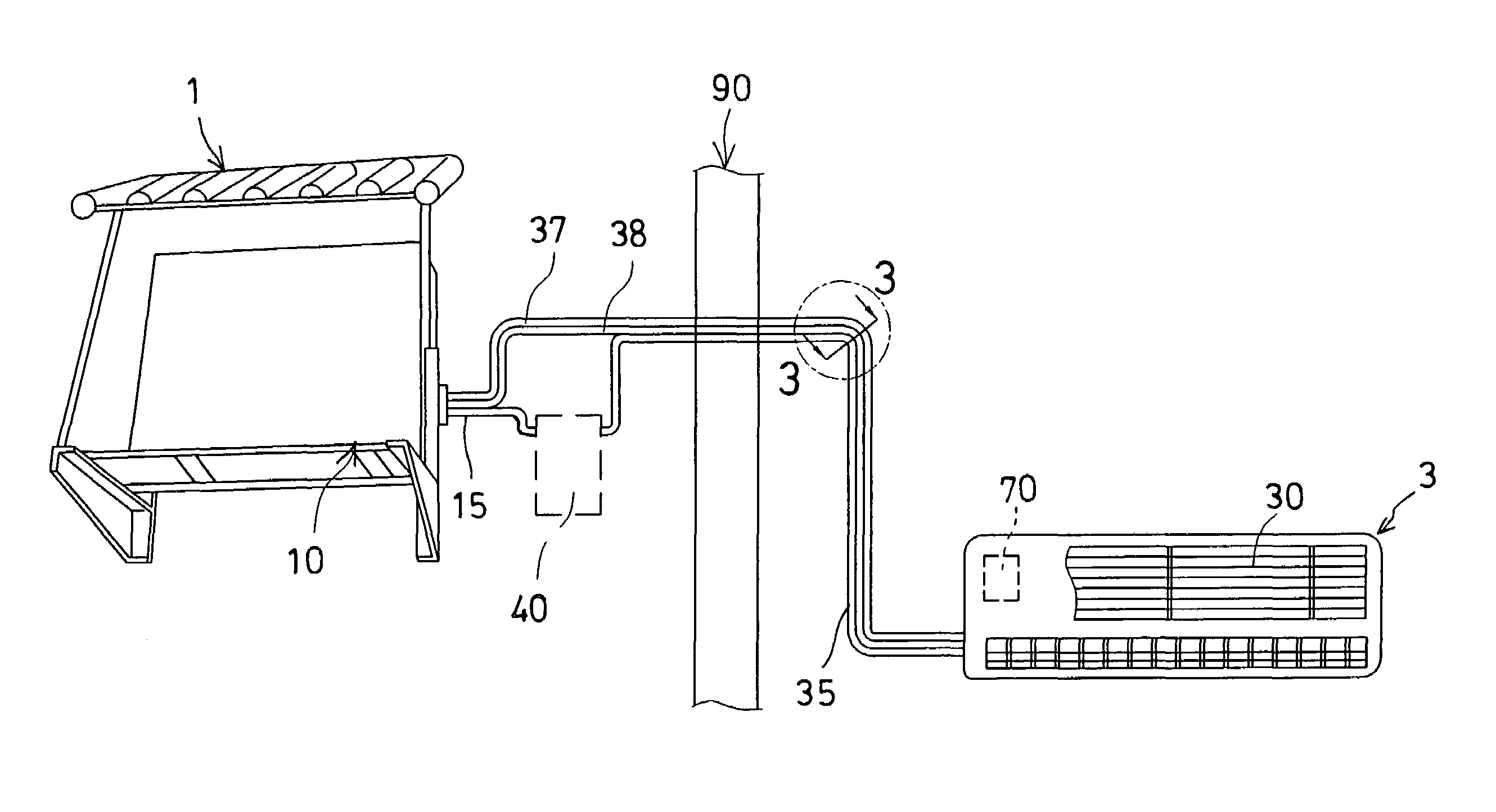

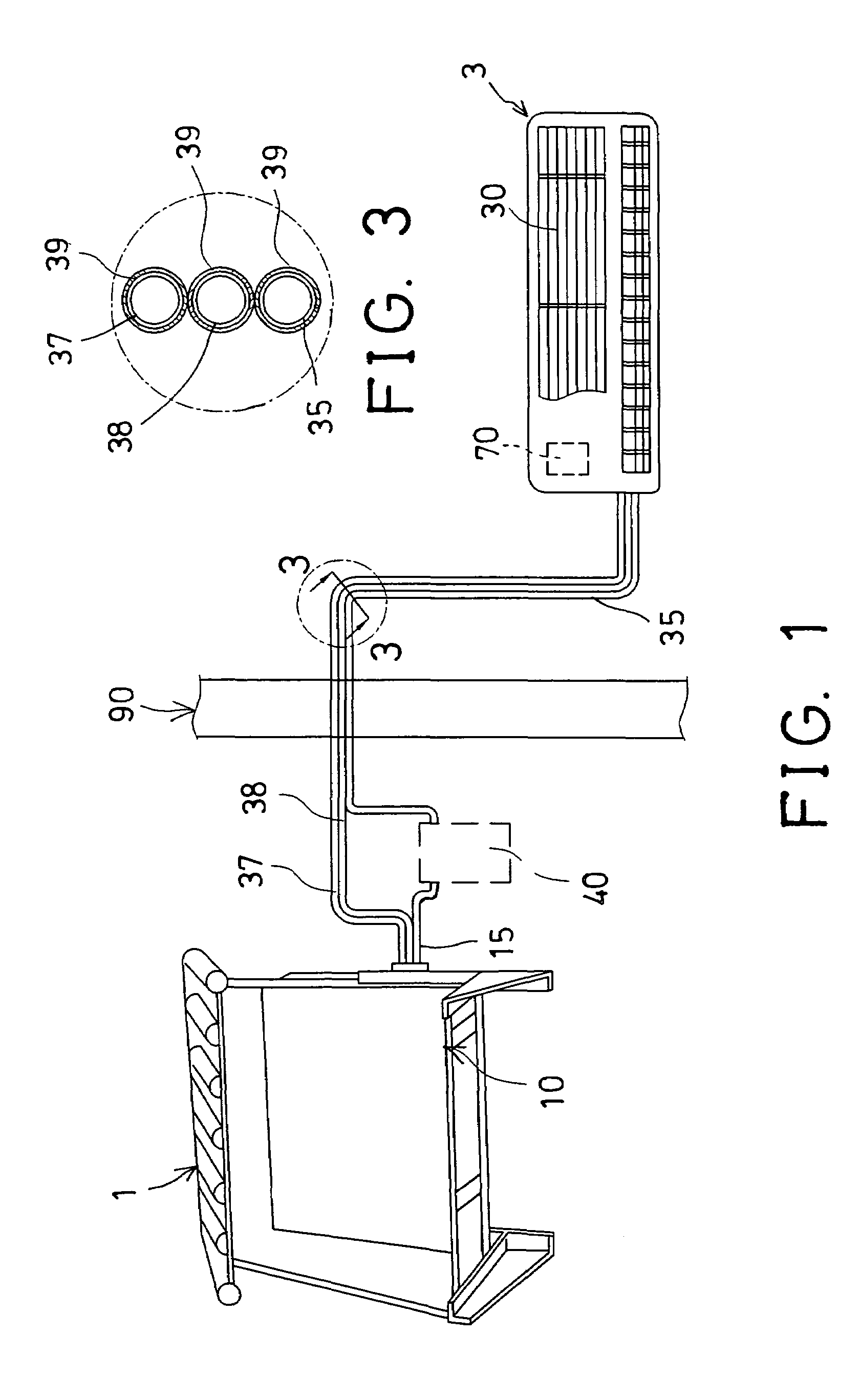

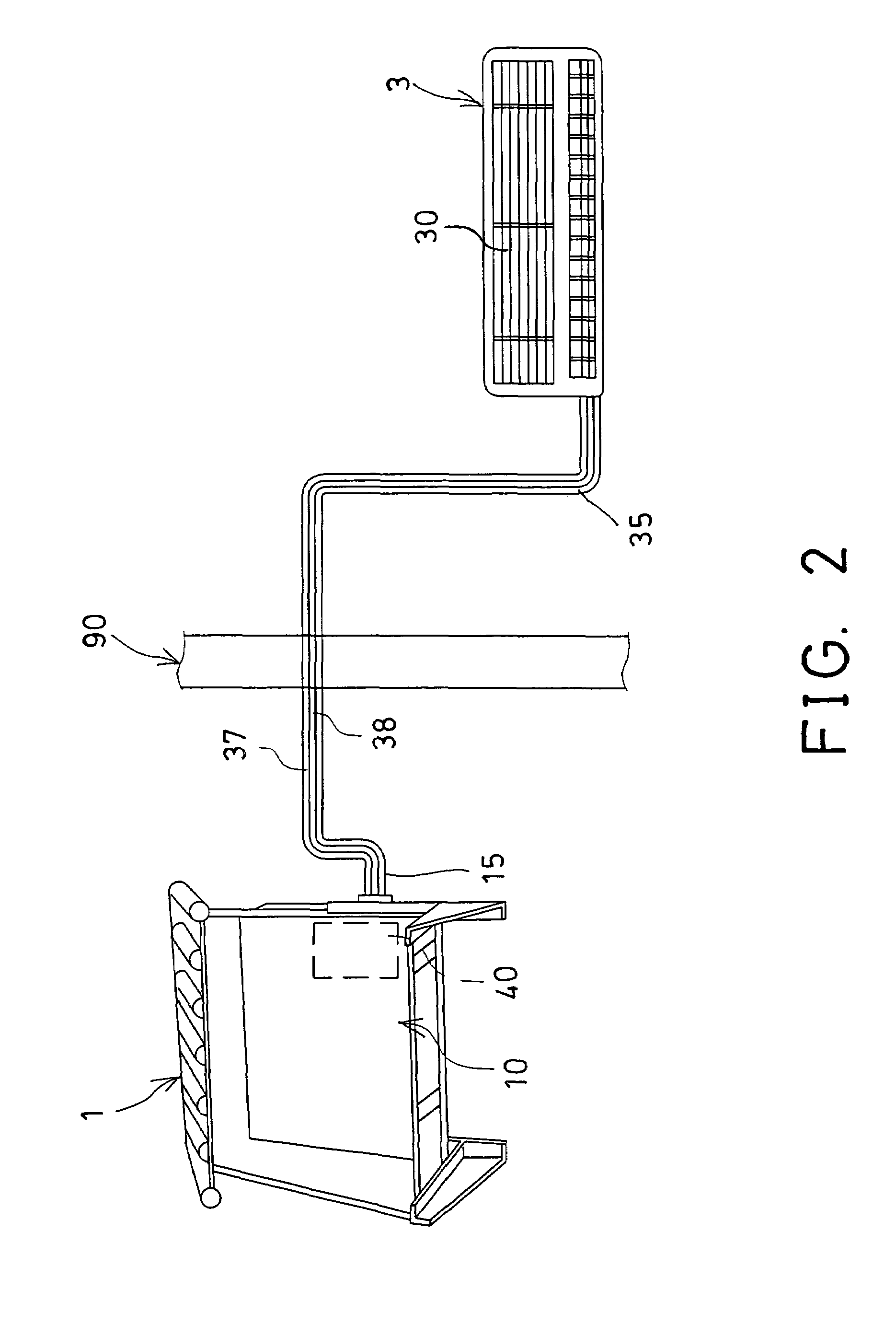

Air conditioner having water draining device

InactiveUS20060010897A1Avoid dropPrevent fallingCorrosion preventionSpace heating and ventilation detailsPistonWaste management

An air conditioner includes an outdoor device coupled to an indoor device via a hose, and a water draining device coupled between the outdoor device and the indoor device, to force water that may be generated in the indoor device from the indoor device to the outdoor device, and to prevent the water from dropping from the indoor device. The water draining device includes a casing having a channel to slidably receive a piston which may pump the water from the indoor device to the outdoor device. The indoor device includes a tray disposed in a container to collect water. The outdoor device includes a fan device to blow and to dry the water.

