Method for boring hole on screw shaft pipe subsection in supertanker construction

A stern tube and super-large technology, which is applied in the field of shipbuilding, can solve the problems of large hole ovality and taper, the quality of boring holes cannot be guaranteed, and the accuracy of adjustment cannot be guaranteed, so as to improve the accuracy and progress, The effect of reducing the rate of duplication of labor, reducing risk and labor input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The boring method of the segmented stern tube in the construction of the VLCC of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

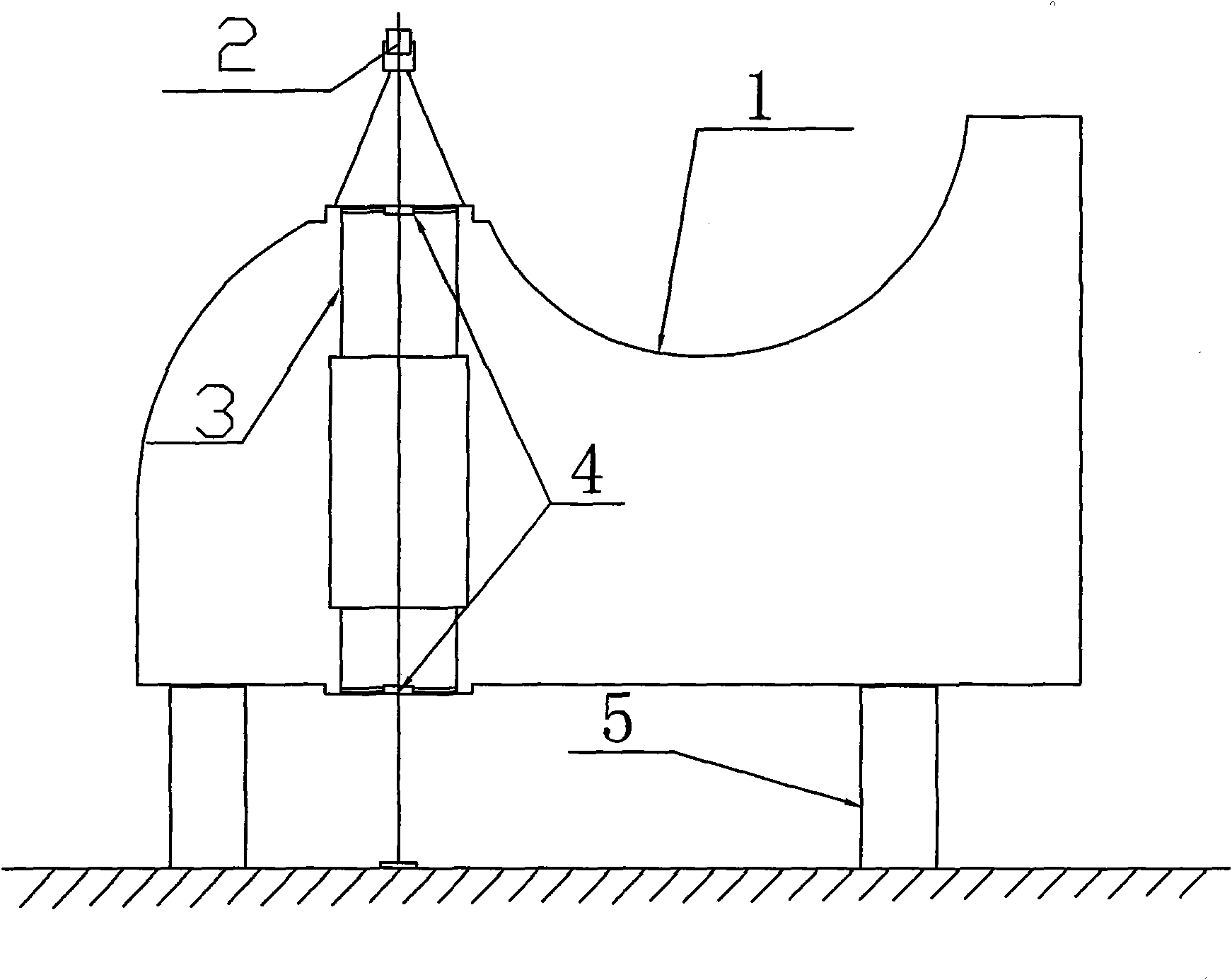

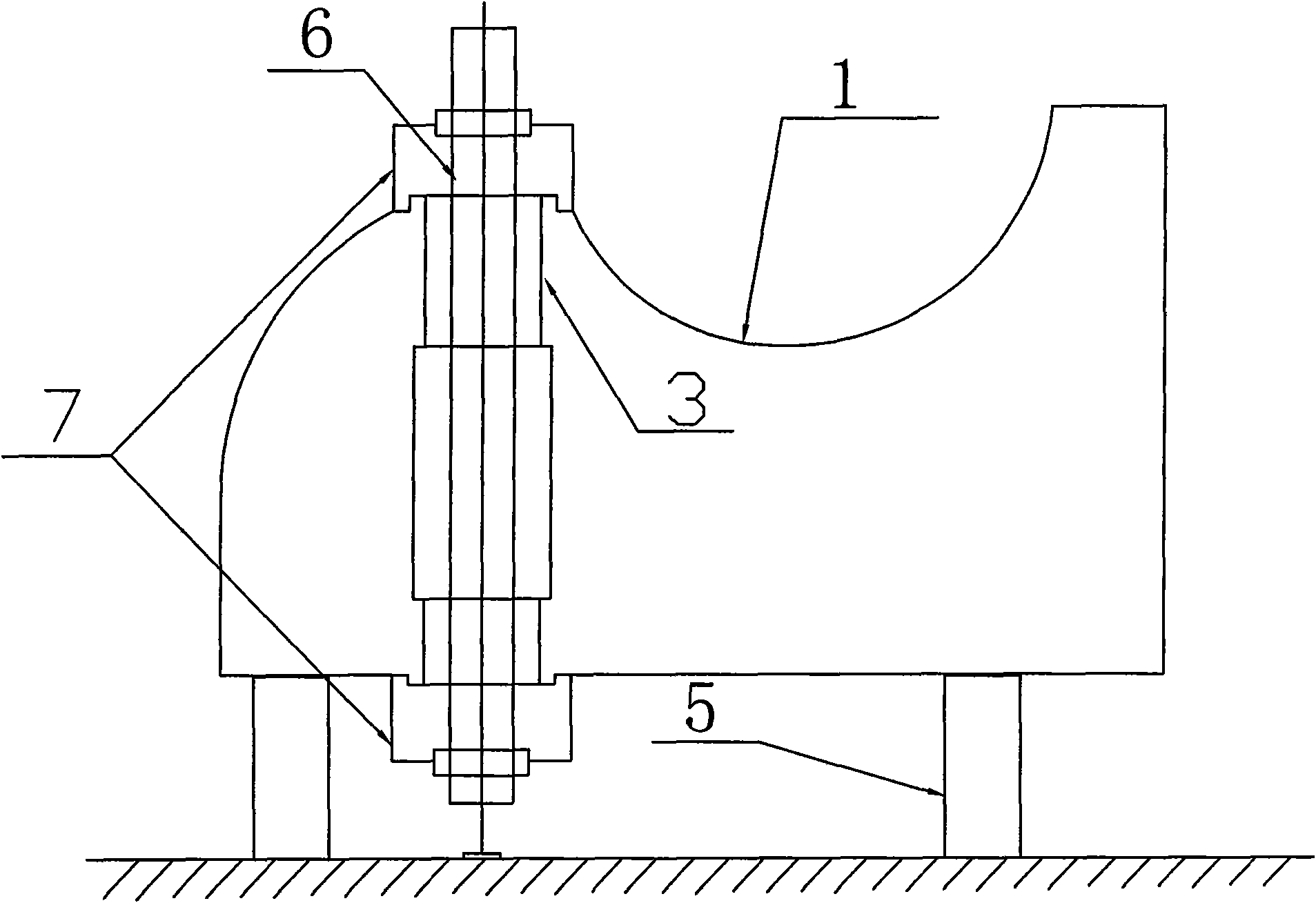

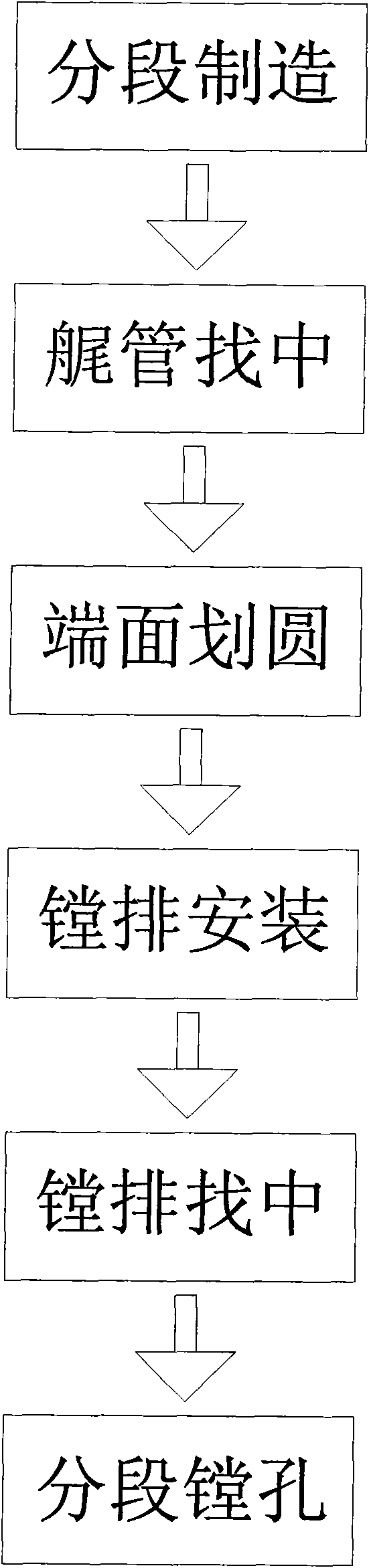

[0028] The boring method of the segmented stern tube in the construction of the ultra-large oil tanker of the present invention is that the segmented stern tube 1 is placed on the tire frame 5 in a horizontal state for manufacture, and after the segmental manufacturing is completed and accepted, according to Segment the datum line and the horizontal line, use the laser plummet 2 and two sets of cross laser targets 4 to center the stern tube 3, draw the processing circle and the inspection circle on the two end faces of the stern tube 3 after the centering is completed, and process After the circle and the inspection circle are drawn, the laser plummet 2 and two sets of cross laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com