Novel welding roller carrier electrode mounting structure

A technology of installation structure and roller frame, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of blocked current conduction, large welding spatter, poor welding, etc. The effect of improving electrical conductivity and eliminating friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be described in detail below with reference to the accompanying drawings and embodiments.

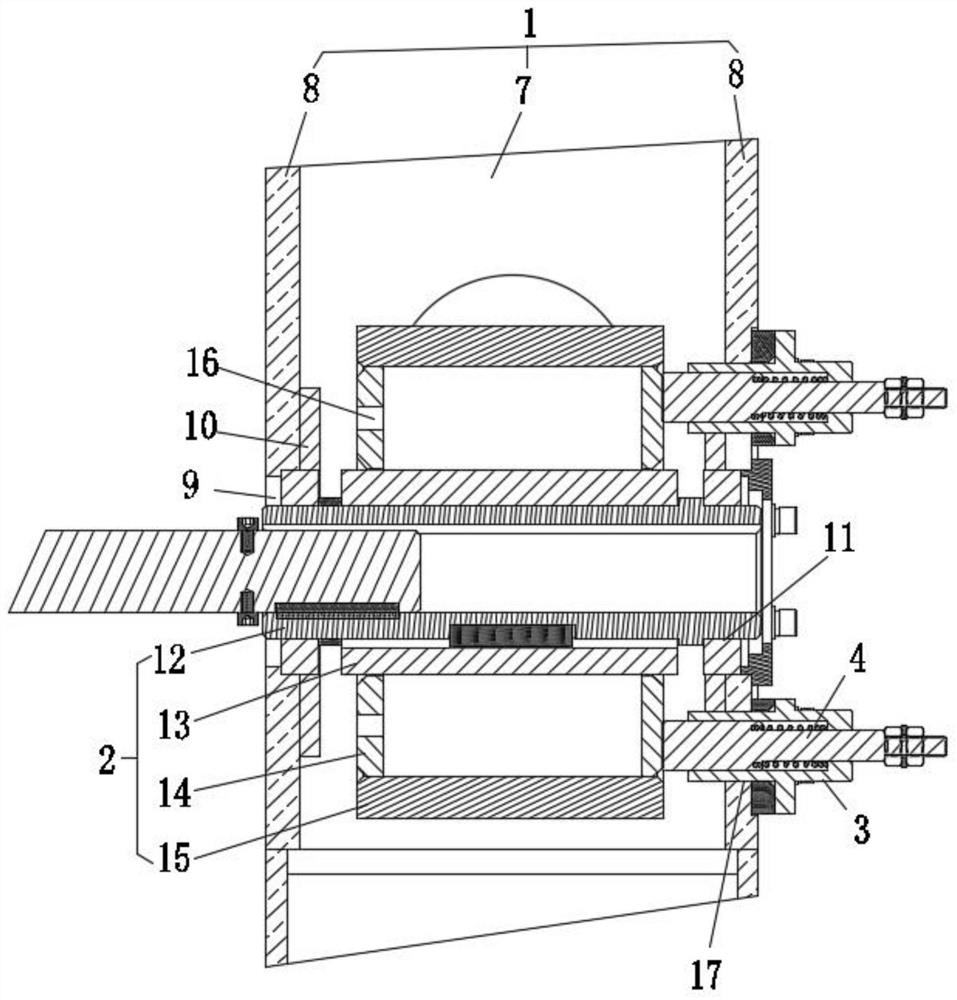

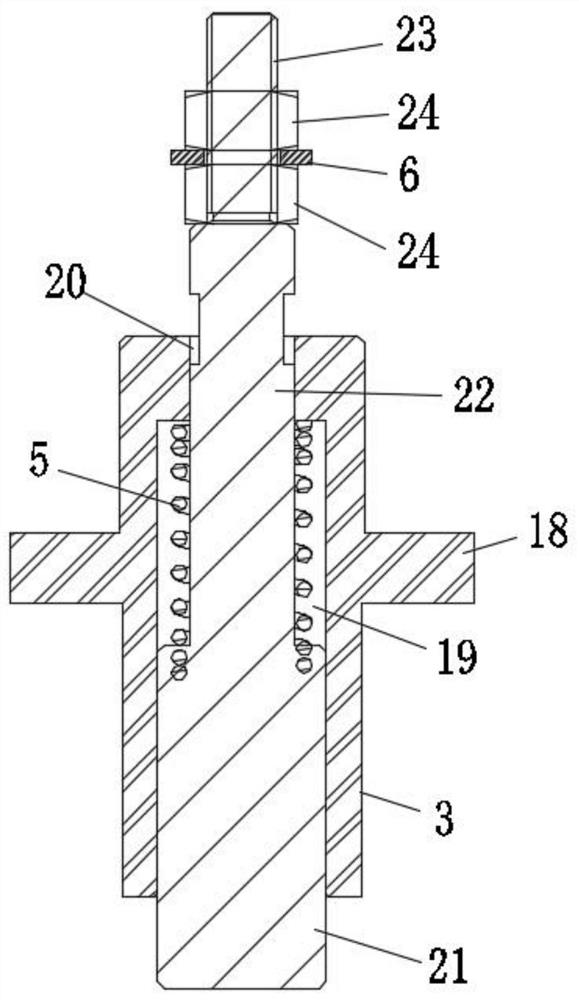

[0016] Such as figure 1 and figure 2 As shown in the figure, a new electrode installation structure of a welding roller frame includes a roller frame 1 and a roller 2. The roller frame 2 is rotatably mounted on the roller frame 1, and an insulating guide sleeve 3 is installed on the side of the roller frame 1 on the roller frame 2. A copper electrode 4 is set in the insulating guide sleeve 3, and a compression spring 5 is sandwiched between the copper electrode 4 and the insulating guide sleeve 3. The flat end of 2 abuts, and the afterbody of copper electrode 4 is equipped with wire lug 6, and wire lug 6 is connected with the negative pole of welding power supply with cable.

[0017] In this technical solution, the copper electrode electrically connected to the negative pole of the welding power source is directly contacted to the roller of the roller frame,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com