Owner:HUANG CHIN PIAO

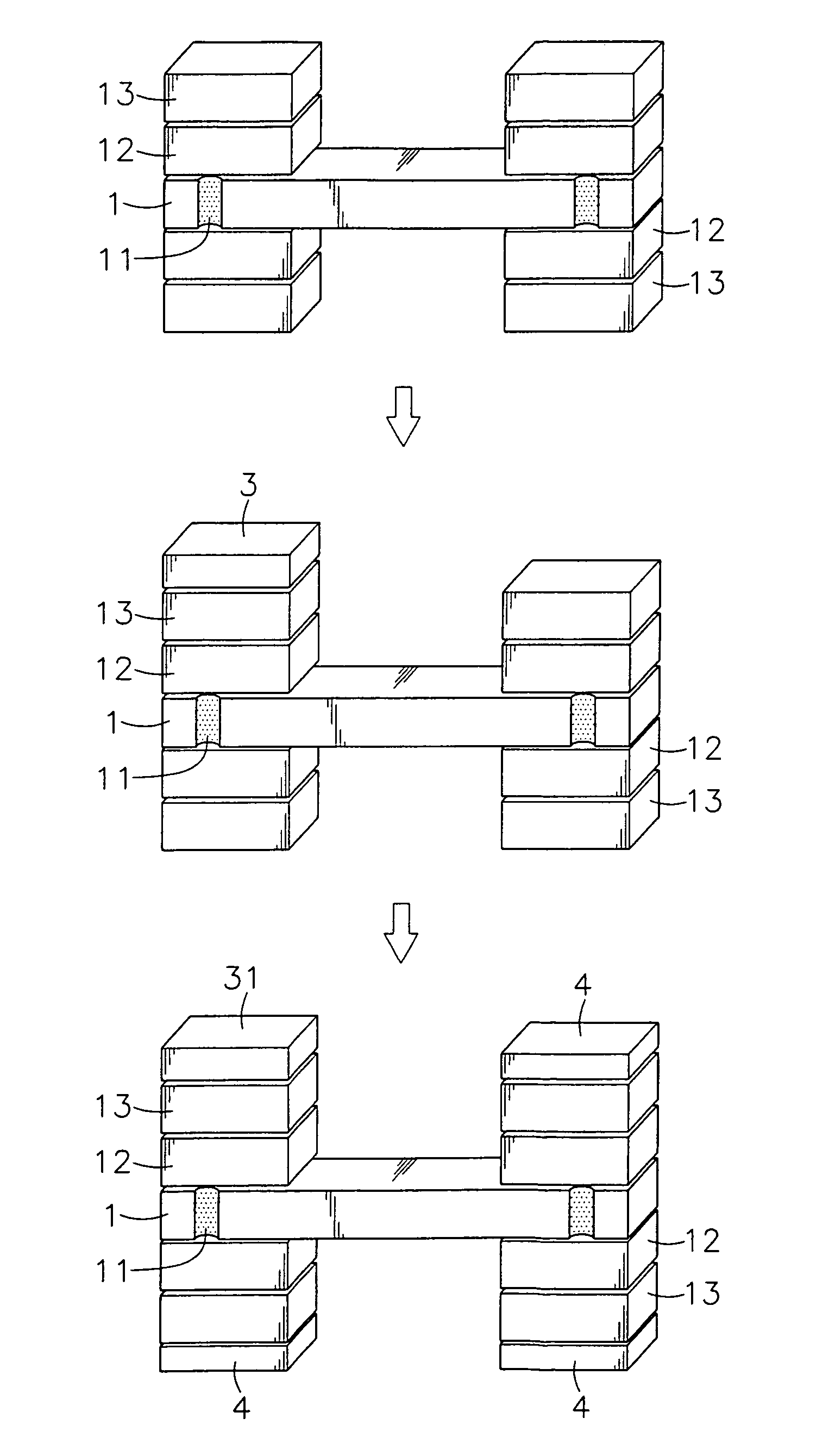

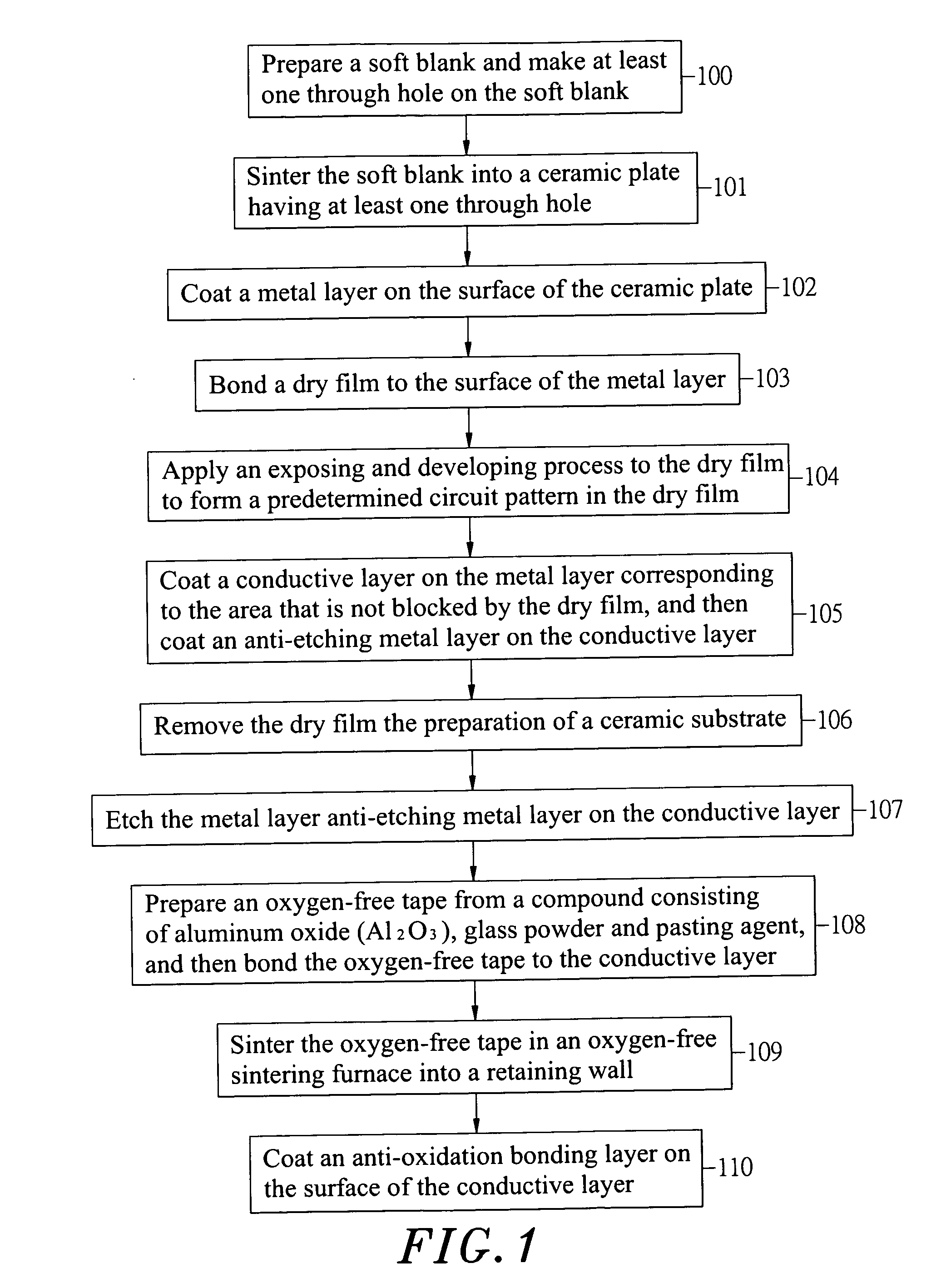

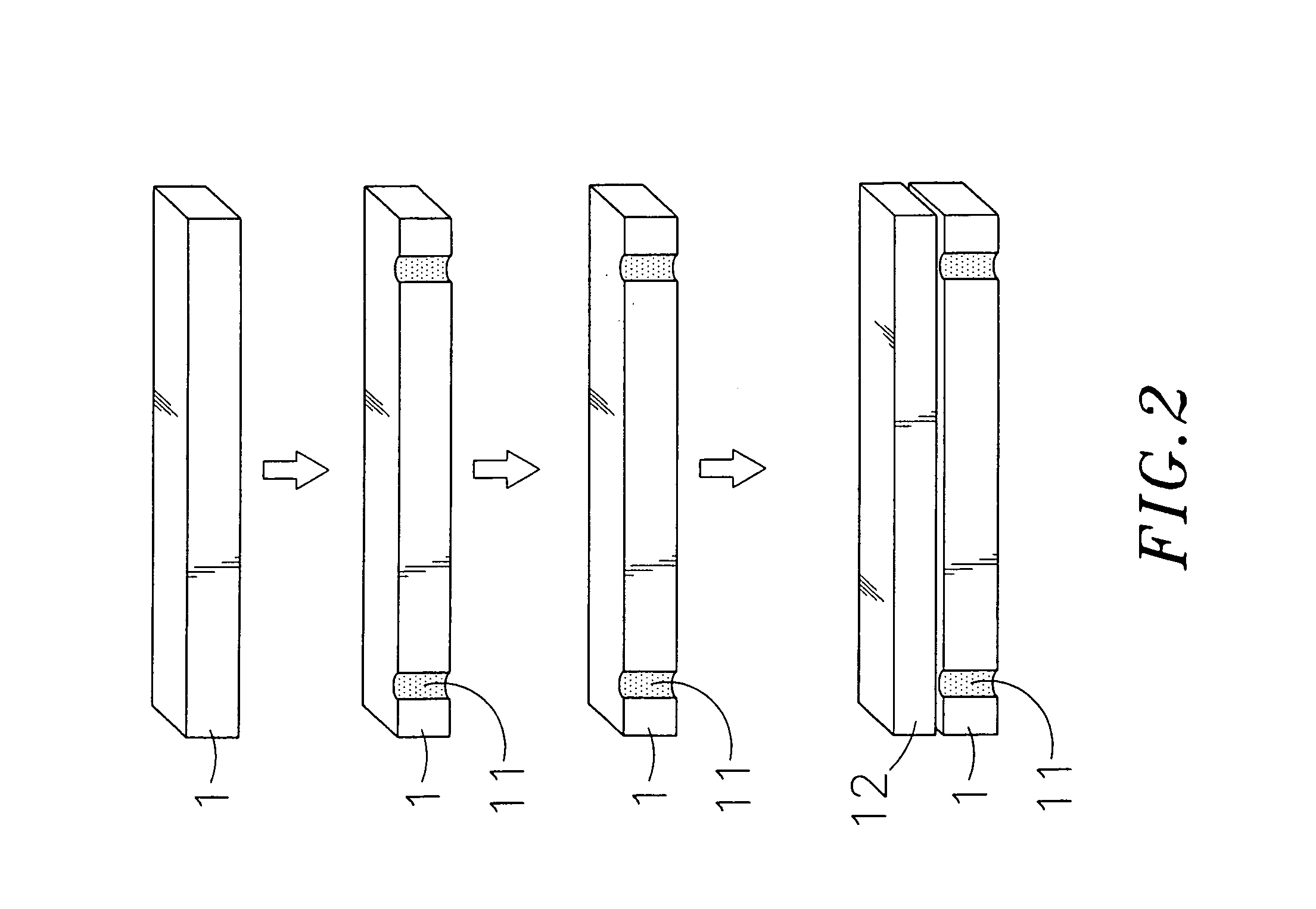

High-precision ceramic substrate preparation process

InactiveUS20110123931A1Quality assuranceSave manufacturing costDielectric materialsSemiconductor/solid-state device manufacturingRetaining wallMetallurgy

A high-precision ceramic substrate preparation process is disclosed to bond a dry film to a metal layer on a ceramic plate, and then to coat a conductive layer on the metal layer and an anti-etching metal layer on the conductive layer after application of an exposing and developing process to form a predetermined circuit pattern in the dry film, and then to remove the dry film and to etch the metal layer, and then to bond an oxygen-free tape, which is prepared from a compound of ceramic powder, glass powder and pasting agent, to the conductive layer, and then to sinter the oxygen-free tape in an oxygen-free sintering furnace into a retaining wall, and then to coat an anti-oxidation bonding layer on the surface of the conductive layer.

Owner:HOLY STONE ENTERPRISE

Partially-balanced hydraulic lifting type ship lift

The invention relates to a partially-balanced hydraulic lifting type ship lift and belongs to the field of navigable buildings for water conservancy and hydropower projects. The partially-balanced hydraulic lifting type ship lift comprises main lifting cylinders, horizontal doors, anti-colliding beams, a supporting beam, a ship lift chamber located between two tower columns, multiple sets of counterweight systems, locking devices and abutting guide devices. The two ends of the ship lift chamber are each provided with the anti-colliding beam and the horizontal door. The supporting beam is mounted at the bottom of the ship lift chamber. The main lifting cylinders are symmetrically mounted on the two sides of the ship lift chamber. The multiple sets of counterweight systems are mounted on the two sides of the ship lift chamber. The locking devices are fixed to the two sides of the top of the ship lift chamber. The abutting guide devices are mounted on the two sides of the ship lift chamber. One end of each abutting guide device is connected with the ship lift chamber. The other end of each abutting guide device is connected with guide rails of the tower columns. The partially-balanced hydraulic lifting type ship lift is reasonable and simple in structural design, safe and stable in operation, high in reliability and low in cost.

Owner:杭州国电机械设计研究院有限公司

Production line

InactiveCN110255181AImprove processing qualityIncrease productivityArticle unpackingDe-stacking articlesProduction lineTransfer mechanism

The invention relates to the technical field of automated production equipment and discloses a production line. Firstly, through the cooperation of a large view detection mechanism and a feeding transfer mechanism, the grasping angle and the grasping position can be precisely adjusted, it is ensured that products at different positions and angles can be grasped steadily, the grasping success rate and the grasping efficiency are improved obviously, the situation that the products are thrown off in the moving process due to grasping unsteadiness can be avoided effectively, and the disposal quality of the production line is improved; secondly, through the cooperation of a feeding conveying assembly and a feeding lifting assembly, the products can be close to the large view detection mechanism, and thus the detection efficiency of the large view detection mechanism and the accuracy of detection results are beneficially improved; and finally, by arranging a tray removal mechanism, the stacked empty trays on the previous layer can be removed quickly, the large view detection mechanism can detect the stacked trays on the next layer, and the detection efficiency is further improved.

