Reshaping method of automobile torque converter blade lattice system

A hydraulic torque converter, automotive technology, applied in fluid transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems such as long design cycle, failure to achieve optimal performance, and large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0117] Please refer to the accompanying drawings for a further description of the present invention.

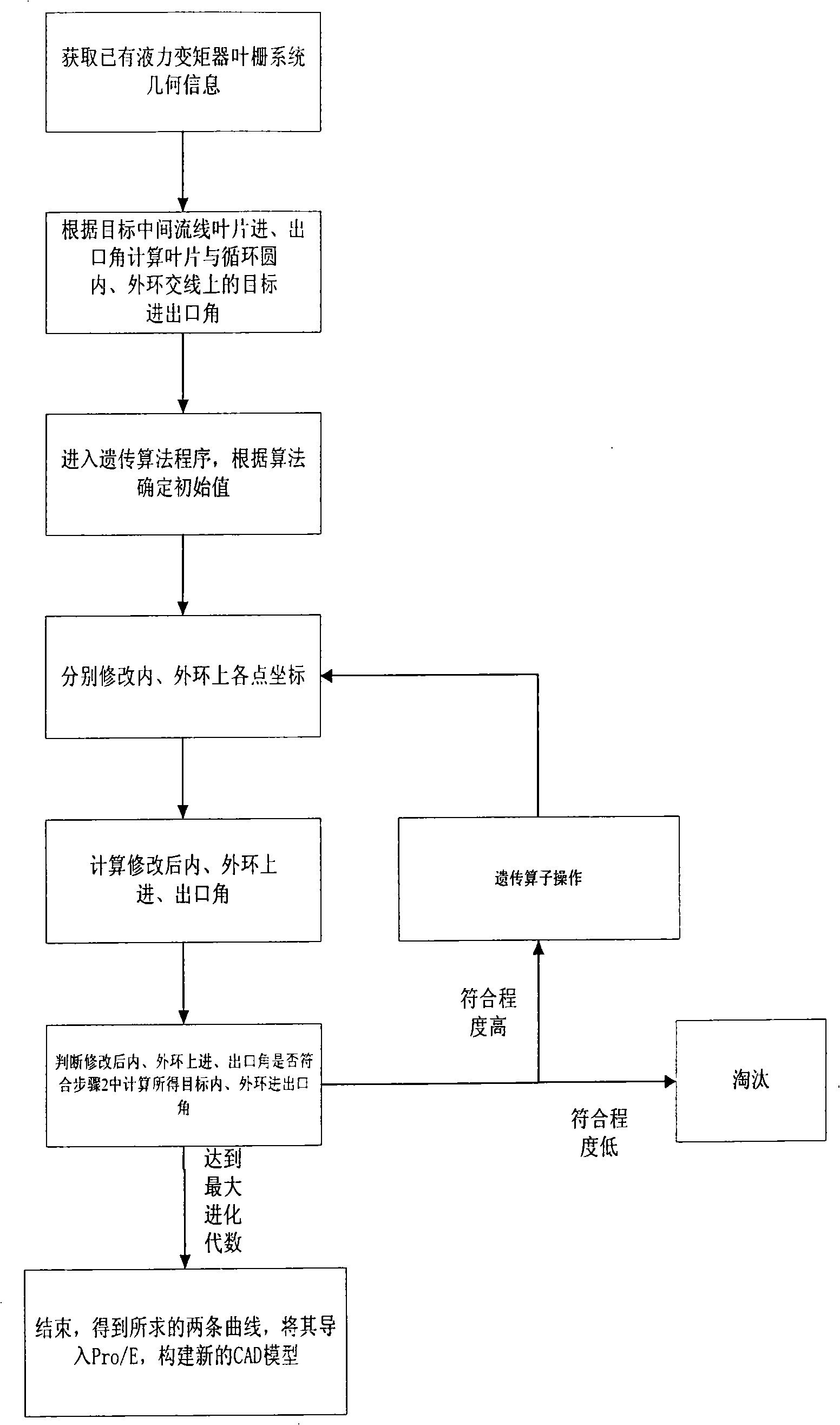

[0118] like figure 1 As shown, the present invention provides a method for modifying the cascade system of an automobile hydraulic torque converter, the method for modifying comprises the following steps:

[0119] ① Obtain the geometric information of the existing hydraulic torque converter cascade system;

