Integrated aqueous medium one-way valve

A water medium, one-way valve technology, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problems of large occupied space, high processing difficulty, high processing cost, high manufacturing cost, and achieve strong corrosion resistance, Wide range of use and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

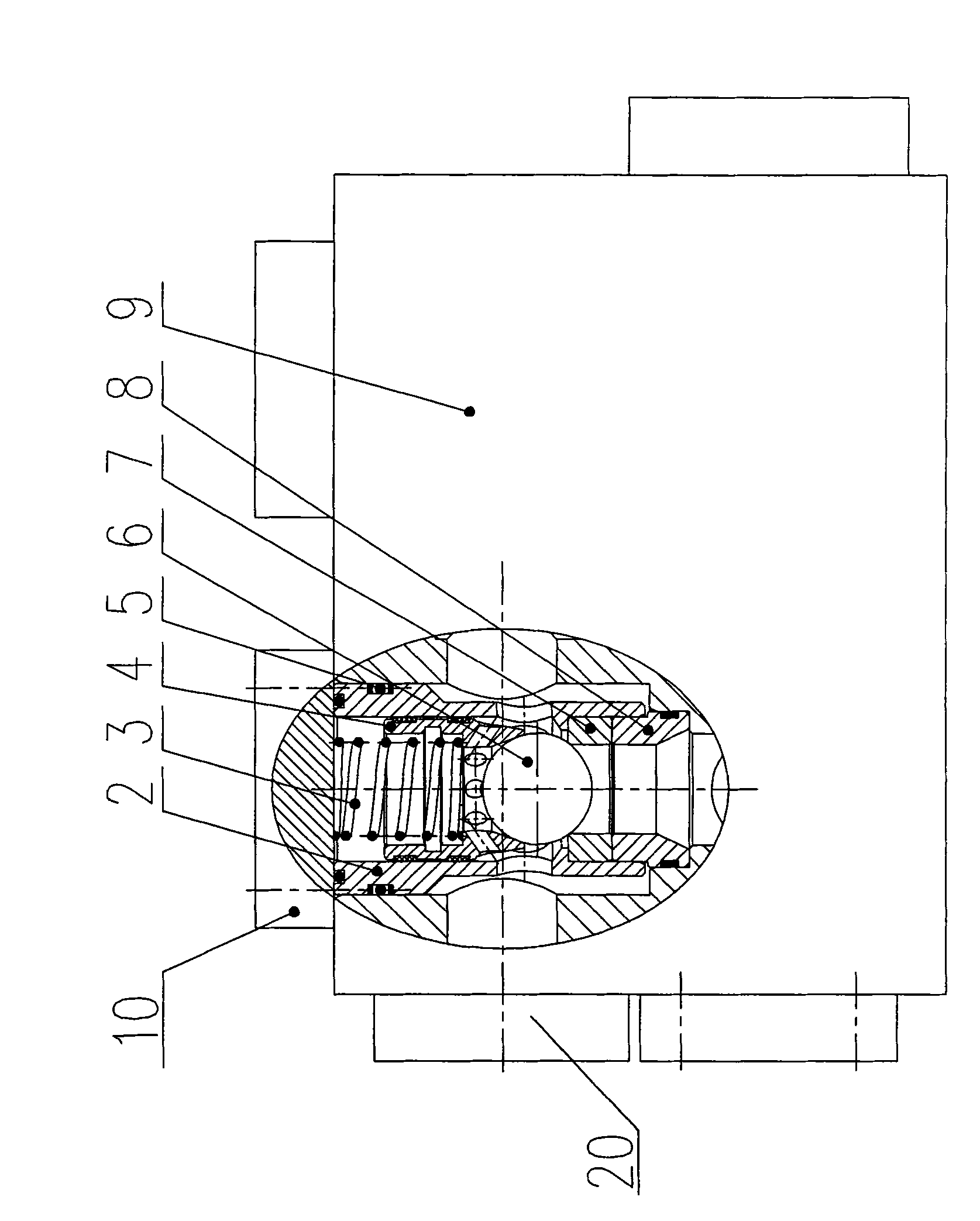

[0022] refer to figure 1 As shown, the integrated water medium check valve of the present invention utilizes an integrated block base 9 to integrate multiple passages and multiple water medium check valves (can be one or multiple) to achieve multifunctional combination to expand the scope of use.

[0023] There can be one or more channels opened in the base of the integrated block. The direction of opening channels (that is, the opening directions can be multi-directional) and the quantity can be specifically set according to actual needs. Each channel can be set independently, or they can be connected together. figure 1 The partial section in , shows two vertically intersecting and intersecting passages. The ports of each channel can be communicated with external pipelines through flanges. figure 1 In the shown embodiment, there are five flanges, representing five ports, which are arranged in three directions, and the channel port flanges where the integrated water medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com