Owner:SUZHOU JINGLAI OPTO CO LTD

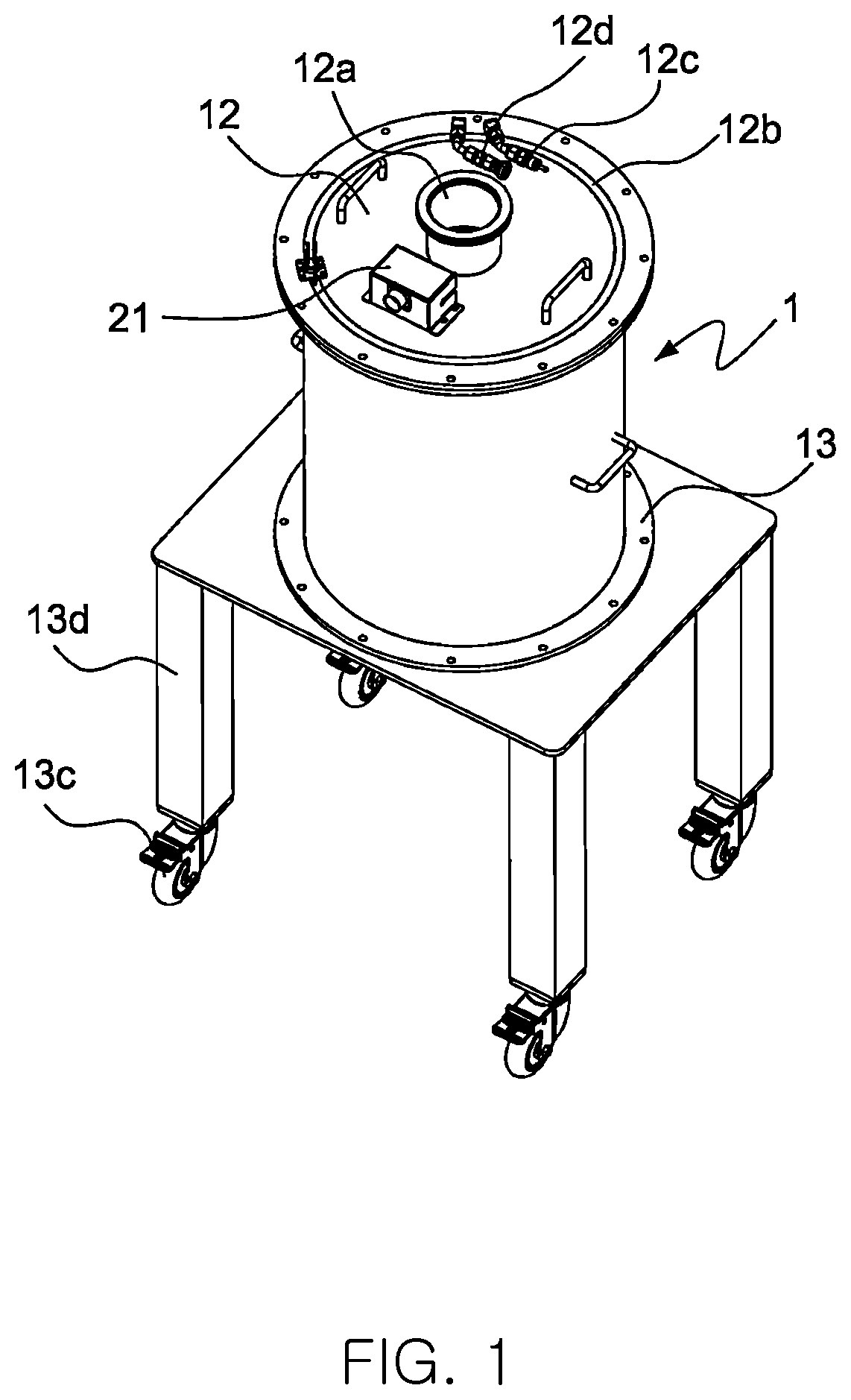

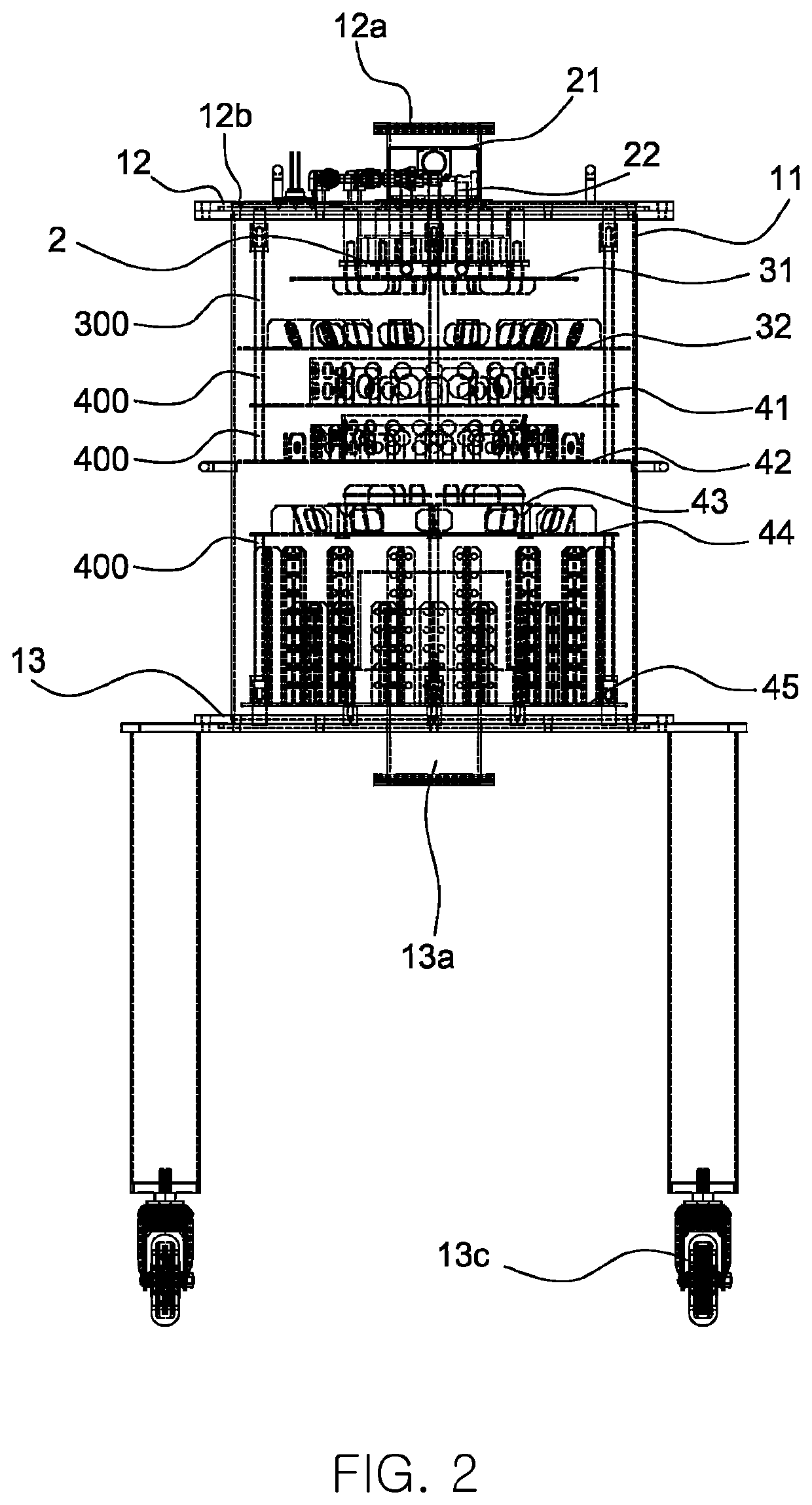

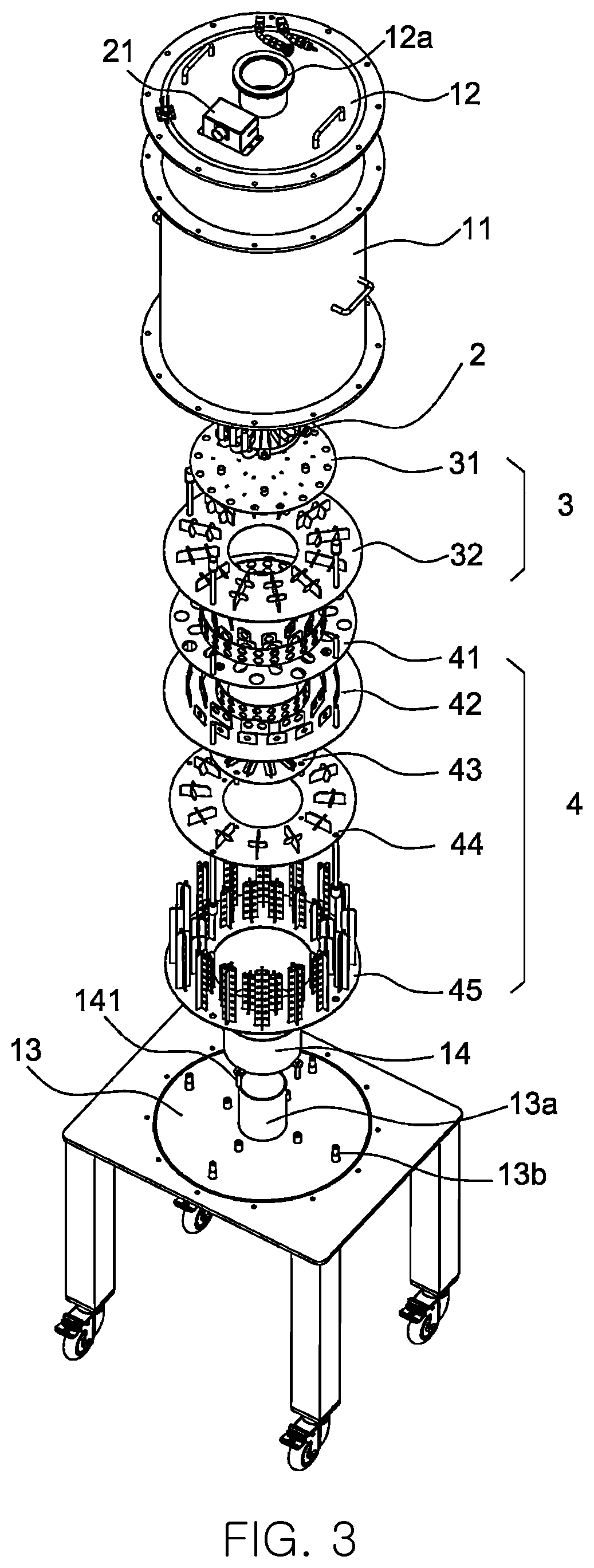

Apparatus for trapping multiple reaction by-products for semiconductor process

PendingUS20220349053A1Prevent fallingShorten maintenance cycleElectric discharge tubesCold traps/bafflesThin membraneTrapping region

An apparatus is for trapping multiple reaction by-products for a semiconductor process, in which a trapping region is divided by a difference in vertical temperature distribution according to a distance spaced apart from a heater and by structures for switching flow path directions and generating multiple vortices using a trapping structure, and reaction by-product mixtures contained in a gas, which is discharged after a process of depositing multiple different thin film layers is performed in a process chamber during a semiconductor manufacturing process, is trapped by a single trapping apparatus, such that a reaction by-product, which is aggregated in the form of a thin film in a relatively high-temperature region, is trapped by a first trapping part in an upper region, and a reaction by-product, which is aggregated in the form of powder in a relatively low-temperature region, is trapped by a second trapping part in a lower region.

Owner:MILAEBO

Clamp and method for polishing plane optical part

The invention provides a clamp and method for polishing a plane optical part. The clamp is a clamp with a rectangular groove shape, and the clamp comprises a base and blocking edges, wherein the baseis a rectangular plate, the periphery of the base is fixedly provided with the blocking edges, and the blocking edges are perpendicular to the base; a groove is defined by the blocking edges and the base, wherein the depth of the groove is smaller than that of the plane optical part; and threads matched with a main shaft of a grinding and polishing machine or a stylus hole matched with a stylus ofthe grinding and polishing machine is arranged on the other surface opposite to the groove surface of the base. According to the clamp and method for polishing the plane optical part, the plane optical part can be directly placed into the clamp when the clamp is used for polishing the plane optical part so that grinding, polishing and other processes can be carried out, and the plane optical partis conveniently taken out after being machined; and meanwhile, the base of the clamp base is provided with the stylus hole or the threads, so that disassembling is convenient, the operation is simple, the damage caused by falling of the optical part is avoided, and the potential deformation caused by taking-out of the plane optical part after machining is finished through a dispensing method is also avoided, so that the product qualifying rate is improved.

Owner:安徽光智科技有限公司

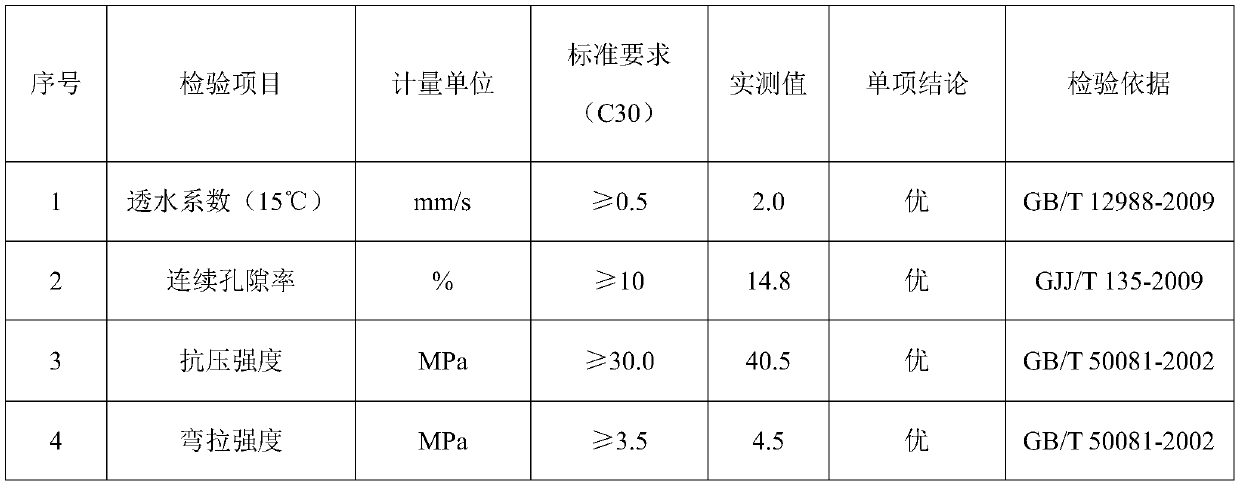

Reinforcing agent for pervious concrete as well as preparation method and construction process of reinforcing agent

The invention discloses a reinforcing agent for previous concrete as well as a preparation method and a construction process of the reinforcing agent. The reinforcing agent is prepared from the following components in parts by weight: 50 to 80 parts of nano-grade silicon powder, 10 to 15 parts of water reducing agent, 2 to 4 parts of cellulose, 8 to 10 parts of calcium sulfate whisker, 5 to 8 parts of trisodium phosphate, 1.5 to 5 parts of calcium carboxylate, 2 to 6 parts of alkali carbonate and 0.5 to 2 parts of formamide. According to the reinforcing agent, the bonding effect of cement canbe enhanced; meanwhile, the compressive strength and service life of a previous concrete pavement are respectively enhanced and prolonged, and the construction process is simplified; the process flowis short, the project progress is quick, and remarkable economic benefit and social benefit are realized.

