Anti-sticking sieve

An anti-sticking and sieving box technology, applied in the direction of sieve, solid separation, grille, etc., can solve the problem that the effect is not very obvious, and achieve the effect of ensuring the screening accuracy and screening efficiency, and highlighting the substantive characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

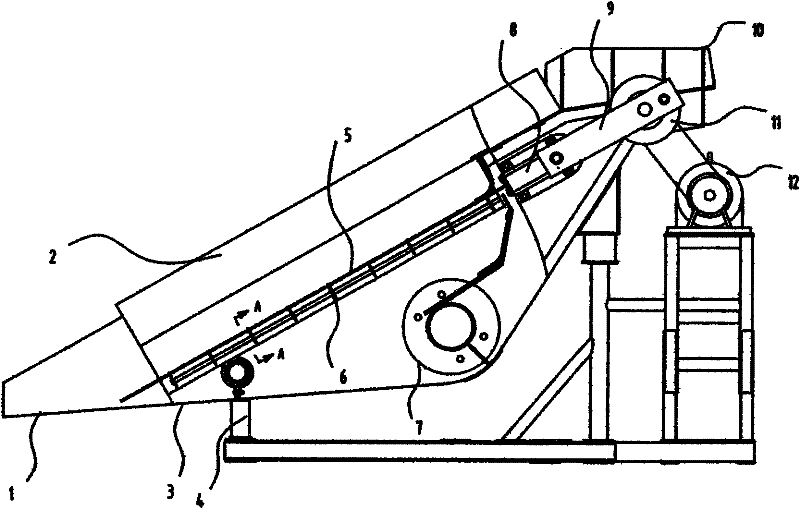

[0010] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

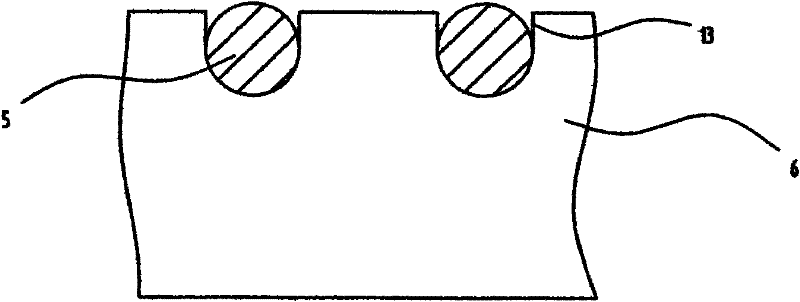

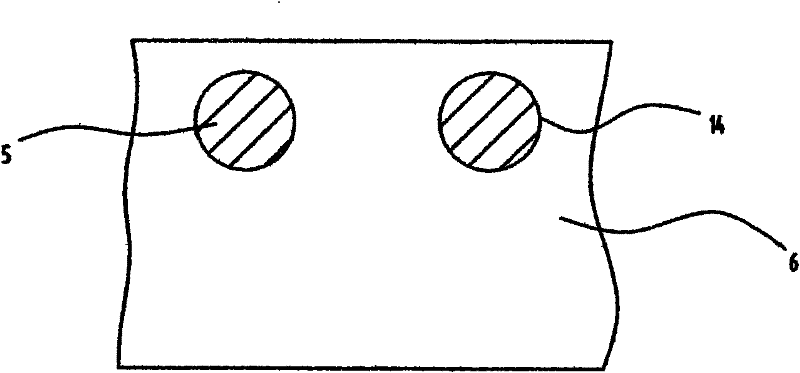

[0011] It can be seen from the accompanying drawings that the anti-sticking screen of this program has a screen box 2 supported on the bracket 4, a feed port 10 is arranged on the top of the screen box 2, and there are 5 screens in the middle part of the screen box 2. The formed screen surface has an outlet 1 for the sieve material before the screen surface of the lower part of the screen box 2, an outlet 3 for the undersize material after the screen surface of the lower part of the screen box 2, and a vibration source 7 at the bottom of the screen box 2. In this scheme, there are a plurality of scrapers 6 whose planes are perpendicular to the axis of the sieve bar 5 in the axial direction of the sieve bar 5 under the screen surface, and the distance between each scraper 6 is equal. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com