Preparation technology of forging elbow

A preparation process and elbow technology, applied in the field of forging elbow preparation technology, can solve the problems of cracking at thin walls, affecting product service life, uneven wall thickness of the inner and outer rings of the elbow, etc., and achieving the effect of simple process

Active Publication Date: 2010-12-01

SHANGHAI CHANGQIANG POWER

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

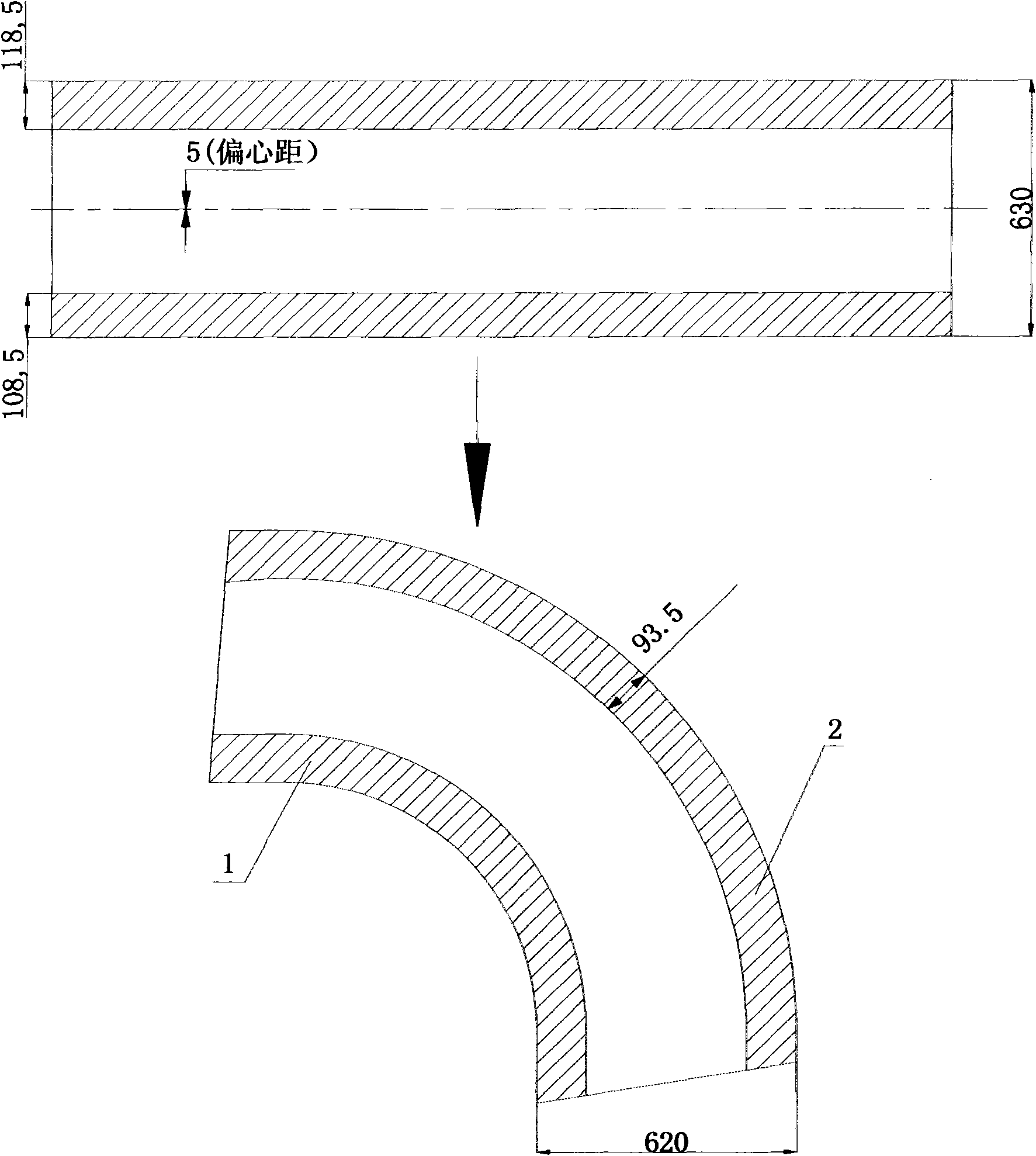

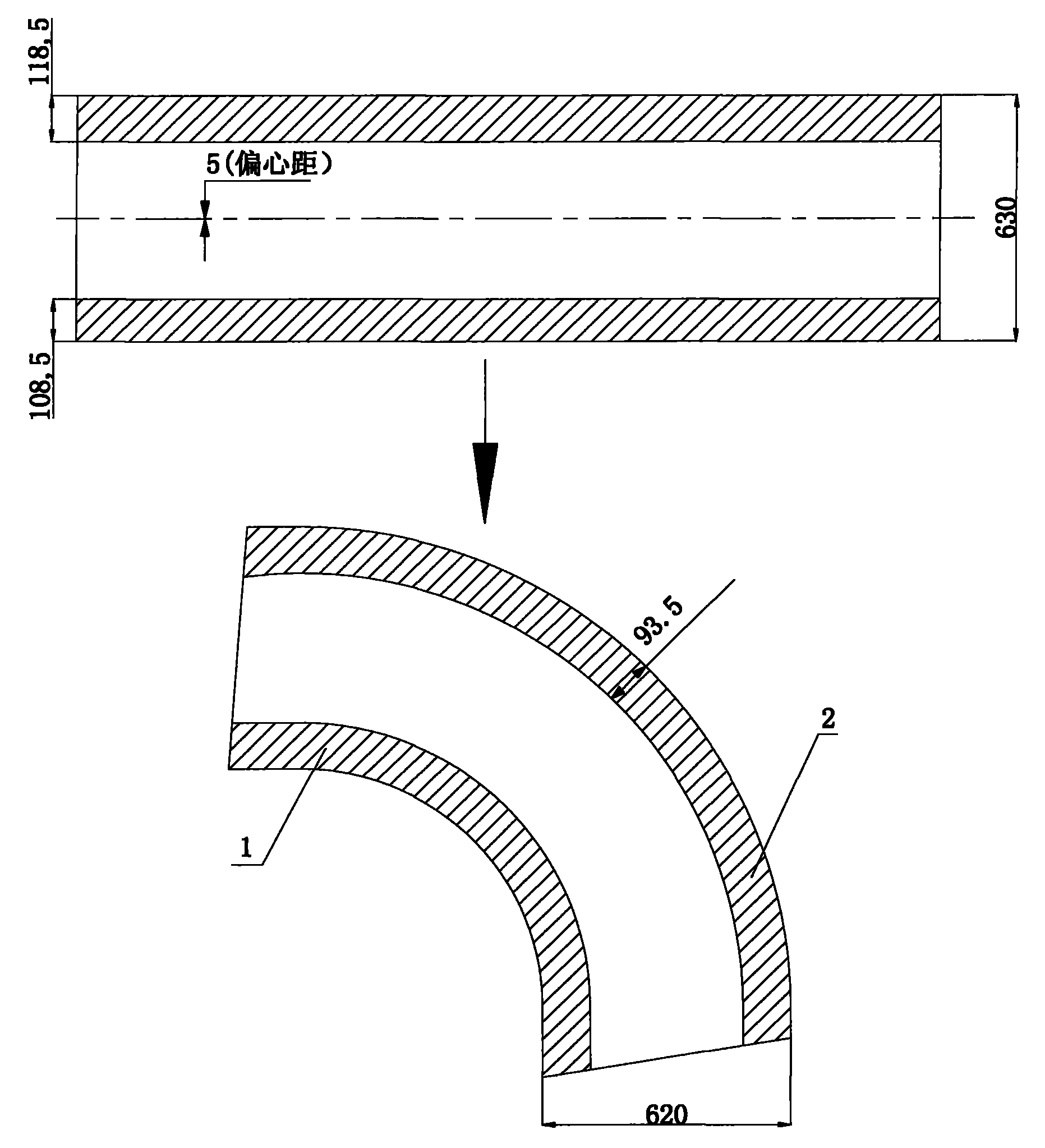

The current elbow manufacturing process is mainly to bend the forged pipe with symmetrical center distance into an elbow, which causes the wall thickness of the outer ring of the elbow to become thinner after bending, while the wall thickness of the inner ring becomes thicker after bending. The wall thickness of the inner and outer rings of the elbow is uneven, so that after welding to related equipment in practical applications, it is easy to cause cracks at the thin wall, which affects the service life of the product

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the elbow preparation technical field, in particular to a preparation technology of forging elbow. The technology is characterized in that: (1) forging a pipe, namely a forging rod is fixed and forged into a forging pipe, and the eccentricity of the forging pipe is 4-6% of the wall thickness of a finished elbow; (2) bending, namely half-round thin pipe wall of the forgingpipe formed by eccentricity is made into the inner ring of an elbow while the half-round thick pipe wall is made into the outer ring of the elbow after the forging pipe is subject to heat treatment, thus the forging pipe is bent into the elbow. Compared with the prior art, the invention has simple technology, large elbow can be bent by adopting the technology, and the wall thickness of the inner ring and the out ring of the elbow can be ensured to be relatively uniform.

Description

Preparation process of forged elbow [technical field] The invention relates to the technical field of elbow preparation, in particular to a preparation process of forged elbows. [Background technique] The current elbow manufacturing process is mainly to bend the forged pipe with symmetrical center distance into an elbow, which causes the wall thickness of the outer ring of the elbow to become thinner after bending, while the wall thickness of the inner ring becomes thicker after bending. The wall thickness of the inner and outer rings of the elbow is uneven, so that after welding to related equipment in practical applications, it is easy to cause cracks at the thin wall, which affects the service life of the product. [Content of the invention] In order to overcome the deficiencies of the prior art, the present invention uses the eccentricity formed during forging to make half of the forged pipe thicker and the other half relatively thinner. The thicker wall is used as t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16L9/02F16L43/00

CPCB21K1/16F16L43/001

Inventor 周菊明

Owner SHANGHAI CHANGQIANG POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com