Owner:南京海牛科技有限公司

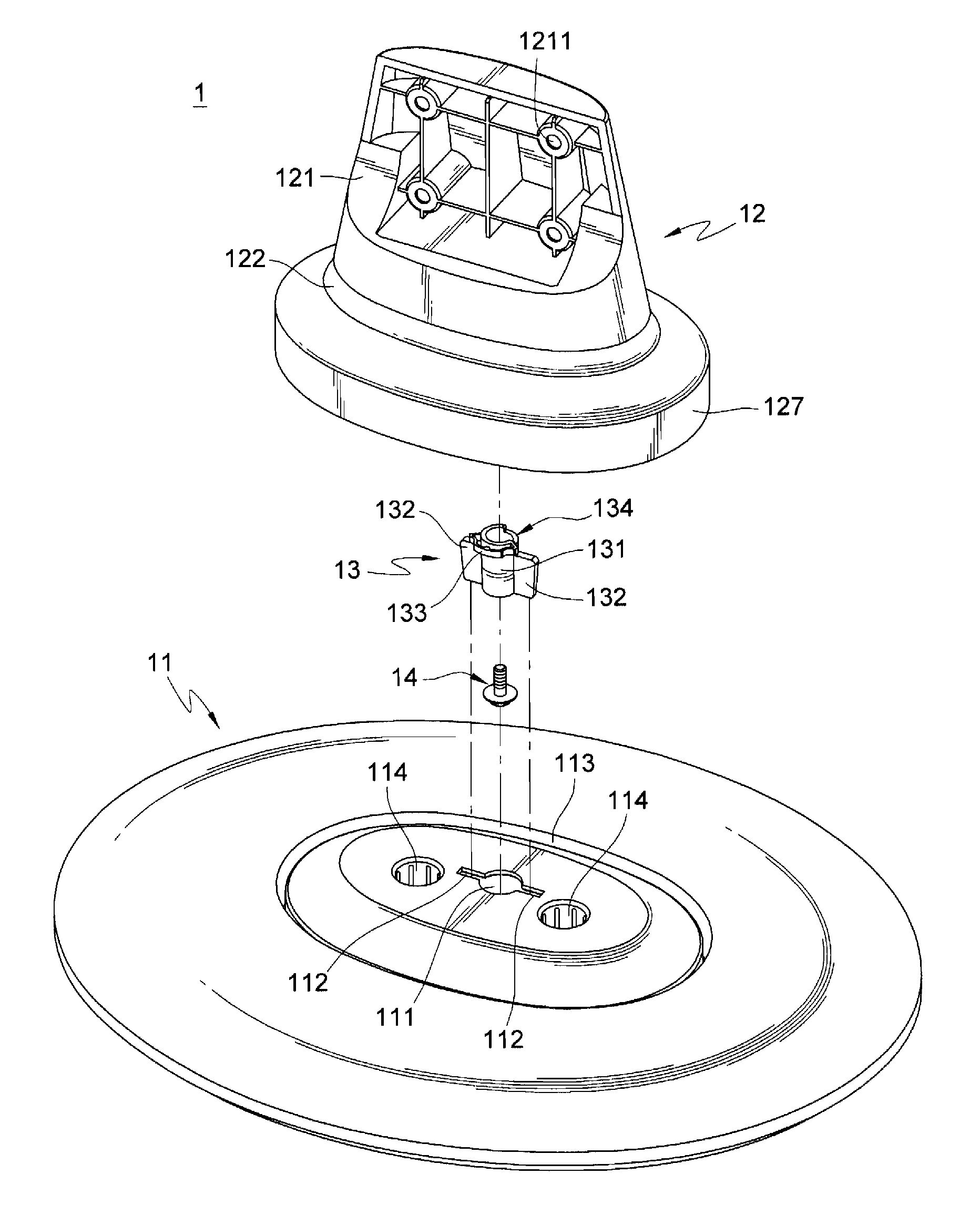

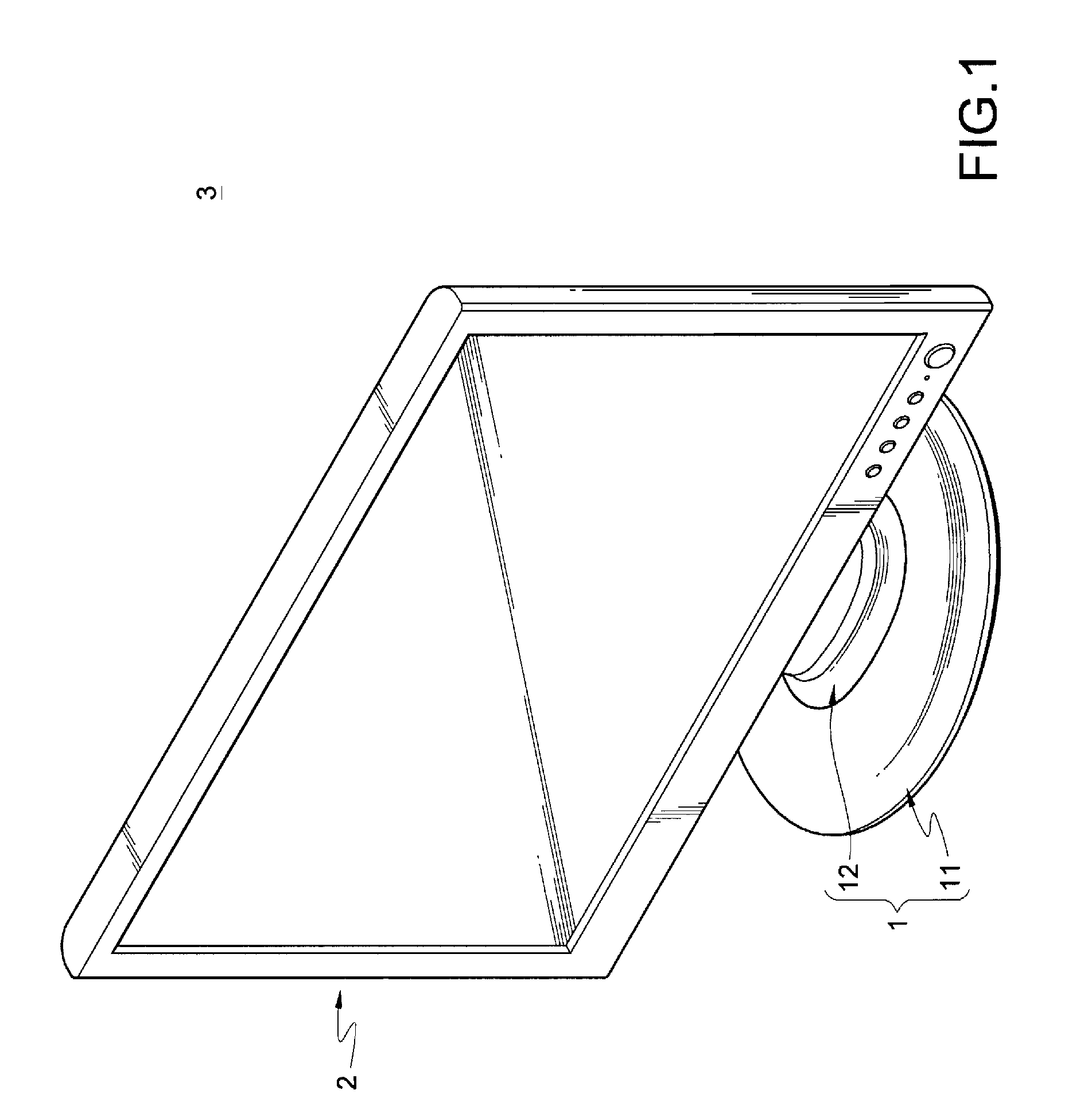

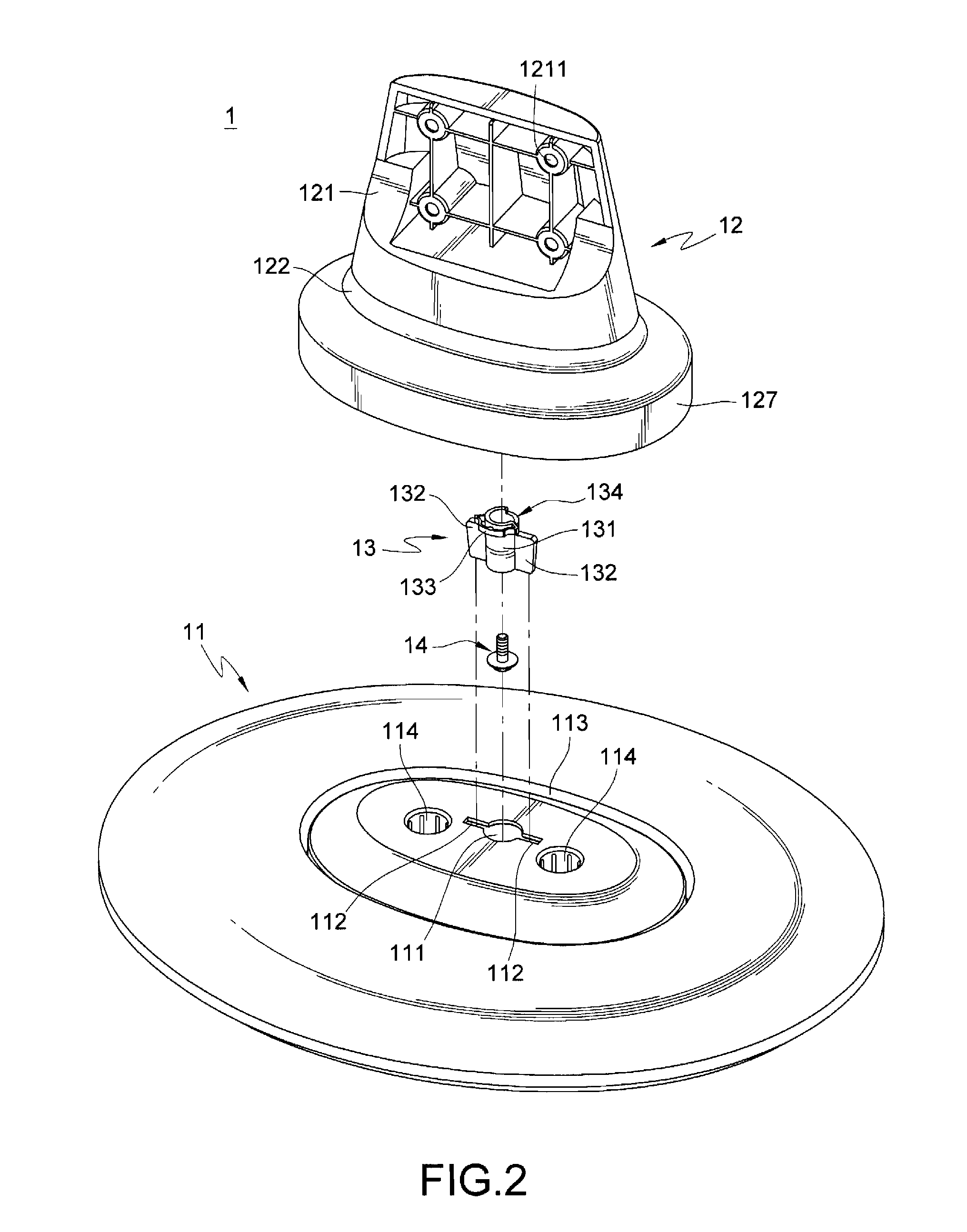

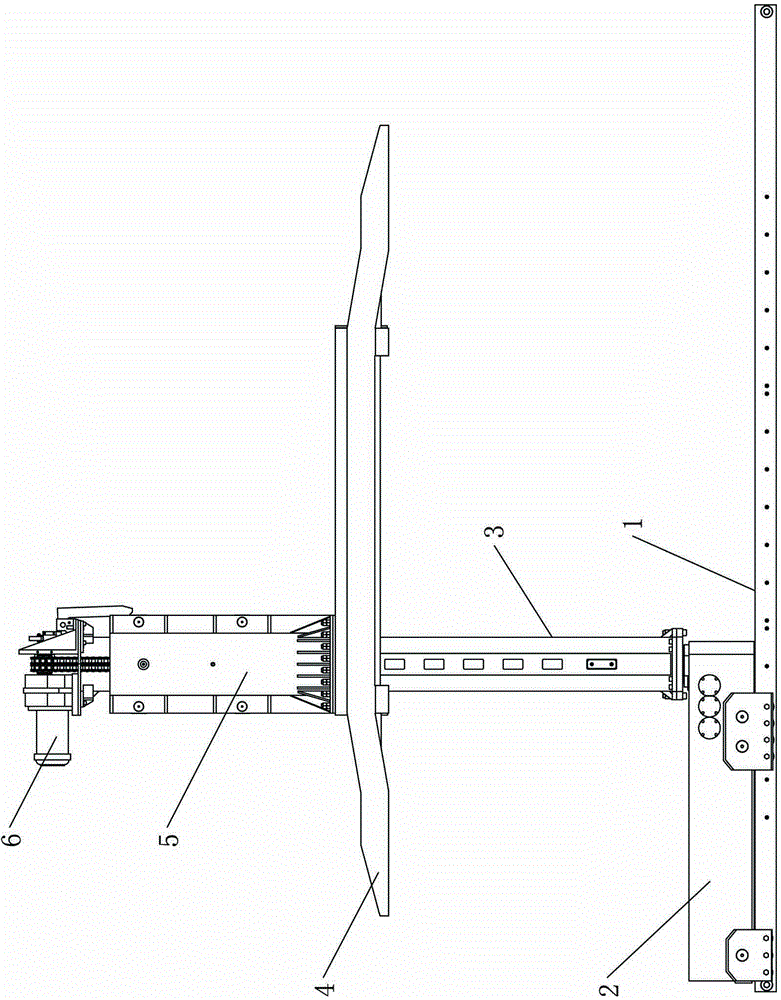

Liquid crystal display and base structure thereof

ActiveUS8149194B2Reduce processing stepsEasy to dropStatic indicating devicesStands/trestlesLiquid-crystal displayDisplay device

