A kind of polymer composite asphalt-based intumescent fire retardant waterproof coating and its preparation method

A technology of waterproof coatings and polymers, applied in asphalt coatings, fireproof coatings, coatings, etc., can solve problems such as structural failure and spread, and achieve the effect of dense coating, easy high-temperature carbonization, and delaying the time of thermal failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

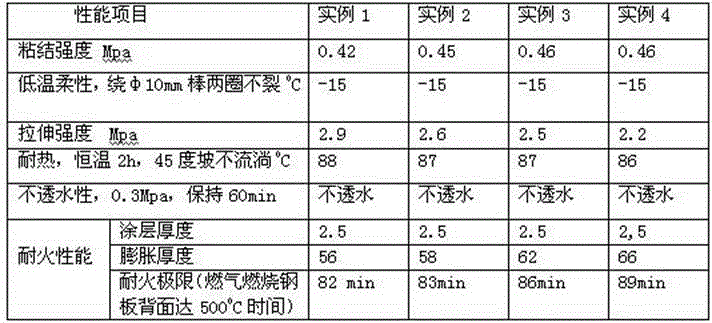

Examples

Embodiment 1

[0027] (1) According to the formula components of the present invention, weigh according to the mass fraction: SIS, 13 parts; UHMWPVC resin, 10 parts; No. 10 construction asphalt, 25 parts; chlorinated paraffin, 6 parts; solvent gasoline, 70 parts; , 10 parts; ammonium polyphosphate, 10 parts; pentaerythritol, 12 parts; lightly burned dolomite, 12 parts.

[0028] (2) According to the preparation method of the present invention, take (1) 35 parts of solvent gasoline as the formula component, add it to the stirring container, start stirring, and sequentially put 6 parts of plasticizer chlorinated paraffin, 10 parts of UHMWPVC resin, and 13 parts of SIS rubber powder. After the addition is complete, stir and disperse at high speed for 60 minutes to obtain a polymer sol.

[0029] (3) According to the preparation method of the present invention, add 12 parts of light-burned dolomite, 10 parts of melamine, 10 parts of ammonium polyphosphate, and 12 parts of pentaerythritol into the ...

Embodiment 2

[0034] (1) According to the formula components of the present invention, weigh according to the mass fraction: SIS, 16 parts; UHMWPVC, 8 parts; No. 10 construction asphalt, 25 parts; chlorinated paraffin, 6 parts; 10 parts; ammonium polyphosphate, 10 parts; pentaerythritol, 12 parts; lightly burned dolomite, 12 parts.

[0035] Preparation steps (2) to (6) are the same as Example 1.

Embodiment 3

[0037] (1) According to the formula components of the present invention, weigh according to mass fraction: SIS, 18 parts; UHMWPVC, 6 parts; No. 10 construction asphalt, 25 parts; chlorinated paraffin, 6 parts; solvent gasoline, 70 parts; 10 parts; ammonium polyphosphate, 10 parts; pentaerythritol, 12 parts; lightly burned dolomite, 18 parts.

[0038] Preparation steps (2) to (6) are the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com