Rocker type fire preventing switch

A rocker and switch technology, applied in the direction of protection switch operation/release mechanism, etc., can solve problems such as potential safety hazards, inability to cut off the power supply, tripping of the tripping mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

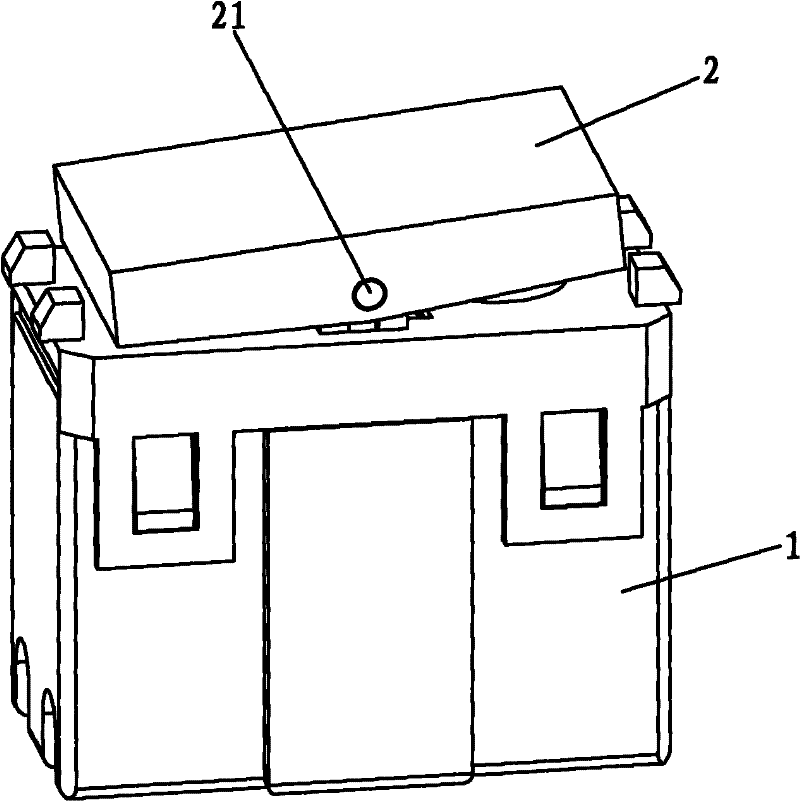

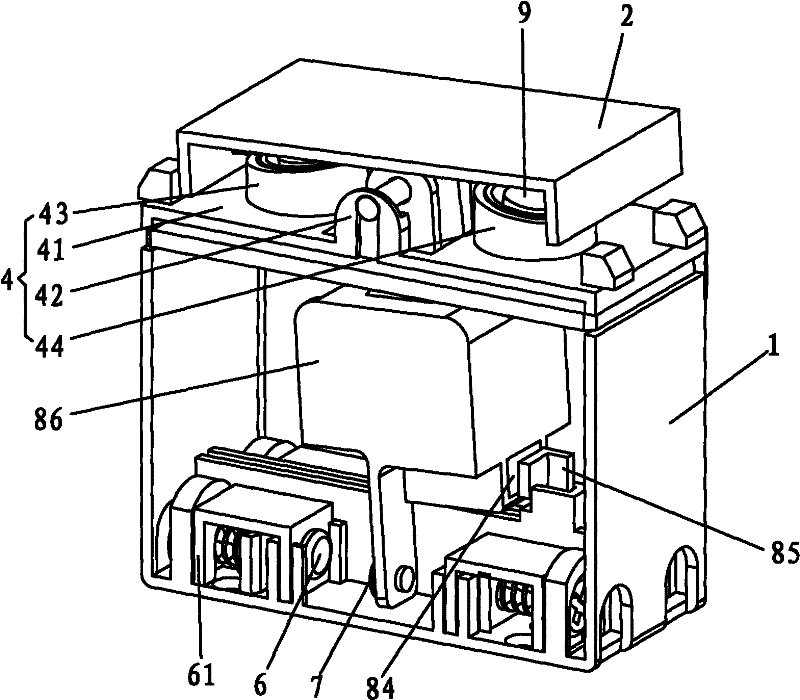

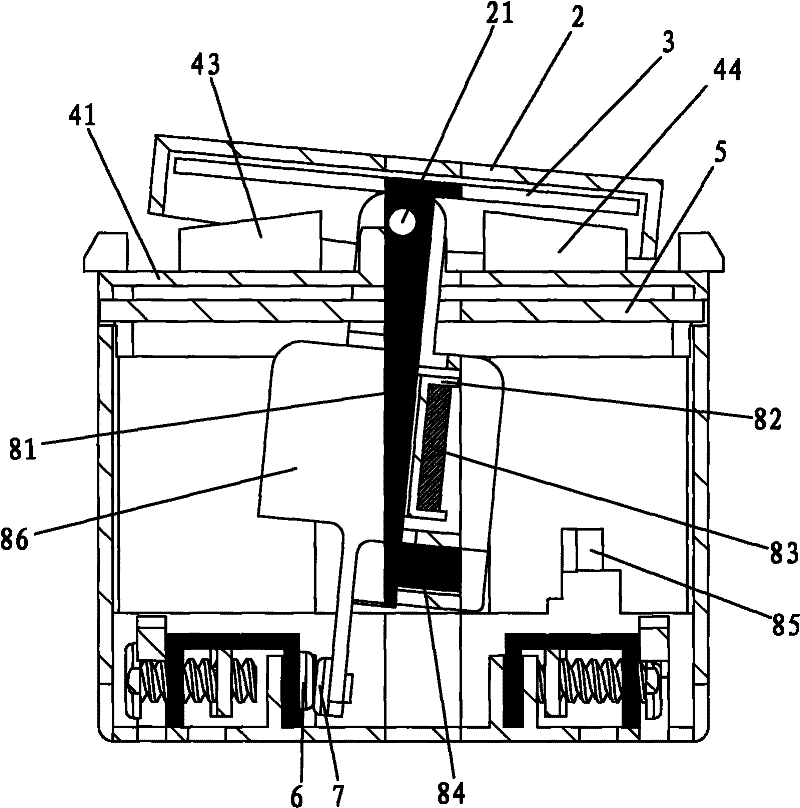

[0016] Rocker type fire switch of the present invention, as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a housing 1, a seesaw 2, a thin iron plate 3, a support seat 4, a circuit board 5, a static contact 6 and a moving contact 7, and also includes a protection circuit and a tripping mechanism.

[0017] The middle part of the rocker 2 is pierced with a pin shaft 21, and the rocker 2 corresponds to one end of the power supply ( figure 2 The right end of the middle) and one end corresponding to shutting down the power supply ( figure 2 The left end in the middle) can rotate around this pin shaft 21, with the pressing surface of the seesaw 2 as the outer surface, and the thin iron plate 3 is covered and fixed on the inner surface of the seesaw 2.

[0018] Support seat 4 is located at the inboard of thin iron plate 3, and support seat 4 is provided with support plate 41, and the two ends corresponding to bearing pin 21 on the support plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com