Owner:AMTRAN TECH CO LTD

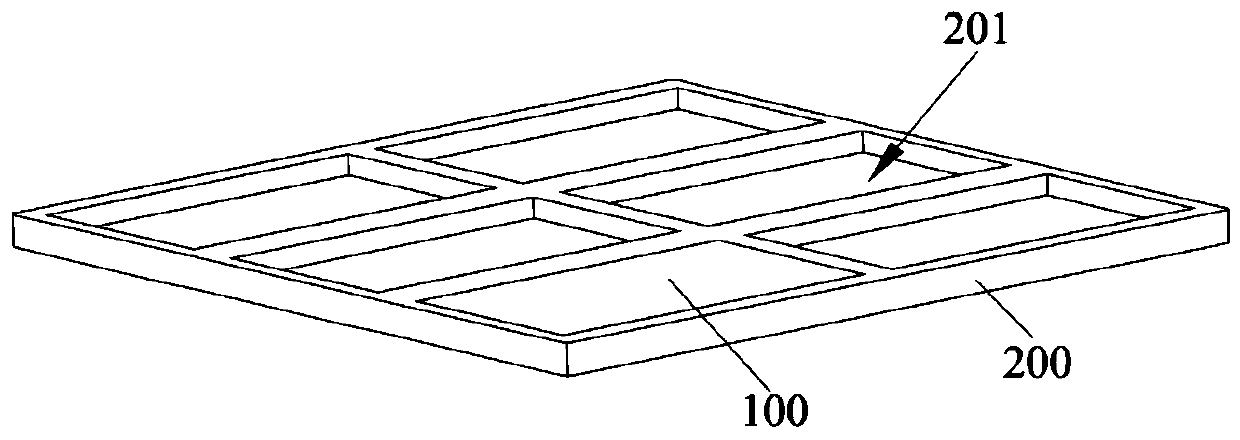

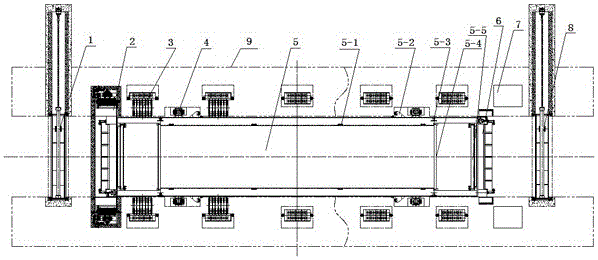

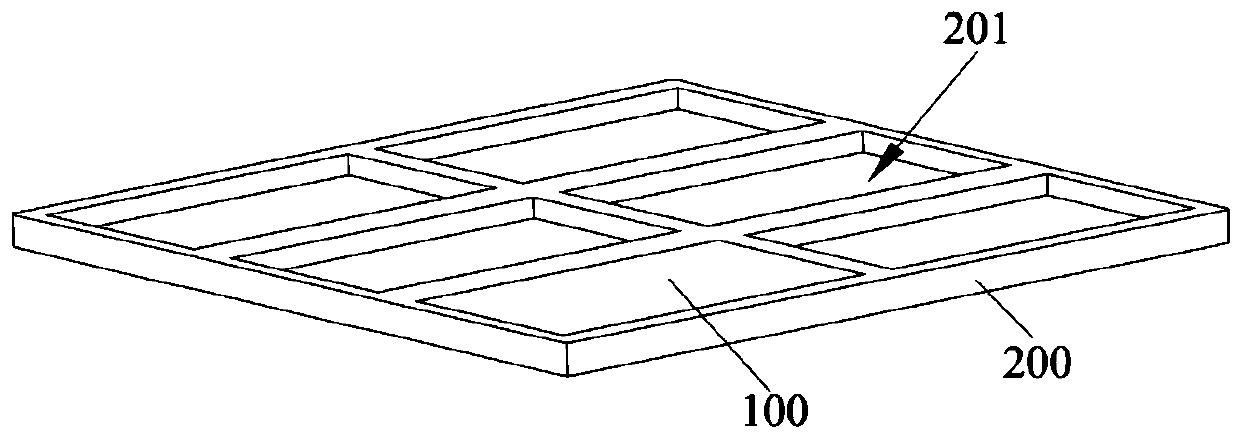

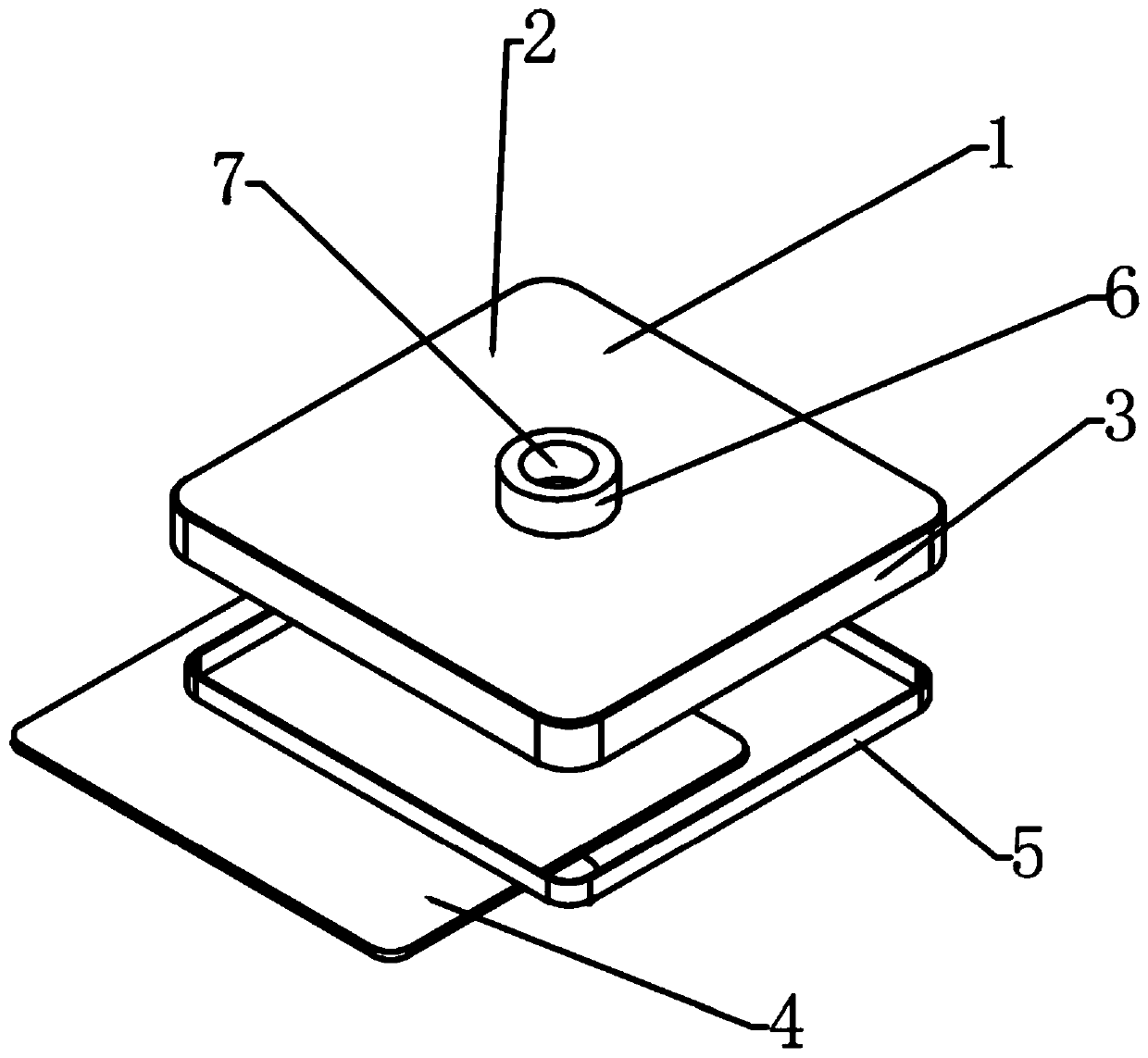

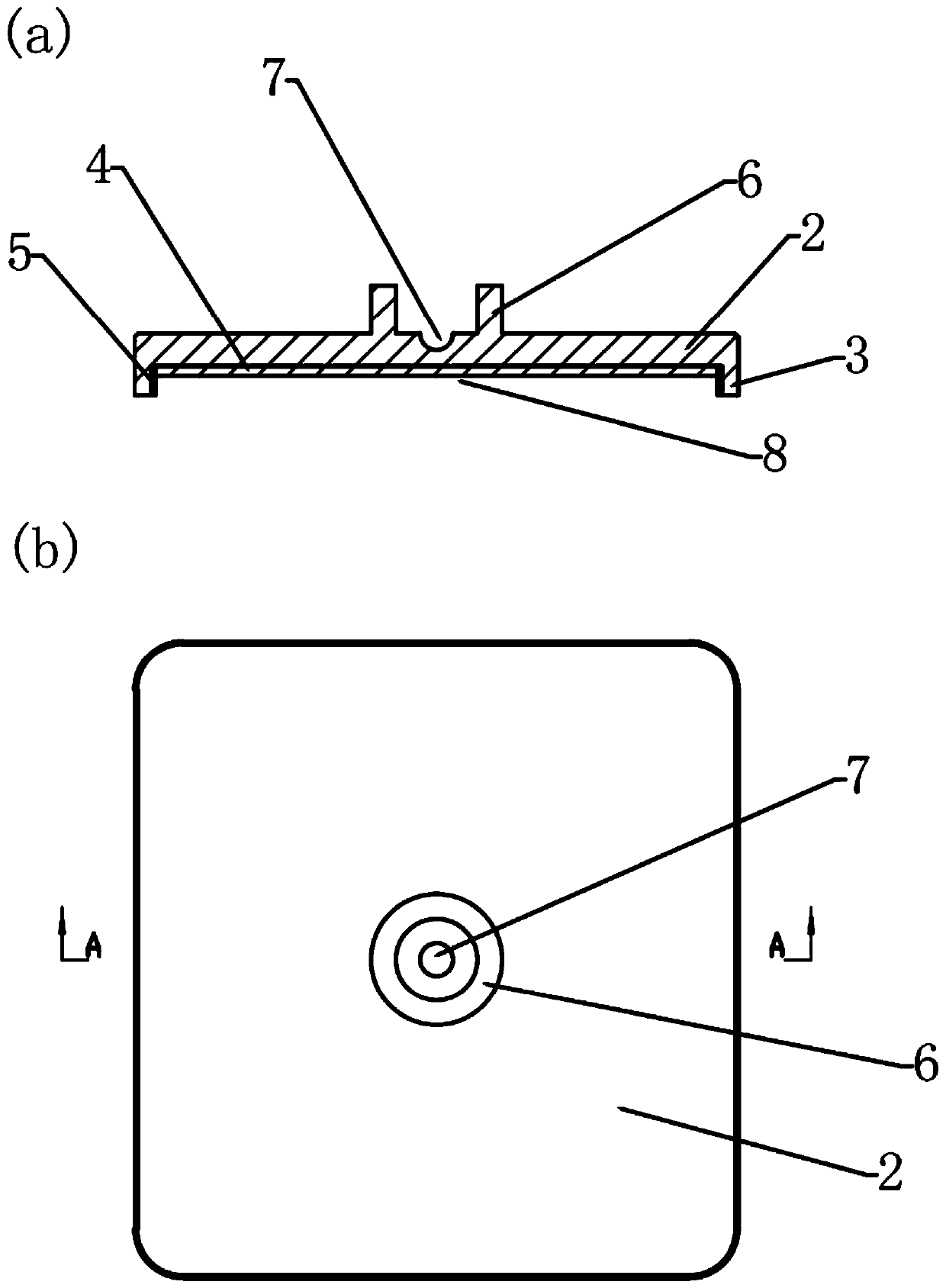

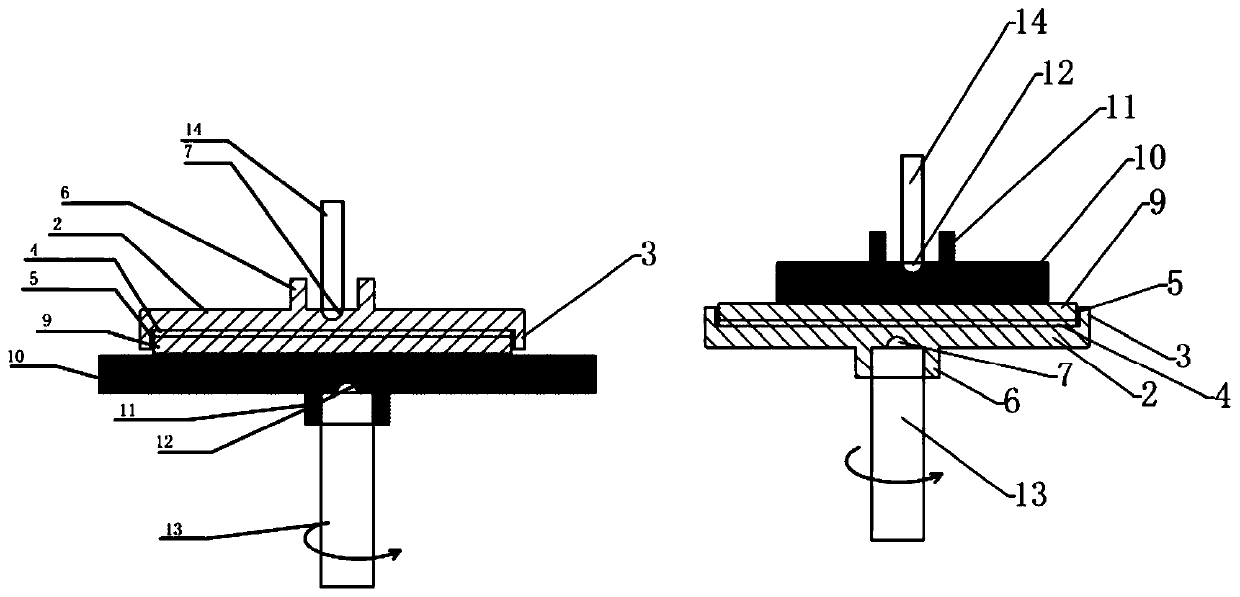

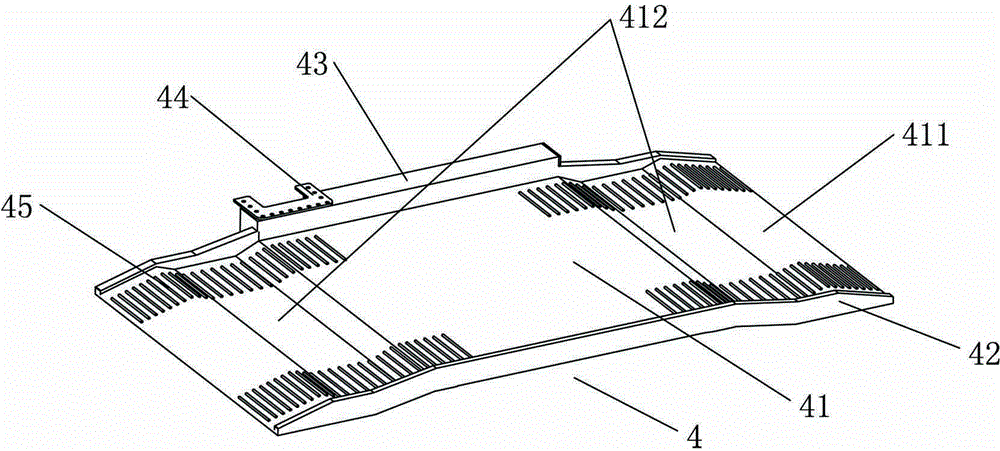

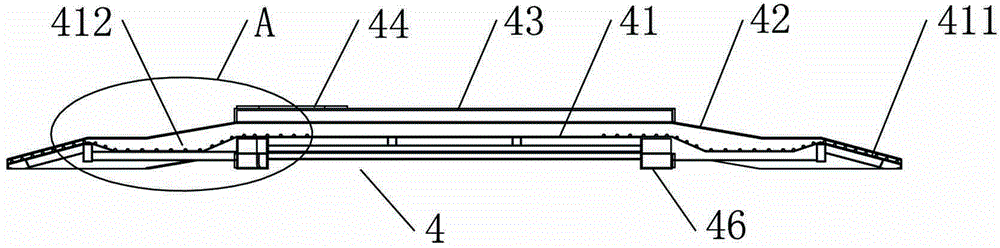

Vehicle bedplate of non-avoidance three-dimensional parking equipment

The invention relates to a vehicle bedplate of non-avoidance three-dimensional parking equipment. The bedplate comprises a support plate, retaining edges and a bottom frame, wherein the retaining edges are arranged at the left side and the right side of the support plate, and the bottom frame is arranged at the bottom of the support plate. The vehicle bedplate is characterized in that the top surface of the support plate is provided with a front tire limiting groove and a back tire limiting groove. The vehicle bedplate has the beneficial effects that (1) the two ends of the support plate of the vehicle bedplate are provided with the tire limiting grooves, so the tires of an automobile are clamped in the tire limiting grooves, and the falling of the automobile parked on the vehicle bedplate in the lifting and rotation process of the lifting vehicle bedplate due to the fact that a user forgets manual braking after parking is avoided; and (2) the left end and the right end of each tire limiting groove adopt an anti-skid design, so the static friction force between the automobile and the support plate is increased, the falling of the automobile is further prevented, and the safety in use is greatly improved.

Owner:佛山市维斯立智能停车设备有限公司

Air conditioner having water draining device

InactiveUS20060272346A1Avoid dropPrevent fallingLighting and heating apparatusSpace heating and ventilation detailsCheck valveWaste management

Owner:HUANG CHIN PIAO

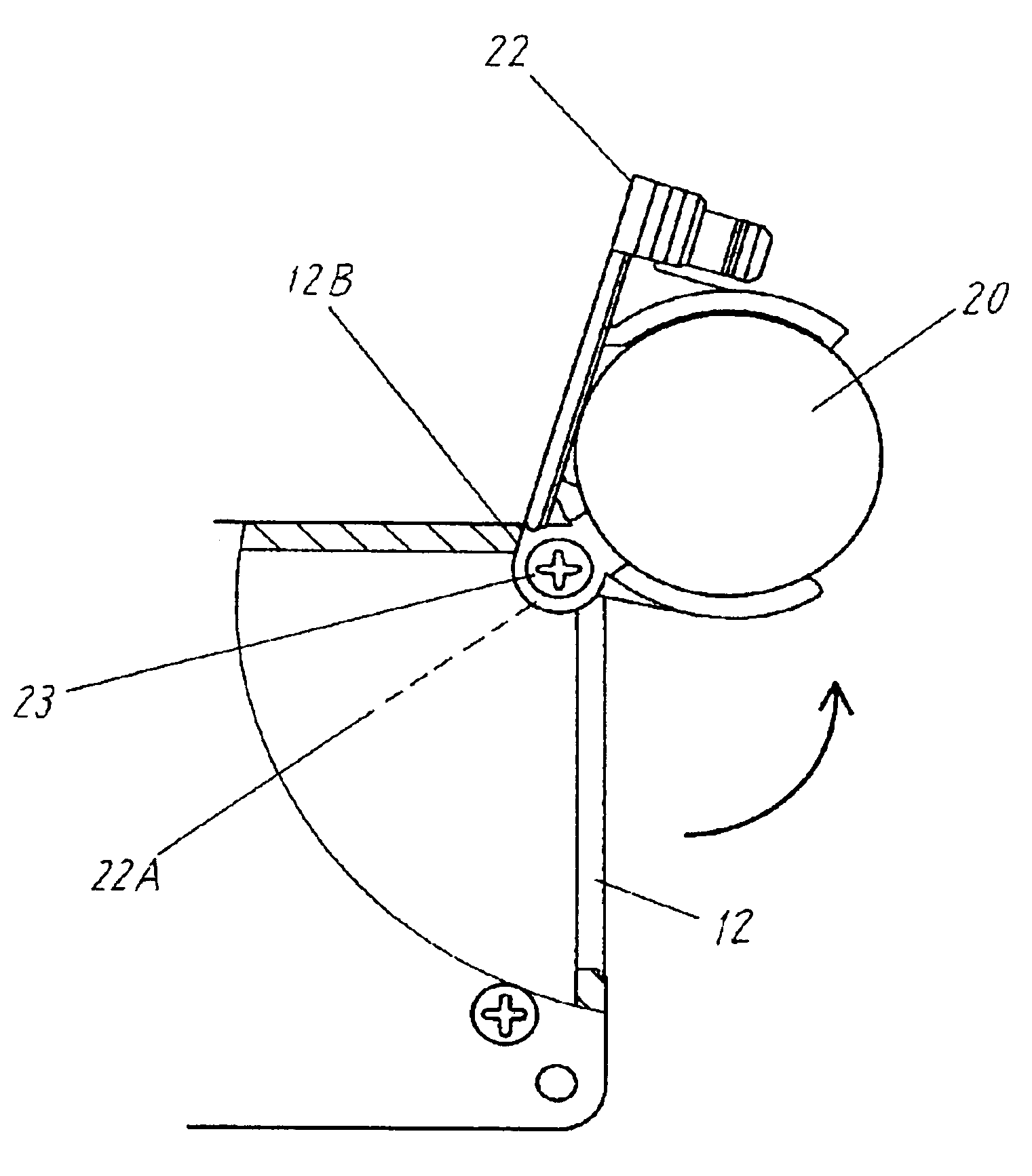

Remote control transmitter

ActiveUS7212146B2Avoid dropAvoid lostElectric signal transmission systemsTelemetry/telecontrol selection arrangementsButton batteryRemote control

A control section with control keys arranged therein is formed, and upper and lower casings for storing a circuit, and holder capable of loading a button battery and sliding within said casing are respectively provided with stopping portion abutting each other when the holder is pulled out, and thereby, it is possible to obtain a remote-control transmitter which is free from dropping or losing of the holder.

