Measuring instrument for the axial position of the r-groove of the roller cone bit for oil

A roller cone bit and groove axial technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of inaccurate measurement, downhole accidents, failures, etc., and achieve simple measurement, simplified inspection procedures, Intuitive effect of reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

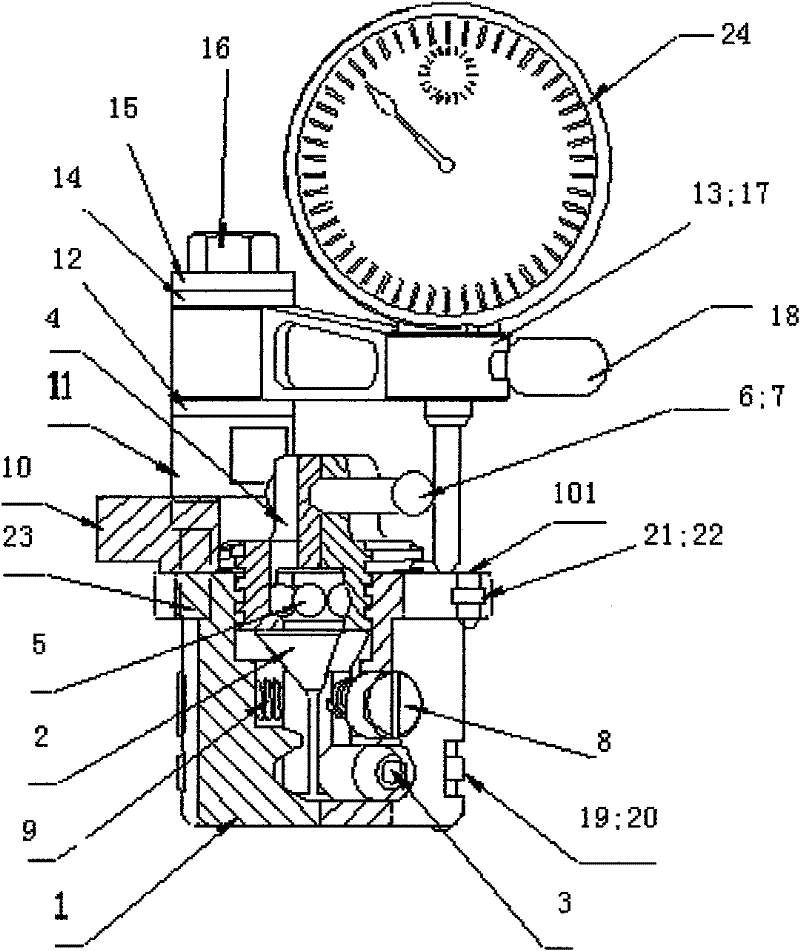

[0014] Example: such as figure 1 Shown, the present invention uses the roller cone bit cone hole R groove axial position measuring instrument of the present invention, comprises structural main body (1) and pushes cone (2), is provided with screw rod (4) on main body (1), screw rod ( 4) Rotate the handles (6, 7) and drive the push cone (2) to move down.

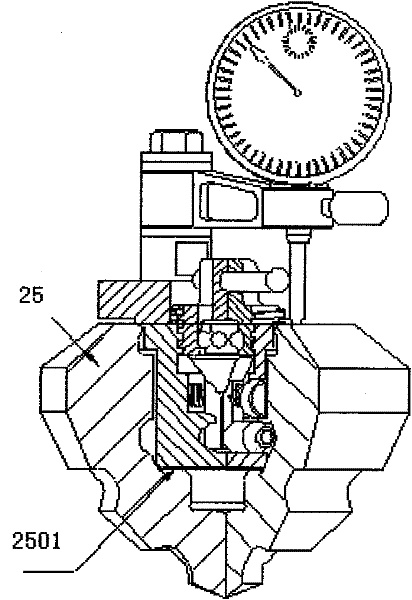

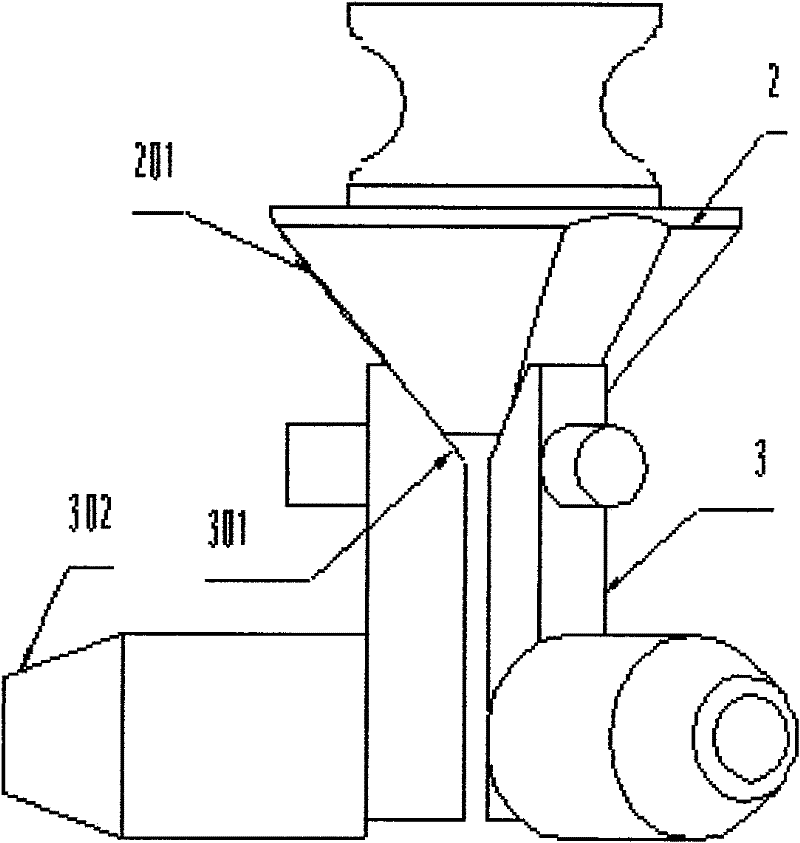

[0015] Such as figure 1 , image 3 As shown, the three slopes (201) of the push cone (2) cooperate with the slopes (301) of the three probe bodies (3), so that the three probes (302) protrude outward from the main body (1), Tighten the screw rod (4), so that the three detection heads (302) can be locked in the R grooves of the tested cone (25). The three probe bodies (3) and the three probe heads (302) must be kept on the same radial plane, otherwise the measurement result will be incorrect. The dial indicator (24) is clamped on the rotating arm (13) through the split sleeve (17) and the fixing screw (18), and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com