Wind driven generator blade lightning protection device with metal blade tip

A technology for fan blades and lightning protection devices, which is applied to wind turbines, wind turbines, motors and other directions that are consistent with the wind direction, can solve the problems of unsatisfactory conduction effect, self-heavy protection device, poor lightning protection effect, etc., and achieves a simple structure. , low cost, reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

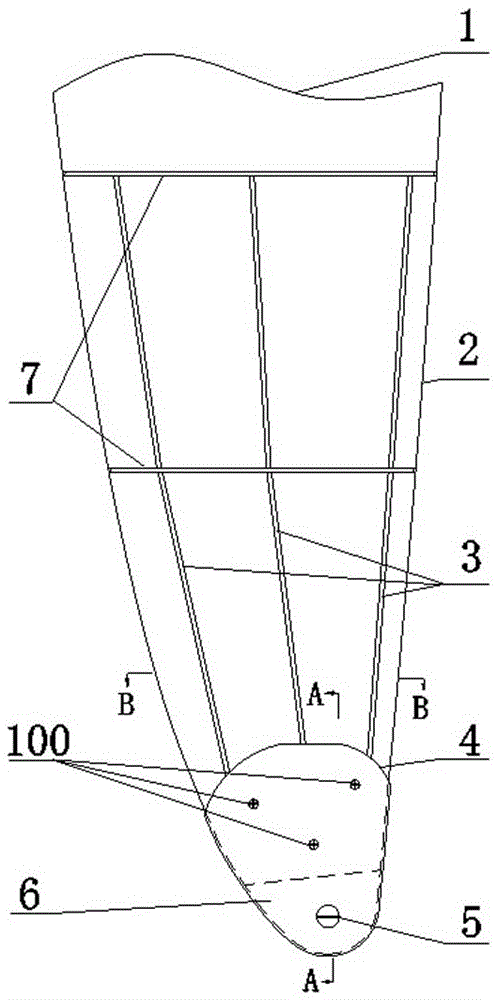

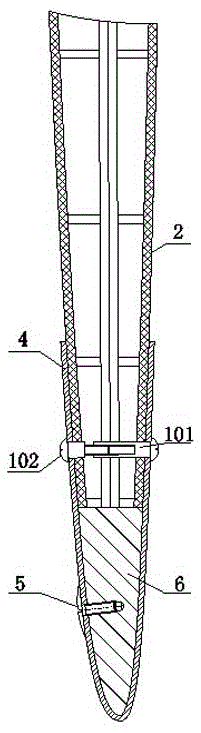

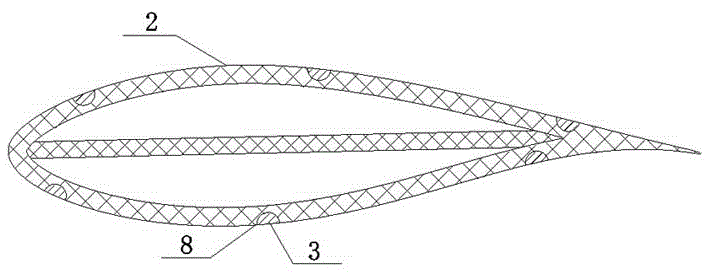

[0024] Embodiment 1: as Figure 1-3 As shown, the fan blade lightning protection device with metal blade tip, the metal blade tip 6 arranged on the fan blade tip 2, the metal protective cover 4 that is set on the metal blade tip 6 and electrically connected with the metal blade tip 6, At least two conductive strips 3 are respectively extended on the upper and lower two arc-shaped surfaces of the open end of the metal protective sheath 4. In this embodiment, the number of conductive strips is preferably 6, and the length of the conductive strips 3 is 100 Å of the metal protective sheath. 3 times of 4, the conductive strip is a metal wire with a cross-sectional area of 10mm 2 , the conductive strip 3 extends axially along the fan blade 1 and is arranged radially at intervals, and two conductive rings 7 are arranged around the blade tip 2 at the rear of the opening end of the metal protective sleeve 4, and the conductive ring 7 is arranged along the 2 axis of the blade tip. Ar...

Embodiment 2

[0025] Embodiment 2: as Figure 1-3 As shown, the conductive strip is a metal strip with a cross-sectional area of 30mm 2 The diameter of the pan head of the conductive connecting bolt 5 is 35 mm. The material of the metal protective cover 4, the conductive connecting bolt 5, the conductive strip 3 and the conductive ring 7 of this embodiment is stainless steel, and the rest of the structure is as described in embodiment 1.

Embodiment 3

[0026] Embodiment 3: as Figure 1-3 As shown, the conductive strip is a metal strip with a cross-sectional area of 50mm 2 The diameter of the pan head of the conductive connecting bolt 5 is 40 mm. The material of the metal protective cover 4, the conductive connecting bolt 5, the conductive strip 3 and the conductive ring 7 of this embodiment is aluminum, and the rest of the structure is as described in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com