Owner:PANASONIC CORP

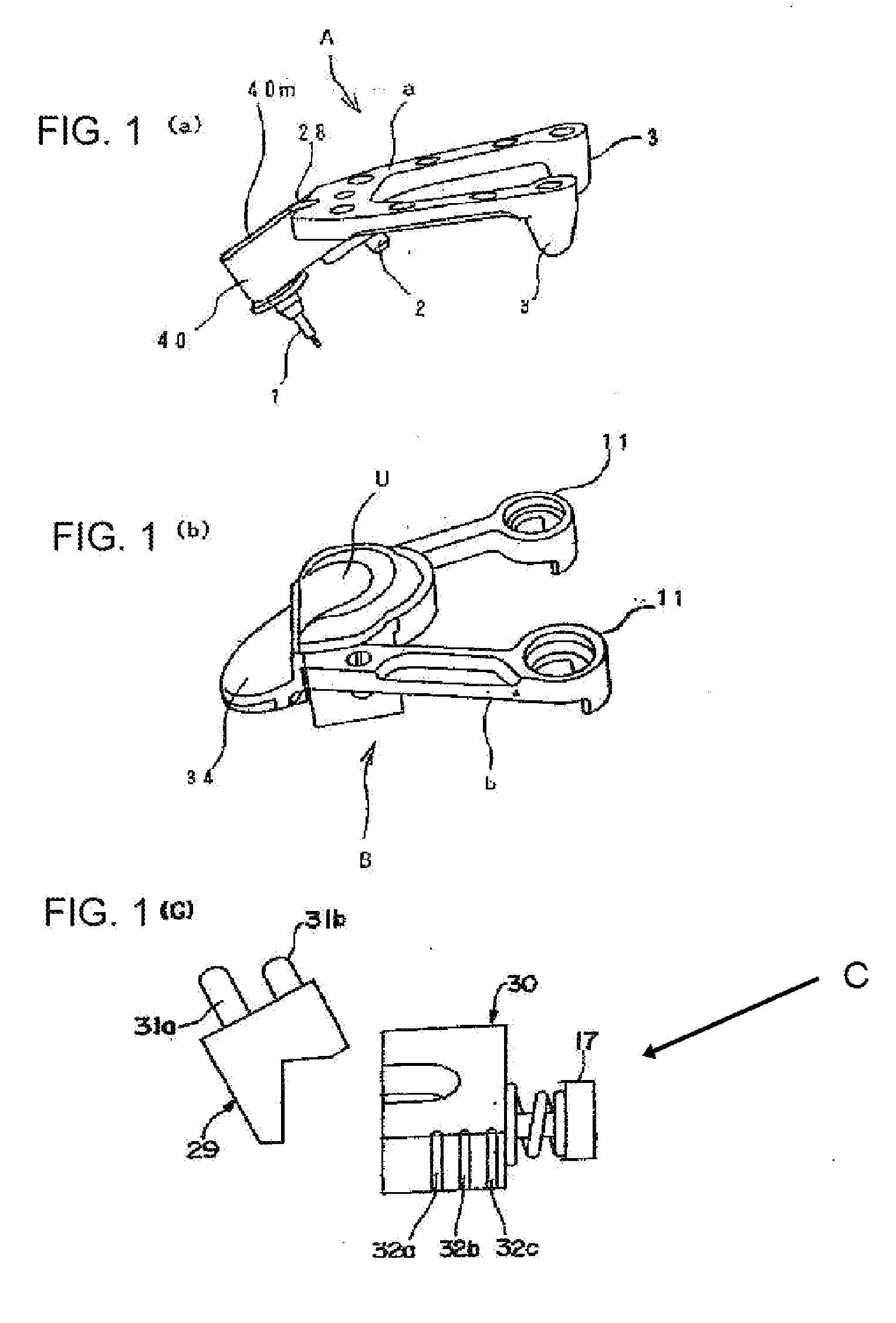

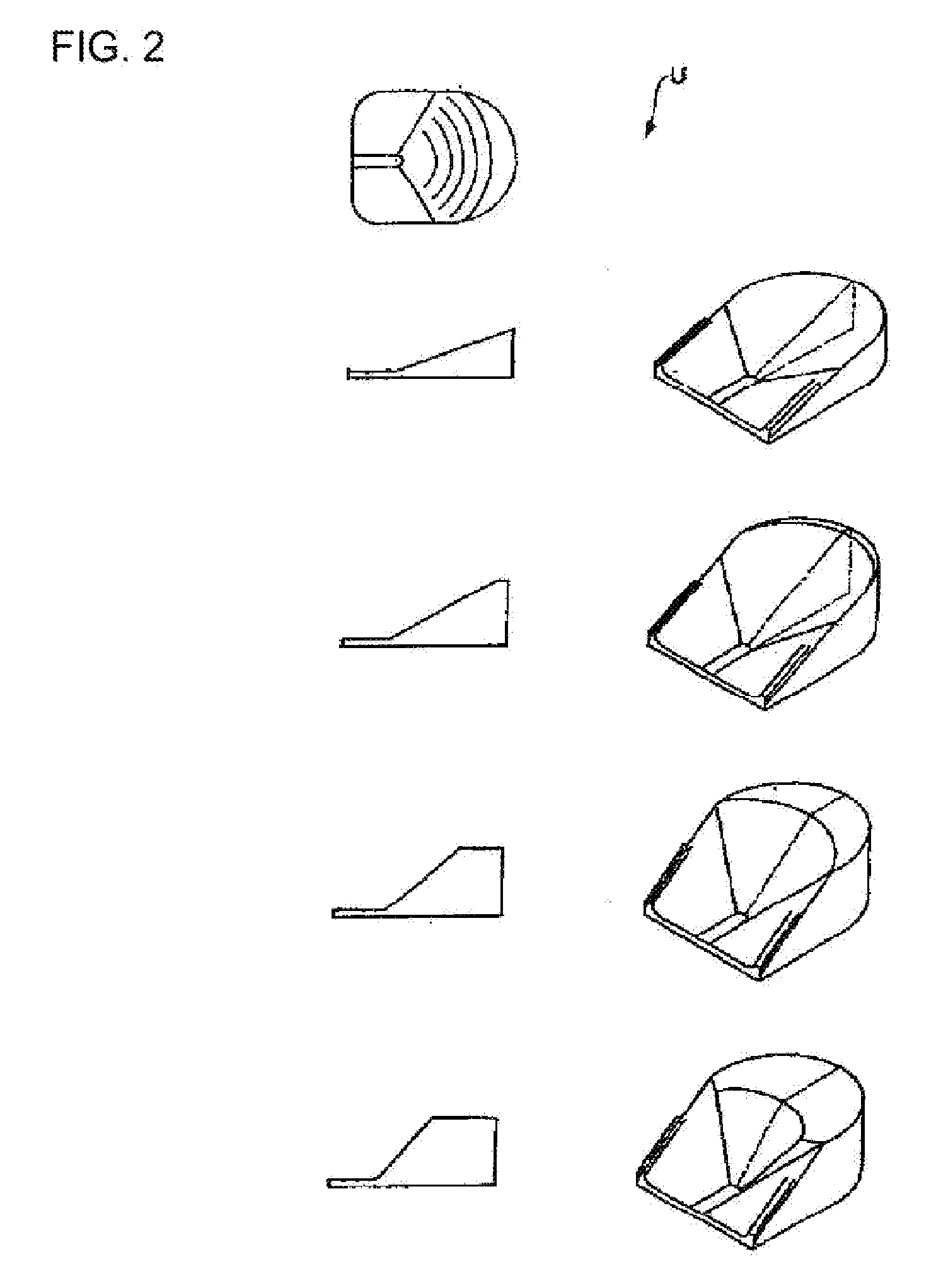

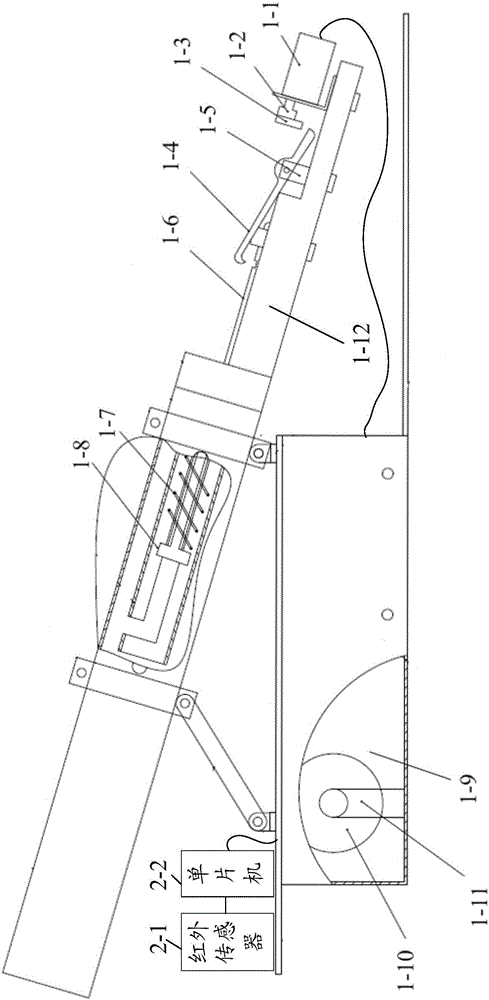

In-mouth cavity tracing device

A tracing device for use in the mouth cavity in which a center relation and a jaw movement are recorded in the odontology clinic can include an upper jaw plate, a lower jaw plate, and a coupling tool that connects the above jaw plates. The upper jaw plate can be provided with a guide prop stud, a stud installation pore, a tracing pin, a tracing pin installation pore as well as an auxiliary stud. The lower jaw plate can include a guide tracing table, a connection pore, as well as a movement line formation table. The coupling tool can include an upper jaw plate connection part, a lower jaw plate connection part as well as plate interval fixing screw. A part of, or the whole of, the connection pore, stud installation pore, tracing pin installation pore can be made of a magnetic material or associated with a magnet. The in-mouth cavity tracing device can include a lower jaw inducement guide plate made of plastic and having three dimensional slopes, and a guide tracing table having a tracing plate, and can be freely attachable / detachable to / from the main body of the lower jaw plate.

Owner:CASTING IN

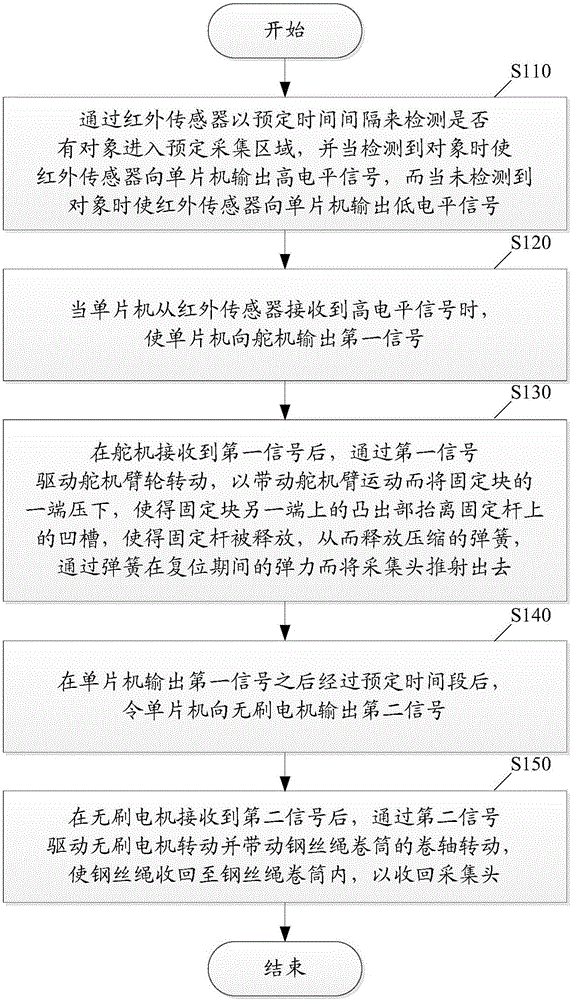

Collection method of automatic collection device for hairs of wild animals

The invention provides a collection method of an automatic collection device for hairs of wild animals. The collection method comprises the following steps: detecting whether an object enters a preset collection area at a preset time interval by an infrared sensor, and when detecting the object, driving a steering-engine arm wheel to rotate by a first signal outputted by a single chip microcomputer, so as to drive the steering-engine arm to move and press down one end of a fixed block, and enabling a convex part on the other end of the fixed block to raise from a groove in a fixed rod, so as to release the fixed rod and further release the fixed block; ejecting a collection head by elasticity of a spring during resetting; after the preset time interval, driving a brushless motor to rotate by a second signal outputted by the single chip microcomputer and drive a winding shaft of a steel-wire-rope winding drum to rotate, so as to wind a steel wire rope into the steel-wire-rope winding drum and take back the collection head. The collection method provided by the invention has the advantages that automatic collection on the hairs of the wild animals can be realized, baits are not needed, and the application range is wide.

