Automatic locking tailstock used for printing ink roller cleaning machine

A cleaning machine and automatic locking technology, applied in the general parts of printing machinery, printing machines, printing and other directions, can solve the problem of inconvenient installation and removal of ink rollers, locking, inappropriate initial pressure setting of the ink roller tailstock locking device, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

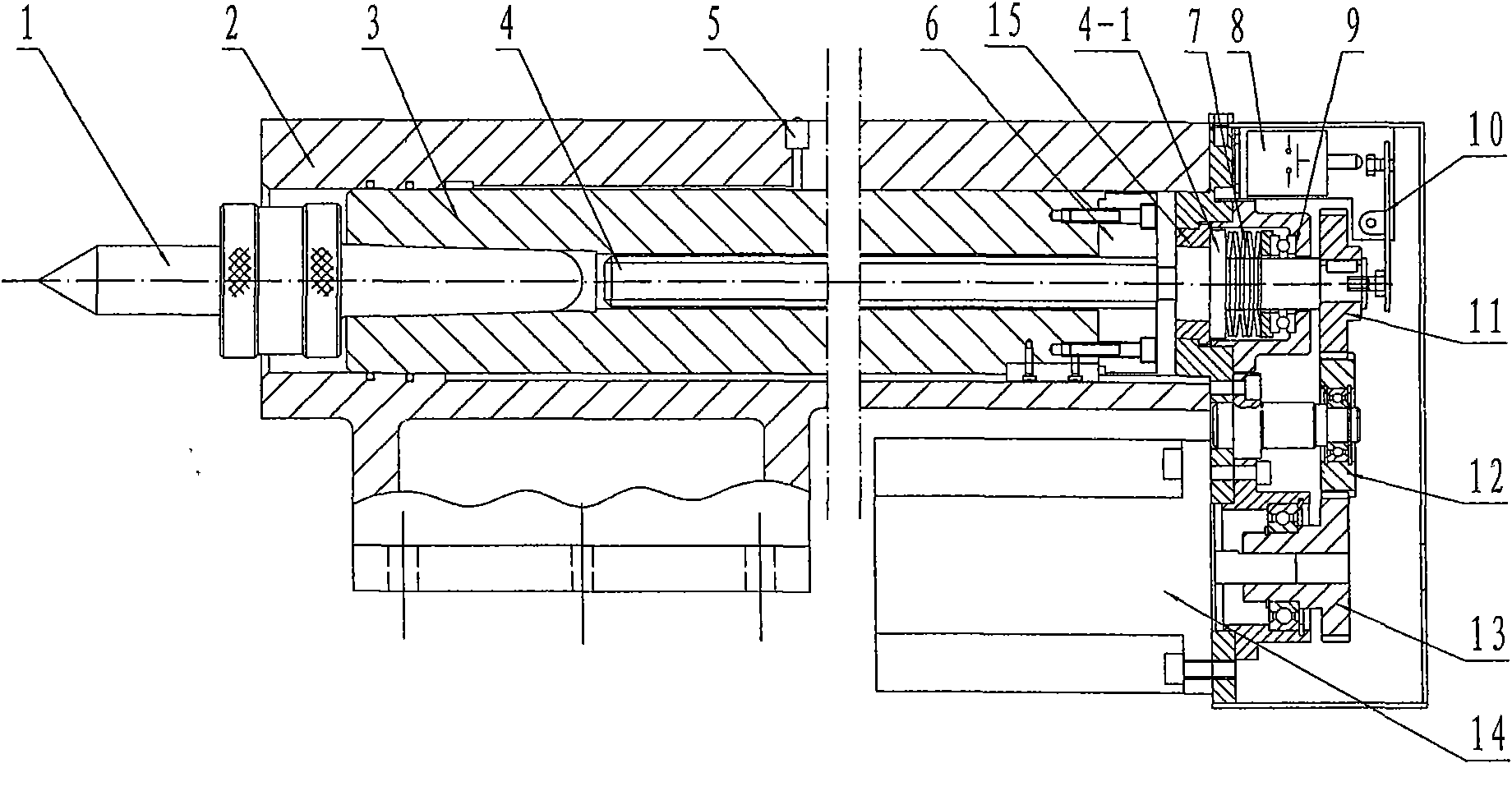

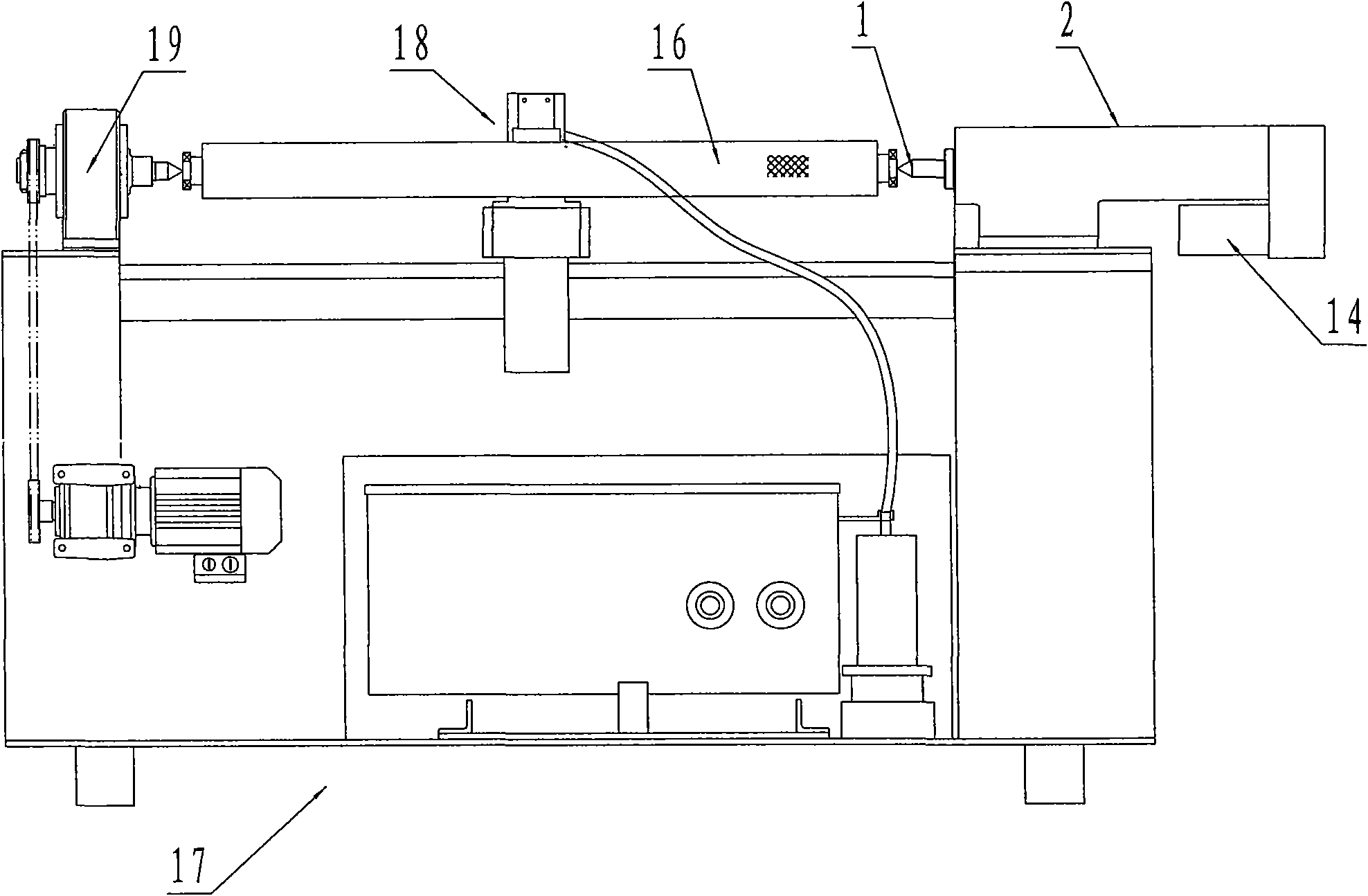

[0012] see figure 1 , the present invention consists of a top 1, a base 2, a top sleeve 3, and an automatic locking device. The top sleeve is located in the axial hole of the base, and the top shank is located in the tapered hole of the top sleeve. Described automatic locking device comprises stepper motor 14, driving gear 13, intermediate wheel 12 and driven gear 11, screw shaft 4, top cover nut 6, limit switch 8, fork 10 and hold down spring that are meshed in sequence, Wherein, the top sleeve nut is fixedly connected to the top sleeve and spirally fits with the screw shaft. The driving gear is fixed on the output shaft of the stepping motor, the driven gear is fixed on the right side of the screw shaft, and the stepping motor forms a transmission connection with the screw shaft through gear transmission. The hold-down spring is a disc spring 7 that can bear a relatively large load with a small deformation. And the one-way thrust ball bearing 9, the one-way thrust ball bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com