Device for detecting positions of bolt mounting holes

An inspection device and mounting hole technology, which is applied to measuring devices, mechanical devices, mechanical measuring devices, etc., can solve problems such as lack of inspection tools, and achieve the effects of convenient inspection, easy production and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

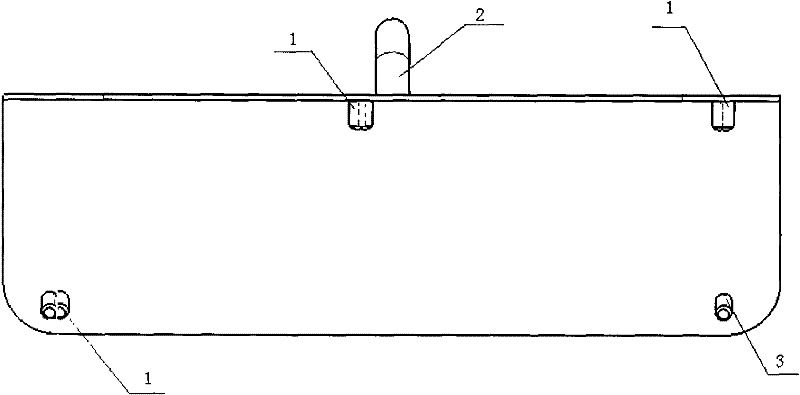

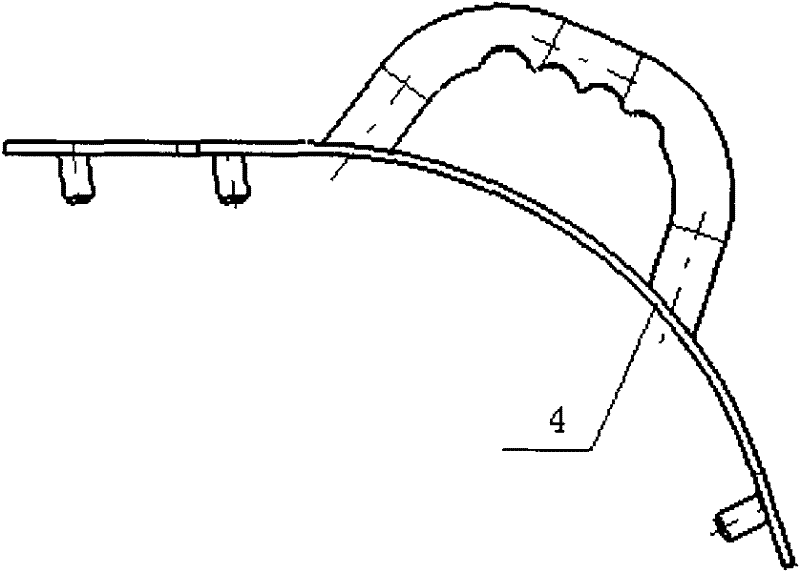

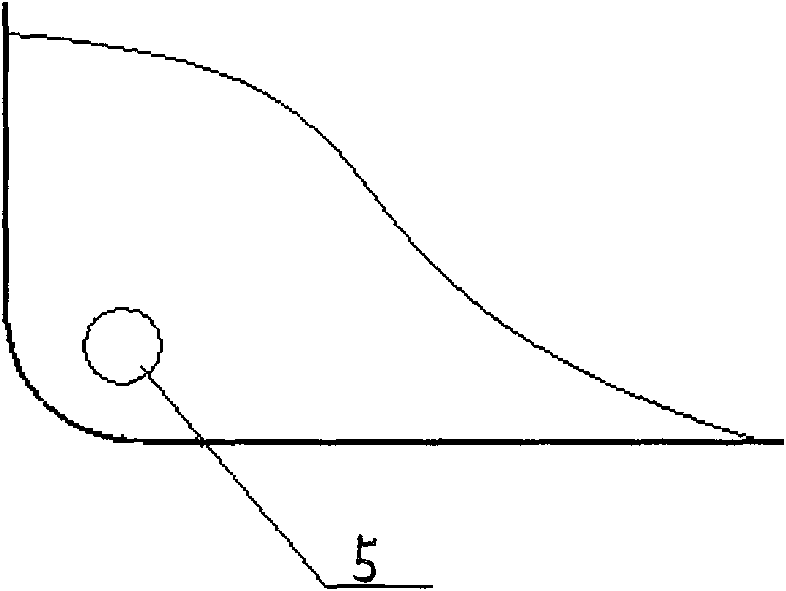

[0012] Hereinafter, the present invention will illustrate the specific structure of the inspection device by taking two mutually assembled parts of the engine exhaust manifold and the heat shield as an example.

[0013] Due to the influence of the exhaust gas, the cast iron exhaust manifold of the engine often has a high temperature and is easy to cause burns to people. Therefore, a heat shield is generally installed on its surface, and the two are connected by bolts. Therefore, there is a corresponding relationship between the exhaust manifold and the bolt installation holes of the heat shield. Since the shape of the exhaust manifold is a curved surface, the location of each mounting hole is usually a spatial curved surface structure. It is difficult to control the position tolerance of the bolt mounting holes of the exhaust manifold and the heat shield during the drilling and punching process. If the control is not good, it is easy to dislocate, thus affecting the assembly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com