Owner:NORTHEAST FORESTRY UNIVERSITY +2

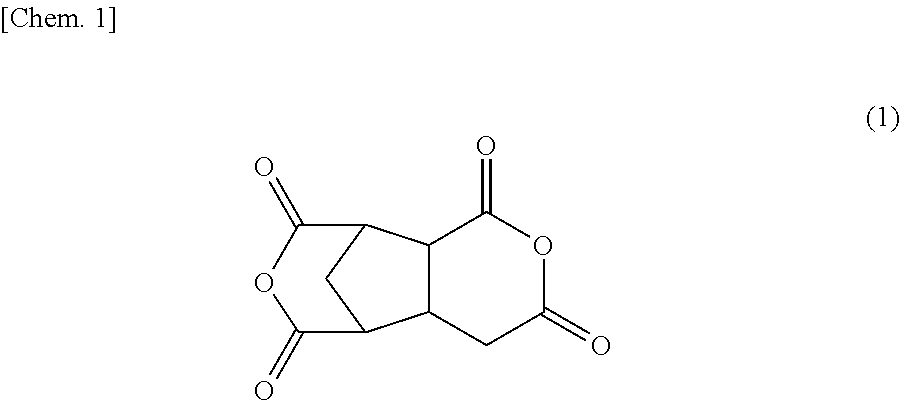

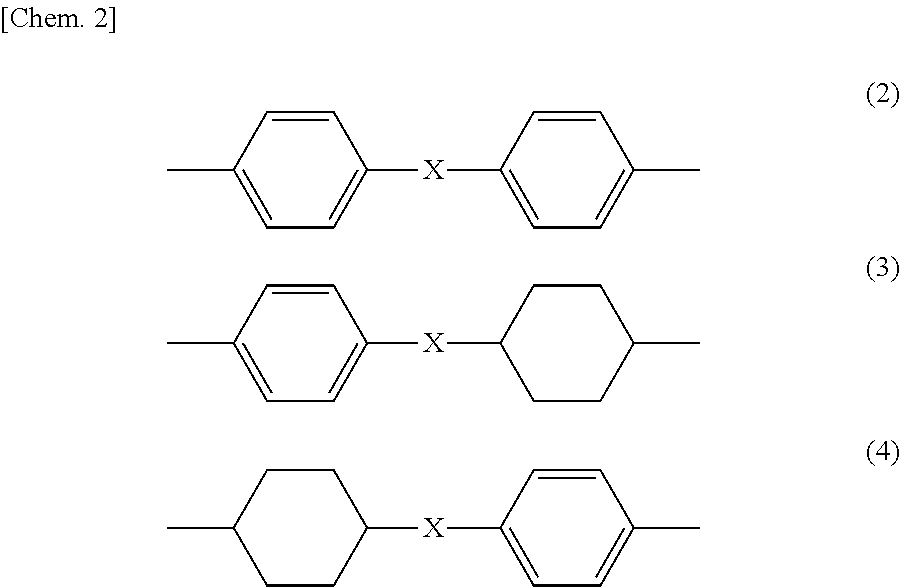

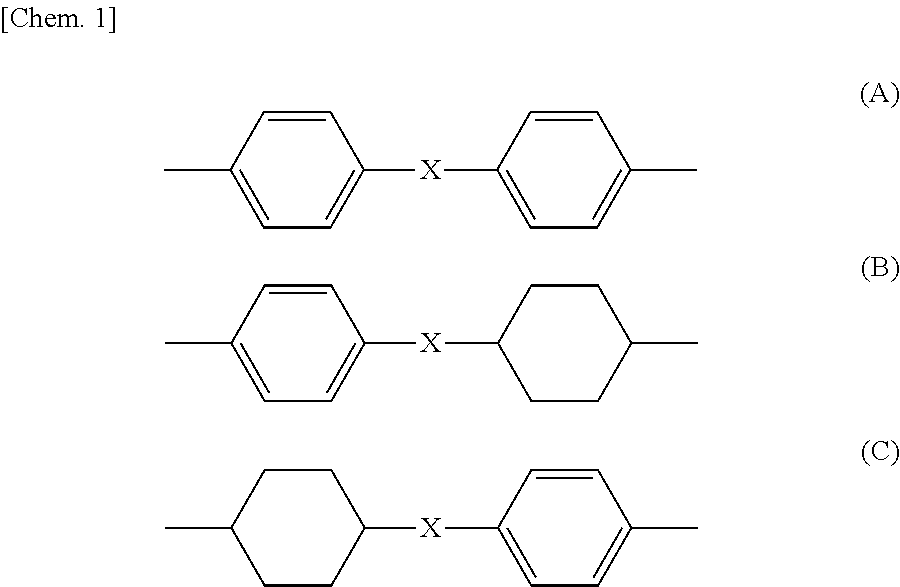

Method for manufacturing liquid crystal display device

ActiveUS20160178968A1Improve display qualityAvoid failureTube/lamp screens manufactureCoatingsPhotoisomerizationIn plane

The present invention provides a method for manufacturing a liquid crystal display device including a photo-alignment film and capable of sufficiently improving the display quality. The method for manufacturing a liquid crystal display device of the present invention is a method for manufacturing a liquid crystal display device including a photo-alignment film. The method for manufacturing a liquid crystal display device successively includes a step (1) of forming on a substrate a film from a photo-alignment-film material that contains a solvent, a polymer including a photo-functional group that is capable of causing at least one chemical reaction selected from the group consisting of photodimerization, photoisomerization, and photo-Fries rearrangement, and a polymer including a polyamic acid backbone and free from the photo-functional group; a step (2) of pre-heating the film to evaporate the solvent; a step (3) of irradiating the pre-heated film with polarized light; and a step (4) of main-heating the polarized-light-irradiated film. The liquid crystal display device is of an in-plane switching mode or a fringe field switching mode in each of which a pre-tilt angle is substantially 0°.

Owner:SHARP KK

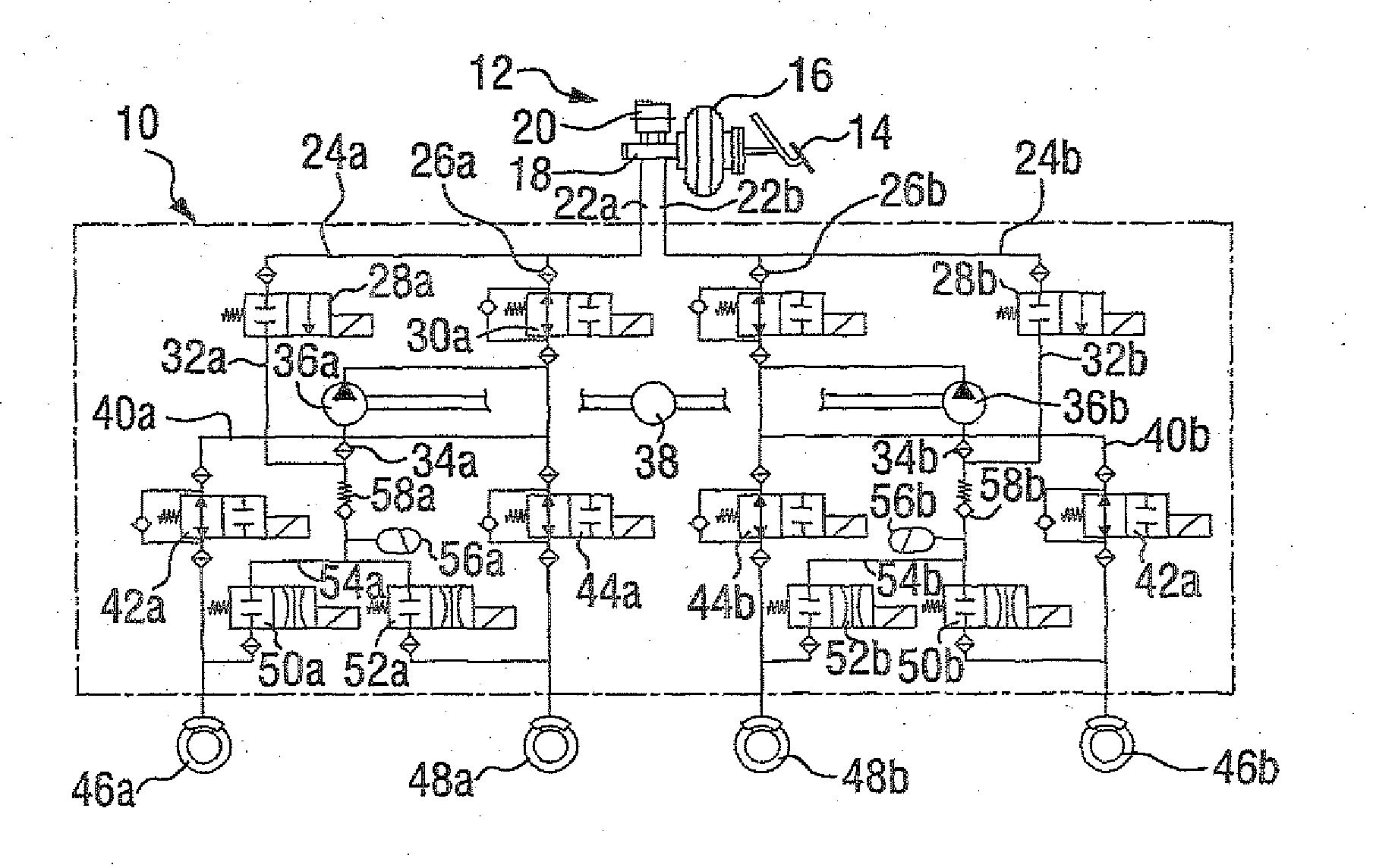

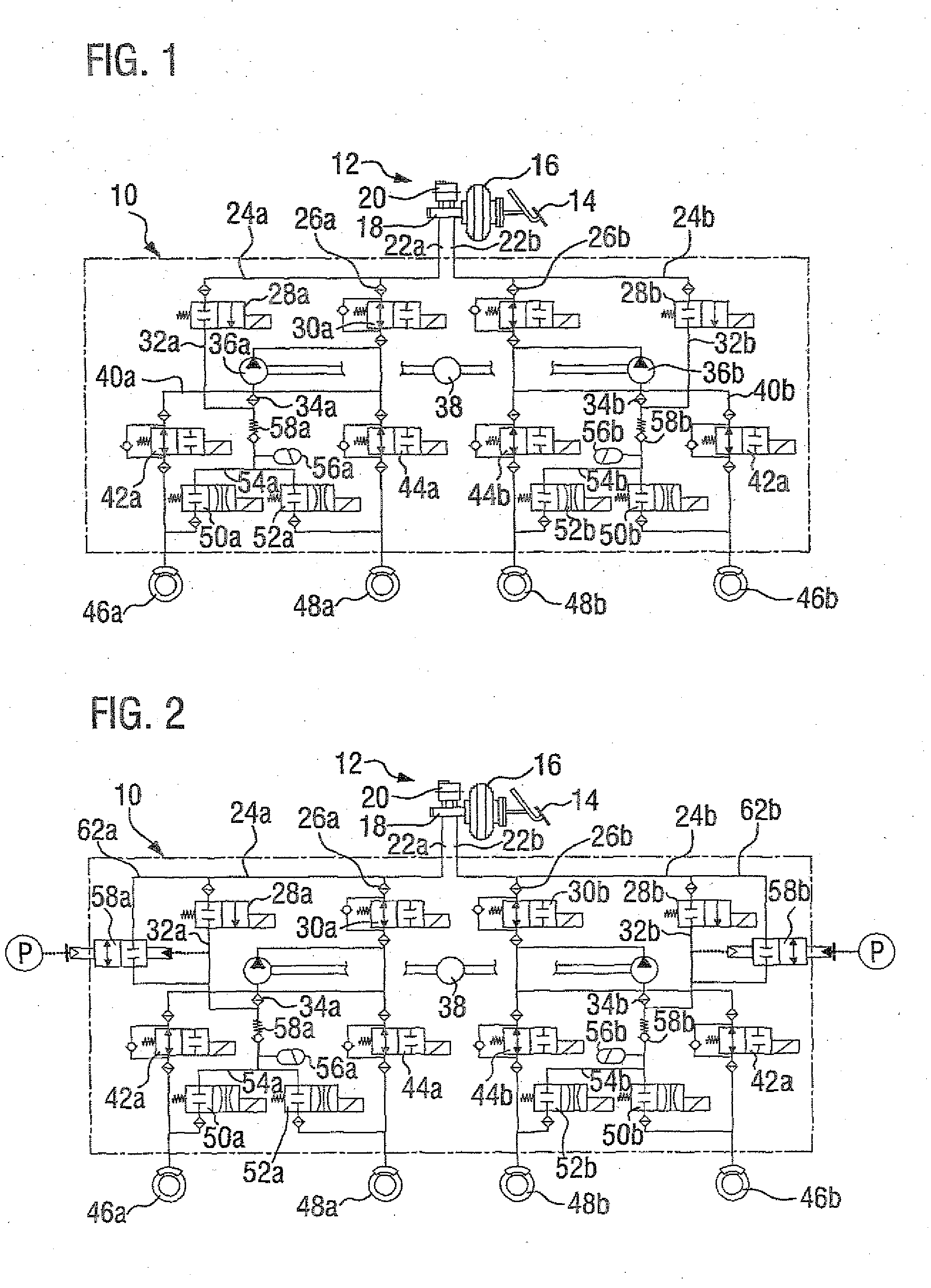

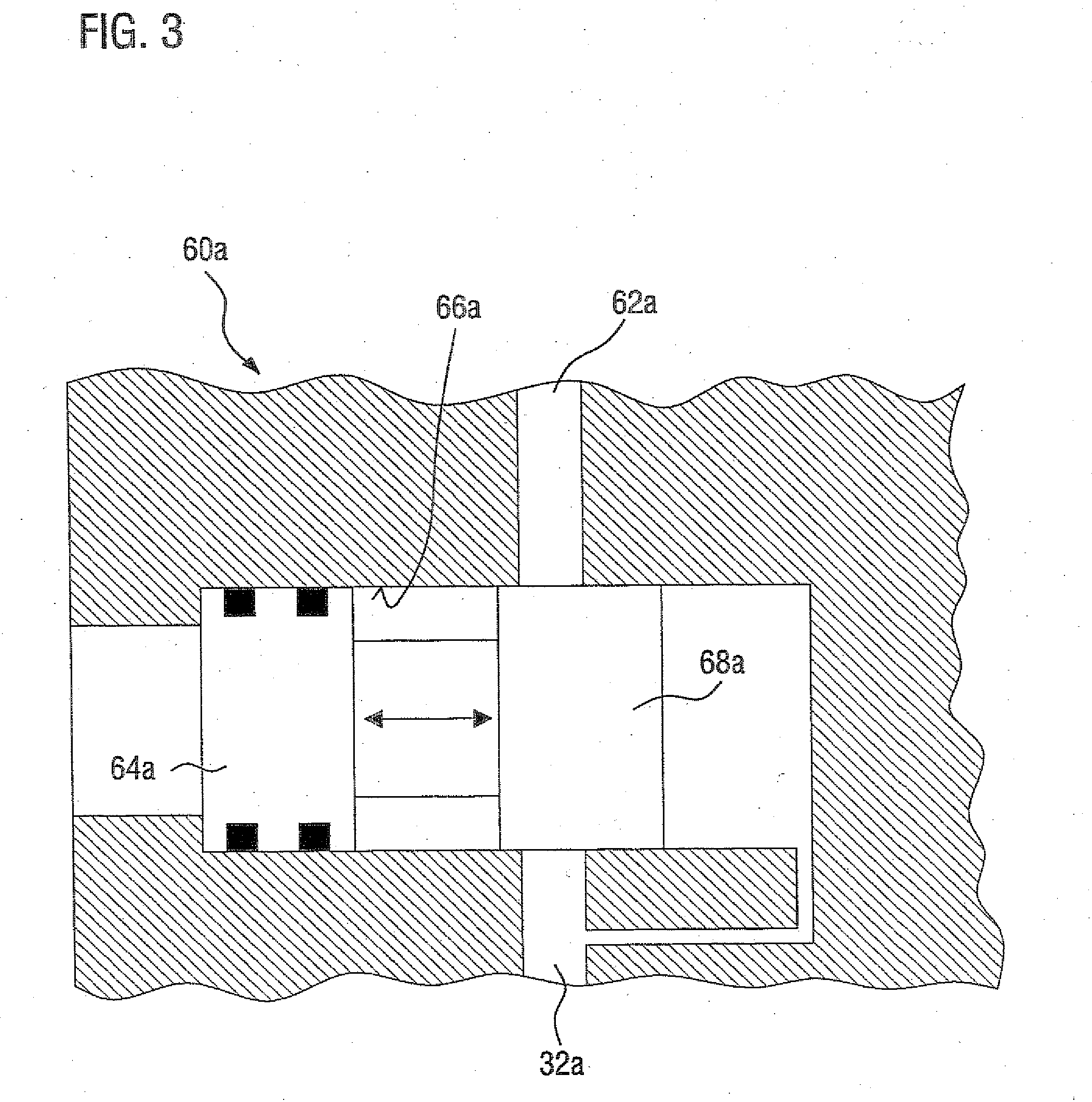

Vehicle Brake System Having A Pump

InactiveUS20080201049A1Avoid side effectsAvoid noiseAnalogue computers for trafficComputations using stochastic pulse trainsAmbient pressurePressure difference

Disclosed is a vehicle brake system having a pump and a prechamber, from which the pump can extract a fluid by suction, and having a switching valve, by means of which fluid can optionally be fed to the prechamber. A bypass valve connected in parallel with the switching valve is switched as a function of the pressure difference between the ambient pressure and the prechamber pressure.