[0120] ② Calculate the target inlet and outlet angles on the intersection line between the blade and the inner and outer rings of the circulation circle;

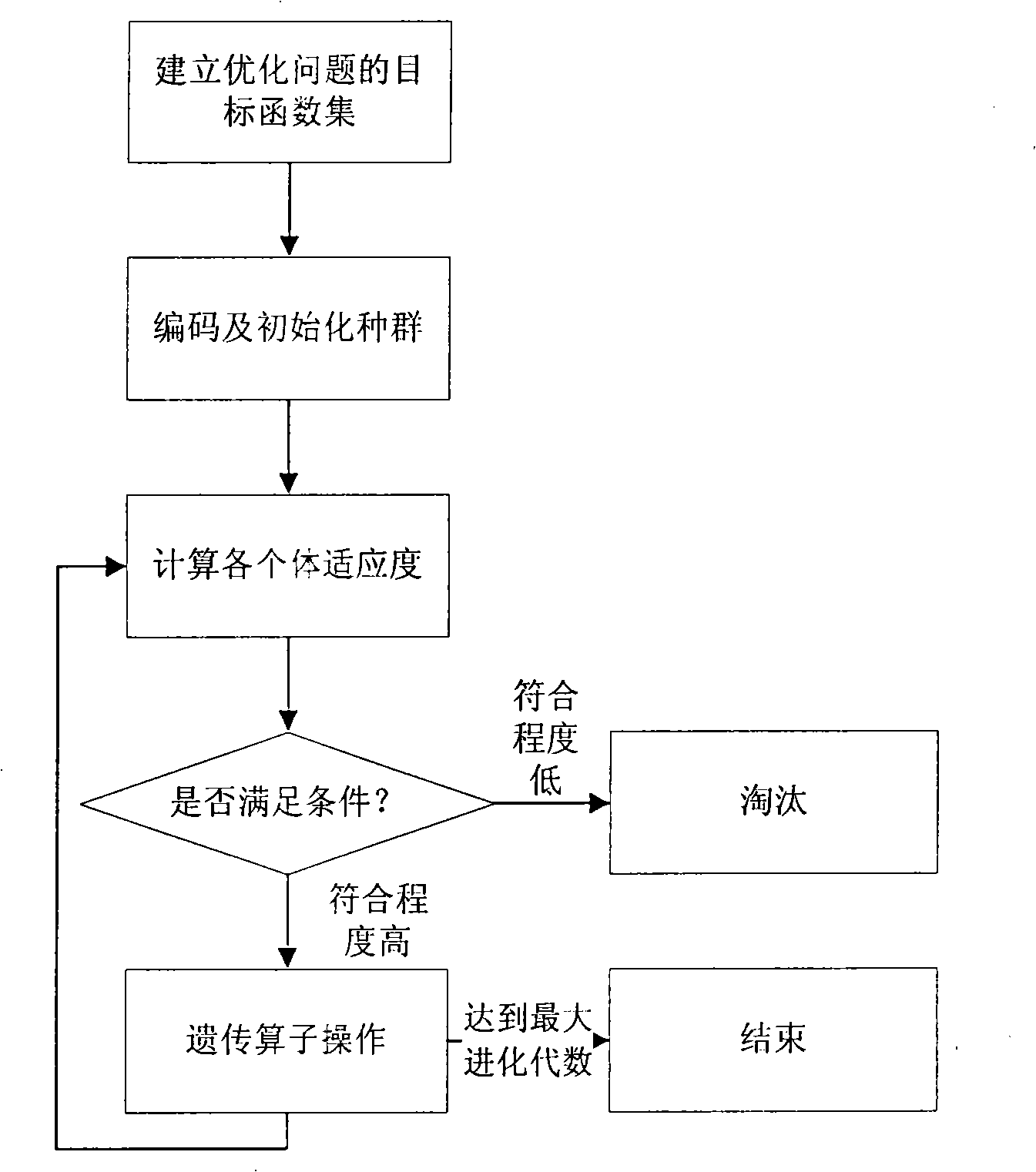

[0121] ③Enter the genetic algorithm program to start iterative calculation;

[0122] ④ Randomly modify the coordinates of each point to generate an initial group;

[0123] ⑤ Calculate the inlet and outlet angles on the intersection line between the blade and the inner and outer rings of the circulation circle after modification;

[0124] ⑥Judge the degree of conformity between the inlet and outlet angles on the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com