Fireproof and pressure-resistant glass and preparation method thereof

A glass and pressure-resistant technology, applied in glass manufacturing equipment, glass furnace equipment, glass pressing, etc., can solve the problems of increasing glass cost, life safety and property threats, mold spots, etc., to improve uniformity and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

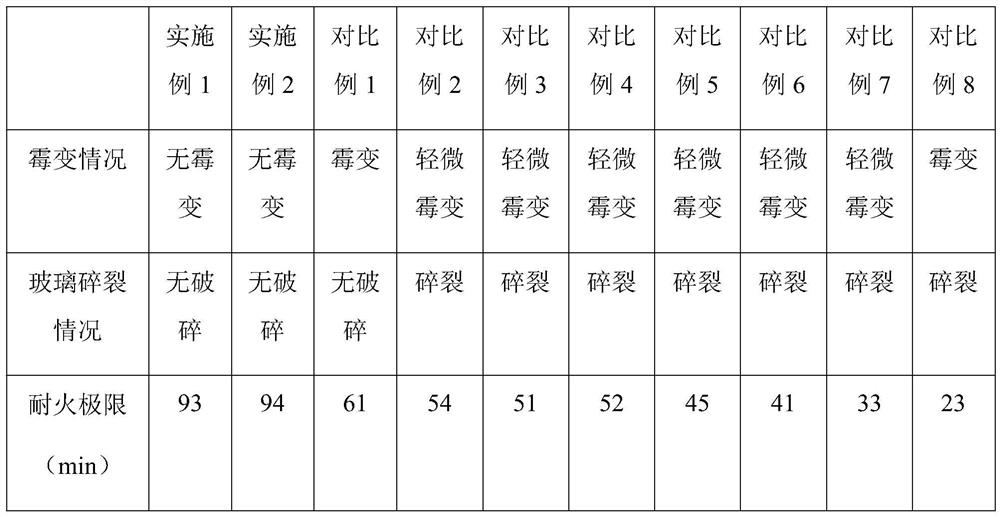

Examples

Embodiment 1

[0033] A fireproof and pressure-resistant glass, mainly comprising: 70 parts of modified silicon dioxide, 40 parts of self-made fireproof coating, 2 parts of alumina, 3 parts of calcium carbonate, 0.3 part of borax, 1 part of sodium silicate, in parts by weight, 0.09 parts of antimony oxide.

[0034] A method for preparing fireproof pressure-resistant glass, the method for preparing fireproof pressure-resistant glass mainly includes the following preparation steps:

[0035] (1) Chemically modify silicon dioxide to obtain modified silicon dioxide; add modified silicon dioxide, aluminum oxide, calcium carbonate, borax, sodium silicate and antimony oxide to the mixer according to the formula, and stir for 10 minutes at 200 rpm get mixed;

[0036] (2) Put the mixture in a melting furnace at 800°C, heat it under pressure in stages, and keep it warm for 9 hours to obtain a molten liquid;

[0037] (3) Put the molten liquid in induction plasma equipment, after processing for 30 minute...

Embodiment 2

[0053] A kind of fireproof pressure-resistant glass, mainly comprising: 90 parts of modified silicon dioxide, 50 parts of self-made fireproof coating, 5 parts of aluminum oxide, 6 parts of calcium carbonate, 0.5 part of borax, 5 parts of sodium silicate in parts by weight, 0.1 part antimony oxide.

[0054] A method for preparing fireproof pressure-resistant glass, the method for preparing fireproof pressure-resistant glass mainly includes the following preparation steps:

[0055] (1) Chemically modify silicon dioxide to obtain modified silicon dioxide; add modified silicon dioxide, aluminum oxide, calcium carbonate, borax, sodium silicate and antimony oxide to the mixer according to the formula, and stir for 5 minutes at 300 rpm get mixed;

[0056] (2) Put the mixture in a melting furnace at 900°C, pressurize and heat in stages, and keep it warm for 7 hours to obtain a molten liquid;

[0057] (3) Put the molten liquid in induction plasma equipment, after processing for 45 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com