Owner:ROBERT BOSCH GMBH

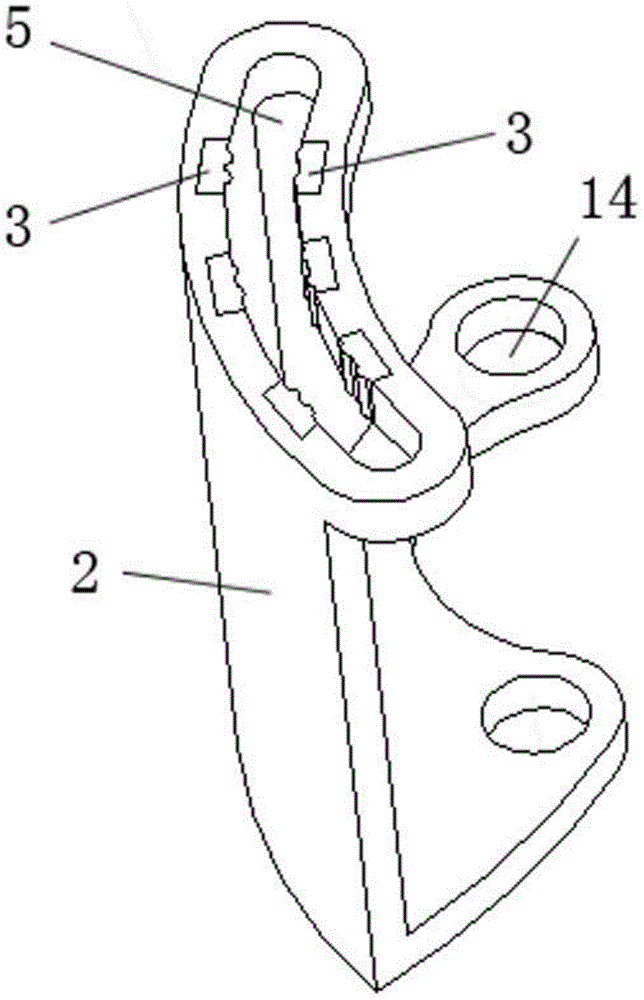

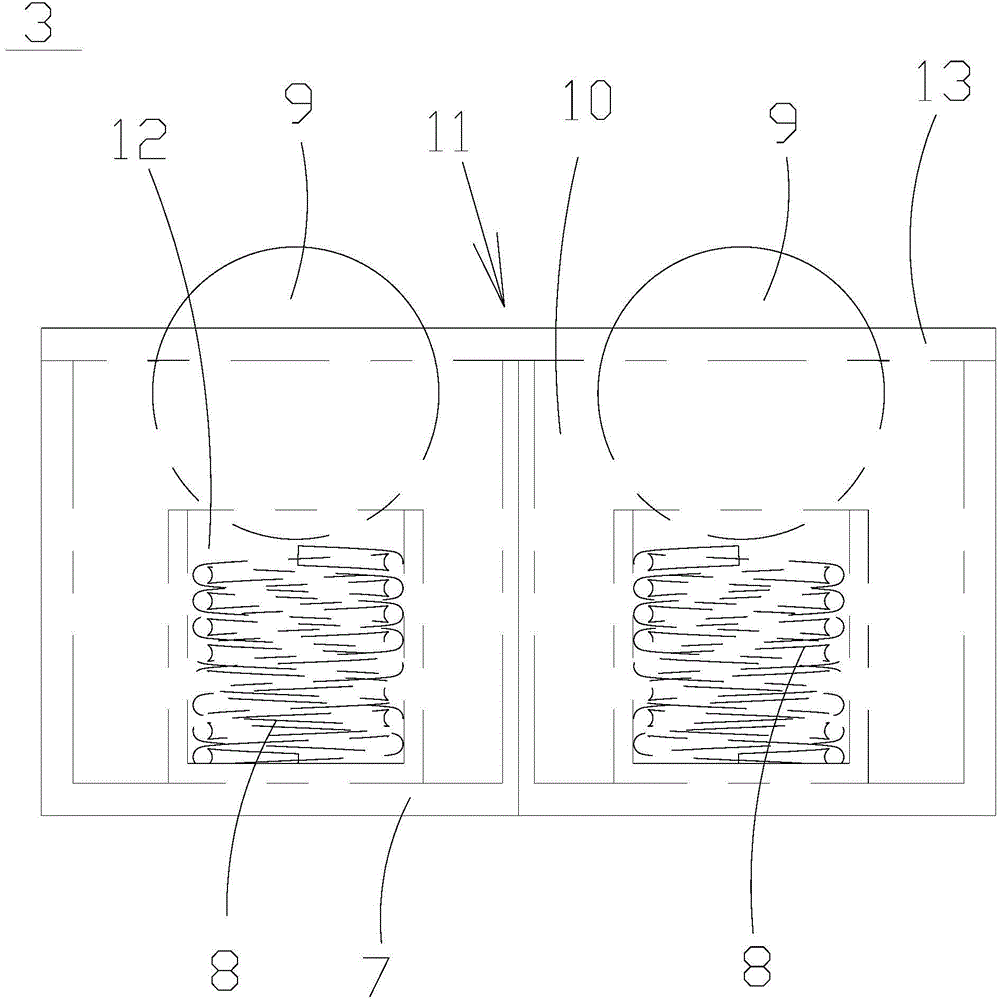

Transmission shifting mechanism, shifting rocker arm and damping device for shifting rocker arm

InactiveCN106286793AIncrease the feeling of shifting gearsAvoid dropGearing controlEngineeringRocker arm

The invention relates to the technical field of vehicles, and provides a transmission shifting mechanism, a shifting rocker arm and a damping device for the shifting rocker arm. The damping device for the shifting rocker arm comprises a damping support and elastic damping blocks, a slideway which extends and is used for containing a protruding rod of the shifting rocker arm is formed in the damping support, the elastic damping blocks are arranged on the damping support so as to be used for pressing the protruding rod when the elastic damping blocks make contact with the protruding rod, and therefore the phenomenon that the shifting rocker arm and a shifting rod shake due to internal vibration of a transmission is significantly eliminated; the shifting feeling of transmission is correspondingly increased, and the situation that the transmission is failed in shifting is prevented.

Owner:GREAT WALL MOTOR CO LTD

Air conditioner having water draining device

InactiveUS7266968B2Avoid dropPrevent fallingLighting and heating apparatusSpace heating and ventilation detailsCheck valveWaste management

Owner:HUANG CHIN PIAO

Air conditioner having water draining device

InactiveUS7150161B2Avoid dropPrevent fallingCorrosion preventionStationary conduit assembliesPistonWaste management

An air conditioner includes an outdoor device coupled to an indoor device via a hose, and a water draining device coupled between the outdoor device and the indoor device, to force water that may be generated in the indoor device from the indoor device to the outdoor device, and to prevent the water from dropping from the indoor device. The water draining device includes a casing having a channel to slidably receive a piston which may pump the water from the indoor device to the outdoor device. The indoor device includes a tray disposed in a container to collect water. The outdoor device includes a fan device to blow and to dry the water.

Owner:HUANG CHIN PIAO

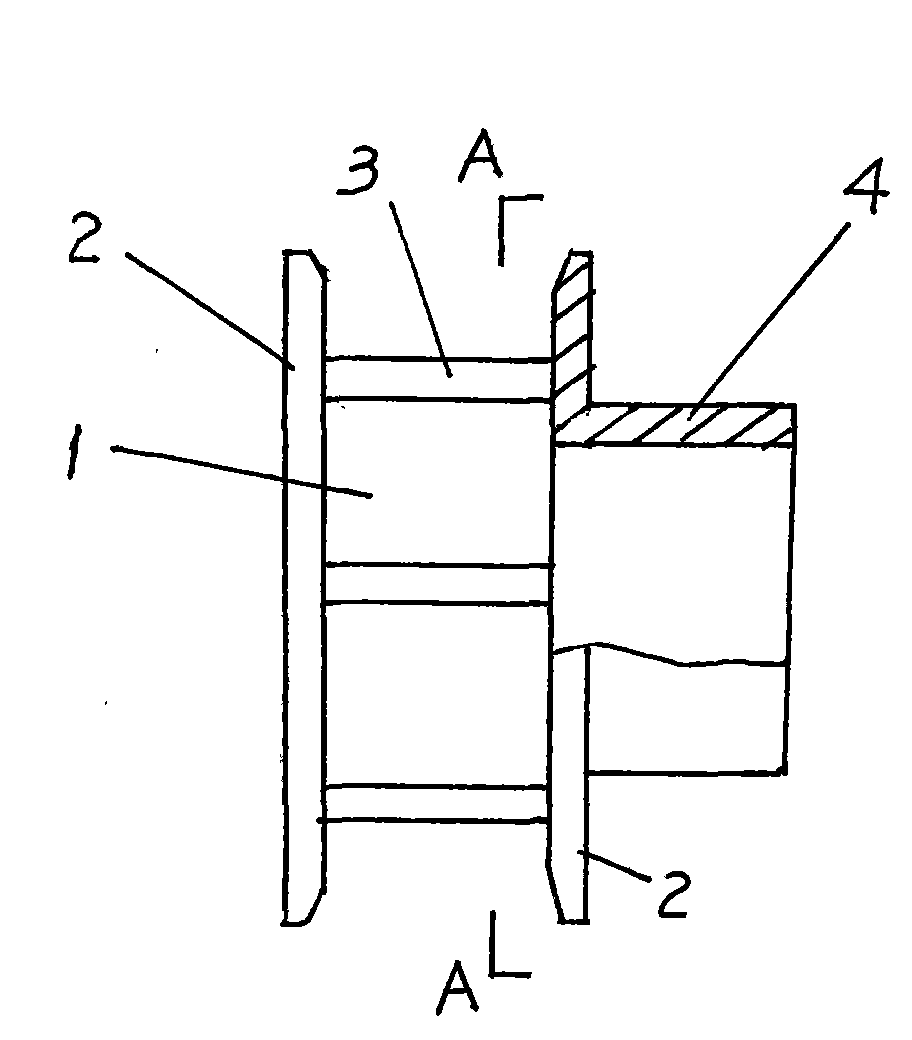

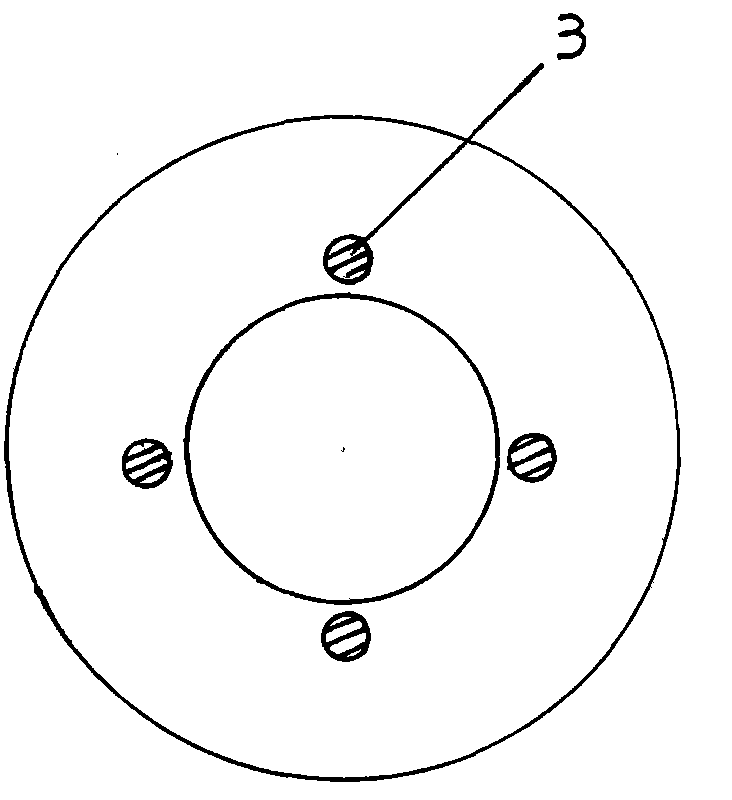

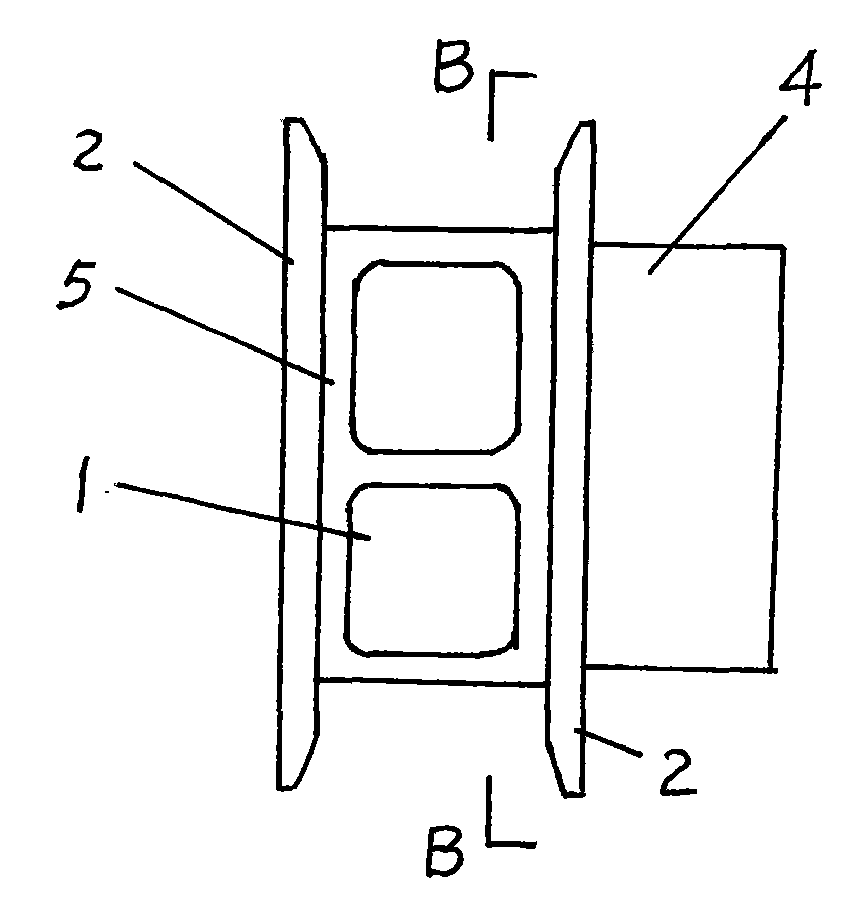

Novel belt pulley

The invention relates to a novel belt pulley comprising a groove pulley main body with a notch. The novel belt pulley is characterized in that the groove pulley main body is provided with two pulley pieces which are connected by a connection part with a leakage hole and form the notch with a connection part. The utility model has the advantages that the notch of the groove pulley can internally leak earth and sundries, the falling-off of the pulley is prevented, the structure and the technology are simplified, the cost is low, and the maintenance is avoided.

Owner:刘建国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com