Preparation method of anti-static high-strength medical fabric

A high-strength, anti-static technology, applied in the direction of conductive/antistatic filament manufacturing, cellulose/protein conjugated artificial filament, conjugated synthetic polymer artificial filament, etc., can solve the problem of insufficient toughness, easy damage, easy Generate static electricity and other problems to achieve the effect of enhanced conductivity, excellent chemical corrosion resistance, and enhanced conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

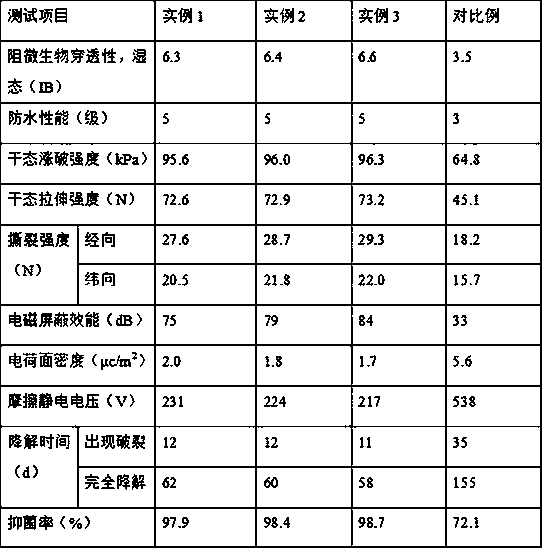

Examples

example 1

[0024]Weigh 500g of bamboo slices and put them into a beaker, soak them in sodium hydroxide solution with a mass fraction of 8%, put the beaker in a water bath with a water bath temperature of 95°C, and react at a constant temperature for 3 hours. After the reaction is completed, filter to obtain a filter residue and wash it with distilled water After 3 times, put the filter residue into the flask; add a sulfuric acid solution with a mass fraction of 12% to the above flask to impregnate the above filter residue, put the flask into a water bath with a water bath temperature of 95°C, react at a constant temperature for 3 hours, and cool naturally after the reaction Filtrate to room temperature to obtain a filter cake, put the filter cake in an oven with a temperature of 85°C and dry for 2 hours, put the dried filter cake in a muffle furnace, raise the temperature to 450°C under a nitrogen atmosphere, and calcine at a high temperature for 60 minutes, Put it into a grinder to grind...

example 2

[0026] Weigh 550g of bamboo slices and put them into a beaker, soak them in a sodium hydroxide solution with a mass fraction of 10%, put the beaker in a water bath with a water bath temperature of 97°C, and react at a constant temperature for 3 hours. After the reaction is completed, filter to obtain a filter residue and wash it with distilled water After 4 times, put the filter residue into the flask; add a sulfuric acid solution with a mass fraction of 13% to the above flask to impregnate the above filter residue, put the flask into a water bath with a water bath temperature of 97°C, react at a constant temperature for 3 hours, and cool naturally after the reaction Filtrate to room temperature to obtain a filter cake, put the filter cake in an oven with a temperature of 87°C and dry for 2 hours, put the dried filter cake in a muffle furnace, raise the temperature to 475°C under a nitrogen atmosphere, and calcinate at a high temperature for 65 minutes, Put it into a grinder to...

example 3

[0028] Weigh 600g of bamboo slices and put them into a beaker, soak them in a sodium hydroxide solution with a mass fraction of 12%, put the beaker in a water bath with a water bath temperature of 100°C, and react at a constant temperature for 4 hours. After the reaction is completed, filter to obtain a filter residue and wash it with distilled water After 5 times, put the filter residue into the flask; add a sulfuric acid solution with a mass fraction of 15% to the above flask to impregnate the above filter residue, put the flask into a water bath with a water bath temperature of 100°C, and react at a constant temperature for 4 hours, and cool naturally after the reaction Filtrate to room temperature to obtain a filter cake, put the filter cake in an oven with a temperature of 90°C and dry for 3 hours, put the dried filter cake in a muffle furnace, raise the temperature to 500°C in a nitrogen atmosphere, and calcinate at a high temperature for 70 minutes, Put it into a grinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com